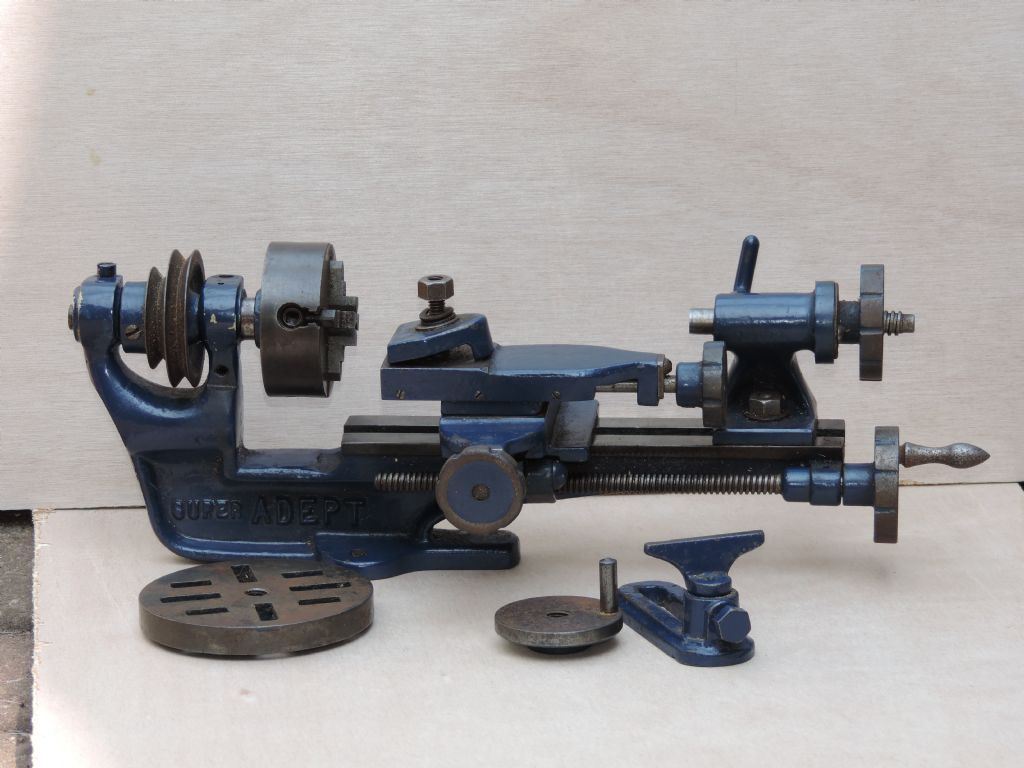

OK, I've come clean and to the disgust of at least one bodger I have acquired a lovely blue Super Adept.

It's completely worn out in the spindle department, but the rest of it seems reasonably OK. I suspect high speed running with little lubrication, as the spindle was 2 thou undersize at the front bearing and the headstock had cracked during an attempt to compensate.

I'm not sure quite how radical the rebuild will be, not CNC, but I do want to see if it can become a back-geared screwcutting machine.

So, here is what I acquired from fellow forum member Steve. He feels he let it go cheap, I think I was ripped off. Or did I think I got a steal and he felt he'd asked too much? With so much confusion, it was probably a fair price – certainly not the silly money you see on Ebay.

As you can see, it looks pretty and it was clean, but it's clearly had a busy life.

The first mod will be a new headstock top replace the cracked one. First part of the design process, is the spindle and an excuse for me to get to grips with Turbocad 21 for more than just opening author's files:

OK, I obviously need to set the number of facets for 'spin extrude' to more than the default 14, but considering! I also need to be aware that a clockwise extrude in a negative direction gives a left handed thread!

In short the new spindle will have a taper bearing at the front and plain at the back, with a hardened thrust washer against the front of the rear bearing bush. Both bushes will be Colphos 90.

Hopefully we will get beyond my first clumsy steps in rendering!

Wish me luck!

Neil

Saskatoon Model Engineering Society.