I have a penchant for wooden toolboxes, engineers type that is.

I have many, all donate prior to or after death by some very skilled men I have had the fortune to work with and learn from. It's one way of remembering these men and their skills.

I also have some that I have made over the years although I am not a good woodworker or really have an interest in it. More an interest in nice boxes.

We had a truck garage up until 1990 when we closed the doors as lease hire was killing the game. In hindsight and for other reasons it was the best thing we could have done. We closed at end of January 1989 and spent the whole of January closing up and selling off but there wasn't a lot to sell but we still had to be there.

All the old spares unsold were thrown in the skip after the auction and the racks broken up for burning but when these were smashed up, under all the grime and oil they were oak.

So I took a saw bench and small router bench to work and cut then up and made some toolboxes for my next job.

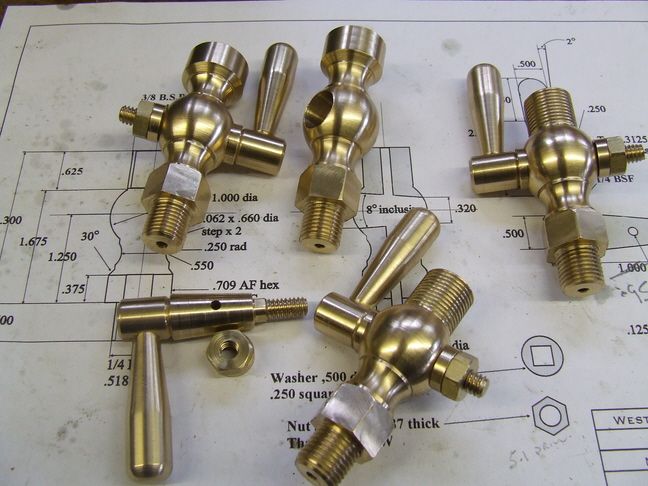

The knobs were added later from the other job as these are what holds the action into a grand piano.

So enough waffling about the past and fast forward to today.

Thinking about doing some nice boxes I must admit I like to see the dovetail joints but other than using CNC and spending more time than I have it's not going to happen. So what about fudging it. The laser can cut as well as engrave where wood is concerned, so what about engraving the lines of the dovetail joints whilst still using a quick half lap joint ?

Three examples [ one didn't come out, weird font ] top and bottom are cut letters at low power, third one down is engraved or scanned.

This is just a bit of crappy ply packing case sprayed afterwards with a rattle can of easing oil to get a uniform finish.

Certainly looks promising and needs a bit more input.

JasonB.

JasonB.