Capacitors, Resistors, and Inductors have properties that can be built into useful circuits.

Resistors limit the passage of AC and DC current equally well. They're good for dropping voltages and preventing over-current. Physically resistance wire or carbon.

Capacitors block DC, but allows AC to pass. They do this by storing energy, charging and discharging. The frequency that can pass depends on the capacitance, so 50Hz mains requires hundreds of microfarads, whilst 5MHz will flow through 1000 picofarads. No heat is lost. Capacitors can be used to short unwanted AC to ground, or to pass AC from one circuit to another, without effecting DC functions. Physically, two plates separated by an insulator. It behaves like a secondary battery, except massively faster.

Inductors block AC while allowing DC to pass. They do this by storing energy, charging and discharging like a capacitor but in the opposite sense. The frequency that's blocked depends on the inductance, so 50Hz mains requires several henrys, whilst 5MHz requires about 100 micro-henries. Not much heat is lost. Inductors can be used to short DC to ground whilst keeping AC, or to pass DC from one circuit to another whilst blocking unwanted AC – a choke. Inductors generate a magnetic field, which can be picked up by an adjacent coil – a transformer. The ratio of turns converts volt-amps on one side to different volt-amps on the other, converting say, 10V @ 1A AC to 1000V @ 0.01A . Physically a coil of insulated wire,

Gets interesting when these characteristics are combined. For example, a single DC pulse fed into a capacitor and inductor connected in parallel will charge the inductor up by creating a magnetic field. When the inductor is fully charged, the field collapses causing current to flow into the capacitor until it is fully charged and the inductor is empty. At which point the capacitor discharges into the inductor, and the circuit oscillates at a frequency dependent on the combined capacitance and inductance. It would oscillate forever where it not for losses in the components.

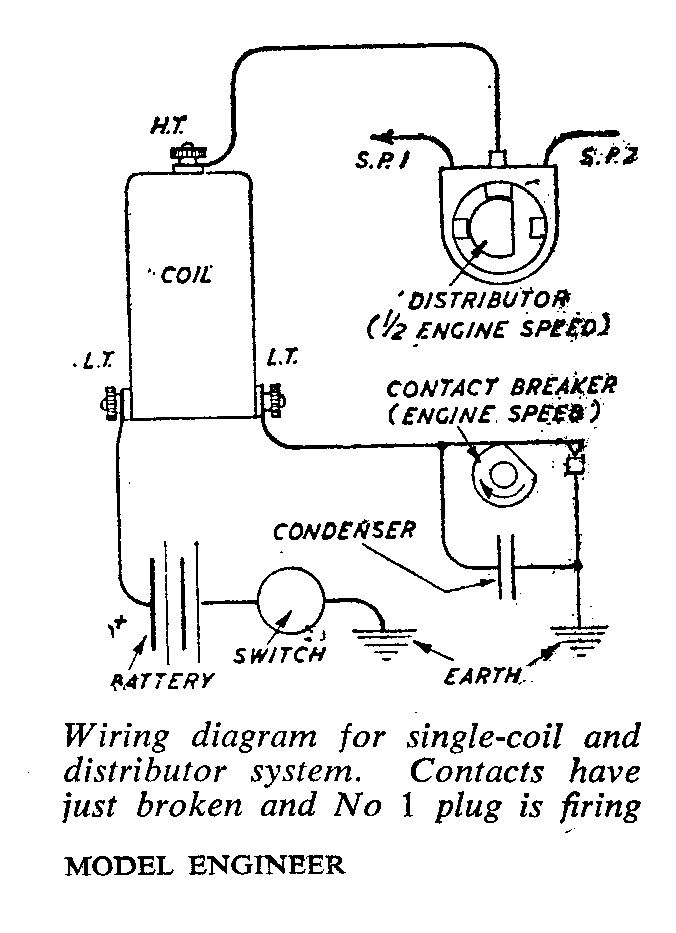

In the ignition circuit:

- The contact breaker rotates switching DC power from the battery ON/OFF to the LT windings of the coil (a transformer) The OFF's are set to occur near TDC by moving the cam.

- When the contract breaker is closed, power from the battery flows into a low number of turns at the base of the coil and creates a magnetic field.

- When the contact breaker opens, the collapsing magnetic field induces a voltage into a large number of turns in the upper coil. As the magnetic field is changing, the induced voltage looks like AC to the coil, and so is magnified up to several thousand volts at the HT terminal. The energy is dissipated as a spark inside the cylinder where it ignites the fuel/air mix.

The capacitor has more than one function:

- The spark generates a large amount of Radio Frequency energy that can interfere with radios and TV's. The capacitor value is chosen to suppress these frequencies by shorting them to ground. Something between 0.2 and 0.01microfarads AC is usual. Note it's earthing high frequency AC whilst the DC battery is unaffected.

- The capacitor absorbs energy that would otherwise cause the contacts to arc as they open, so the contacts last much longer when one is fitted.

- The capacitor absorbs energy extra quickly when the magnetic field collapses after the contact breaker opens and the faster changing collapse puts more energy and voltage into the spark.

The circuit is an efficient and reliable way of creating timed high-voltage sparks from a low DC source. It exploits both AC and DC characteristics. No resistor in this particular circuit, but they were used in the past to drive a 6V coil with a 12V battery. The extra 6V causes the magnetic field to change faster and boosts the spark, but it's essential not to overload the coil. The resistor, or 'ballast', prevents the coil from getting more than 6V continuous. No doubt the extra-fat spark improves combustion, but I believe the main reason was better cold-starting. Cranking a heavy engine full of gummy oil on a cold morning would cause an ineffective spark due to the voltage of a chilled 6V battery being pulled down low.

In a way, the Art of Electronics is manipulating mixtures of AC and DC to create wanted effects. As the number of effects is almost unlimited, electronics is an entire field of engineering – bigger and more complicated than anything done by rude mechanicals!

Dave

Howard Lewis.