I thought this may be beneficial to any Myford turners out there.

I own an Atlas 618 and recently added a gem of a Myford Speed 10 complete with most all of the Myford accessories. One thing that the package was lacking was an oil pump. So last week I ordered one from the UK. I received it here in Canada 4 days later, dropped in some of my favourite hydraulic oil and presto… a mess. I gave some thought to polishing out the concave tip but tossed that one aside. Being an advocate of common sense problem solving, I resolved to fix this with a seal. Now, what to use for a seal?? I went on a scavenger hunt in my workshop and settled on a vinyl electrical grommet that came in a kit of assorted sizes. These were the solid rather than split type. I selected the smallest one in the kit. The diameter of the hole was .200 and the overall length .115.

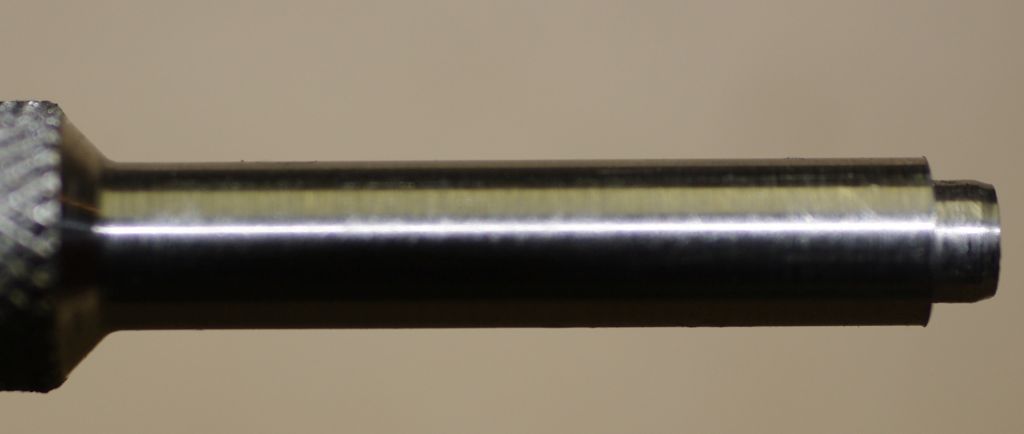

I removed the spout on the oil pump, determined that the diameter was .281, chucked it into the Speed 10, turned it down to .210 for a distance of .115 from the tip. I added a slight chamfer, very slight, to the very tip.

I slipped on the grommet and was amazed at the result. It worked so slick I wanted to keep on pumping.

wolrikm.