Barry,

Started reading this post whilst making breakfast this morning, The inner engineer woke up then the diagnostician started yammering multiple scenarios in my ear, so I was totally distracted. In the meantime I had cut some bread and buttered it. Forgot the toasting part completely!

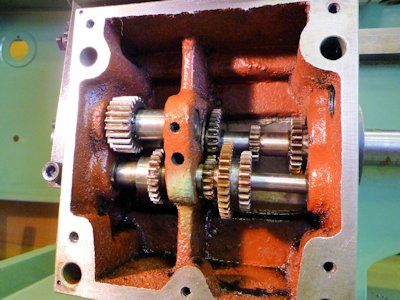

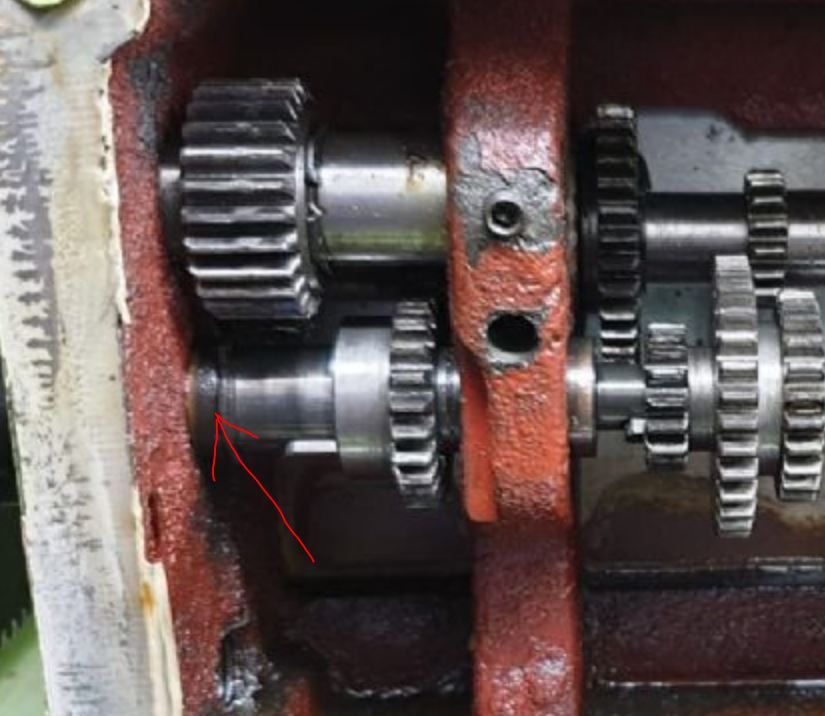

Is there a chance of posting a picture of the damages gears, it would help the model engineering "hive" mind to assist you. Your comment about poor meshing suggests (in my mind) partial engagement along the length of the gear teeth perhaps?

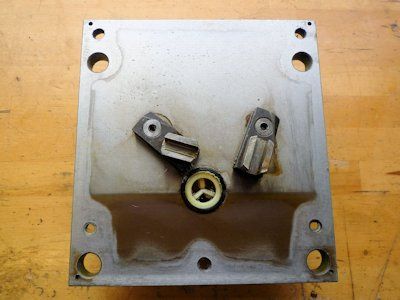

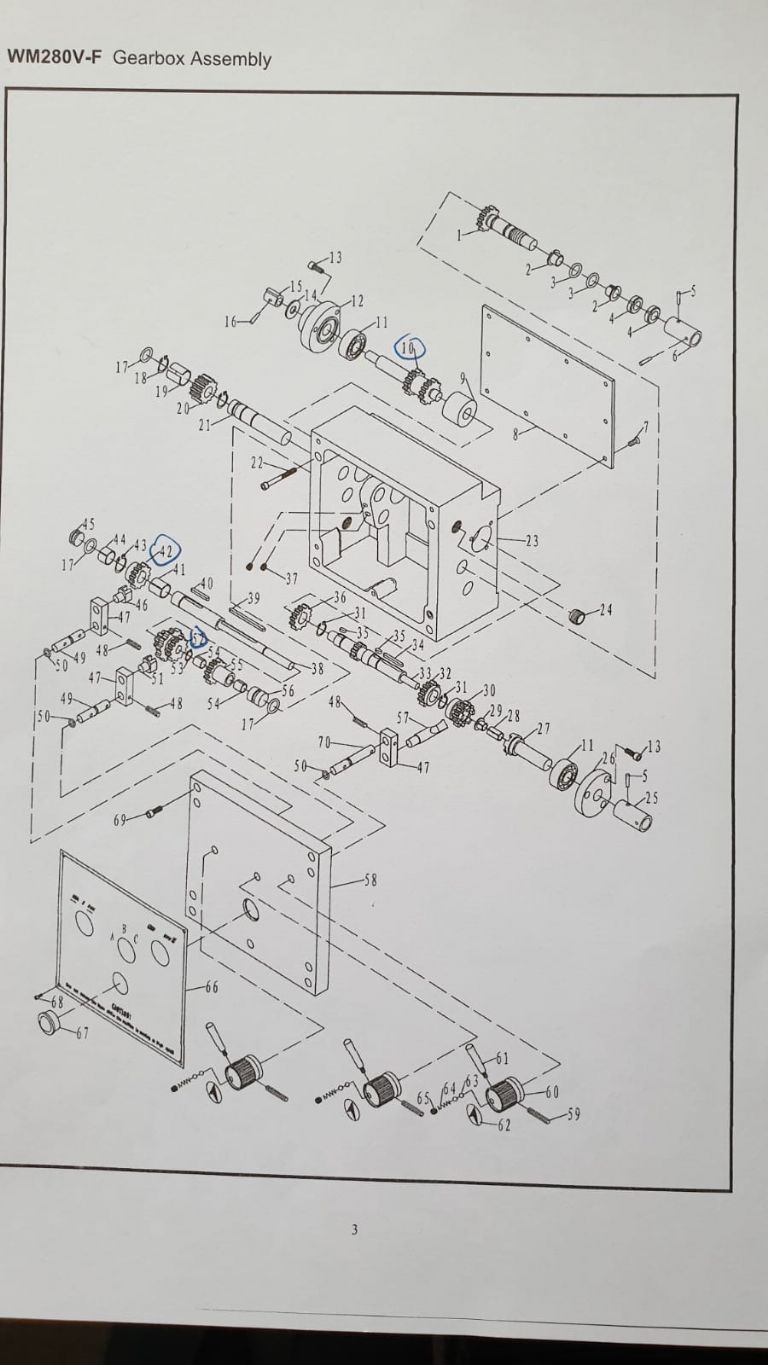

With the cover removed, do the levers move freely and do the detents operate positively. As mentioned by Dave Halford, do the selector forks swivel freely and the floating gears slide freely on the shafts? As you will be stripping the gearbox to replace gears, it is a good time to check that the shafts and bearings are okay.

Are there any signs of excessive wear on the operating faces of the selector forks, particularly if there is damage to the front of the gear.

Yes it is a nuisance that you cant see what is happening with the cover in place, but you could measure the distance from the edge of the cover to selector fork faces in each of the lever positions, then move the gears manually by the same measurement from a suitable datum.. That may help to identify if there is a problem with the geometry/setup of the selector levers and detent positions, a problem found by quite a few owners of bench top mills with the Hi/Lo gear head down to poorly aligned selectors at manufacture.

The comments about crash boxes in posts above reminds me of a few choice phrases spoken by the chap who guided me though the process of driving older generation vehicles, ranging on order of kindness from:

"Its only a crash gearbox if you get it wrong"

"There's one in there somewhere"

"Alright, grind the b*****s down 'till they fit"

"Arrgh! &@!!^ #@££%&!, you **"%@@"

If coronavirus measures cause us to go into full self isolation, can't imaging anything worse than having your favourite toys out of action. Hope you get it sorted out quickly.

Edited to remove the easily spotted blooper, no guarantees that none remain

Edited By Mike Woods 1 on 15/03/2020 12:52:33

Noel Carlyle 1.