I use Corian , A DuPont product – a material consisting of an acrylic polymer and alumina trihydrate. It is extensively used for kitchen counter tops and such like. It machines very well, with conventional milling cutters, carbide mills ( last longer) and Wood Router cutters. It holds sharp edges very, and polishes up to a near gloss – one or two wax coats and glass/carbon composites with laminating resin de-bond very easily.

The definition achieved with Corian allows really sharp, fine wing trailing edges in a two part ( top and bottom) wing mold.

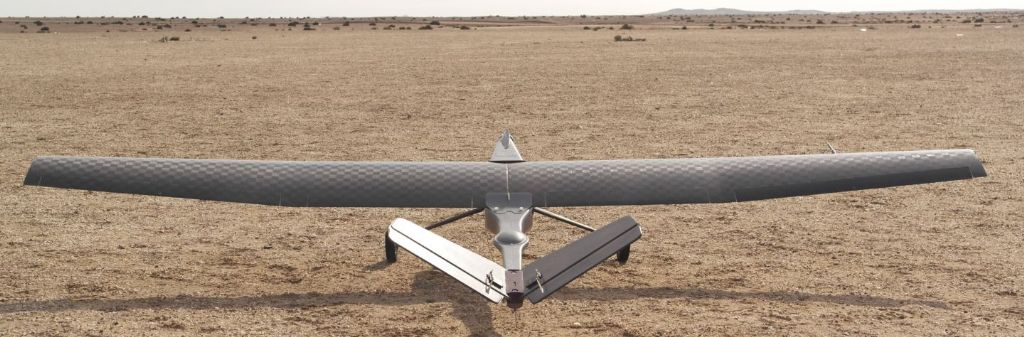

For smaller projects ( the wings below are 3meter span..) many kitchen Installers will give you off-cuts of the stuff. really very nice to work with, although an errant tool path will still break the cutter…

Machining does create fine dust though.

Joe

The tooling board is more stable than aluminium when cut, there is not much stress in it (not stress free though) the tooling board machines faster on large gantry type CNC machines, the tooling block finishes easier by some margin than aluminium, both in rubbing down and sealing/painting. The tooling block is easy to bond into big lumps to make things like F1 chassis patterns or model aircraft wing patterns.

Apart from that aluminium is pretty good. Horses for courses as they say.

Regards

B.

Edited By Joseph Noci 1 on 23/05/2020 17:03:58

Greensands.