Posted by Andrew Johnston on 20/09/2023 11:07:09:

Posted by Andrew Skinner on 20/09/2023 10:34:06:

…I read somewhere that you can stone the sharp corners of the endmill to improve the finish, obviously keeping that one just for facing cuts. Is this advisable?

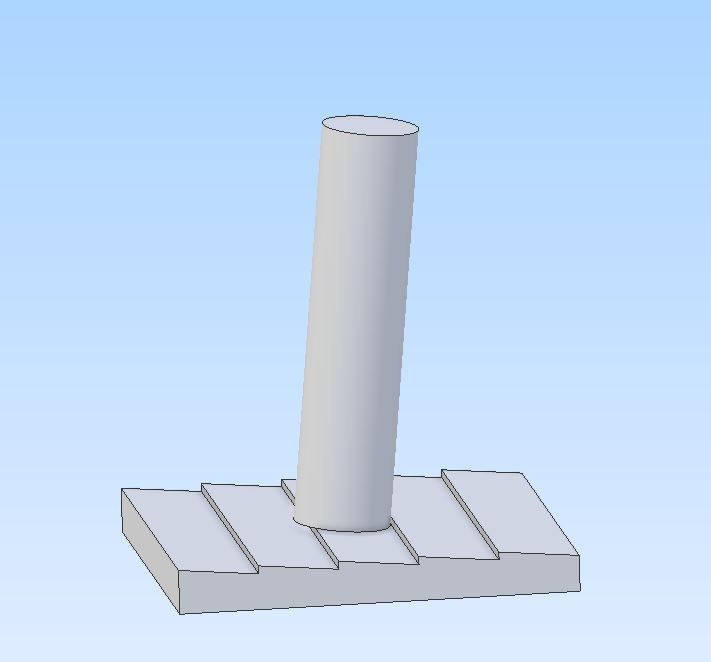

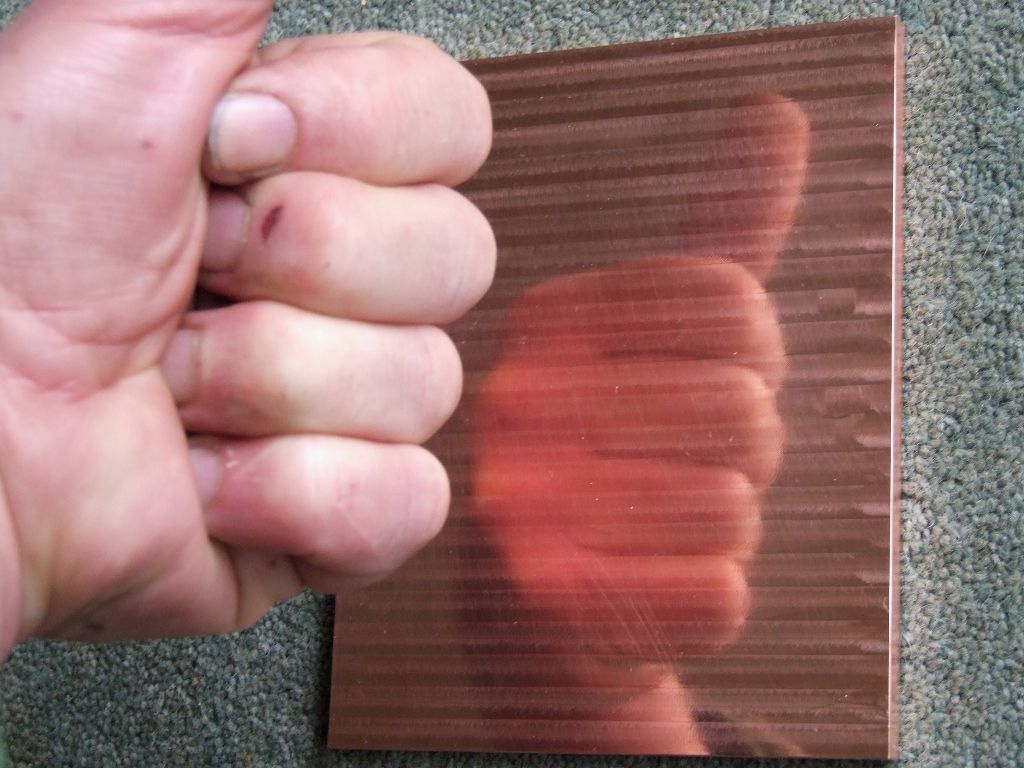

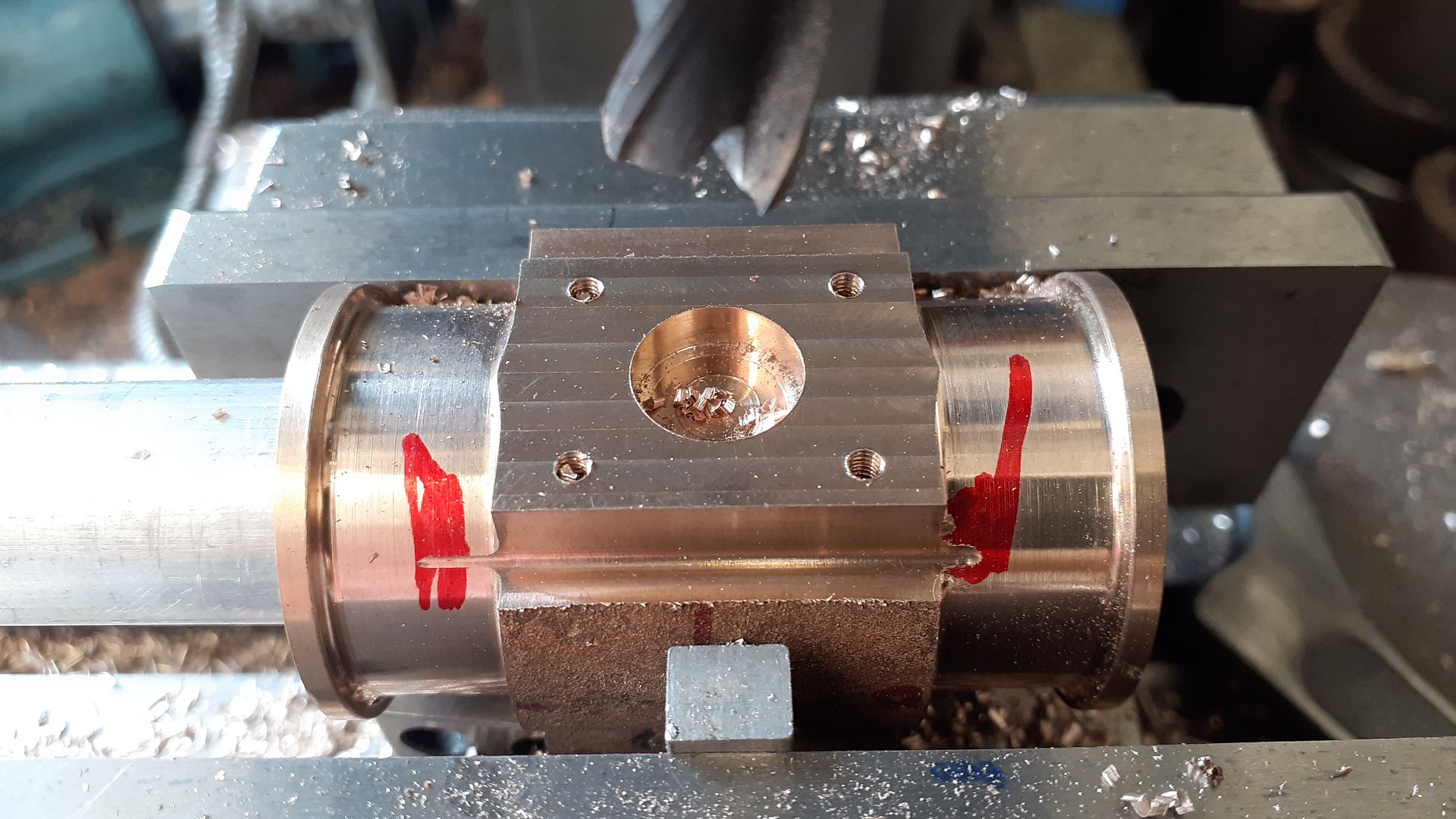

It's an old school trick that should work, although I haven't tried it. The modern equivalent is a cutter with a radius (less than 1mm) ground on the corners. These cutters are expensive, circa £45 for a 10mm diameter one. I reserve them for final cuts when I need a good finish and a flat surface. I used one to finish the valve chest faces on my traction engine cylinders. This shows the sort of finish that can be achieved:

…

…

Nothing wrong with stoning HSS lathe tools because they are easily reground, at least by experienced operators with a good eye. And stoning twist-drills for a special purpose is respectable too. But the idea of stoning a milling cutter upsets me! To my mind the sharp corner edges of a milling cutter are its most precious asset, to be cosseted as long as possible. When they're damaged the cutter loses much of it's utility, and needs to be replaced or sharpened, both a bit painful!

If finish on a large scale was important, I'd prefer Andrew's approach – buy a cutter designed for the job.

Of course being an amateur, I buy inexpensive cutters, use them for roughing out everything from squishy Aluminium to chilled cast-iron, then expect them to produce a mirror finish from fine cuts, and I'm certain they're rubbish unless they last at least 30 years. My mill's not very rigid either!

My first question is, how bad is the problem and does it need to be fixed. Andrew Skinner's photo is visually flawed, but could be acceptably flat (mostly).

Flatness can be established by shining a light on the back of a straight-edge and looking for light escaping between the work and the edge. Also possible to detect tiny ridges by feel – fingertips and nails are remarkably sensitive to surfaces.

Milling cutters almost always leave characteristic marks. They're obvious in Andrew J's excellent copper plate example, which is probably very flat and has classy finish with strong mirror effect. The example is as good as can be expected from a well-adjusted stiff milling machine, set up correctly with an appropriate cutter, and driven by a skilled operator.

The remaining milling marks are unavoidably tiny. If a better finish is needed, change technique. Usually polishing with a succession of ever finer emery paper, and then buffing.

When milling I try cut in parallel straight lines because changing course leaves deep marks. Also use the largest diameter cutter available. Fly-cutters generally produce a better finish than other types but are slow. And an HSS fly-cutter can be stoned without upsetting me!

Dave

Robert Atkinson 2.

Robert Atkinson 2.