Hi All,

As the title says I have finally started my very first model engineering project.

I bought a Myford ML7 lathe and a Sieg mill around six months ago but as I hadn't finished getting my workshop ready I was unable to use them and get anything started, anyway the workshop is all but complete and over the last few weeks I have been busy getting everything I need for my first project.

While waiting to get started I trawled the internet and found what I believed to be the simplest Oscillating Engine I could find check out http://www.steves-workshop.co.uk if anyone is looking for an easy first build. I then got myself the materials and final tools I needed to start.

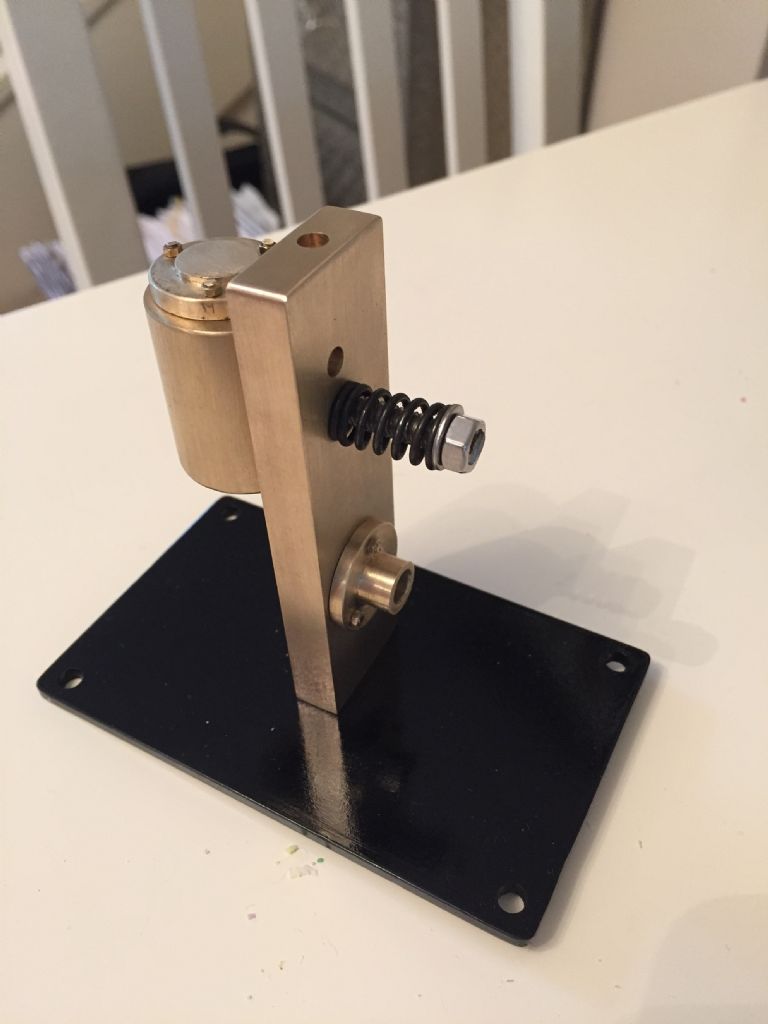

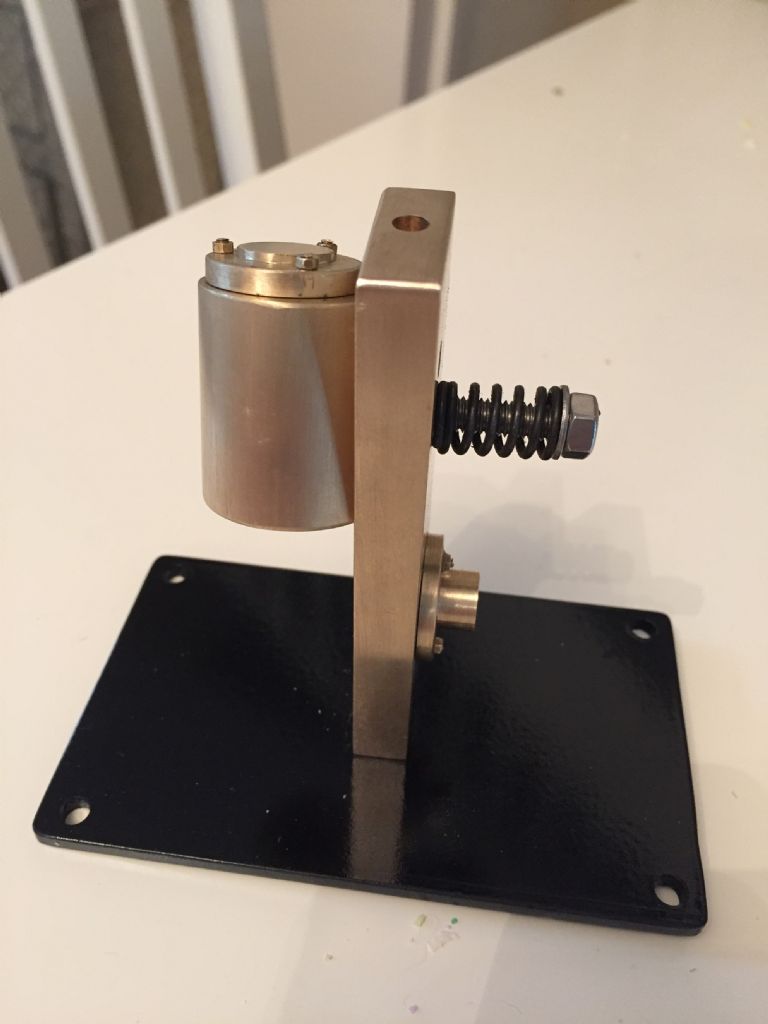

Below are pics of my progress, any helpful hints and tips off the experienced builders out there would be most appreciated.

The picture above shows the cylinder with its cap sat in place (top left), I still need to drill these to fix the cap on, next is the crank bushing (top right), again needs drilling for fixing to the frame and last is the frame also requiring drilling to take the bushing however all of the other holes are drilled including steam inlet hole on the reverse side which enters on the top, also fixing holes have been drilled and threaded on the bottom ready for mounting.

Not the best picture I know and for some reason it turned 90deg between taking it with my phone and uploading it to here. This shows my base plate just sprayed with black enamel paint and drying in sun.

The parts shown aren't absolutely perfect but for my first project and with little to no engineering/machining experience I'm pretty happy and I've learned loads already.

More progress pics to follow!

Mark

Bazyle.

Bazyle.