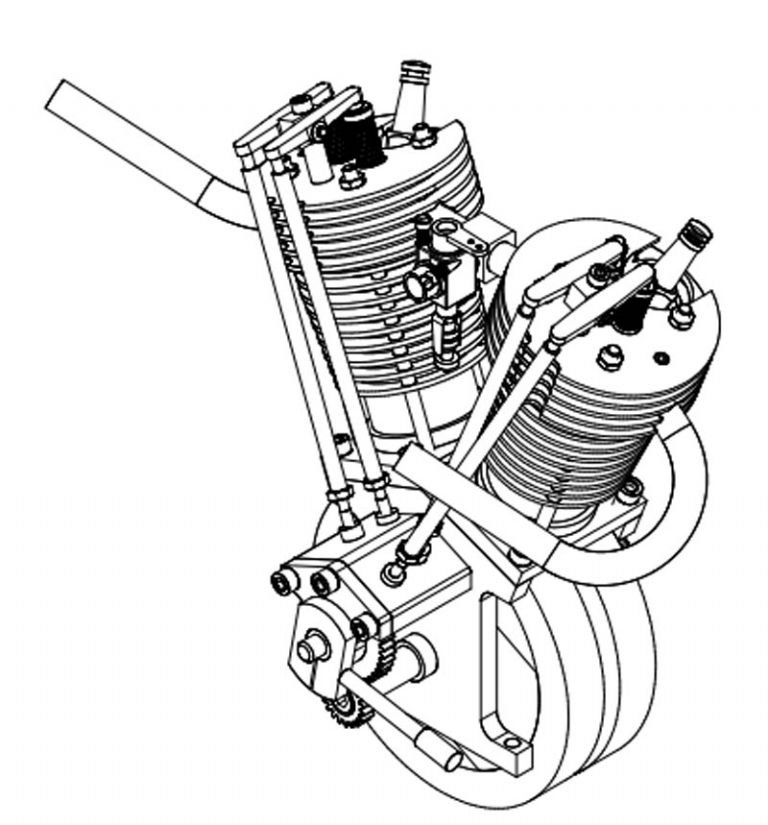

A digression on cams.

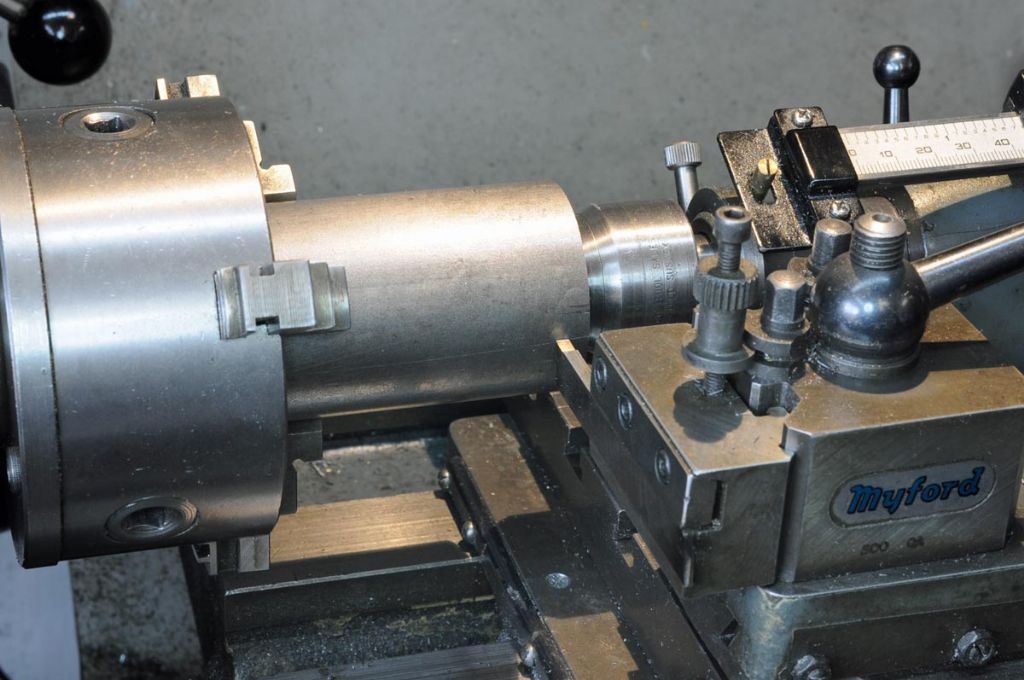

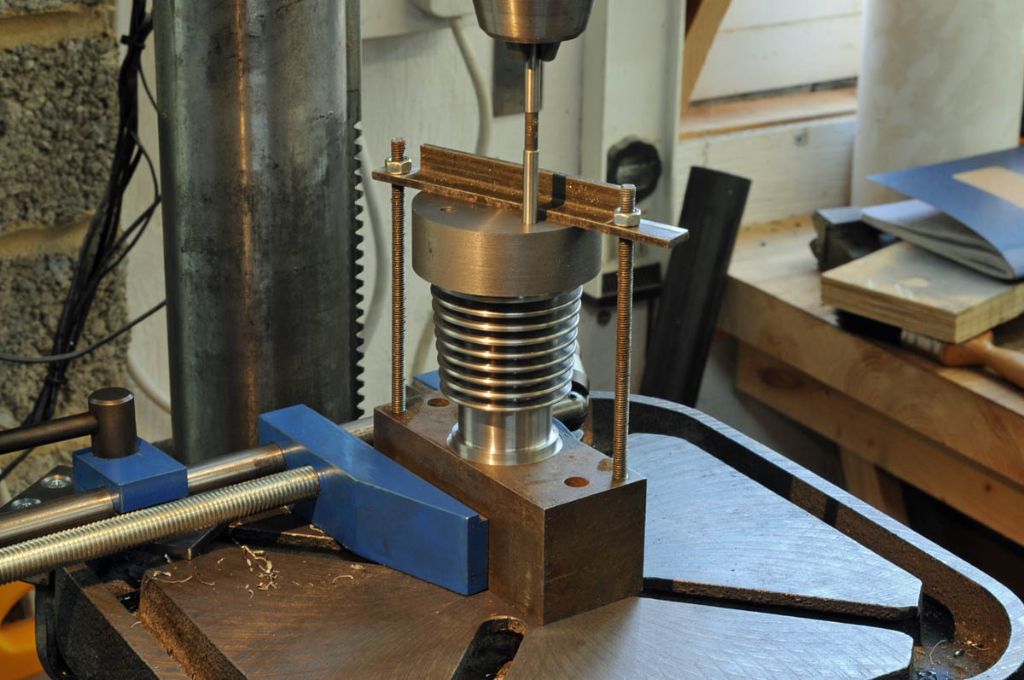

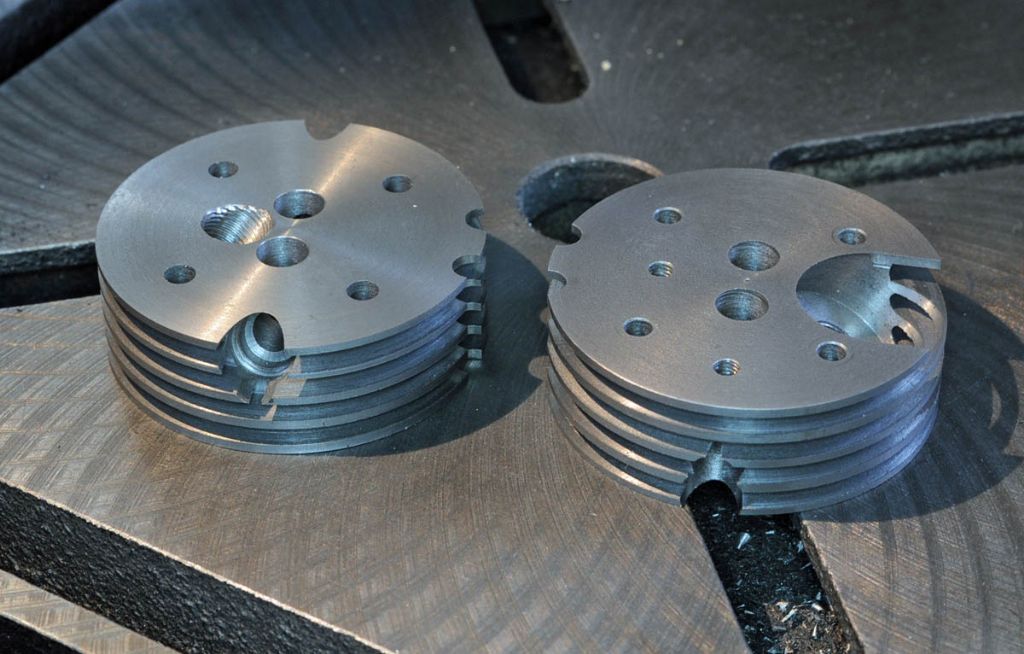

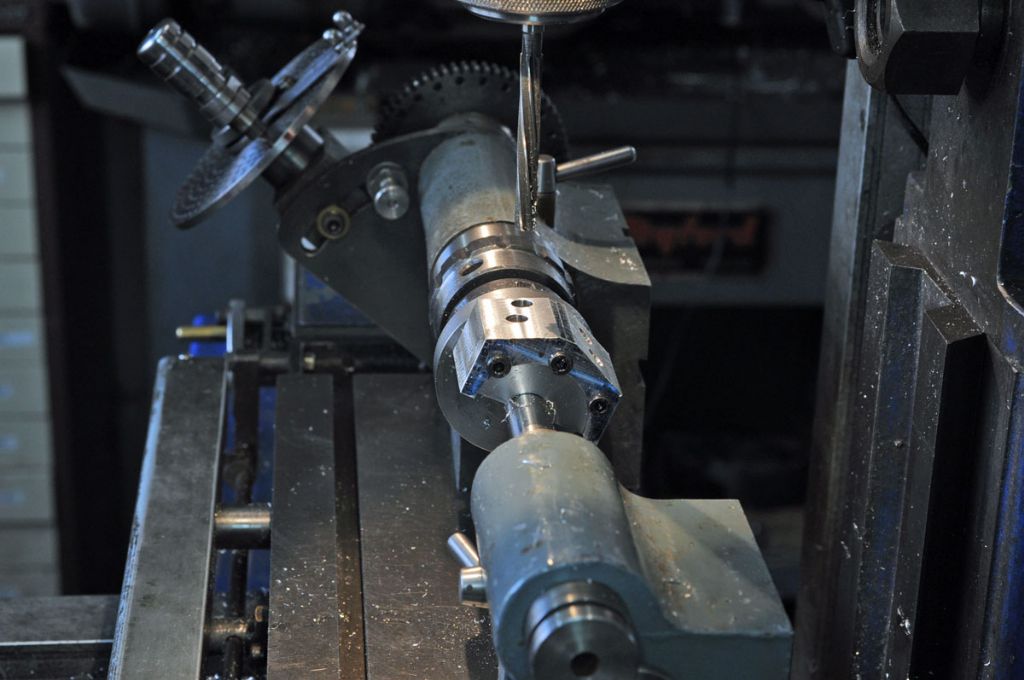

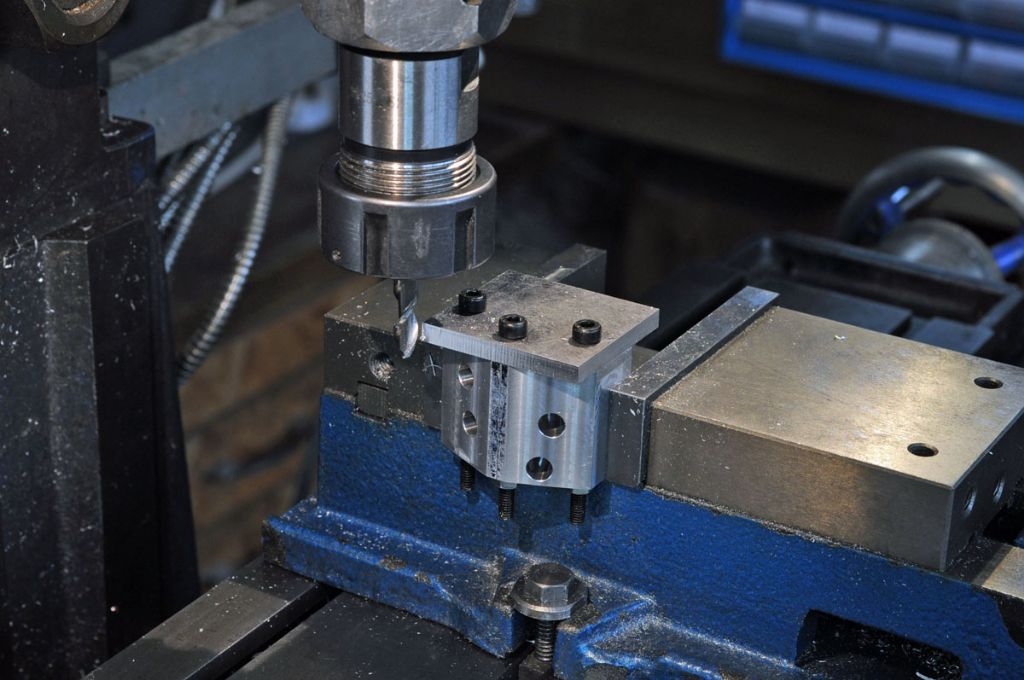

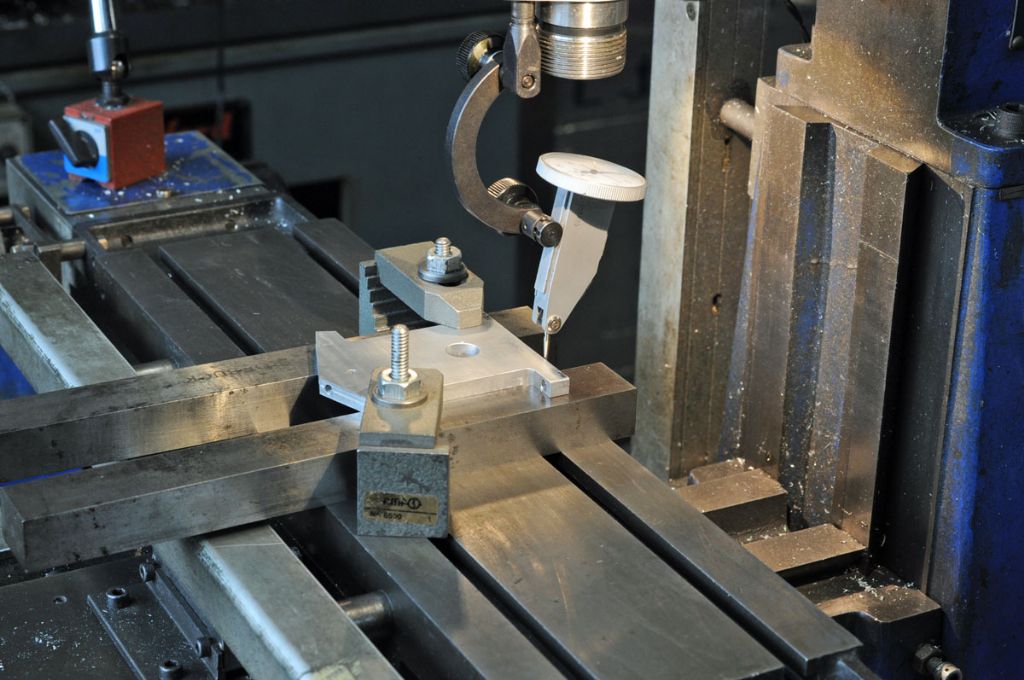

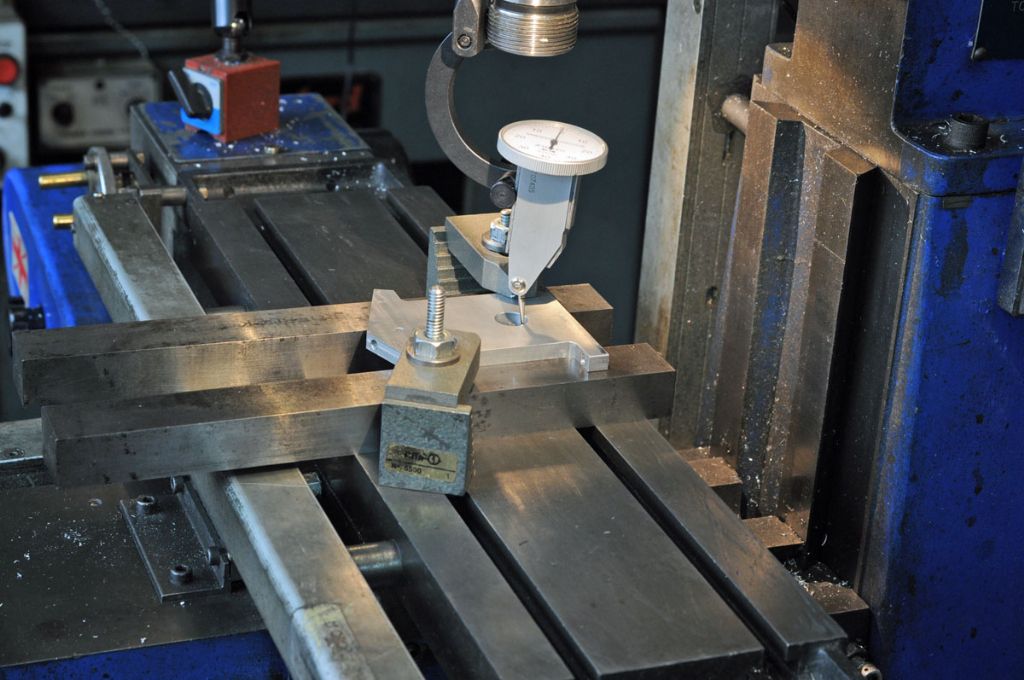

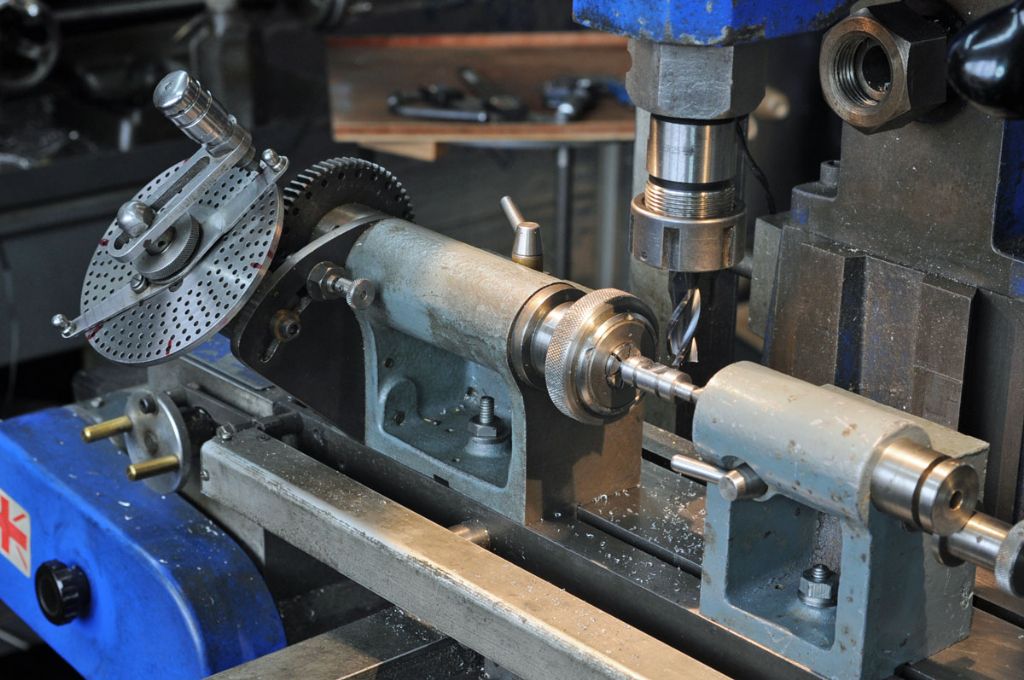

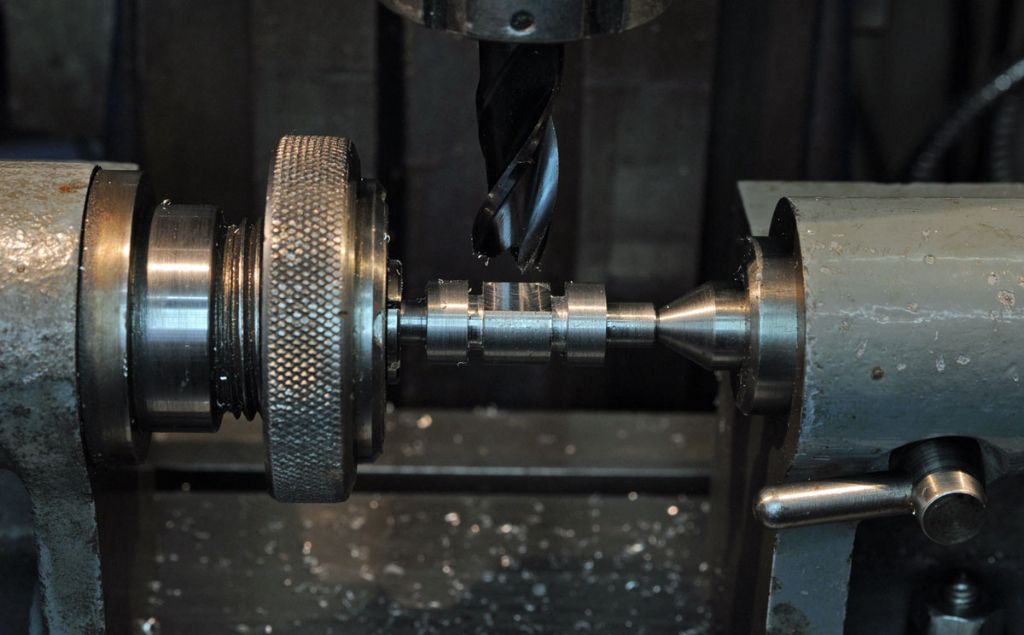

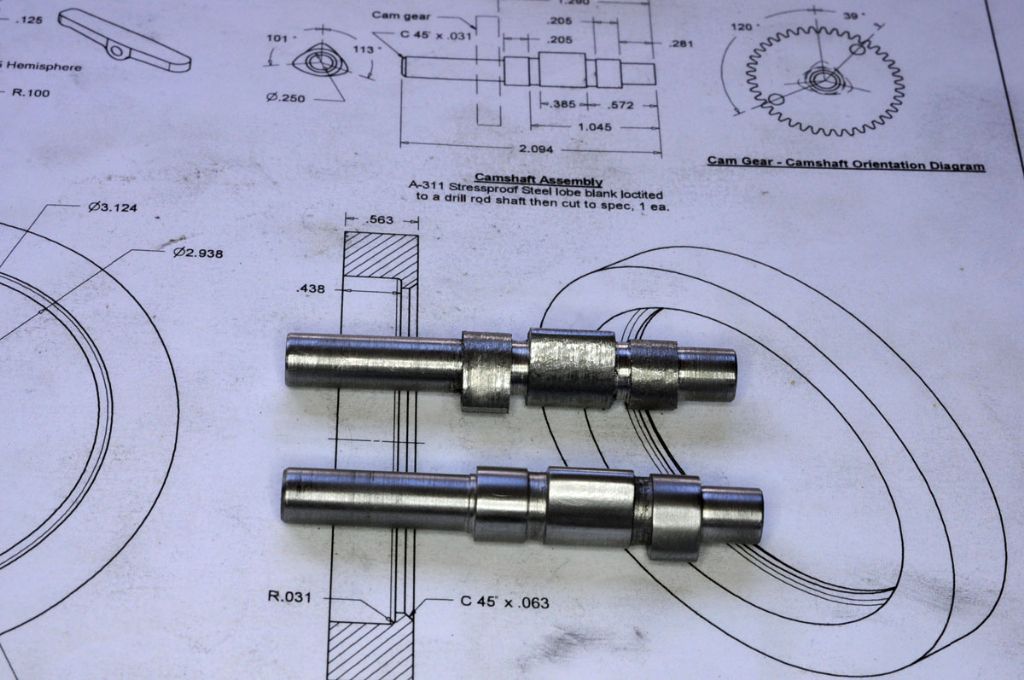

I've been slightly sceptical of the accuracy of the method that Randall Cox uses(and never really understood) to produce the cams (as shown in Jason's pictures) so I thought I would have a look at the process and compare it with the Manual Numerical Control method that is CamCalc. However, I must emphasise that the Cox method clearly works because there are many examples of running Hoglets.

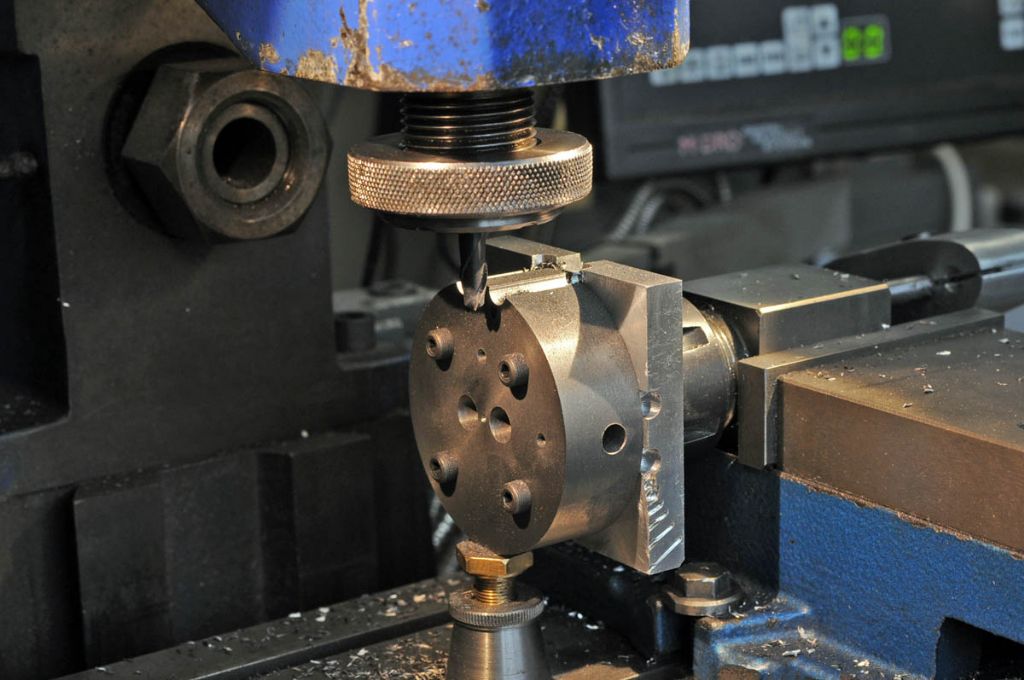

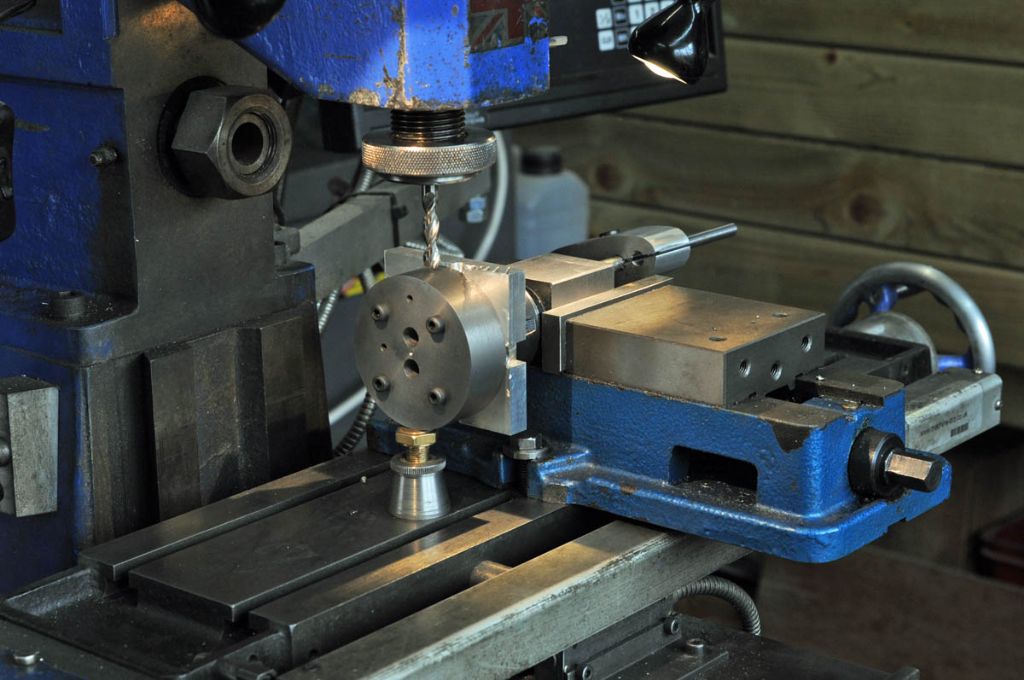

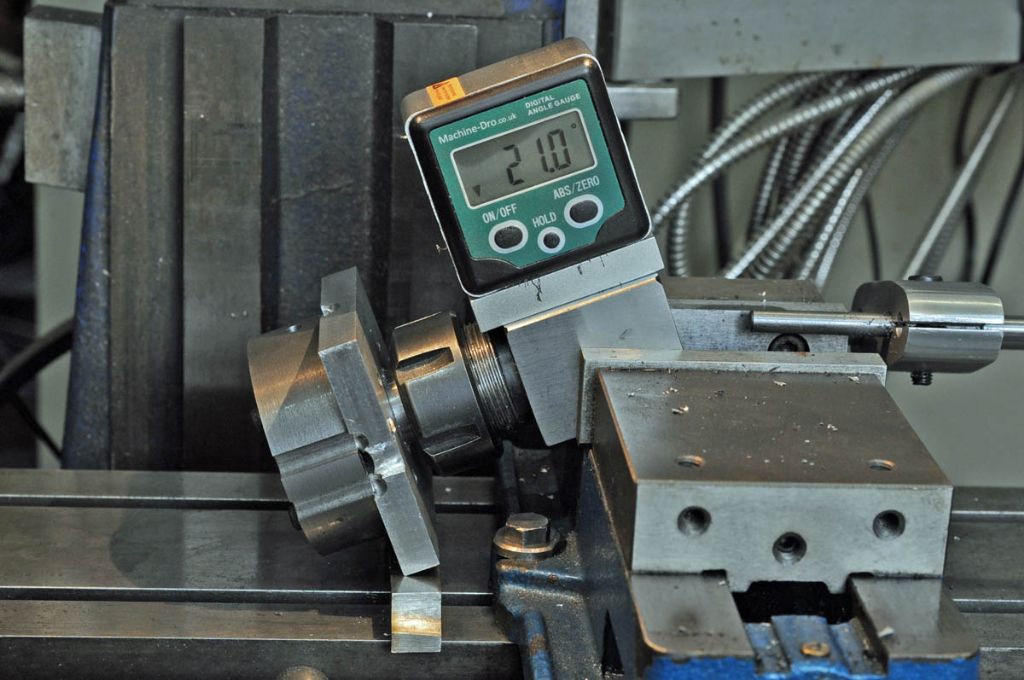

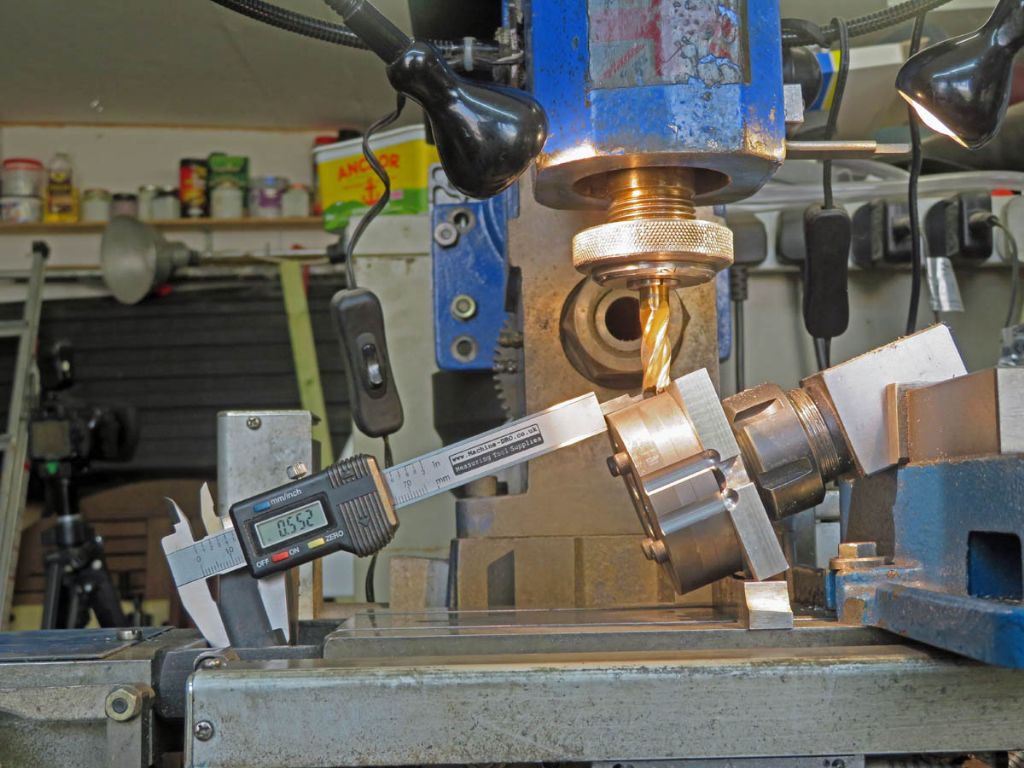

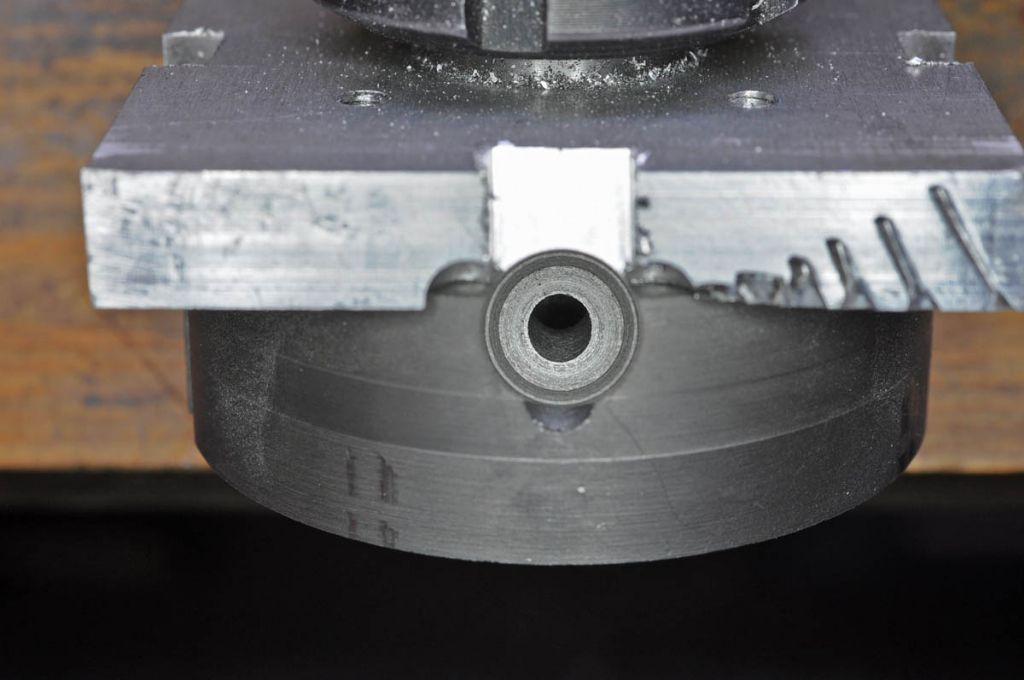

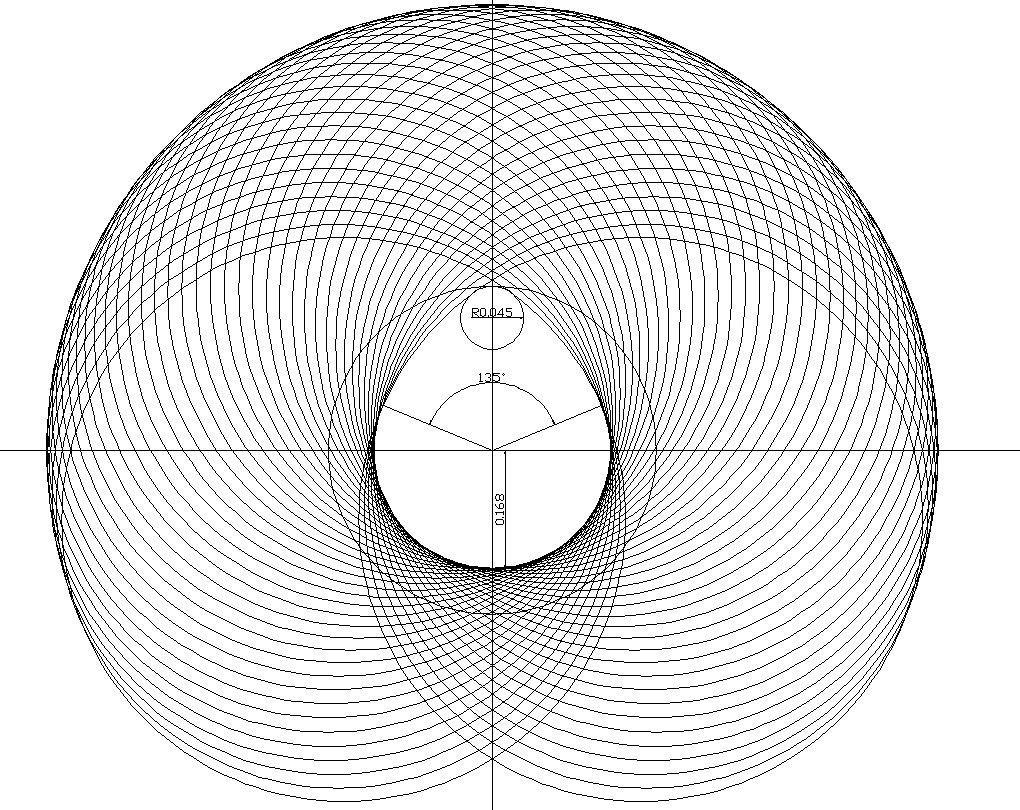

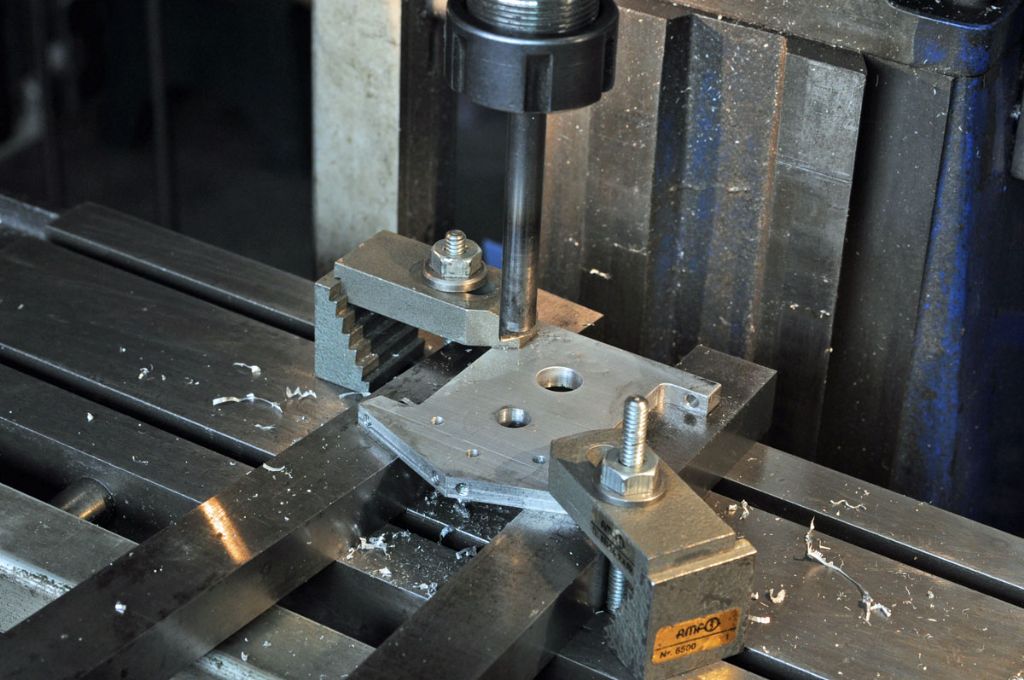

I drew the Cox process (I loved my Spirograph when I was a kid). The large circles are the path of the cutter as it moves around the blank in 5 degree steps with the flank radius offset of 0.4" and a lift of 0.065"

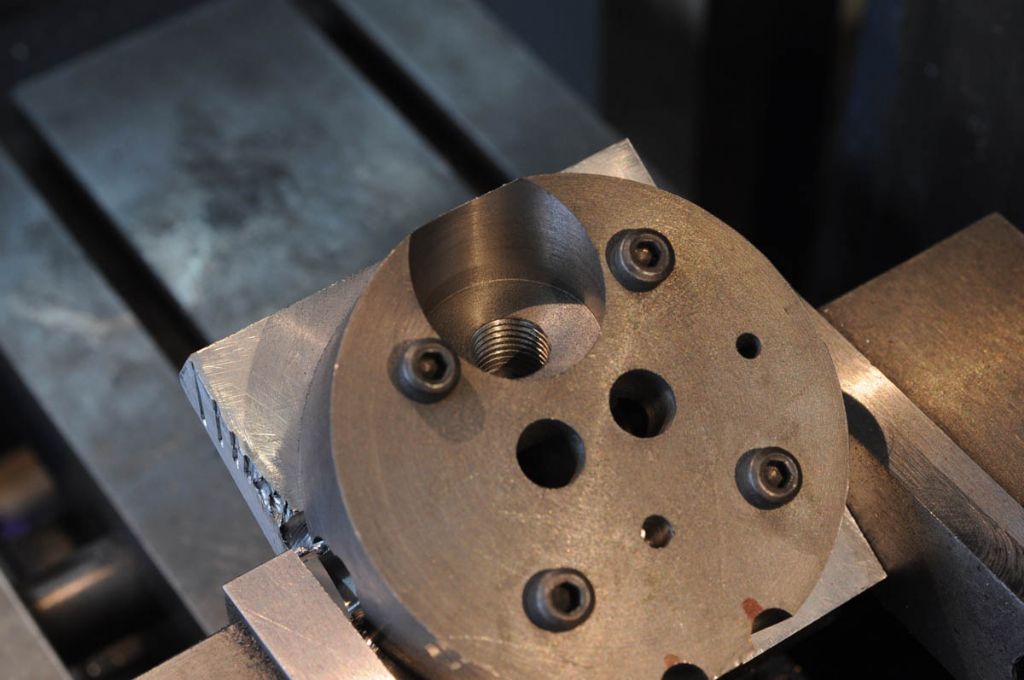

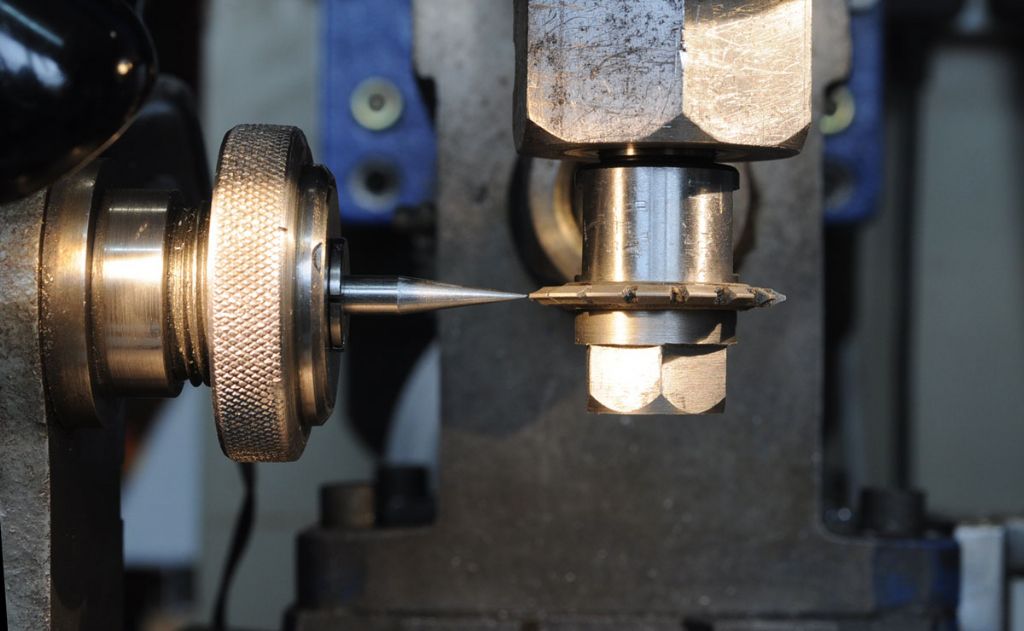

A couple of points first: For a truly Harmonic cam the transitions between the base circle and the flank circle must share a radius, as must the transition between the flank circle and the nose circle. Although not given as a parameter in the Hoglet drawings, the CAD sketch shows that the action angle of the cam (the transition from base to flank) is 135 degrees. The nose circle is drawn as a tan, tan, tan circle to the the 2 flanks and the maximum lift line.

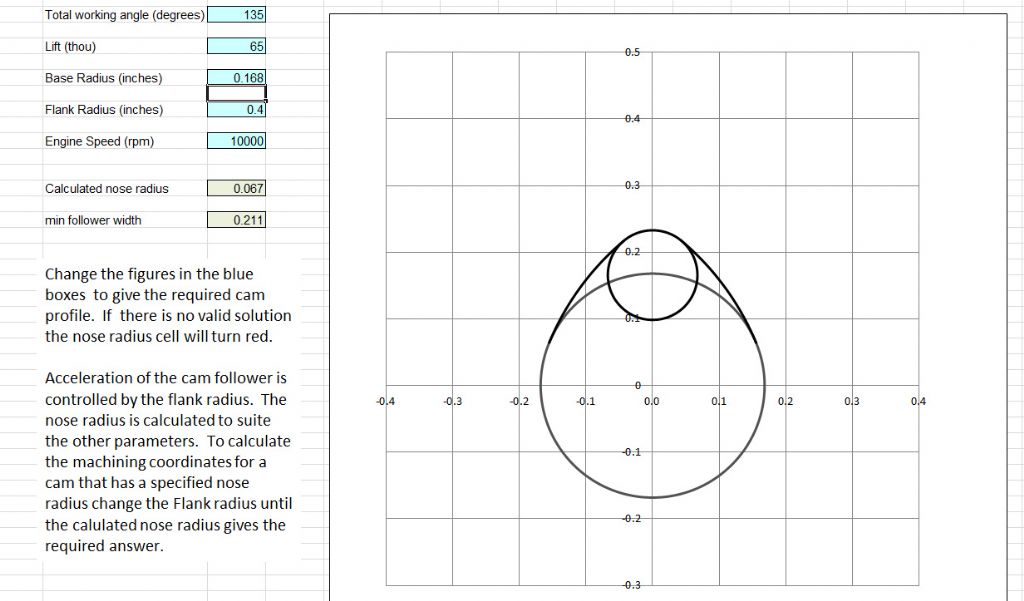

Using these parameters in CamCalc I get this:

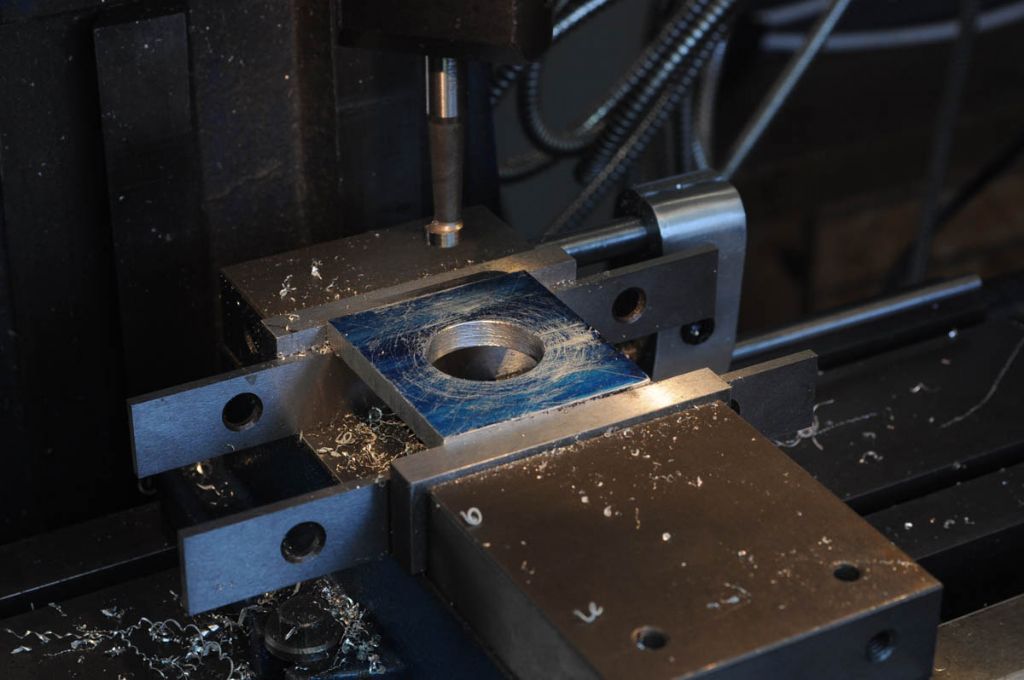

The nose radius from CamCalc is a little larger than the Cox method shows (which is constructed by filing until it looks right). In CamCalc a sharper nose would be given by reducing the flank radius slightly.

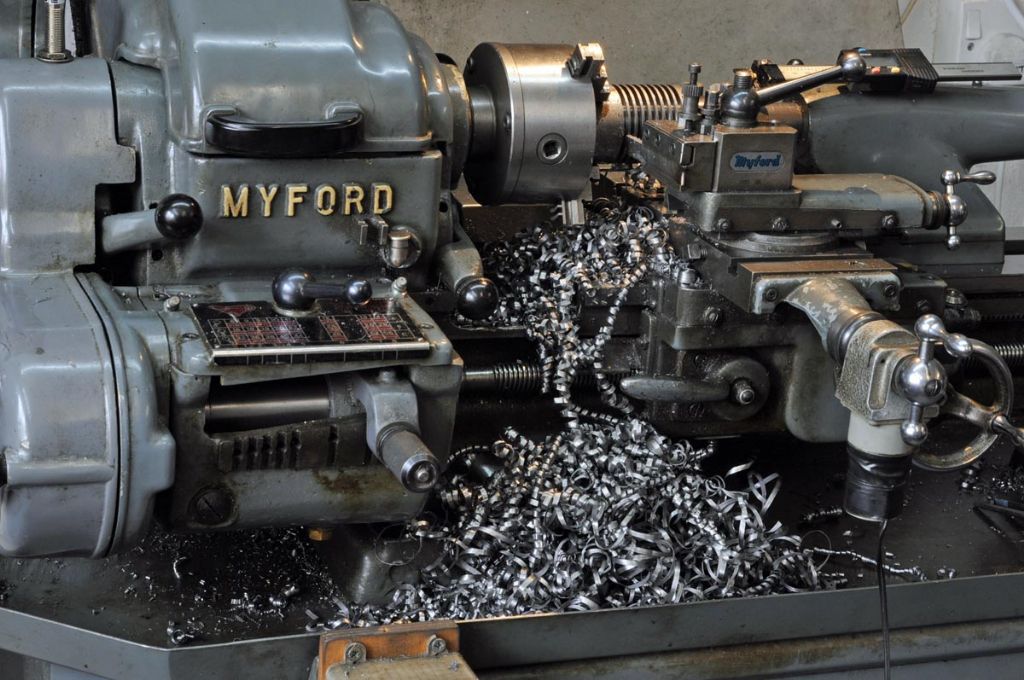

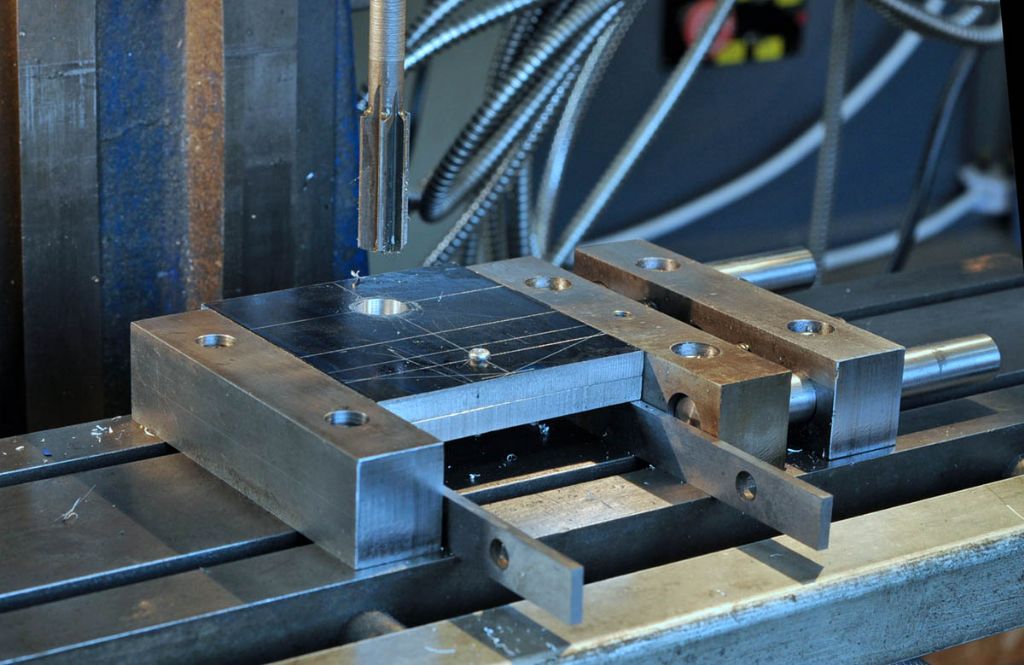

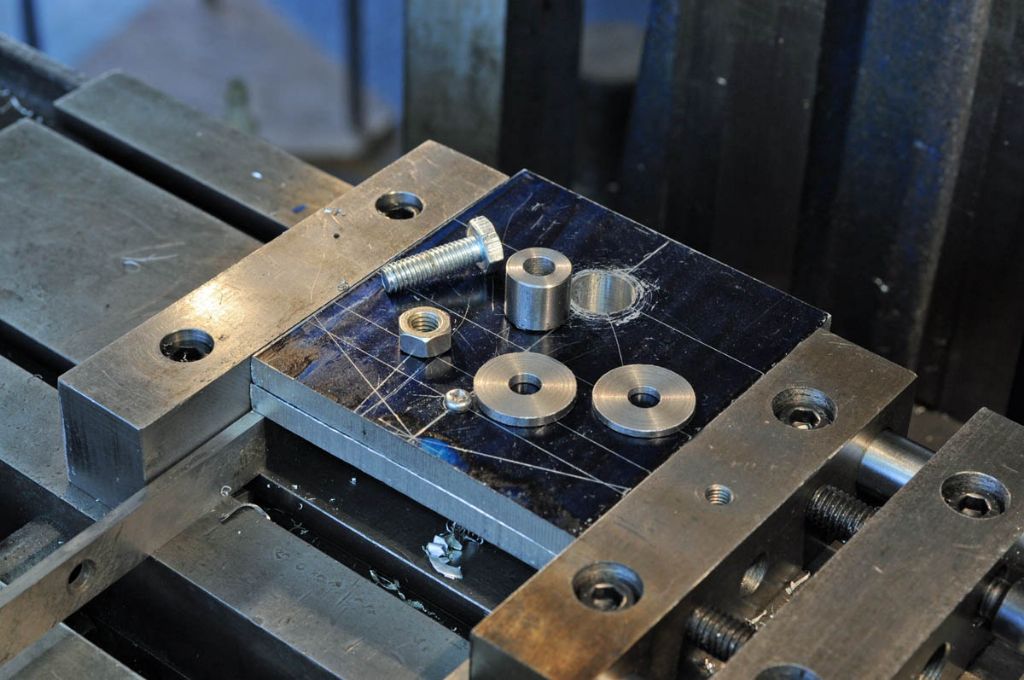

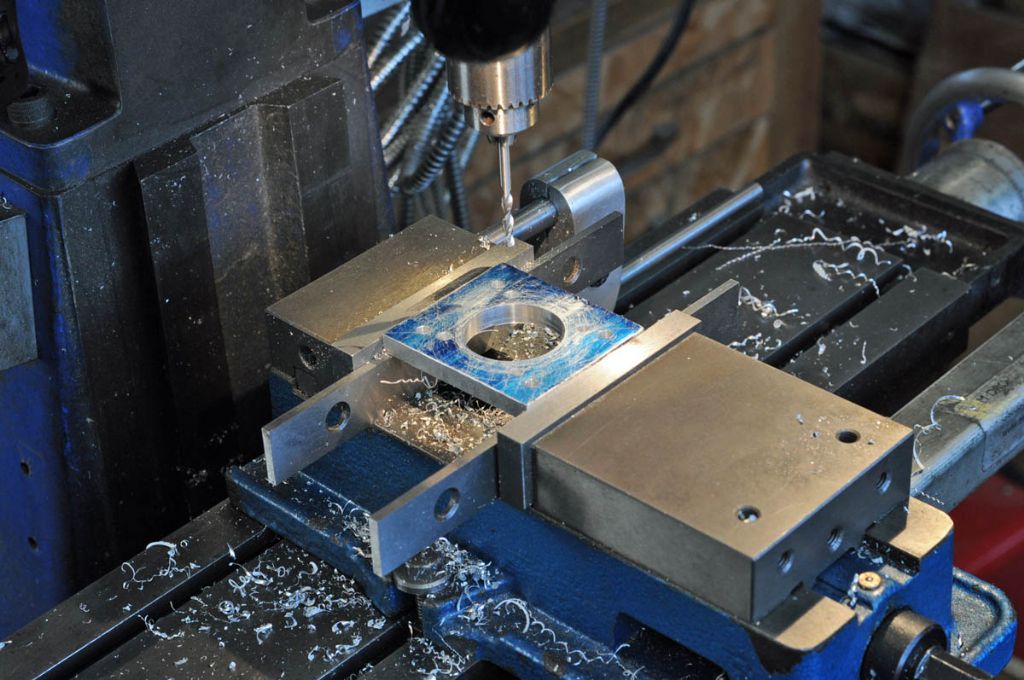

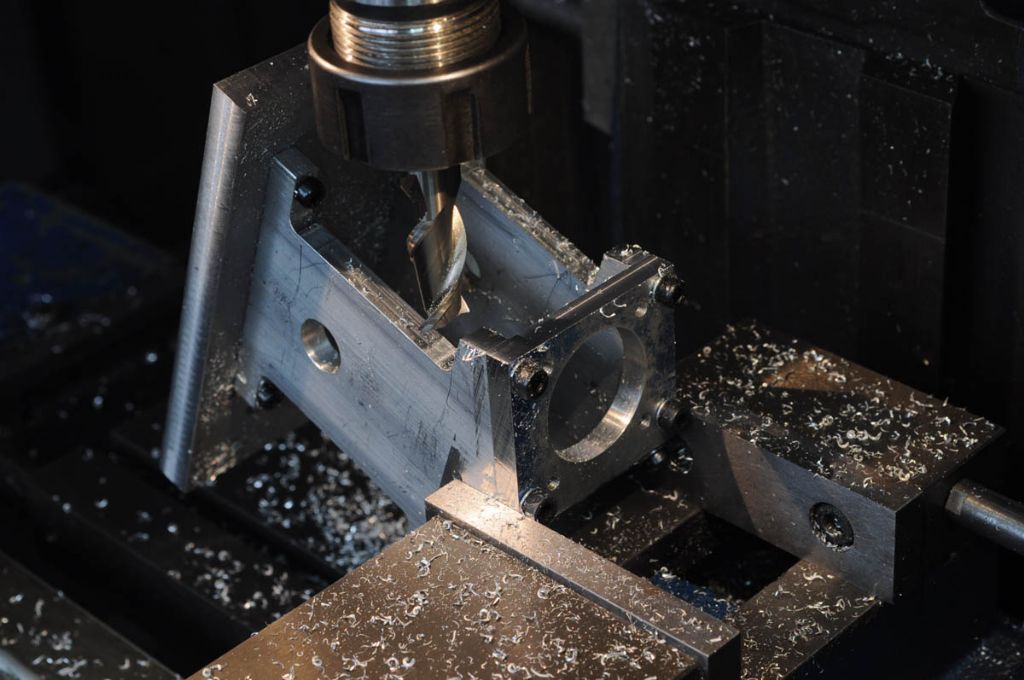

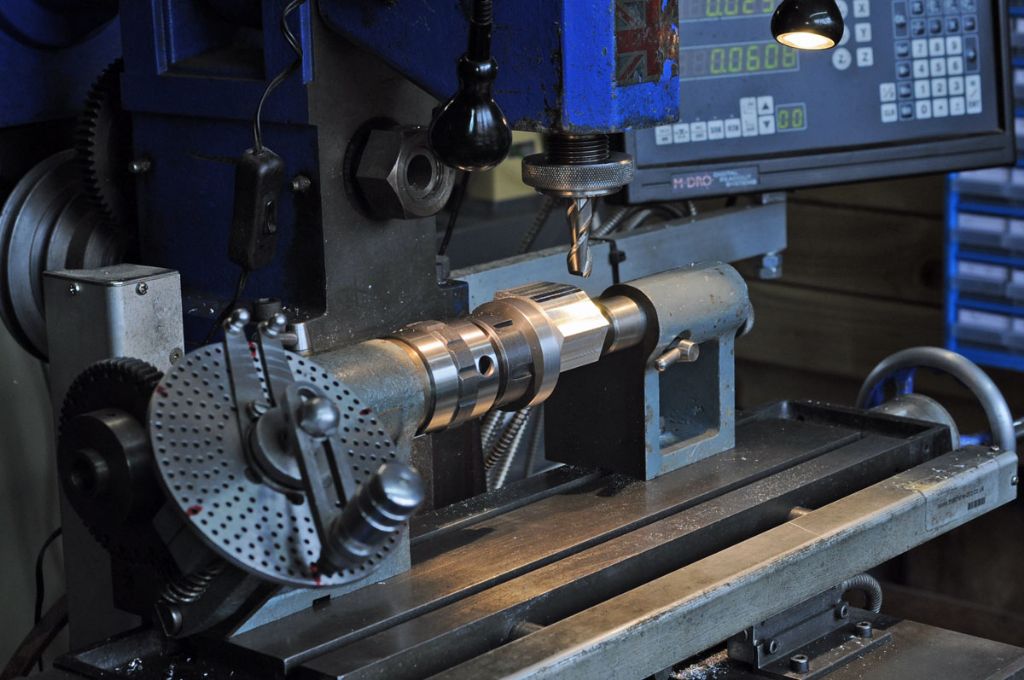

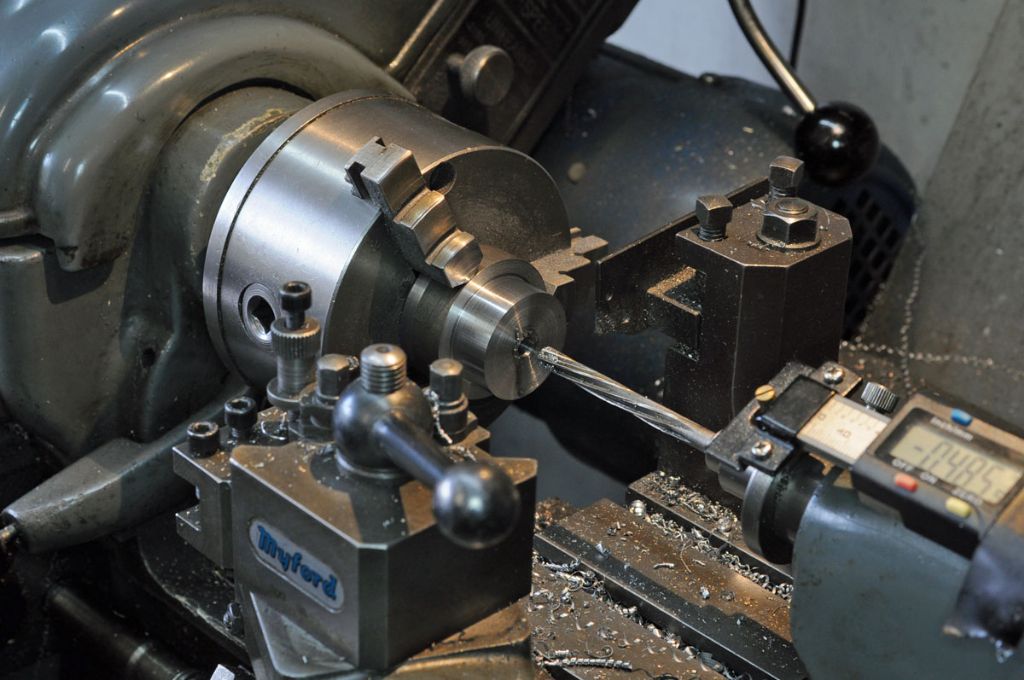

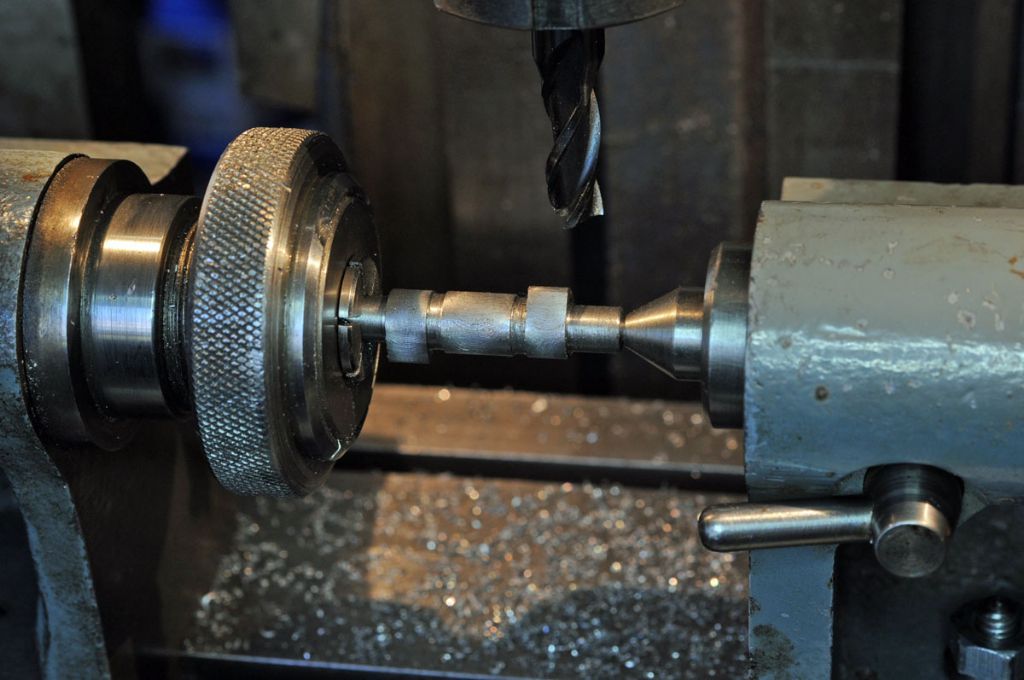

The CamCalc method always seems a little laborious (not to say tedious) – take a cut, wind the handle,move the cutter height, take a cut, wind the handle, move the cutter height, take a cut… but the Cox method is no different really. I would use a 3 degree increment for this size of cam and Cox uses 5 degrees.

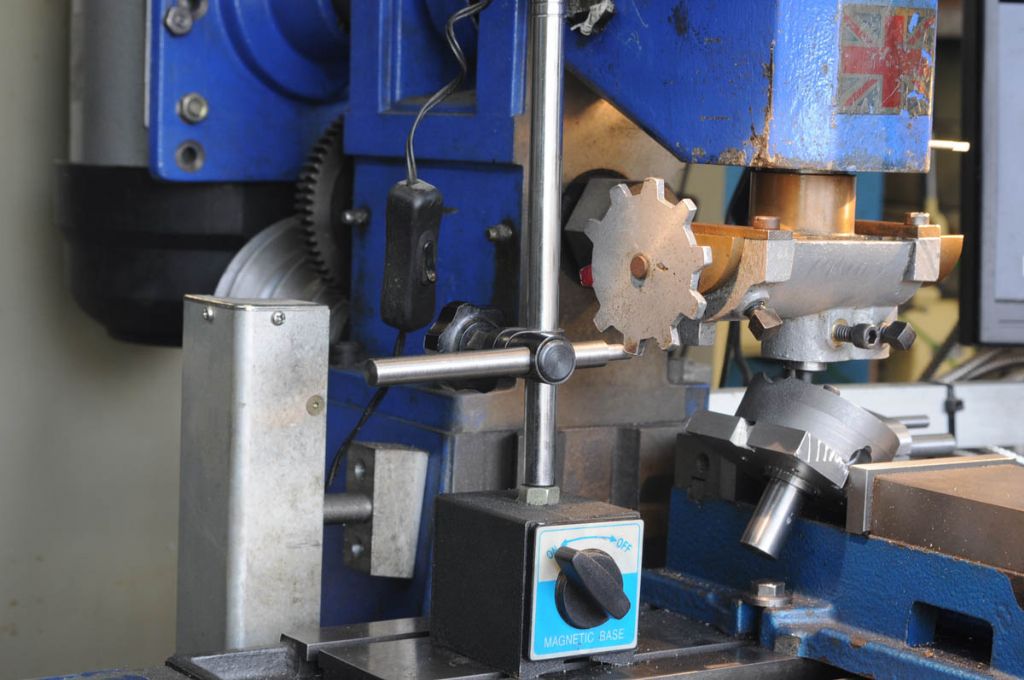

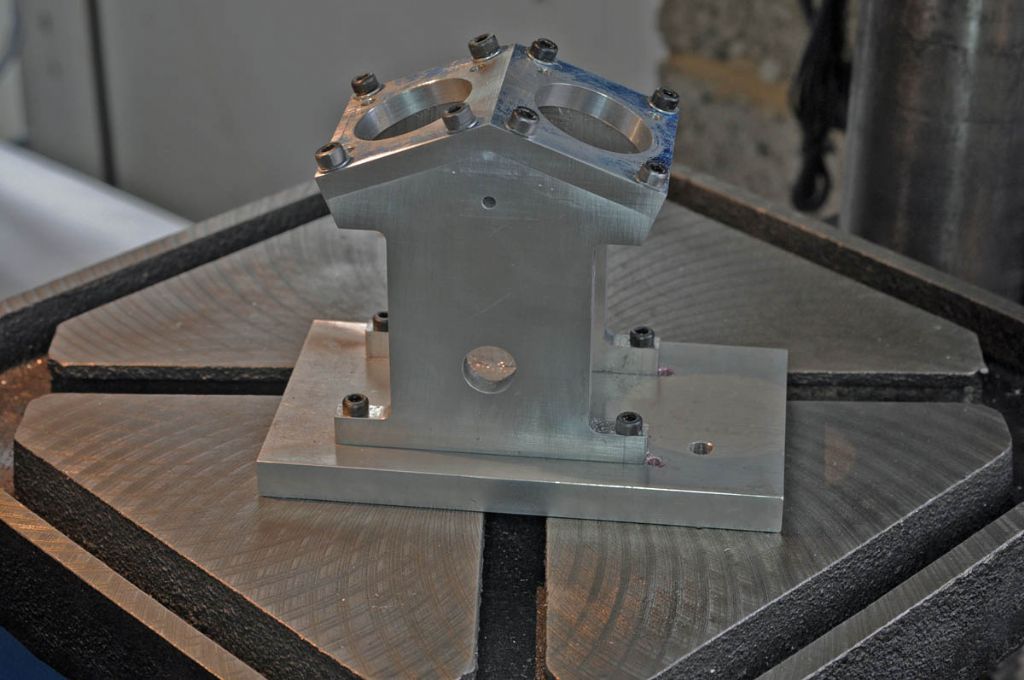

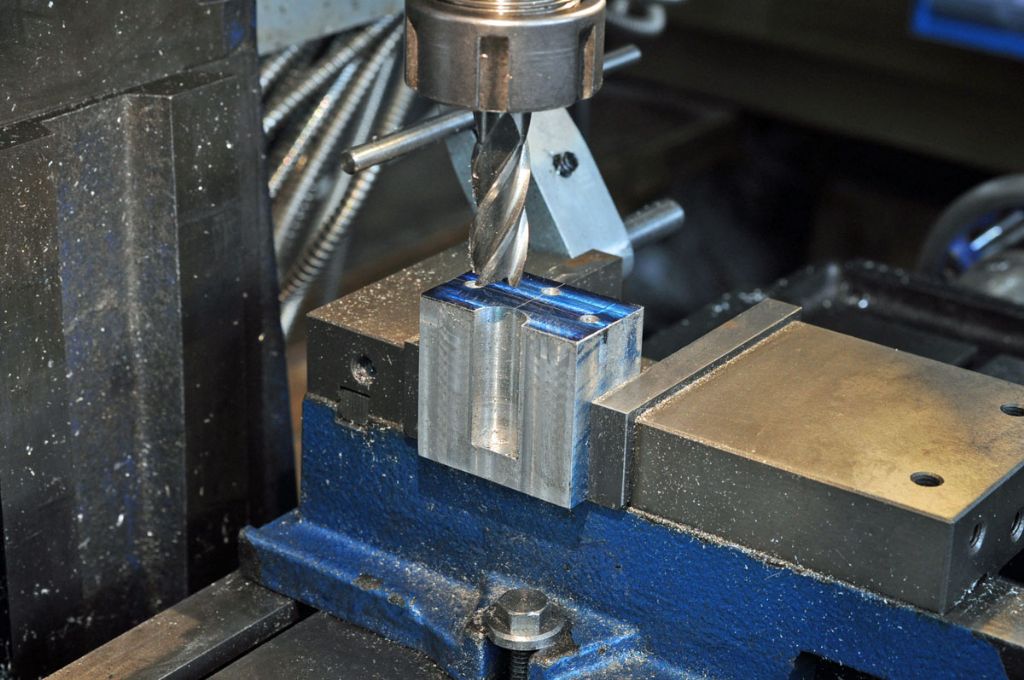

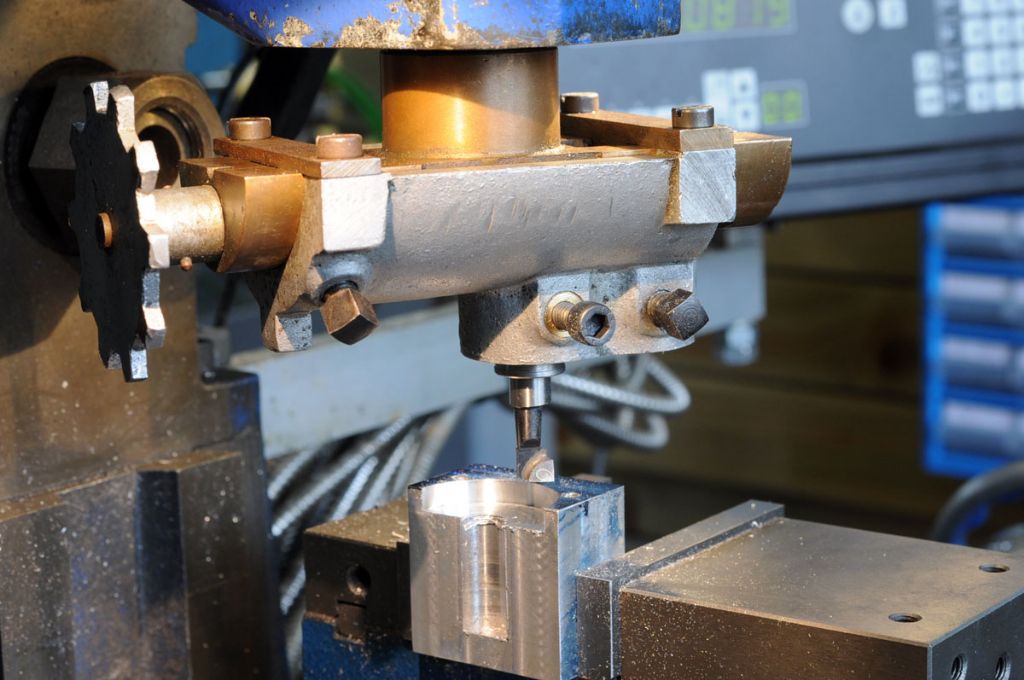

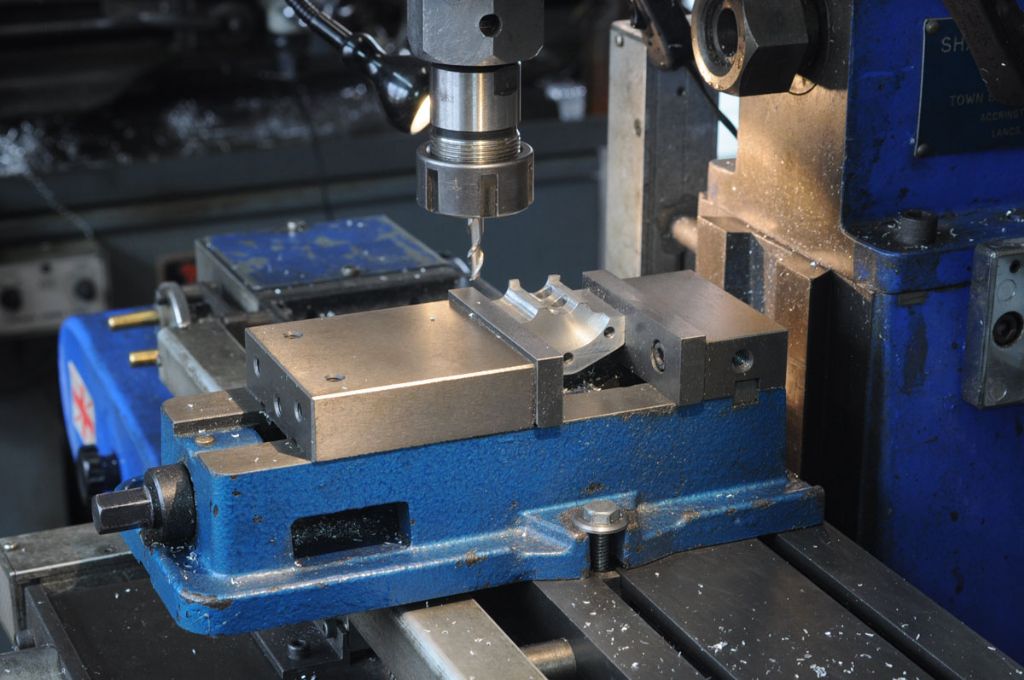

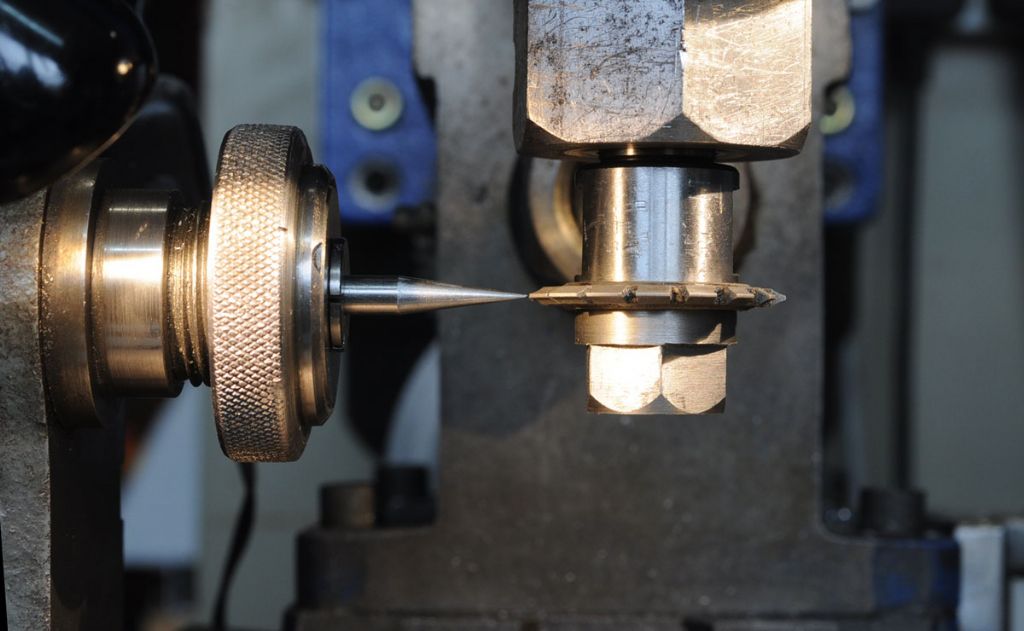

Conclusions: I like the Cox method, it has an elegant simplicity that does not require following a list of numbers. It is not quite as accurate as CamCalc in the nose area but for the sort of engines we make this is immaterial. For this particular engine there is a down side and that is that the cams must be machined in the vertical mode with the ensuing problems of rigidity with an interrupted flycut. With CamCalc the cam blank would be horizontal and the machining is a light cut with an end mill for each increment of rotation and no risk of interference from the boring bar on the subsequent cams.

I shall be using the Cox method for my Hoglet 'cause it's good enough and a different challenge and I like that.

Rod

Edited By Roderick Jenkins on 01/09/2022 11:49:46

GrahamS.