Many thanks for your replies.

I will update my work .

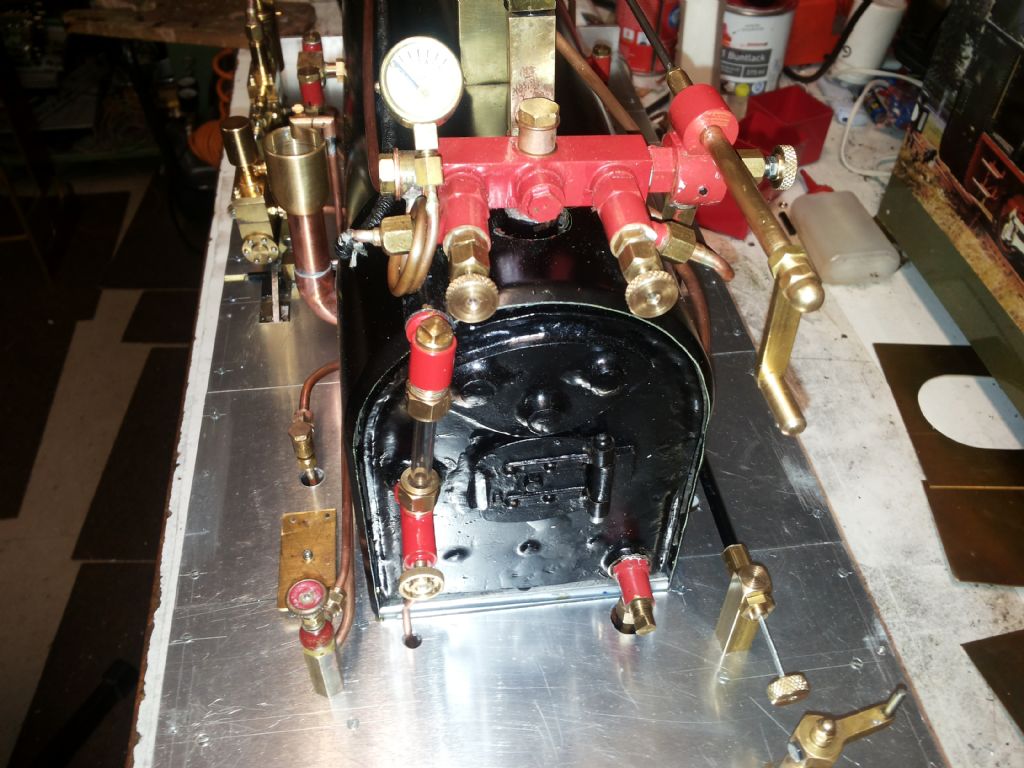

The next step was looking if the boiler is OK . For that I had to make several plugs with M8*1 thread.

I had to learn that teflon tape which tighten with M8*0.75 without problems with M8*1 there were the problem that the tape was shift off the thread and the tighting was only by chance. I had to do it several times,perhaps the fit of the thread was to good.

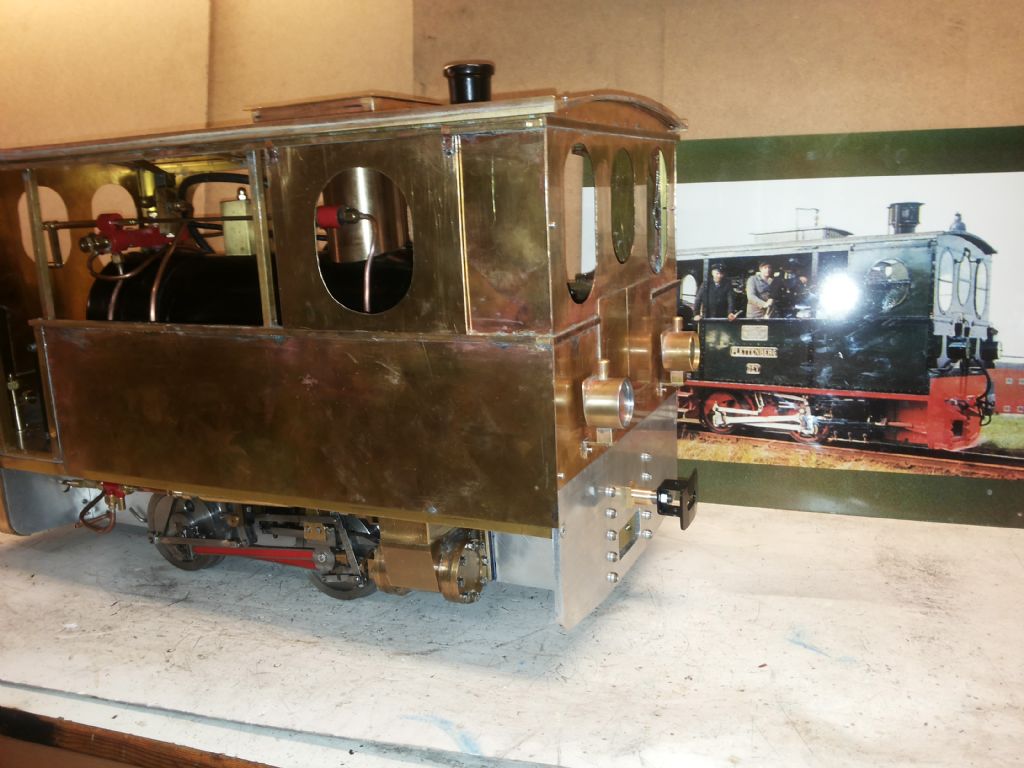

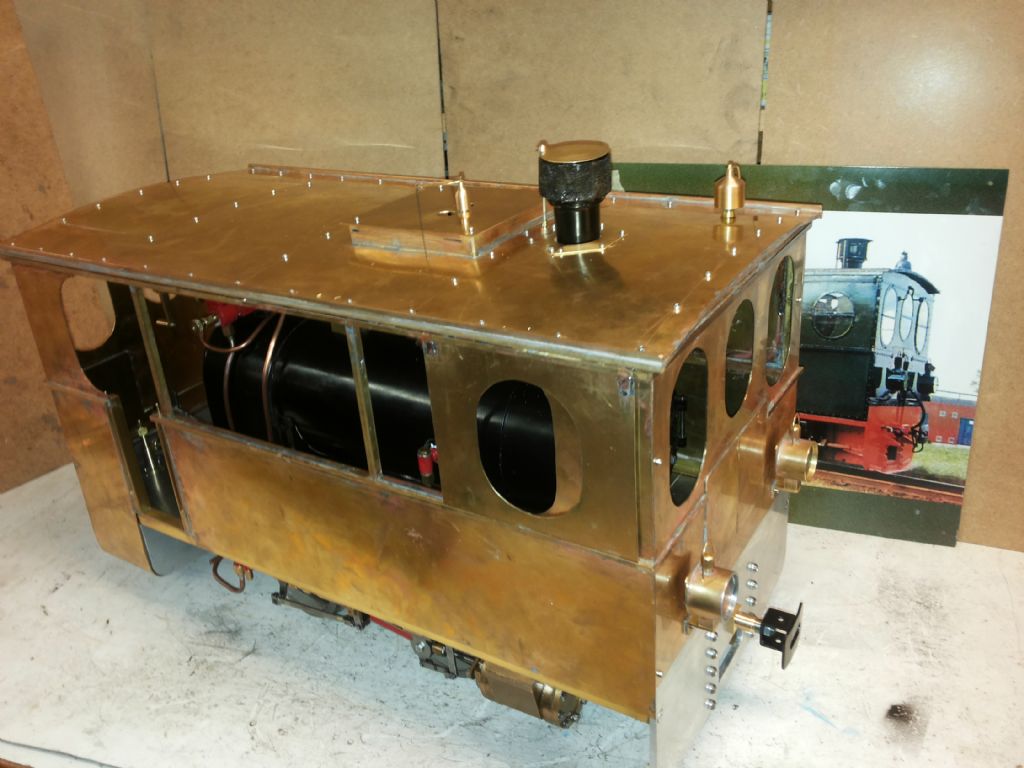

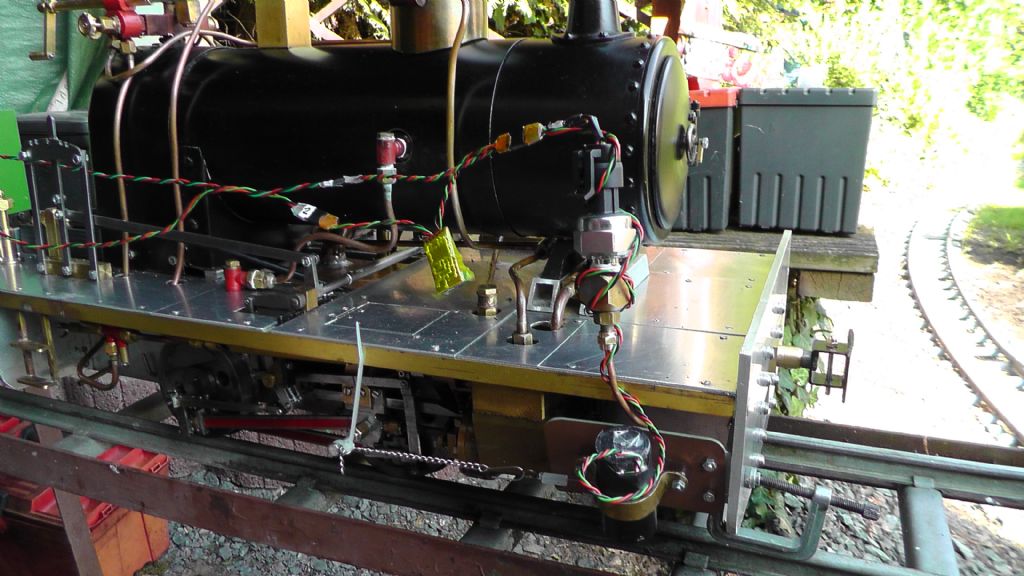

All of the valves I found in the added box ,but they were internally not ready made. It was not a problem to fix it ,but only work to do. At the picture all valves are in place and the boiler is OK a good step forward.

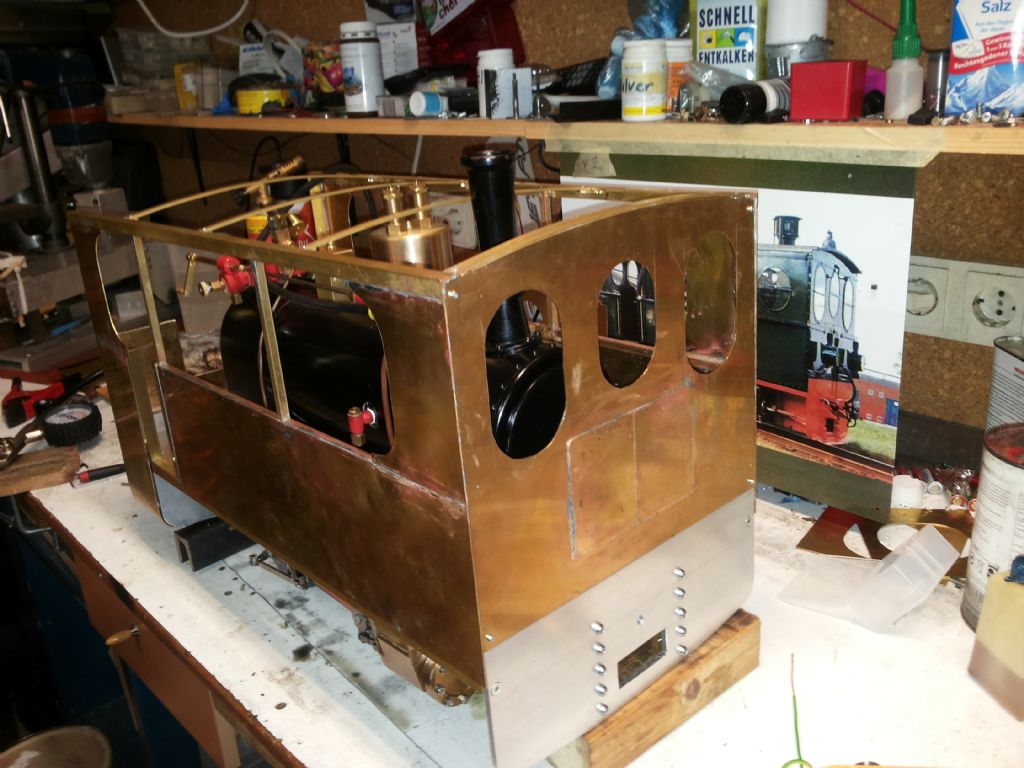

The next step was to make the new 5 inch gauge frame. So I disassemble all parts with the exeption of the wheels. The profil and the diameter was not useable. In the time between I ordered my material and I had to keep in mind ,it was late in November 2018, that over the year when i have time that all important materials are there. for the frame and the housing.

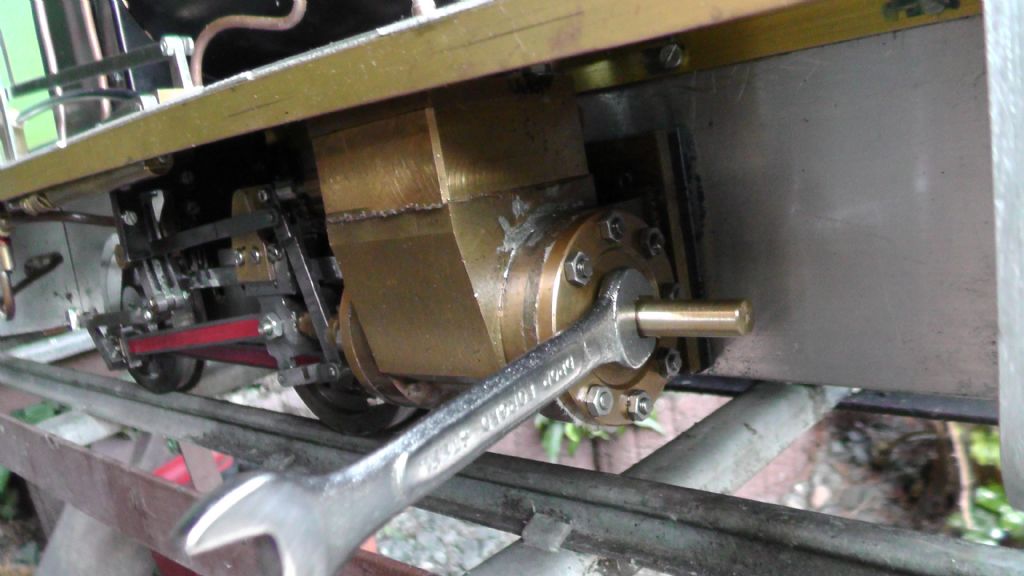

I build the frame in a simple way similar to the principle of my Maxitrak Ruby. That means the rear axle is fix in the frame and the front axle is tiltable. That worked on my locomotives relativ good even on not good prepared tracks.

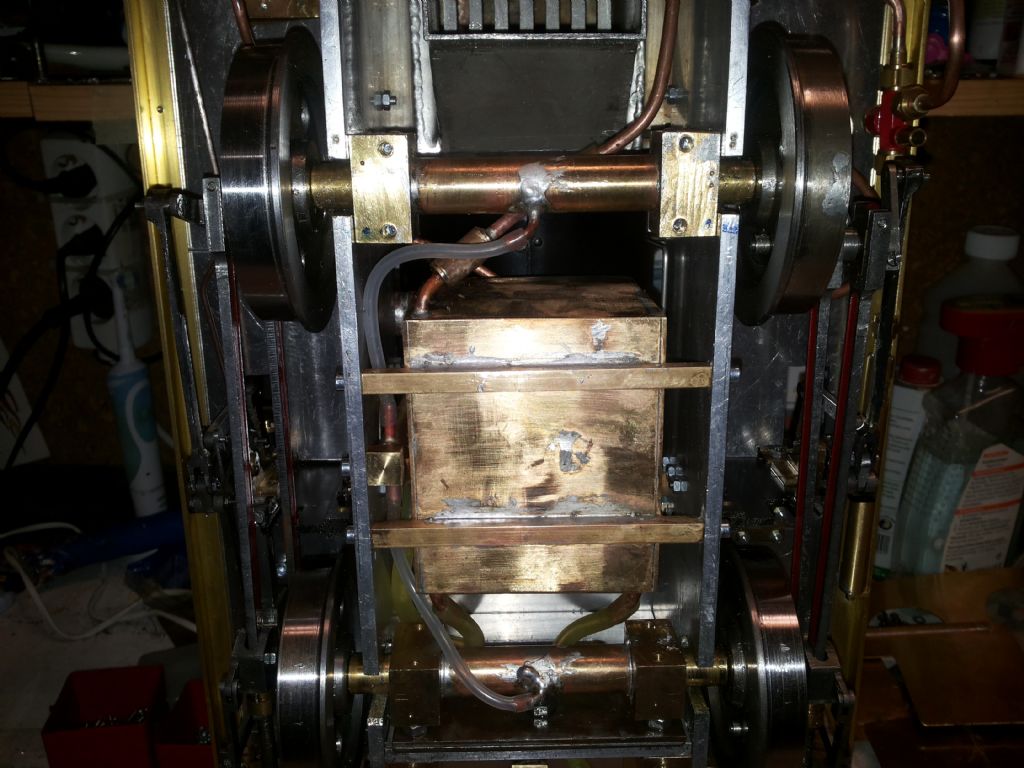

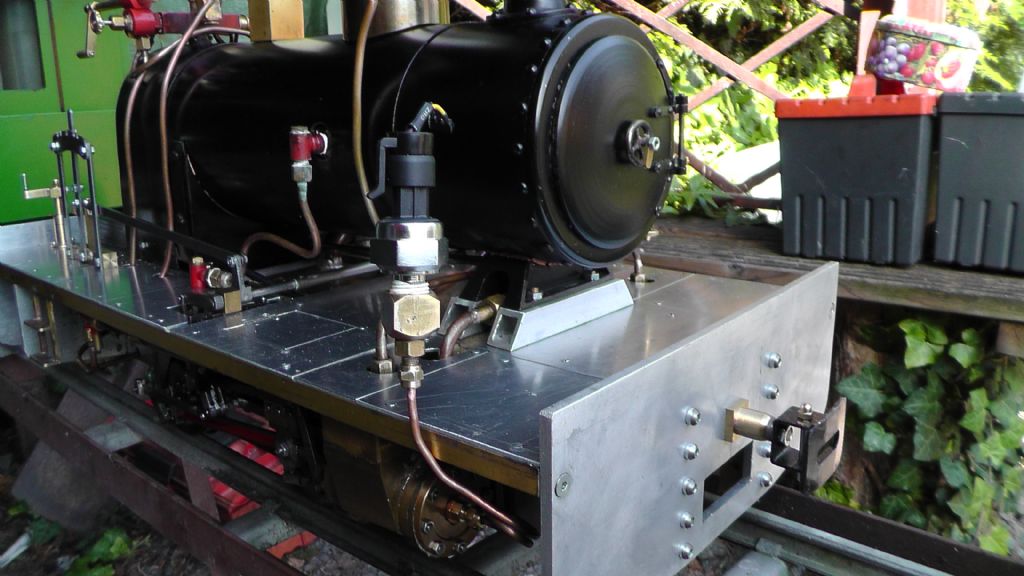

I tried to reuse as much as possible .It was not easy to align all properly. The plans from the Gezina was not very helpful,because the cylinder tighting sketch at the frame was not there. And the guy who build that 25 years ago had not the same hole layout on both cylinder. The wheels had a greater diameter and so I had to arrange all new. But with some patience bot sides got together working. In mid of december the first turns of the wheels were achieved under air pressure.

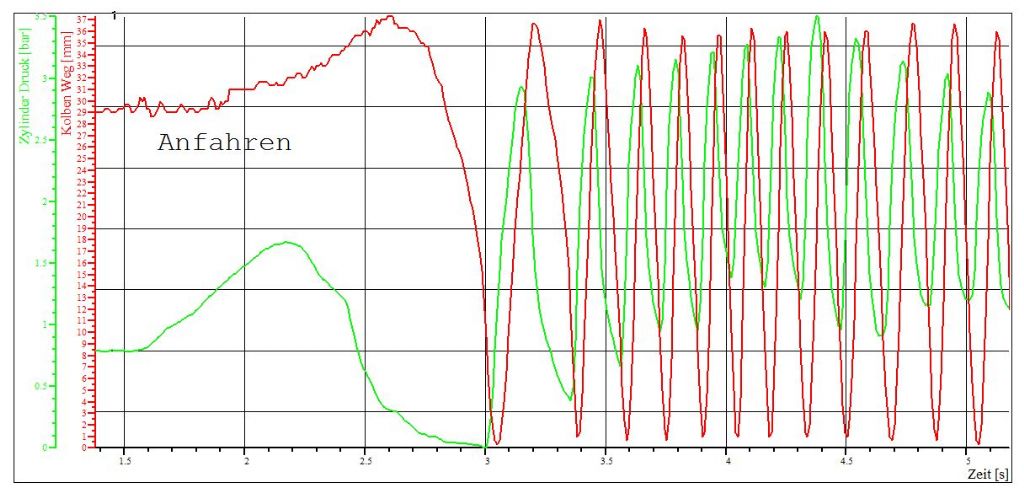

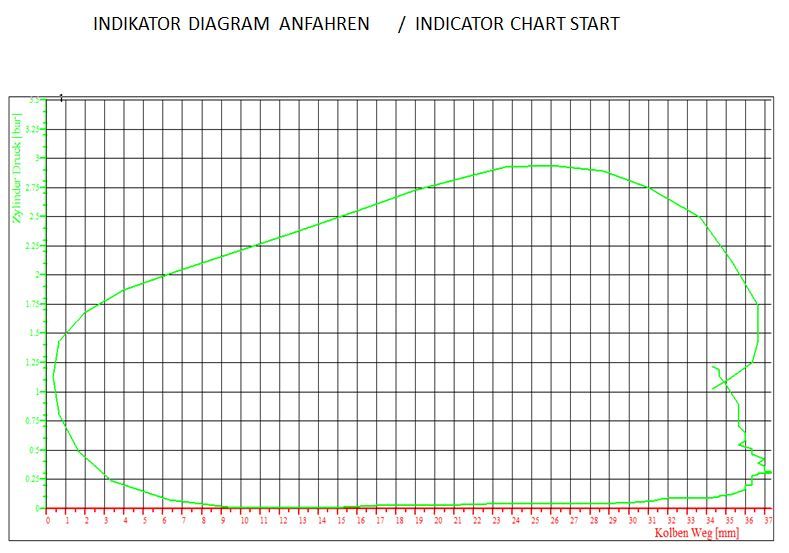

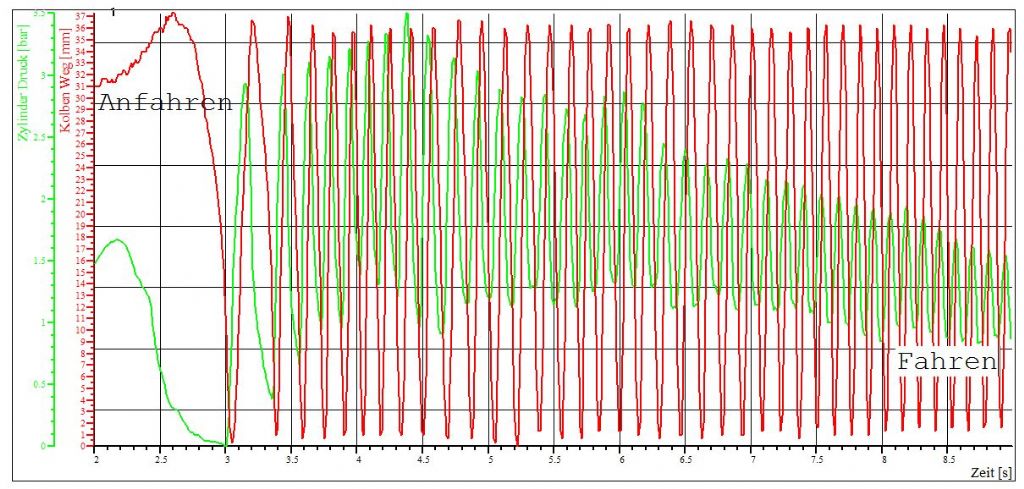

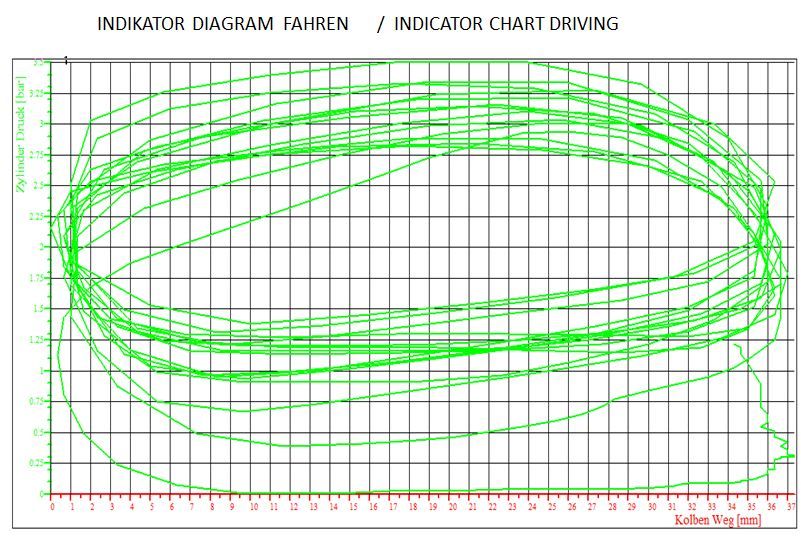

It was noticeable that the cylinder needs a lot of air and the compression was low. I tried to see what happens with a lot of oil.

The system behaviour was better ,but I can see that there was leeaking oil out of the cylinder a leak was recognized.

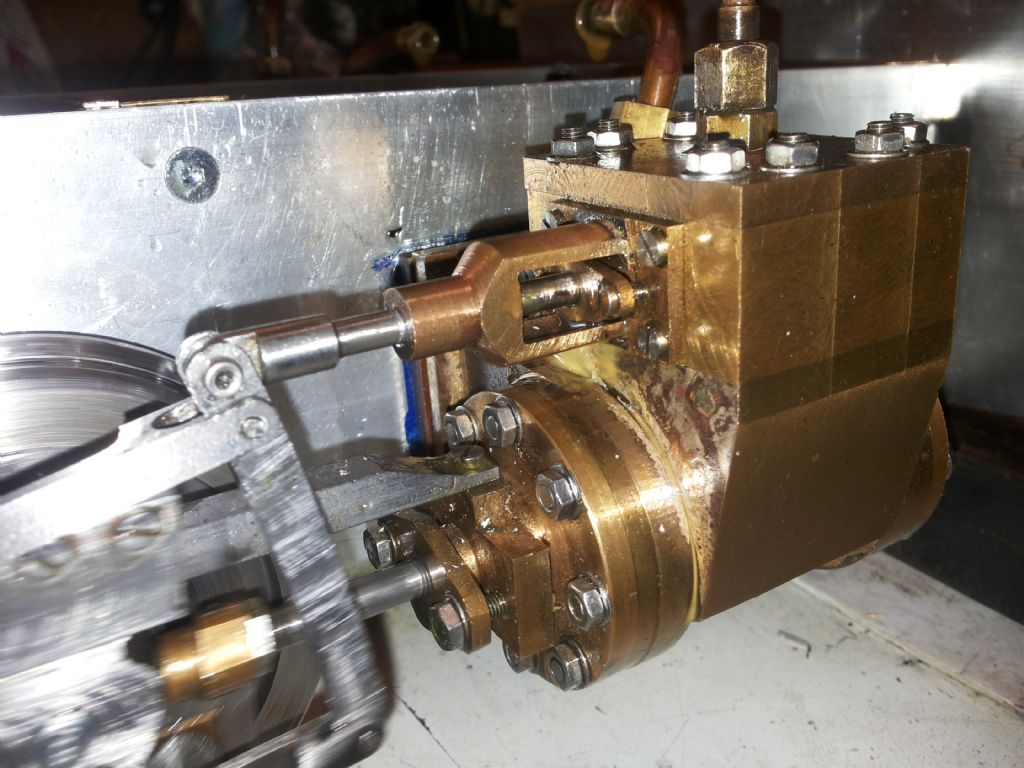

The cylinder were build up with a combination of materials and were silversoldered together. I had to disassemble it and softsolder it steam tight. By stripping all off and out I saw that the pistonring with teflon tape has no connection to the cylinder bore. I machined a new groove to fit a teflon ring with an Oring for static pressure.

With this setup the cylinder had a lot of compression. That was really good .This action I have done on both sides and then I put all together . What a difference in the behaviour after that repair.

will be updated

Werner

Werner Schleidt.