On my test ride I had another issue after assembling all again I found that my fire burns not so good as I had it in mind. A few years ago I bought the book "The Fire Burns Much Better" and in the last pages there were for models a multi jet nozzle with the words " that have a better performance".

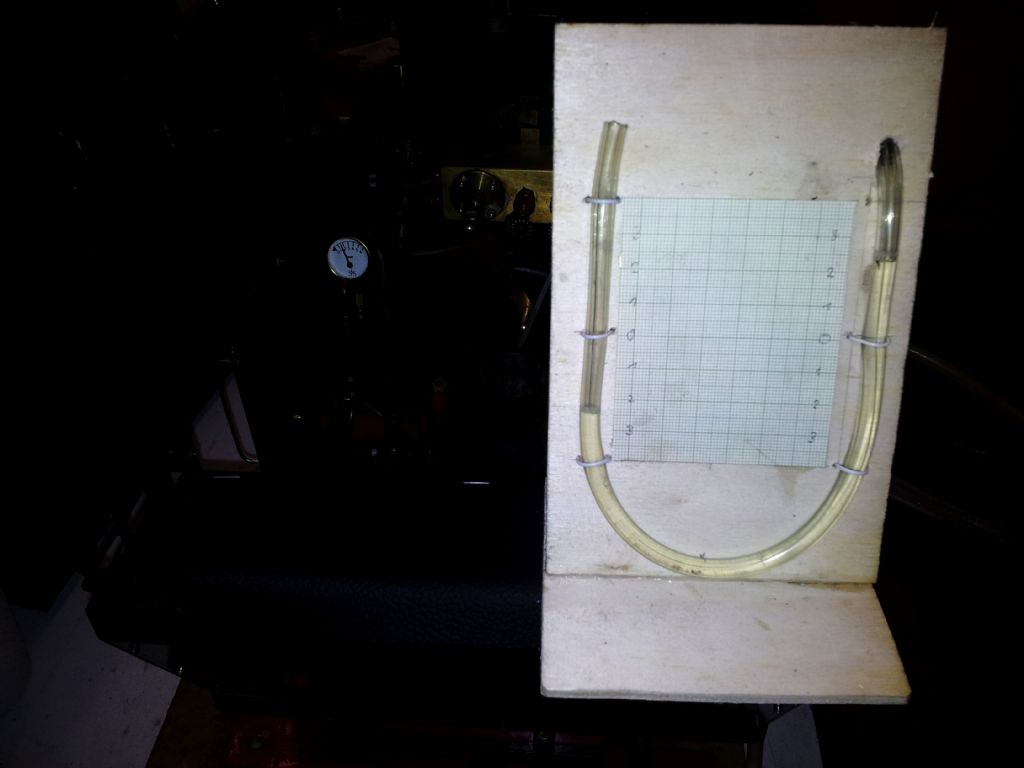

I decided to measure the different steps in the development of a new front end configuration. At first i build a simple u shape low pressure gauge from wood and clear plastic hose. This was filled with water. One end is open the other end is running trough the fire hole and the smoke pipe into the smpke chamber. The smoke chamber had a clamped in rubber sealing for the smoke pipes. Only the measuring hose came in. The test run with air pressure in my basement. So I was able to compare the different nozzle and had readings at the scale of the U Pipe gauge. And I made electronic measurements too.

This is an exampel reading under test with 1.5 bar air pressure. I made several tests, helping blower alone, then with the running engine and both.

So it was easy to compare the different nozzle setups. Without the test both water parts in the gauge have the same height. In the shown picture there is a low pressure from about 4.5 mbar.

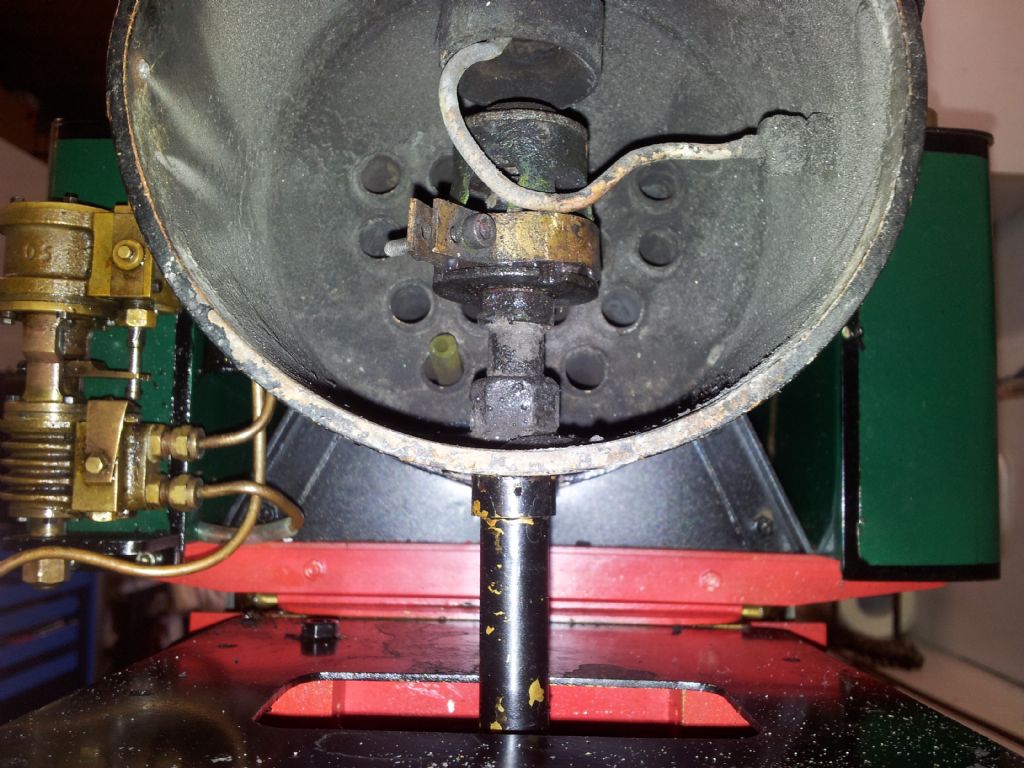

this was the initial setup with a nozzle of 2.5 mm bore hole

new setup with the multijet nozzle.

The initial nozzle had an area of 4.9 mm² the new one 6.64 mm² . I made several tests and I playing with the optimal height setup and so on. The first step was 7 * 1.1 mm bore straigth. this had a better low pressure reading as before. Then i made nozzle where the outside jets have inclination 2° and 5° to the outside.

The last one was in my tests the best one , so I made test rides under steam with this setup. This nozzle have 35 % more area for steam in the nozzle and therefore less back pressure for the steam engine.

The test at my garden track was very good so we decide to go to another club track.

We drove at that day nearly 15 Km with a good test result. The temperature was about 12°C and this was in former times not so good . In the most time during driving the steam out of the chimney is very hot and not noticeable as steam . That showed an improved draught.

After this sucsess I made a new nozzle with 7*1.2 mm 5° outside and this was another big step forward. The engine had a much lower back pressure as before and runs remarkable better. this nozzle had slightly better low pressure redings at the test setup but 66% increased nozzle area.

For my 2 cylinder engine I will try the same this year in practise. We will sse what the outcome is.

Werner

Edited By Werner Schleidt on 03/01/2022 08:08:20

Werner Schleidt.