Hi All,

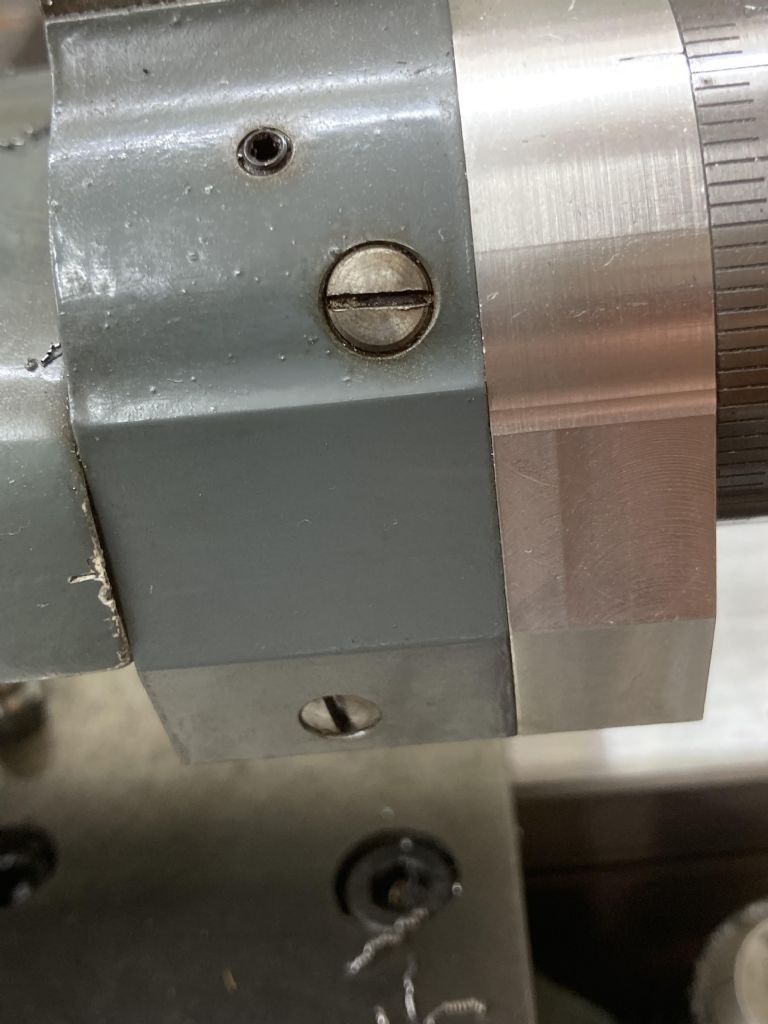

Currently working on a project requiring a couple of small screws which I don't have, so make 'em! It's a Myford accessory so thinking about what I need looks similar to the screws holding the wiper on the side of the cross slide. Don't currently have a ready means of making nice Roundheads so settled for slotted cheese heads, quicker and easier. I chucked a piece of 5/16" steel bar and turned down a half inch length to .186" dia and put starting taper on the end and ran the 2BA die up as far as it would go. I then reversed the die and ran it up again, so as to get thread as close as possible to the head. Parted off with a generous height of head, ready to finish both screw to identical head height. Next, I drilled and tapped 2BA, the same steel bar to make a holder. Time of writing this, it's as far as I got last night. Next step, simple jig making, put screw in end of threaded bar and turn heads down to identical heights. Then mount horizontally in mill vice and set up a thin circular saw central to the screw head diameter and slot both screws in turn. They are to hold the stop plate on the LH side of a GHT rear toolpost, where the plate will protrude below the base against the LH side of the cross slide, providing quick simple alignment.

Vic.

Vic.