The CNC Lathe I am building has live tooling requiring a drive motor. I used a BLDC motor , with modifications to the motor rotor housing, to be able to fit into/onto the ATC mechanism.

The motor is an 'outrunner' where the outer housing, the rotor, spins. I modified this housing to fit into a new housing which has a bearing spigot to take rotational loads in the ATC. These modification require that rotor be balanced again. Very little mass had to be removed, I guess thanks to good setup in the CNC mill during machining.

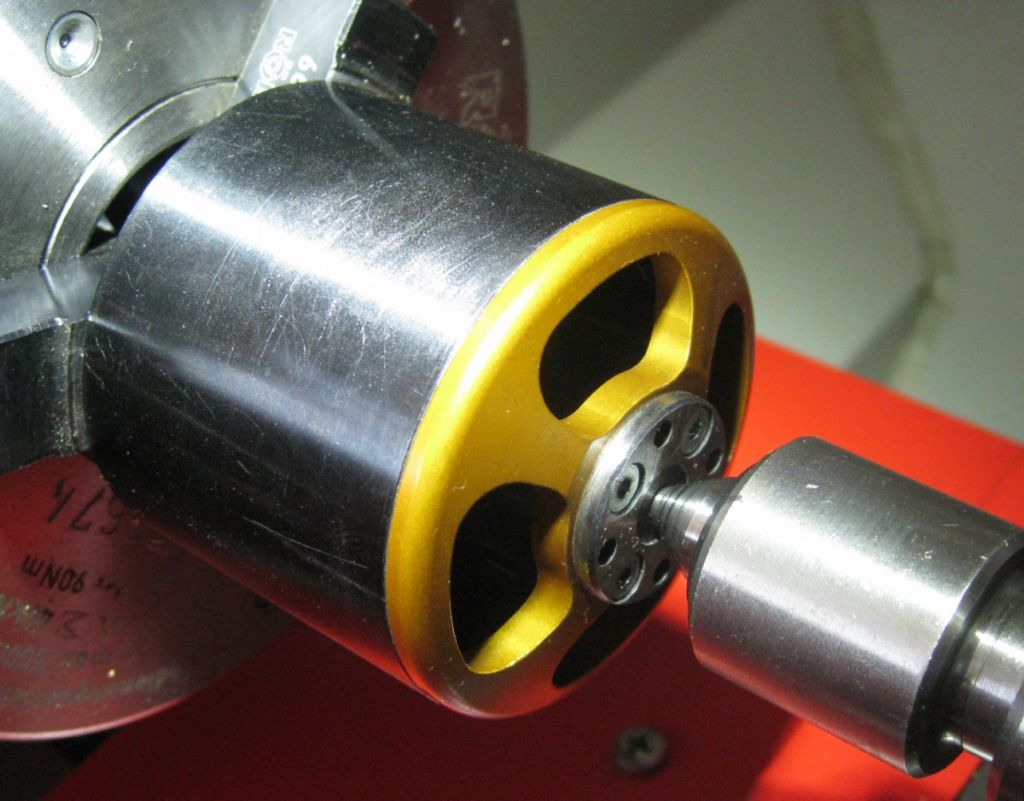

The existing motor rotor bell end was removed and the rotor pressed into the new housing – photo above.

The yellow part to be cut off/out-

End removed and rotor cleaned up.

And pressed into the new Rotor housing.

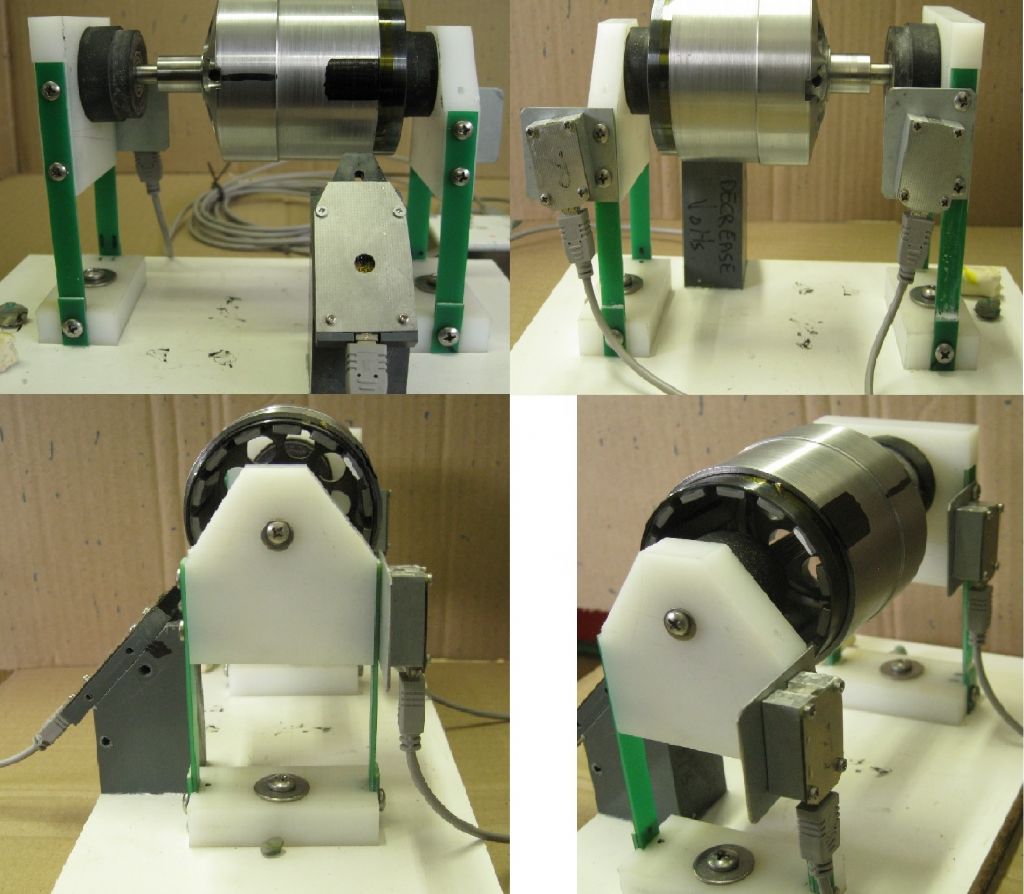

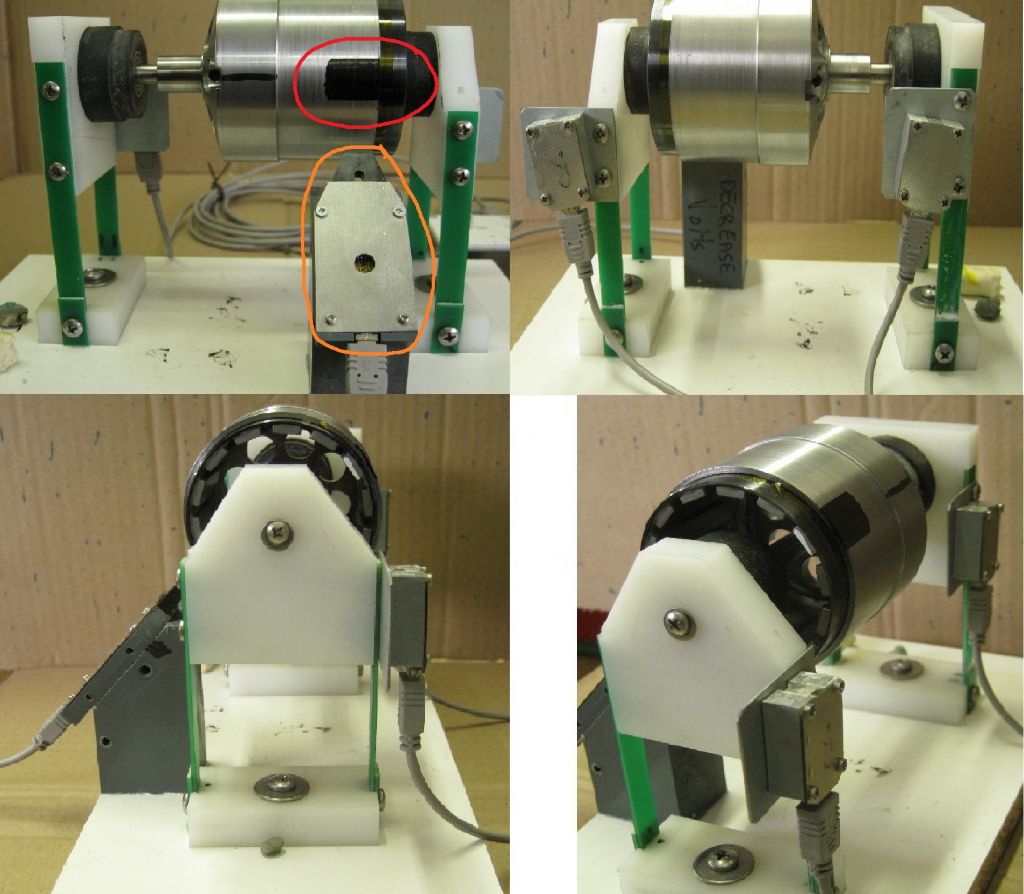

A balance jig allows the rotor to float easily front and back, with accelerometers ( left and right) attached in the same plane.

Views below show;

TOP LEFT = Front View – the lower right is an optical detector detecting the start of the black line on the rotor. This measures RPM and the jig is calibrated by attaching a weight at the rotor reference position which coincides with that detection edge. The rotor is spun up and the referenced This calculates the zero deg angle for weight placement reference. The test weight is then removed.

TOP RIGHT = Rear View, showing the two accelerometers, magnetically attached. Two accelerometers are used, since I need to do two plane dynamic balancing.

BOTTOM LEFT and RIGHT = side and side/rear views.

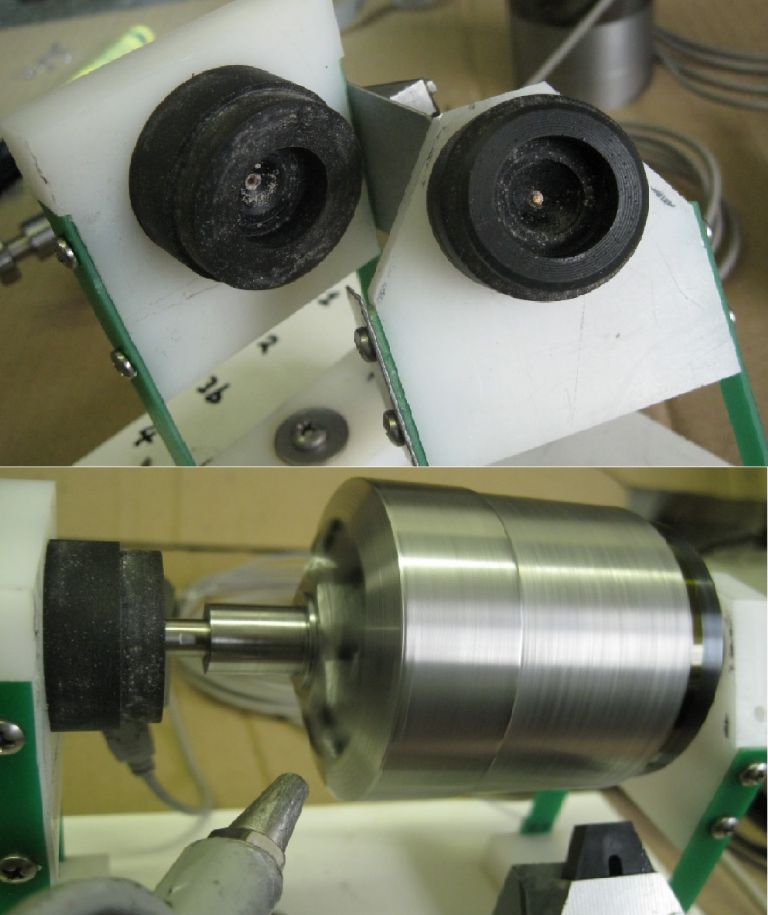

The Upper image of below shows the bearing housings on the test jig, the Lower image shows the air spout used to spin the rotor up.

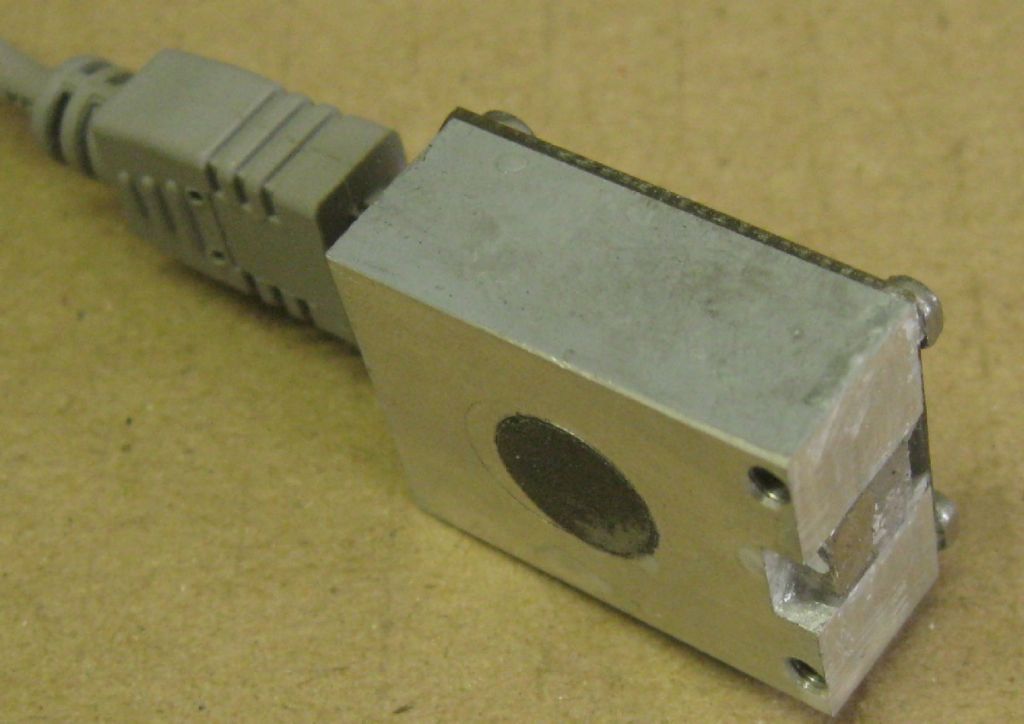

One of the accelerometers – magnets on the Z and Y axes allow quick attachments and removal.

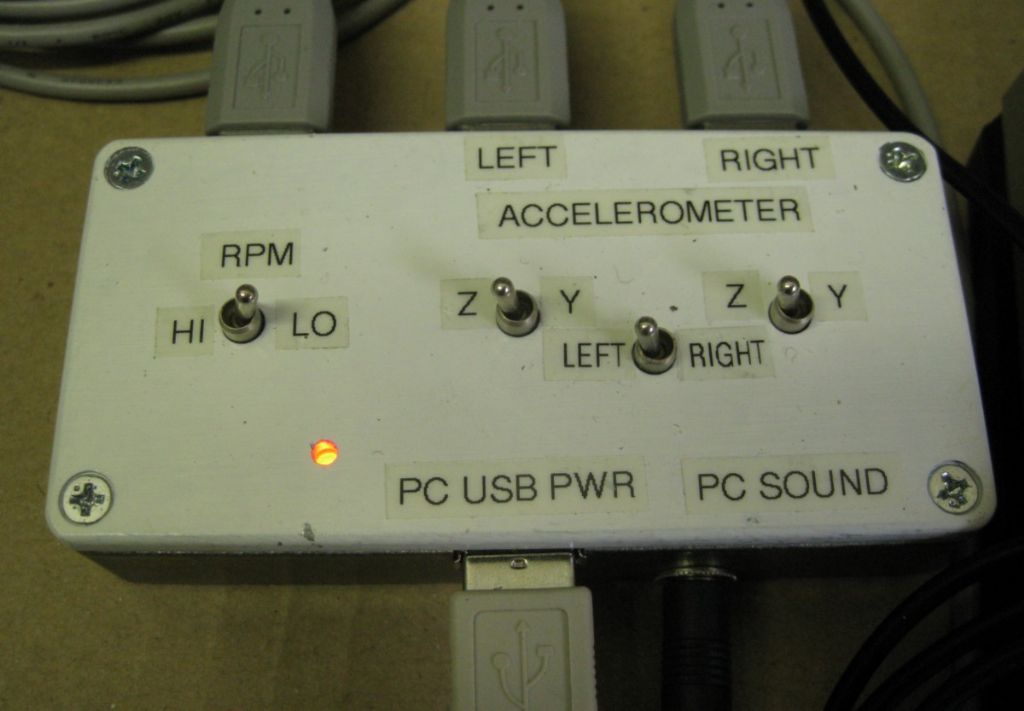

The accelerometers, RPM sensor, all come to this interface box, where the correct planes can be selected. The signals go from here to the sound card in the PC, and the software does the rest..

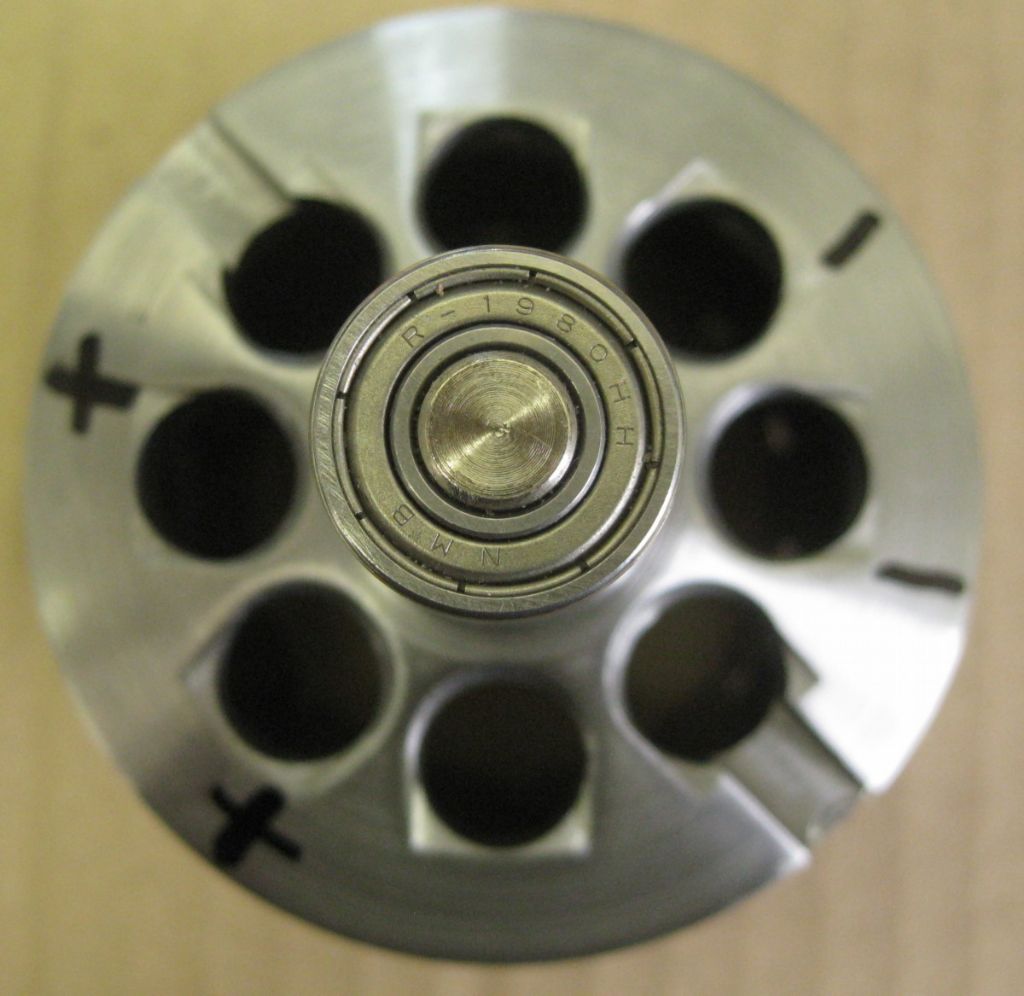

Did not realise the camera focused on the bearing instead of the mass positions..The + signs show where the balance weights are added inside the rotor. The – signs show where to remove mass to balance. The two small weights were then removed and weighed.

A 10gram scale (0.001g 'resolution..) was used – not accurate, but fine for comparative measurements.

The two weights were removed and weighed. To get a feel for how big a hole to drill on the rotor inner to remove similar weight, an M3x5mm grub screw was weighed.

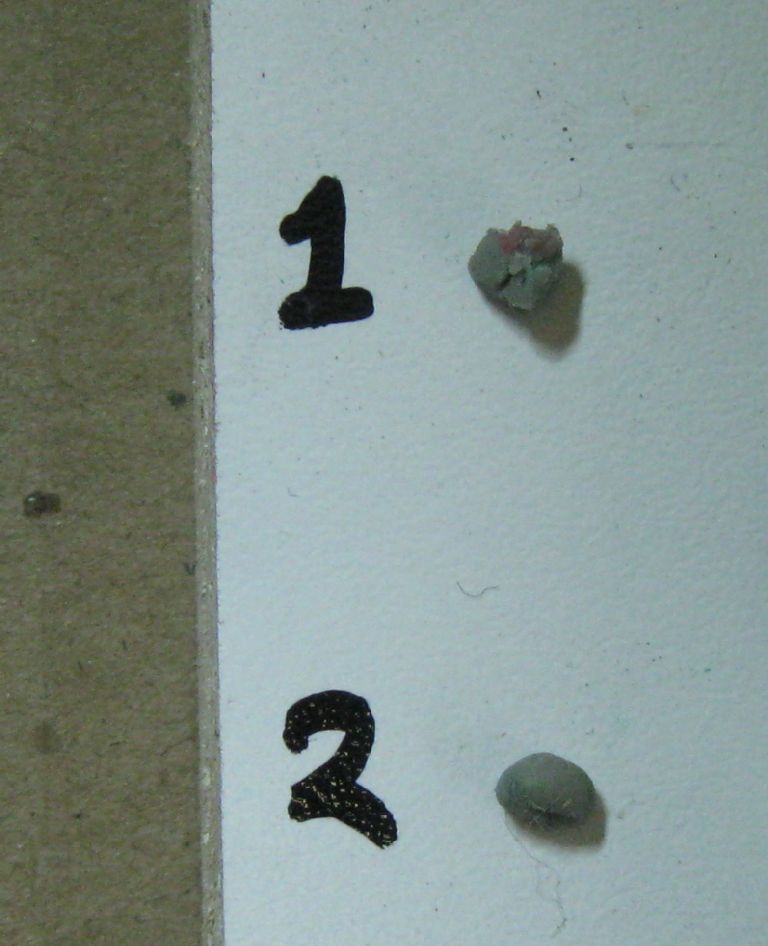

The two little tackytape weights seen here:

The two weigh near 0.085g, the grub screw 0.156g, so need to remove 1/2 grub screw size, spread over the two balance positions.

The two holes are 4mm diameter, 1mm deep each. I started with 3mm x 0.5mm deep. Then 4mm x 0.5mm deep, and repeat deeper till done.

This was all repeated for the right side of the housing , while verifying effects to the opposite sides regularly

Edited By Joseph Noci 1 on 04

Werner Schleidt.