Just finished my latest project, a Topsy Turvy Clock

http://www.workshopshed.com/2014/09/a-working-topsy-turvy-clock.html

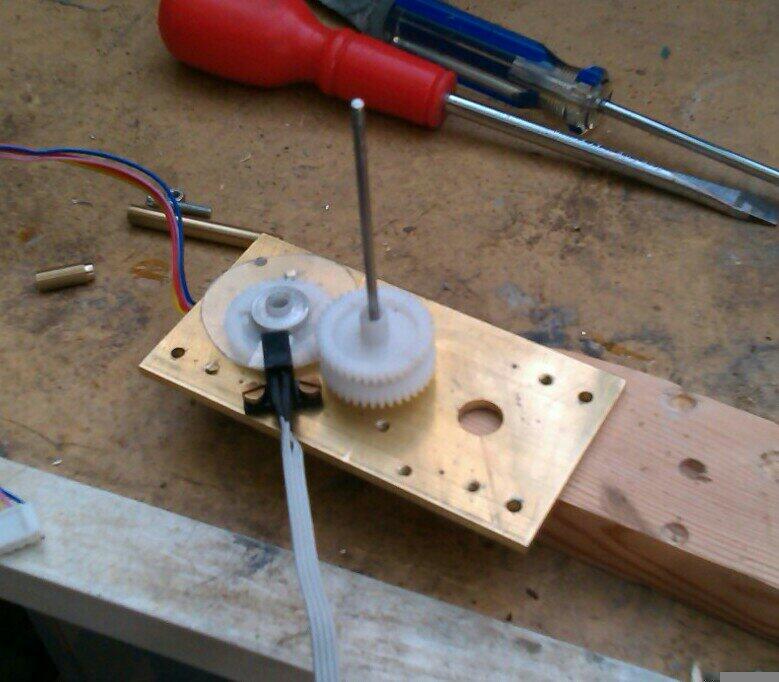

A bit of model engineering in this. It's made from brass, bronze and steel. I had to replace the clock mechanism with my own and the screw that attaches it to the face was also swapped out as I could not acertain the pitch of the origional one.

The brass plates were marked, drilled and tapped, the spacers also drilled and tapped, the hardest part was the concentric shafts for the hands, I initially had problems drilling the small hole through the hour hand shaft but resolved that by upping the speed on my lathe. I don't currently have the skills or tools to make my own gears so I bought some plastic ones. There's also lots of electronics and software but if you want to know about that you'll have to look on the blog.

I created a couple of simple tools to help with the job. A simple plate to file the ends of the screws that were used to connect the motors and sensors to the plate. Also a tool to remove the screw that holds the clock to the face, I'm not sure of the name of the screw or the tool.

Edited By Andy from Workshopshed on 23/09/2014 13:37:32

Andy from Workshopshed.