Hullo David,

In response to your request for help in painting I think I may be able to offer a bit of help on that front.

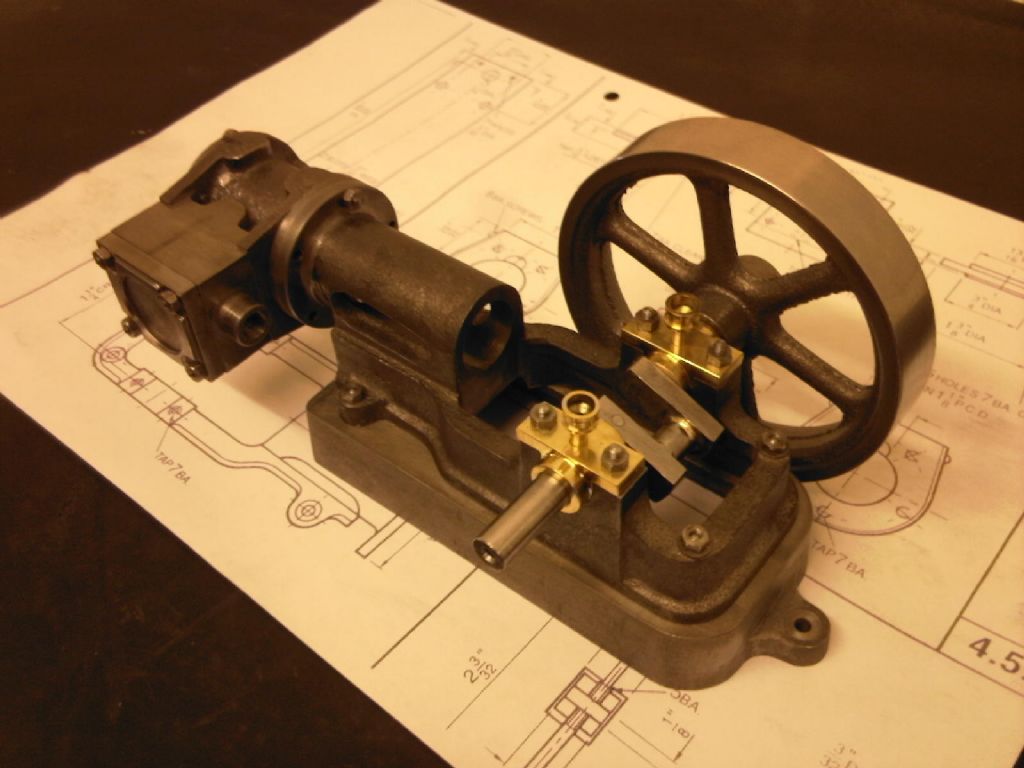

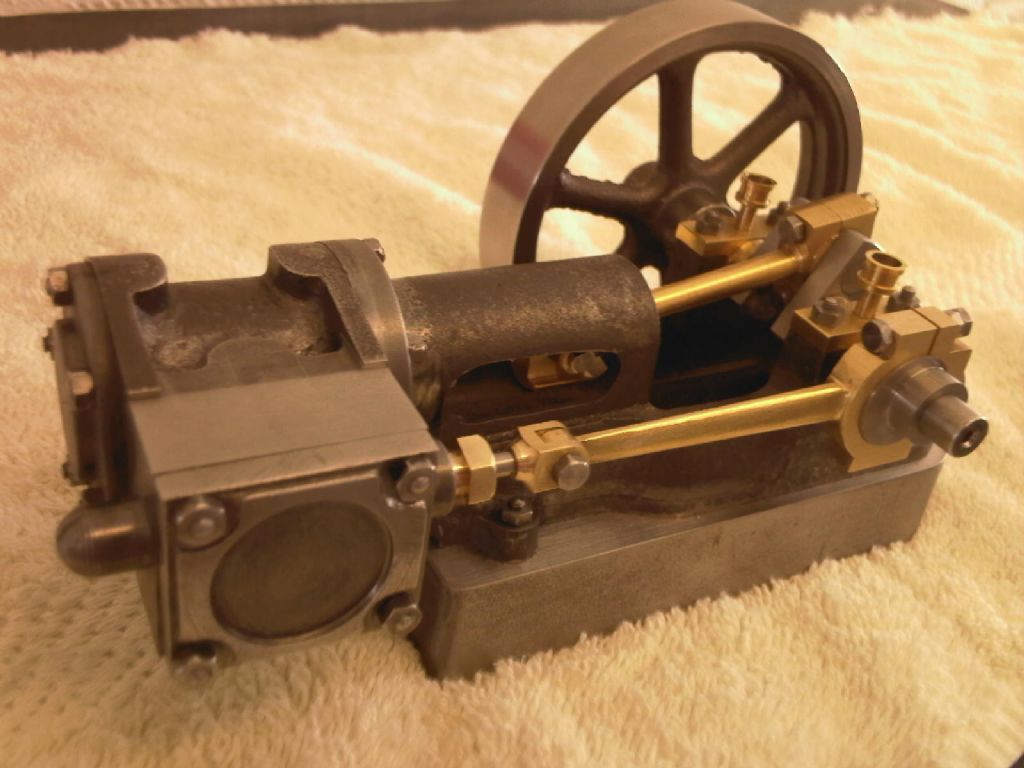

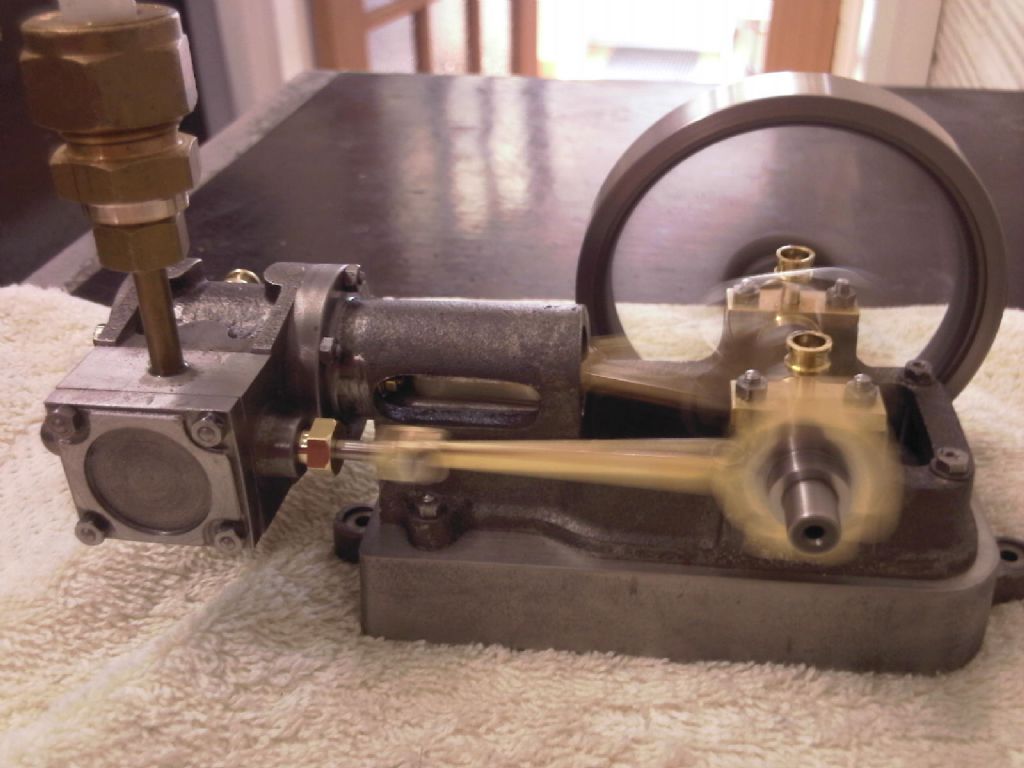

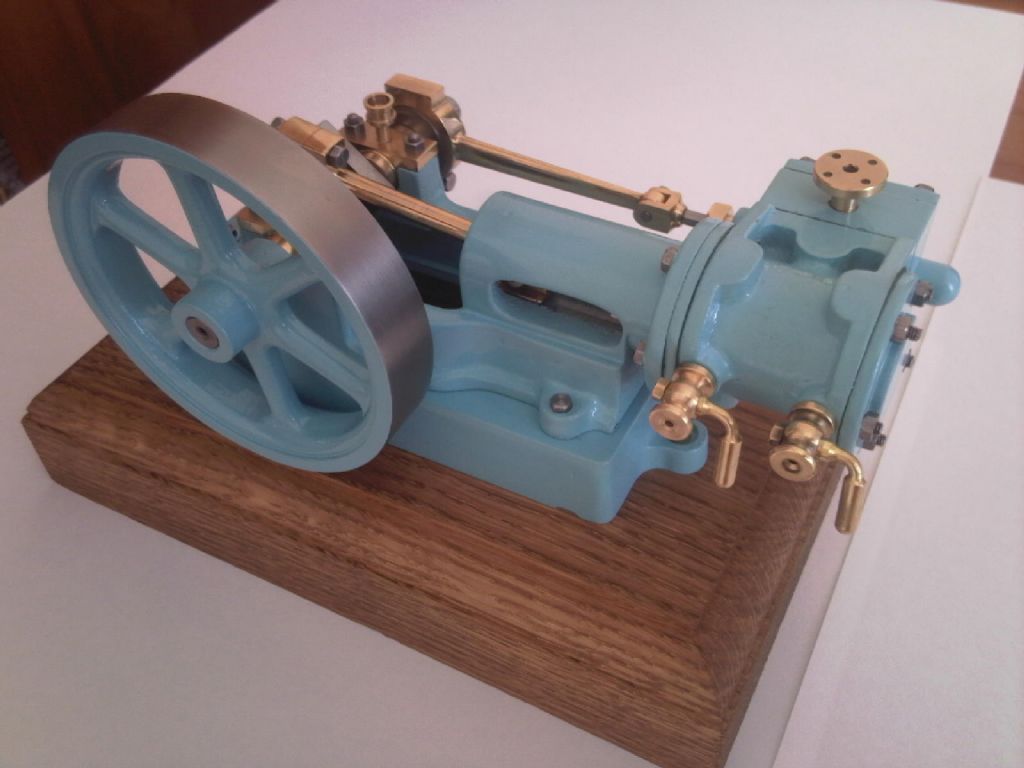

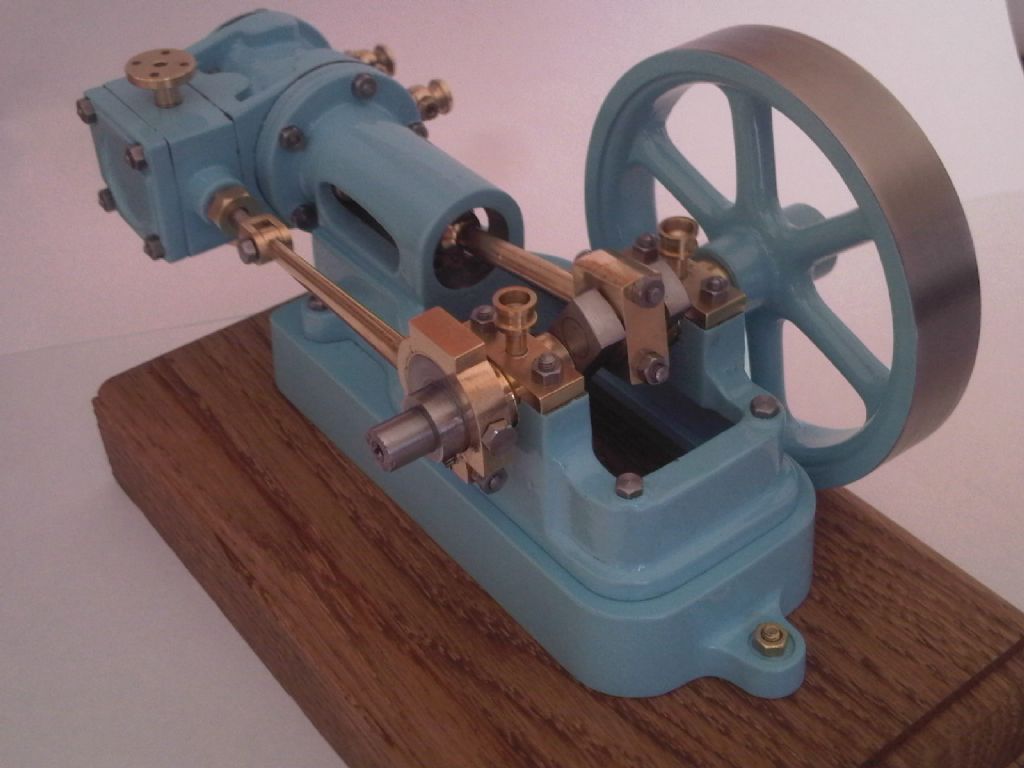

All the old adages on painting hold true except that oft heard phrase ‘A coat of paint covers a multitude of sins’. Quite simply it doesn’t but on the other hand it doesn’t take much effort and certainly less than you have put in so far with this very nice job of building this10H to achieve a reasonable finish. It is always a shame to see a nicely made model let down by a poorly applied paint job.

Achieving a good result depends on several factors but number one has to be good surface preparation followed by good compatible products and means to apply them.

You have the choice of two methods – by brush or by spray – either aerosol or proper spraygun. ‘Generally’ – By brush it is better to use enamels or acrylics and apply cellulose products by spraying though these are getting more difficult to obtain in small quantities. Personally, though I have the means of both, I would unhesitatingly use a brush finish for what you intend at this time.

The castings should be carefully degreased – acetone or cellulose thinner – spray gun cleaner available at car accessory shops is ideal. Then take the time to mask up those areas you wish to leave unpainted. I lay masking tape down on a piece of perspex and cut it to the widths I need with a scalpel and straight edge. I used to think of masking as a pain – a time barrier between ‘now’ and applying the paint. The time for the application of the paint is usually much less than that required for masking so I look at it from the opposite direction now – the masking is much the more important bit of the process.

Once masked up the pores of the casting need to be filled. Ideally – if it’s still available use brush applied car cellulose grey primer. This is the only cellulose product you really want to apply with a brush. Brush on several thin coats – don’t be tempted to put it on thickly – if you do it will appear dry but will still be soft – when the next layer goes on you will drag it off. After about three coats give it a light rub over with wet and dry paper – about 320 grit and repeat it. Finish the final layer or two with 600 used wet. Your final colour finish (two to three coats maximum) will be dictated by these layers. By keeping it thin it can be applied quickly trying not to brush it out and going over the same area twice as this can/will cause dragging. Buy yourself a couple of nice brushes at an art shop. They don’t have to be expensive sable but buy good quality. I use 3/8″ wide flat synthetic bristle brushes (normally sold for water colour or acrylic application) one for primer the other for the colour.

Enamel paint should be thinned slightly, standing the tin on a radiator to warm the paint or in a dish of fairly hot water – this will help the paint flow better. Do not try to get a perfectly even, opaque coverage on the first coat but concentrate more on a thin layer of uniform thickness . Let it dry well – preferably overnight – then cut it back gently with wet and dry 600 grit used wet sufficient for the second coat to adhere to. You should have a very nice smooth finish by the third coat at the most depending on the make of paint and colour chosen. Let it harden for at least week or so before trying to buff a finish into it with silver polish /brasso/T-Cut etc.

Enamel paint will go successfully over cellulose but not the other way. Acrylic paint will also go over cellulose but may, possibly, exhibit a cracked finish in a short time. This is normally due to the paint below ‘moving’ which cellulose does over time. Acrylic is very hard and subsequently cracks. I have not used this combination on metal surfaces but have, to my cost, on a model aircraft, the whole lot having to be stripped off within a week of painting it. If you do decide to use acrylic then I would definitely use an acrylic base on the casting.

Paints – nothing wrong with good old Humbrol, though I prefer ‘Japlac’. International paints are very good too though I don’t think they are available in the small 250ml tins anymore. And of course many others including the Phoenix paints though I have never used them. I would add to always use the recommended thinner. No doubt you can use ‘white spirit’ on some but if it goes wrong it’s too late.

I hope the above gives you a start – no doubt others will add to this but any questions just ask

Best advice is just take your time, don’t be in a hurry to apply the colour but get the sub-surface right first.

Regards – Ramon

Edited By Ramon Wilson on 06/05/2010 23:29:30

Ian S C.