Obviously if you have room to fit a big f*** off boring bar, then you have a simple solution. The difficulty arises where the combination of small bore and big length results in enough spring to make it impossible to machine without encountering instability, even with fairly exotic materials for the bar.

Even if you eliminate the nonlinearities in the system (backlash etc), you still have a mass and spring resonant system that will be prone to resonance under certain conditions. The best solution is often to damp out the resonance rather than simply trying to move it out of the way. Given the wide range of operating conditions (load, speed, materials etc), it's going to be pretty difficult to move the resonances where they won't be encountered – and there isn't much of a choice of materials that would allow a significantly stiffer boring bar body. Carbide and expensive steels are possibly the best that are realistically available and we use those already.

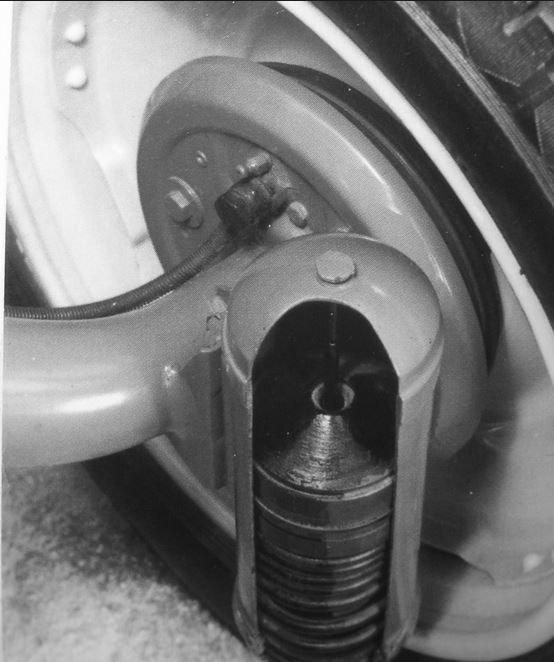

I don't know if the systems used in high speed industrial tooling (mass, spring, damping fluid etc) would actually work in the conditions we encounter in our workshops. And to be honest, I doubt I would be able to do the calculations to start designing them myself. I suspect there will be quite a few PhDs in this area. Might be an area for experimentation!

Murray

mark costello 1.

mark costello 1.