Not sure if I should start splitting the posts – would like to keep the build history in one place, but as I am visually vociferous the post becomes rather large…Will do what is suggested…

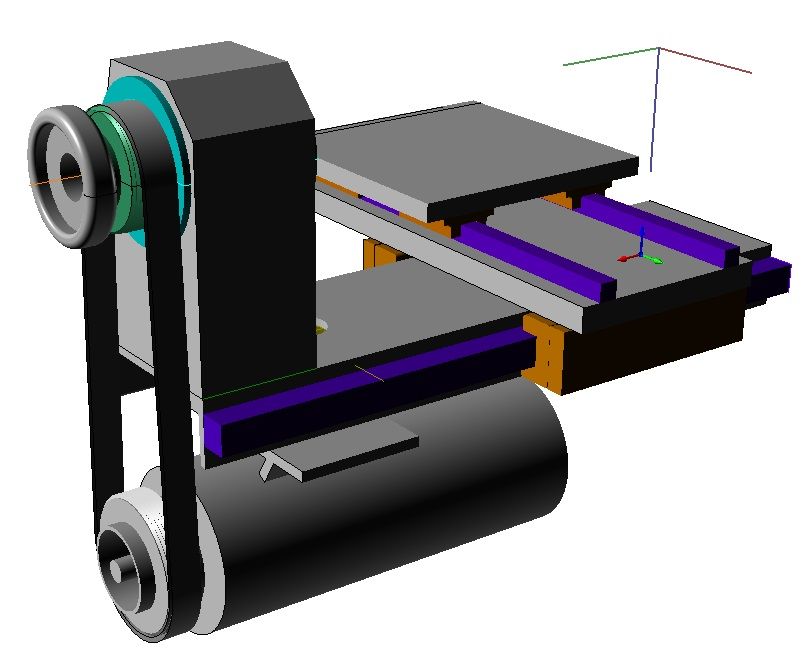

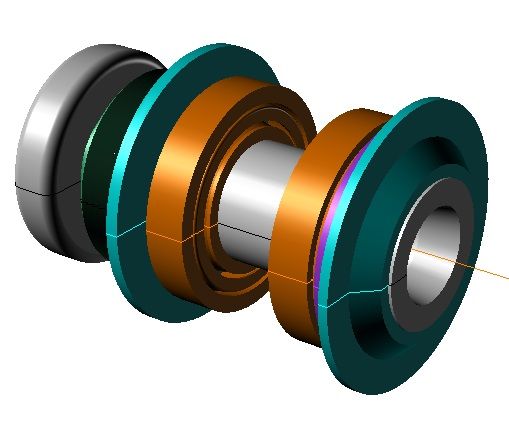

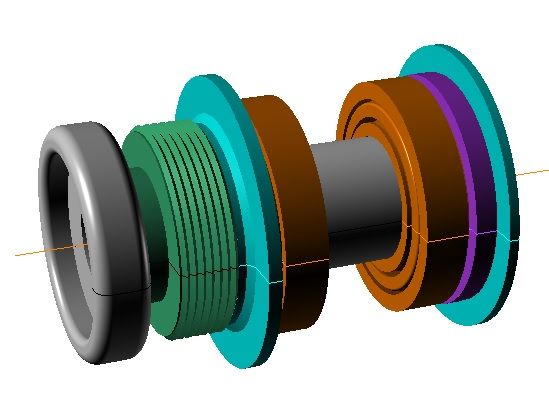

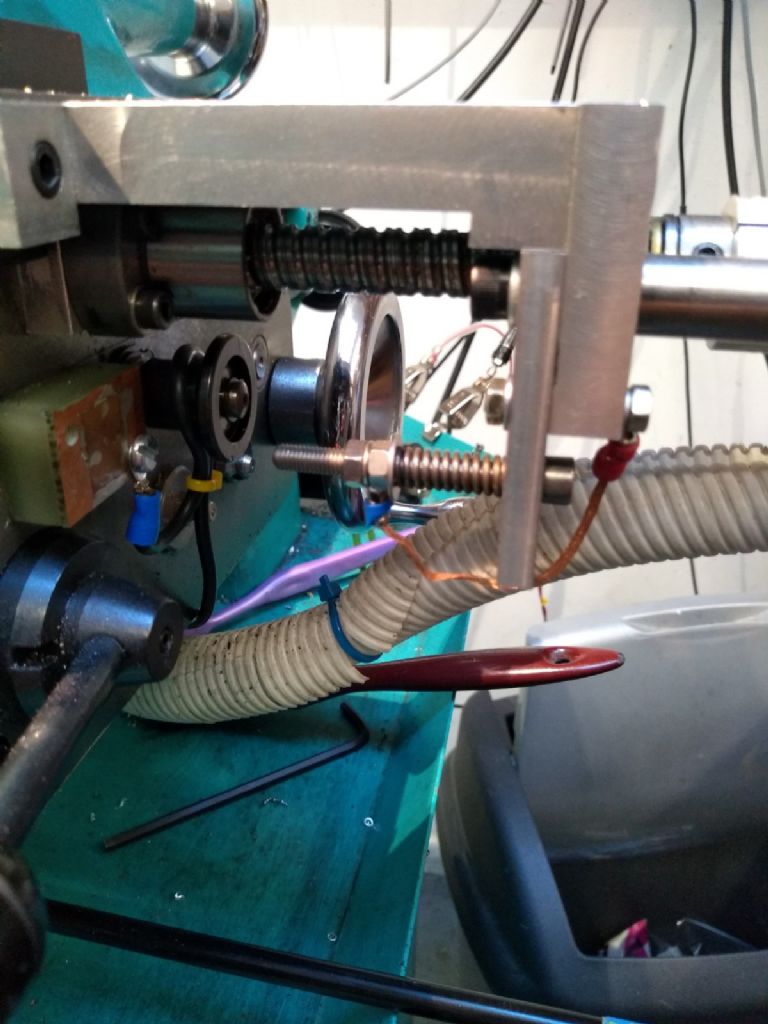

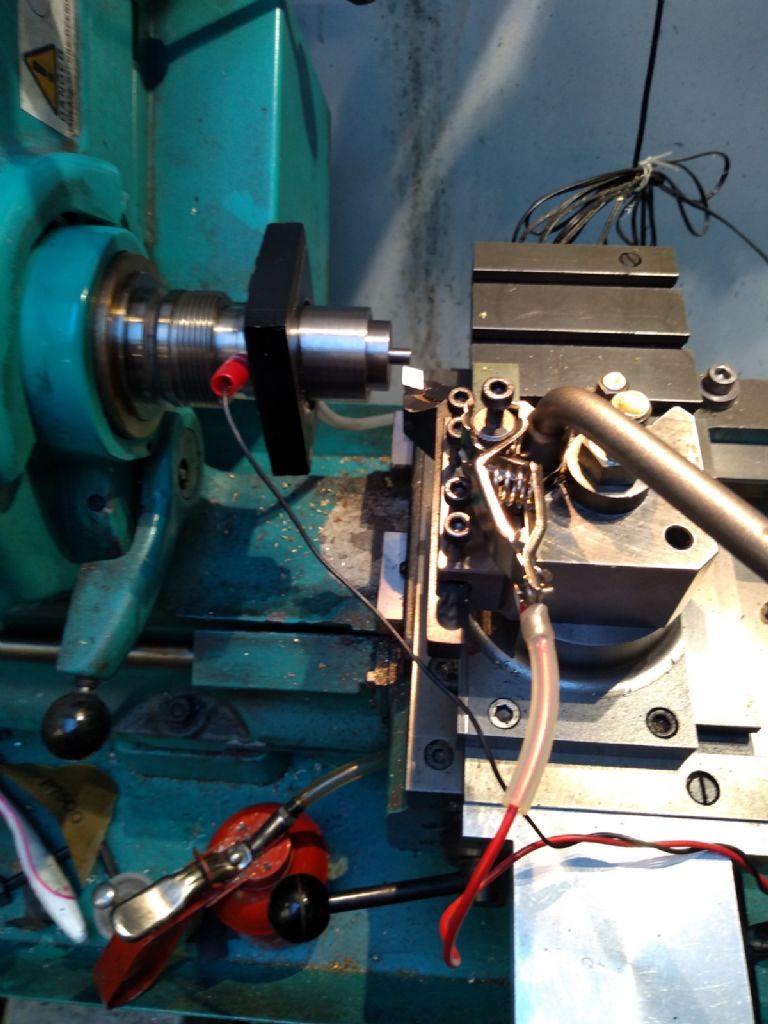

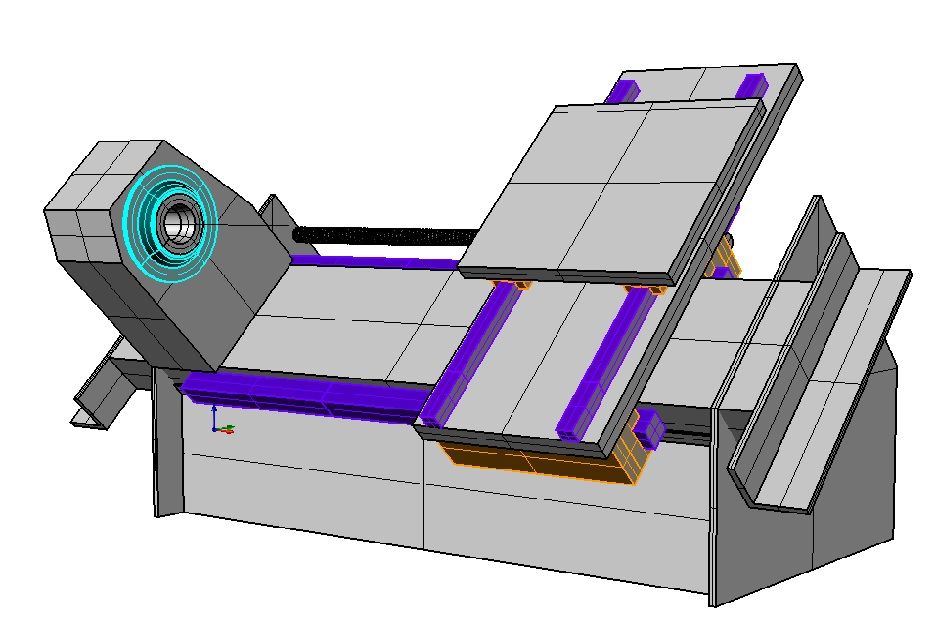

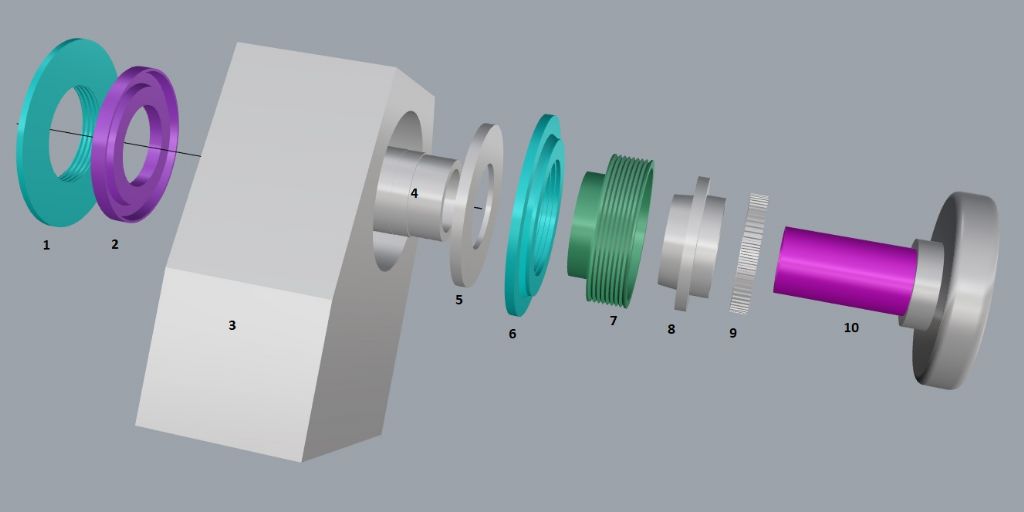

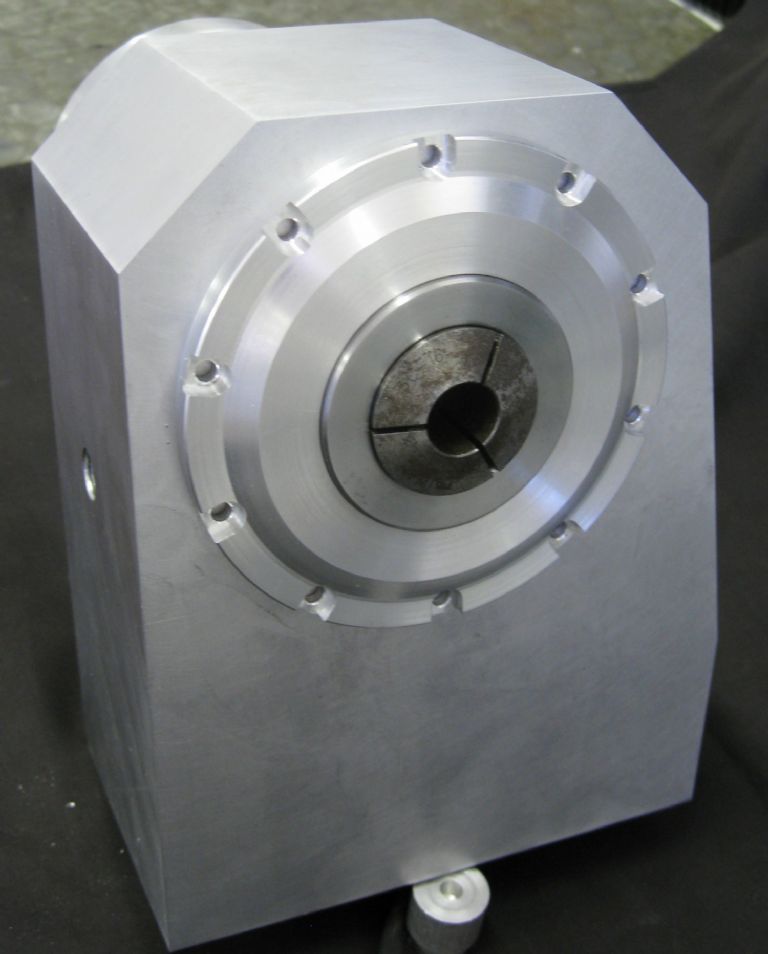

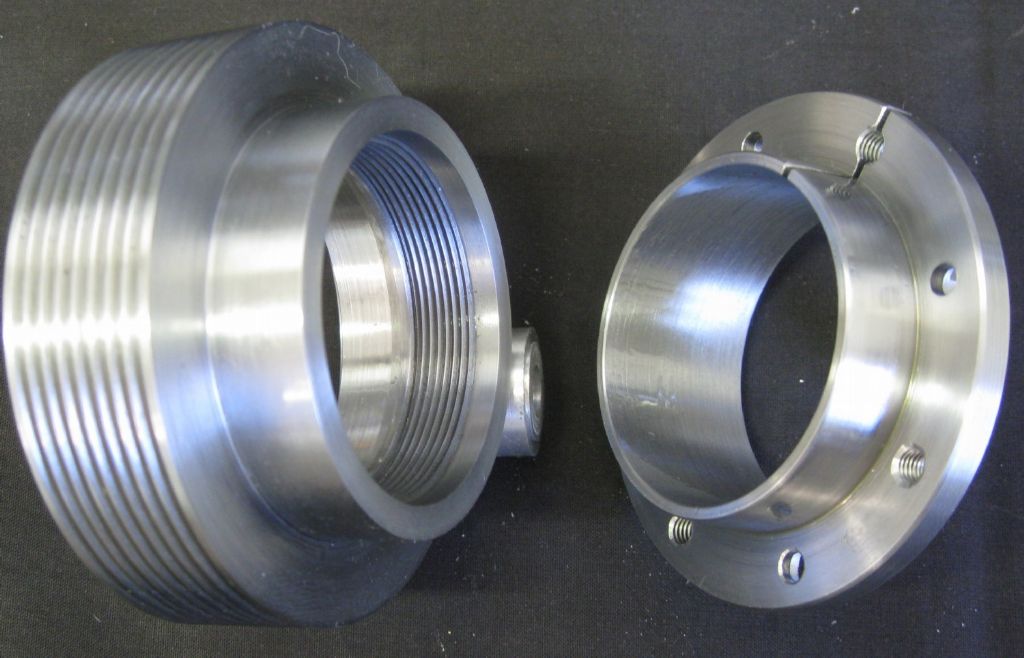

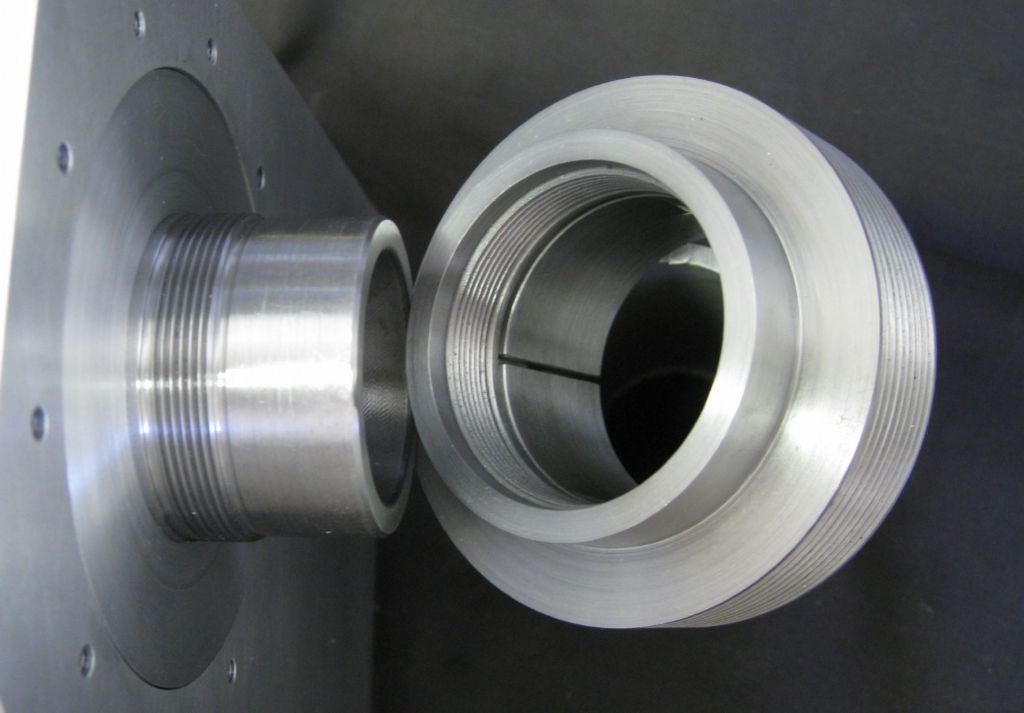

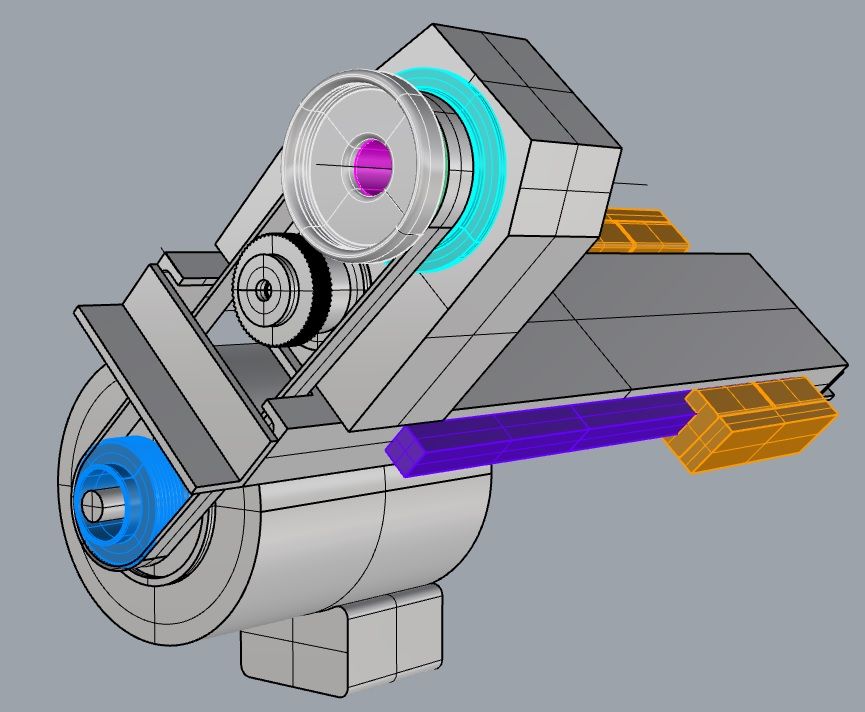

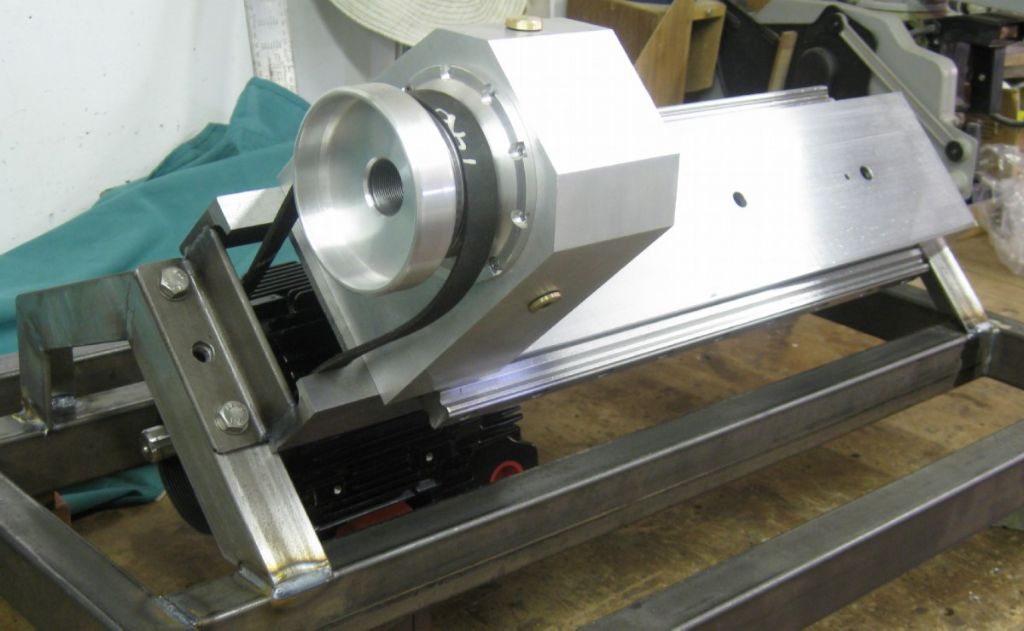

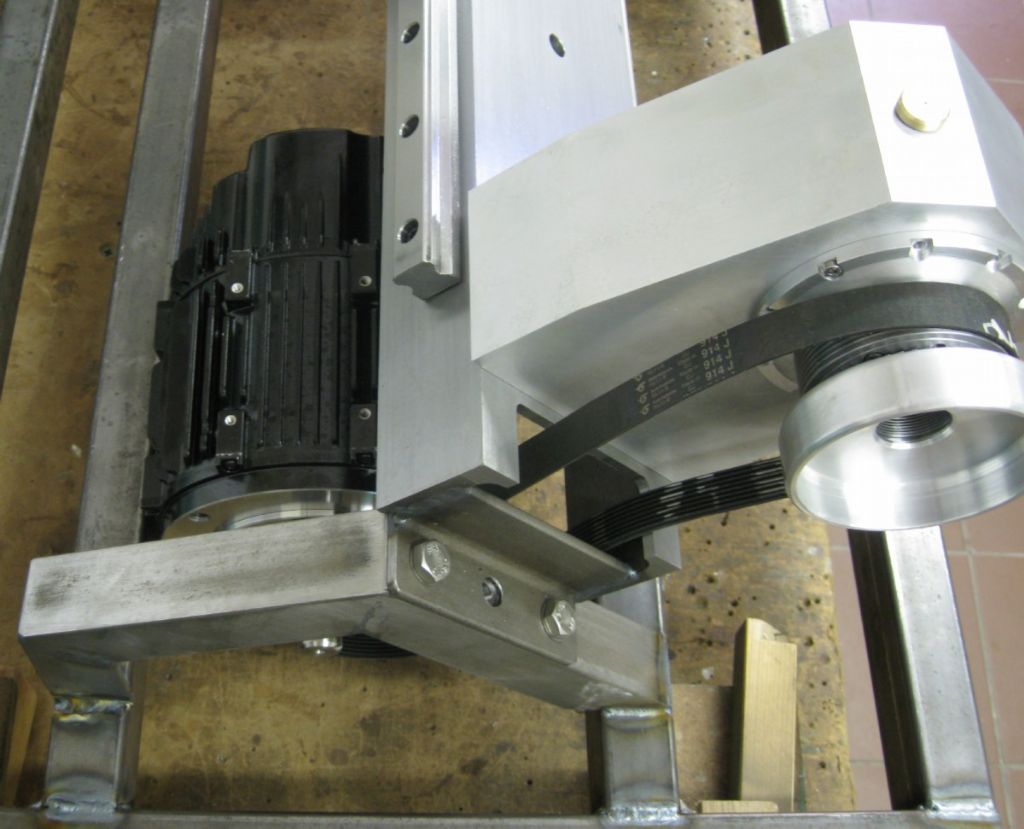

The Lathe bed turned out well, and the base framework is also started – The exercise now being to get the spindle motor positioned with regard to the drive belt, spindle, and motor tilt mechanism. The latter required as the motor will be fitted with a dual sheave pulley, one of 120mm OD and the step below , 80mm OD, giving max spindle RPM of 4000RPM and 2700RPM resp. I am hoping ( torque calcs indicate it is possible) that I will get away with just the 120mm pulley, and still have enough torque at low RPM's – sort of around 20RPM for some 'heavy' cuts.

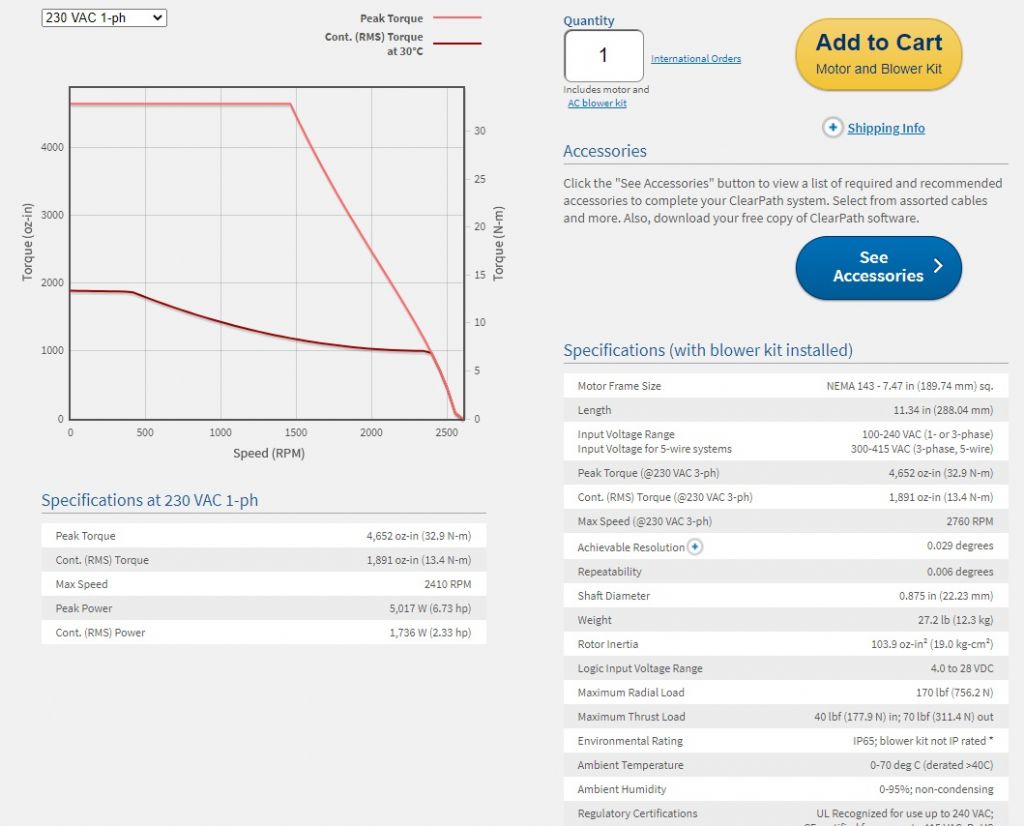

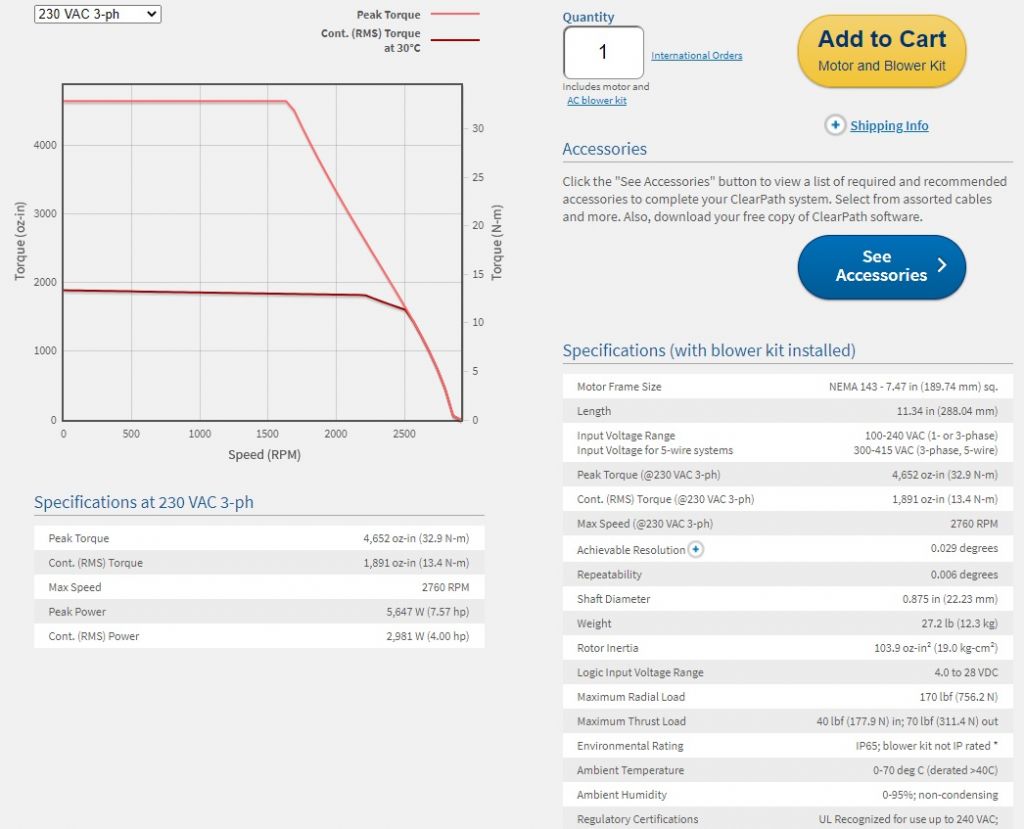

the Motor specs 1PH and 3PH:

In the event that the smaller pulley is needed, the motor needs to be able to pivot to take up the belt slack, and the motor must slide back 20mm, to line the 80mm pulley up with the spindle pulley – this all to be a one lever movement exercise…

The motor is big for the lathe – 1.7KW @ 220VAC 1PH, and 2.9KW @ 230VAC 3PH.

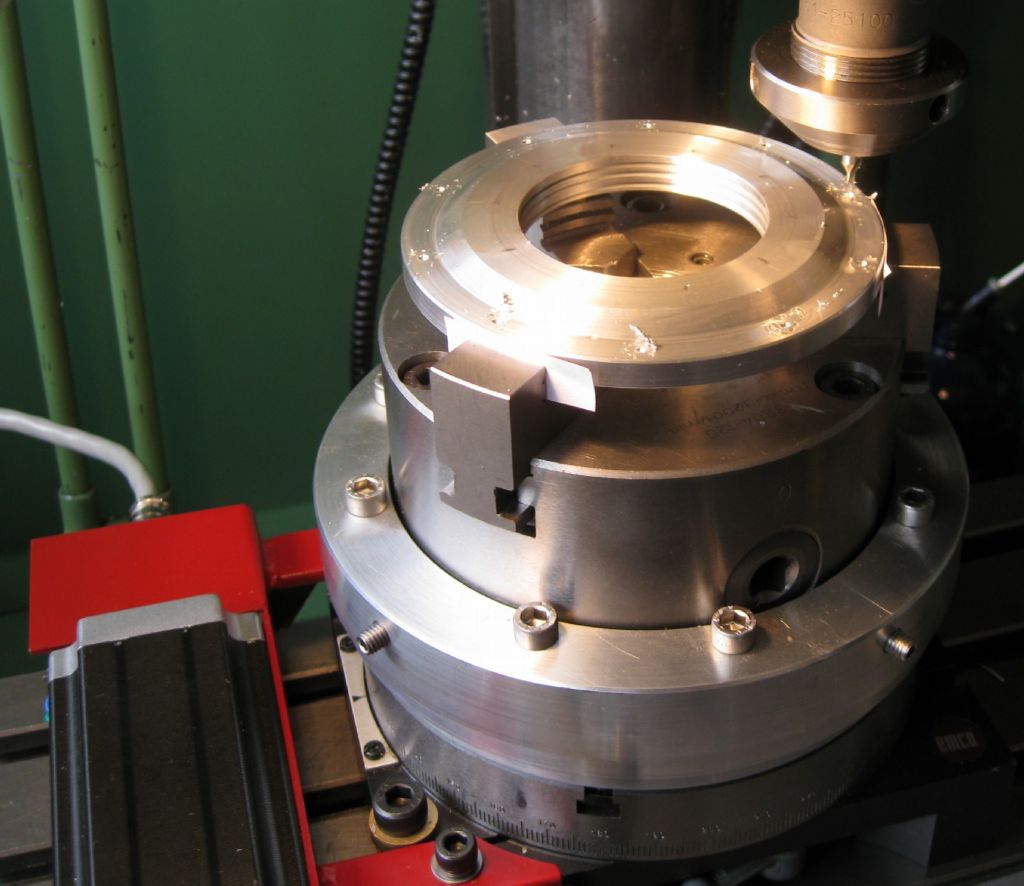

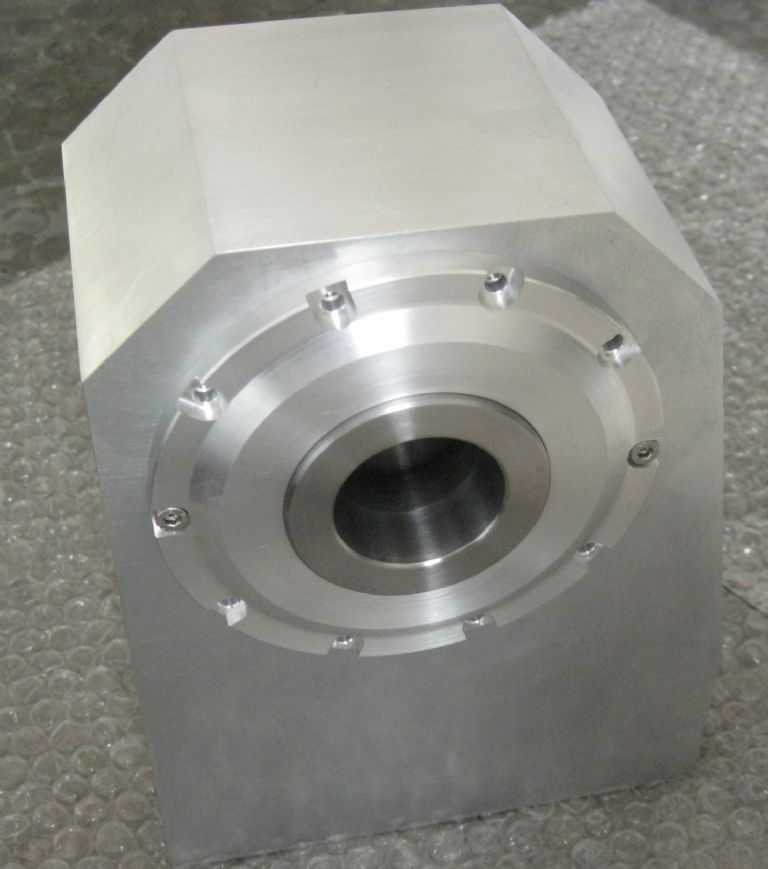

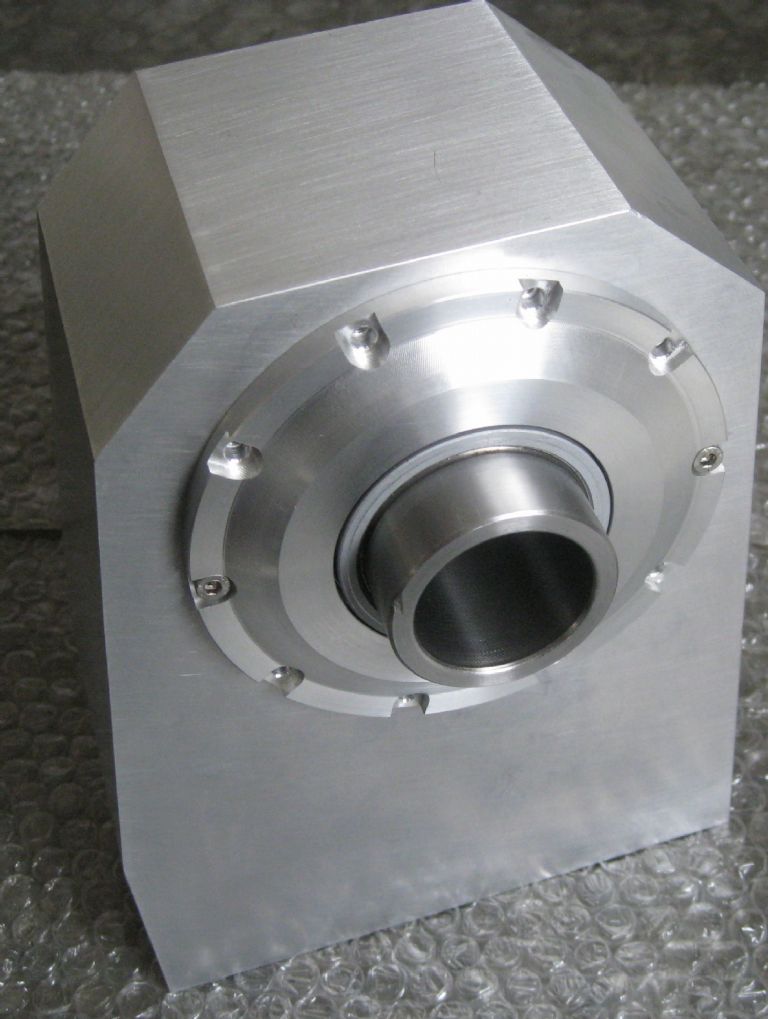

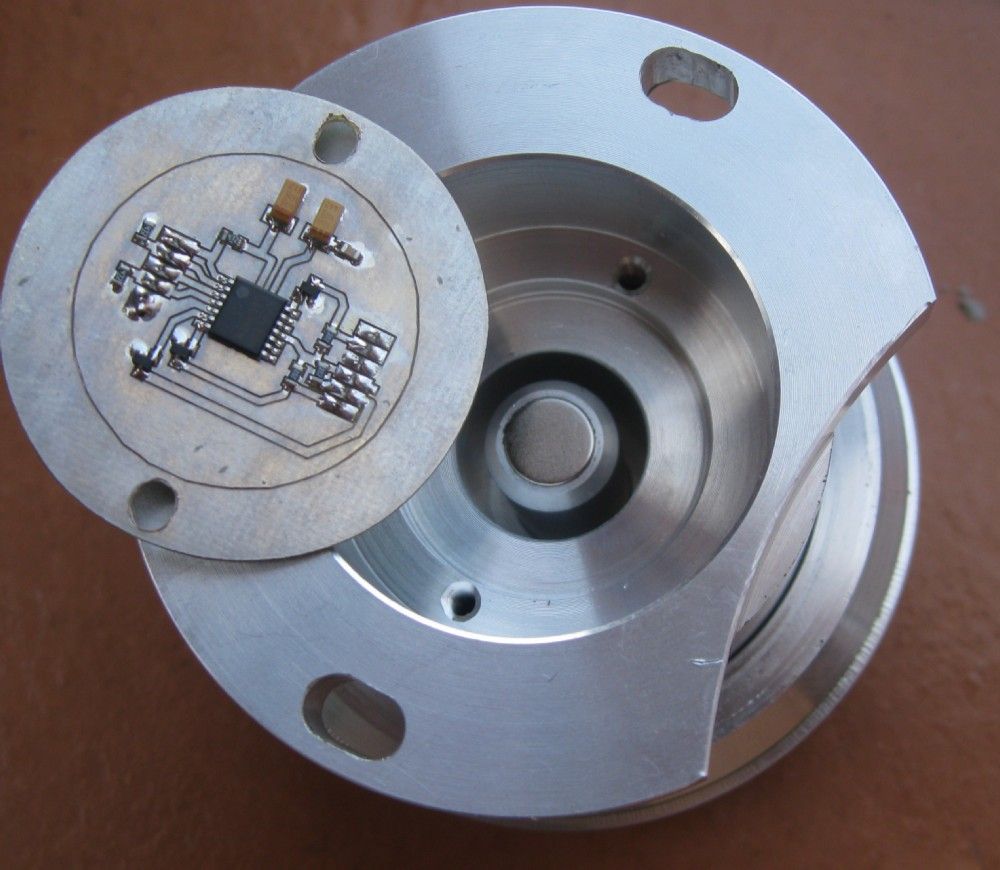

It is a rather special motor – permanent Magnet rotor, and is actually a very high power closed loop 'stepper motor' dead silent in operation, no noise, no step feeling, etc. It is in essence a AC servo motor, driven by step and direction input. It is a closed loop control, with a 32000 count encoder.

The reason for using this motor is that it has full torque from 0 RPM and maintains the torque well up the RPM curve, esp if fed with 3Phase. In addition to driving the spindle for conventional turning, it serves as the lathe's C axis, with rotational position control capability to within 0.08 degrees, allowing use of live-tooling in the lathe to 'mill' the workpiece in the chuck ( Hex heads, High pitch 'threads' and anything else…) Holding torque is very high, so medium milling should be possible, and low speed toque is high, allowing full 'power' at low rpm's.

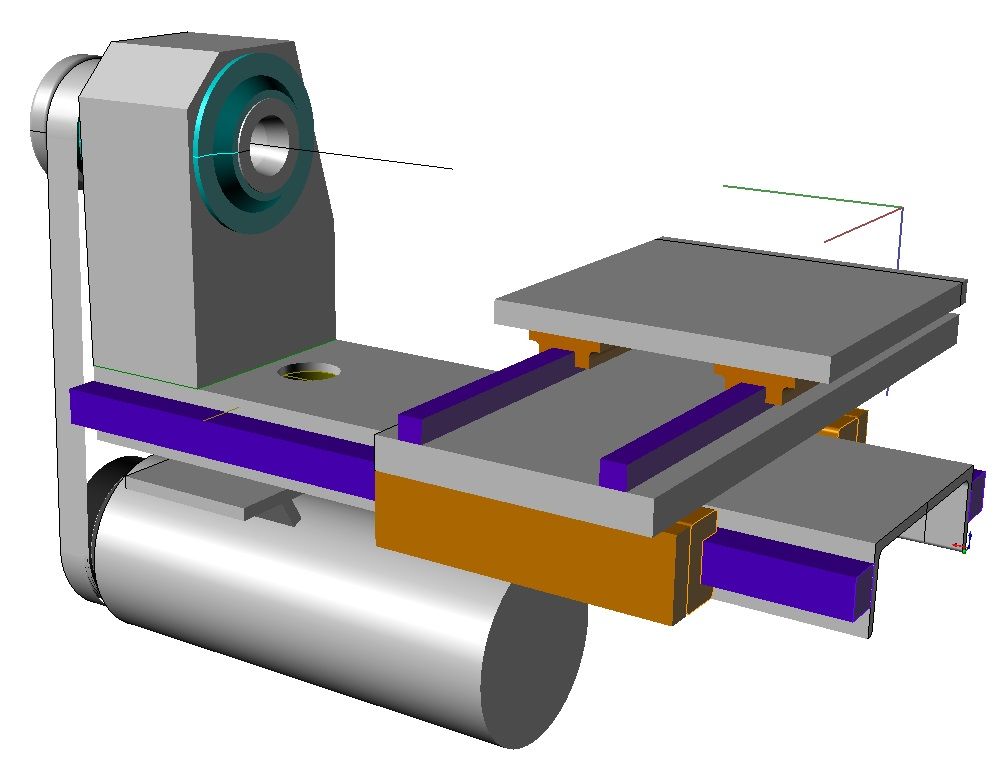

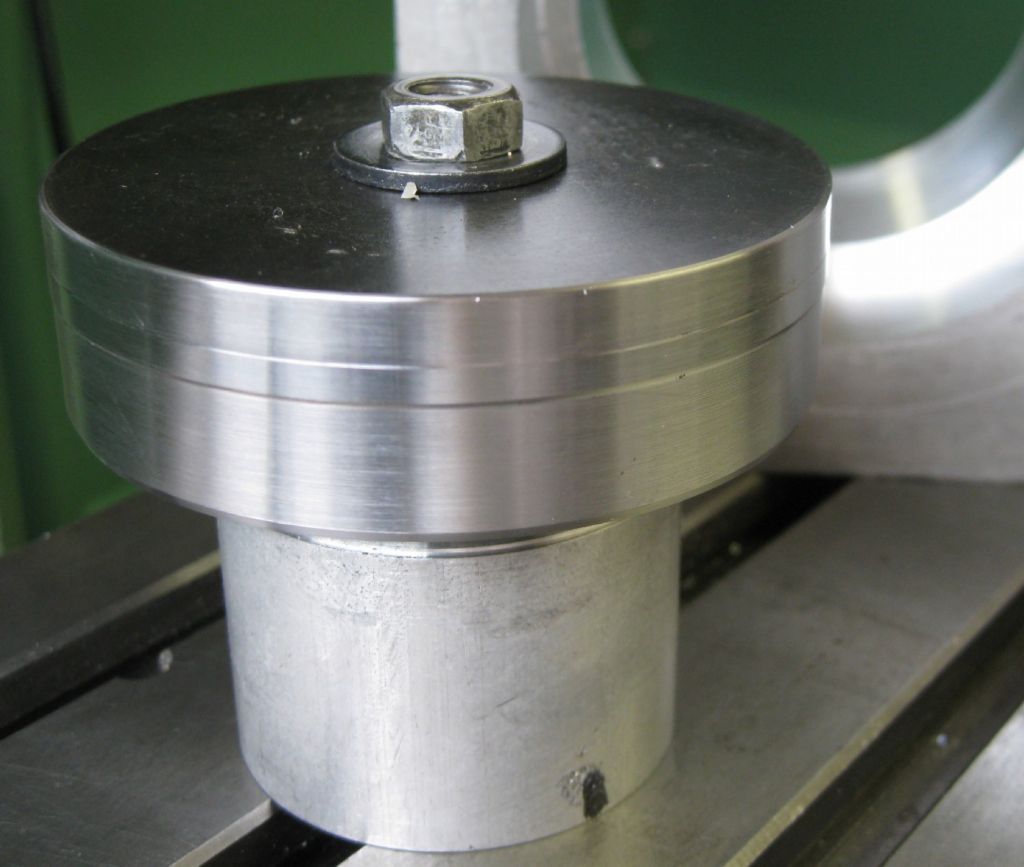

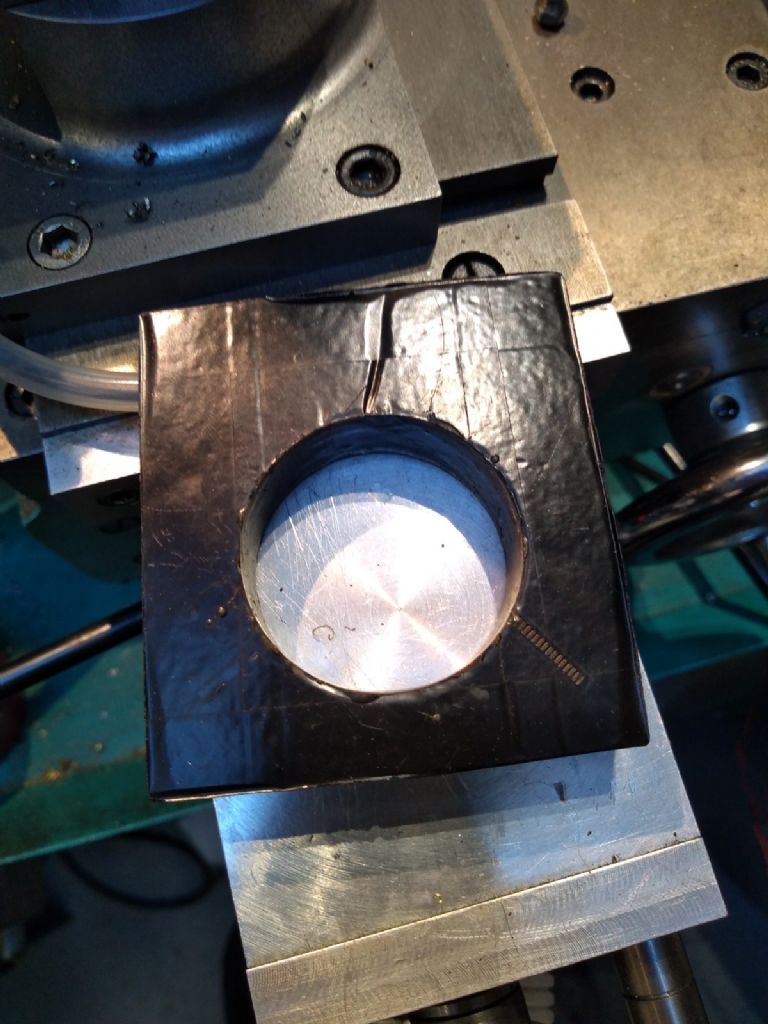

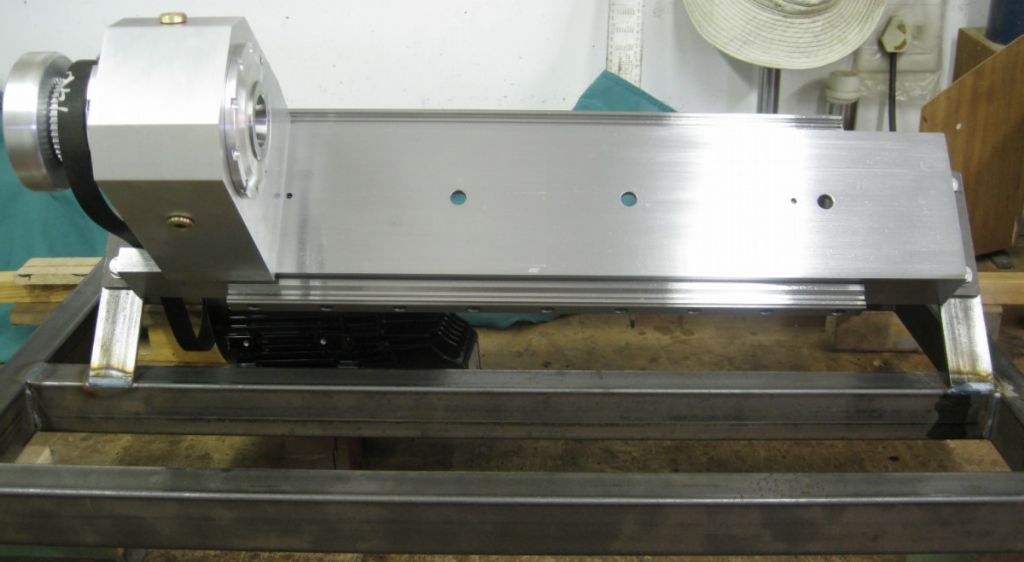

Below – The bed trial fitted to the base framework –

lots of effort went into straightening out the base frame after welding, all checked on a granite table..

The Lathe bed is as flat as the proverbial pancake, and once the base frame was straight, the lathe bed side supports were bolted to the bed, and then the side supports tacked onto the base frame. The welds were then tackled in short steps, alternating left/right and obliquely to help prevent the base frame from distorting. It Worked!

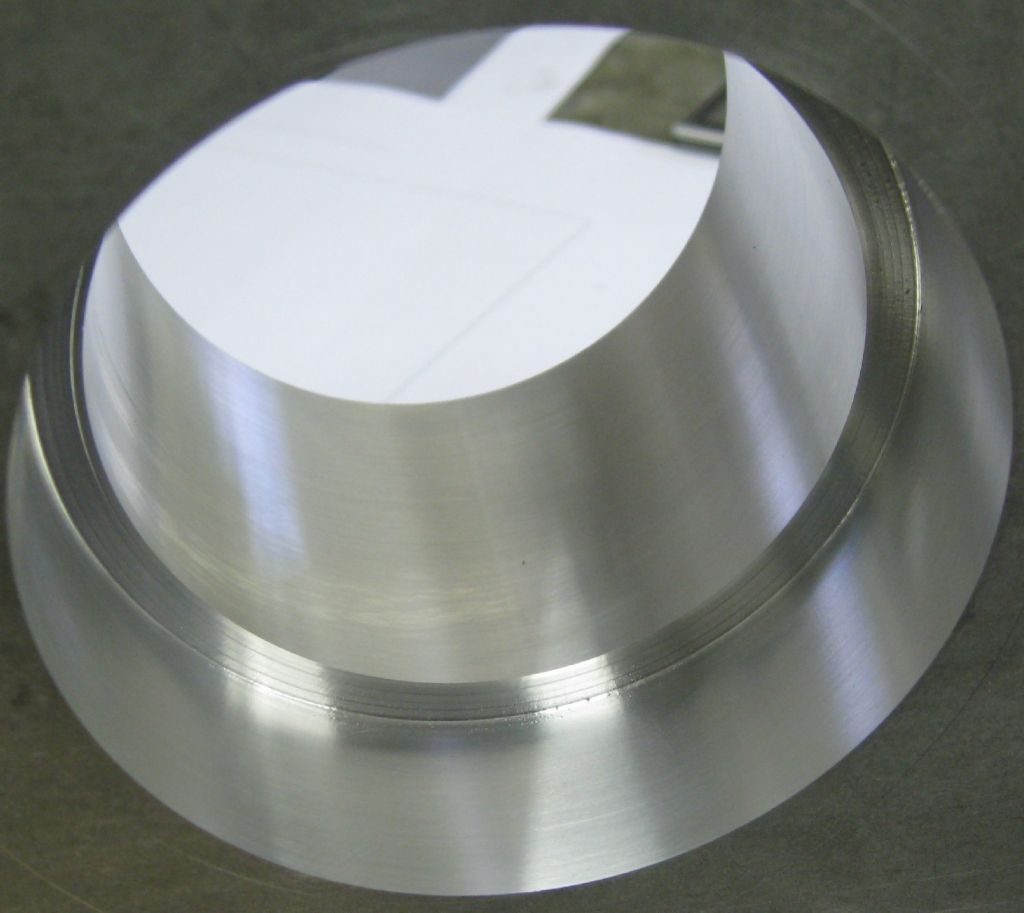

See how nice the bed shaped up!

The slides are 25mm square – nice and beefy..

Lots to do before the next post, so that may be in a good few weeks time!

Joe

Edited By Joseph Noci 1 on 24/12/2020 13:44:09

sam sokolik.