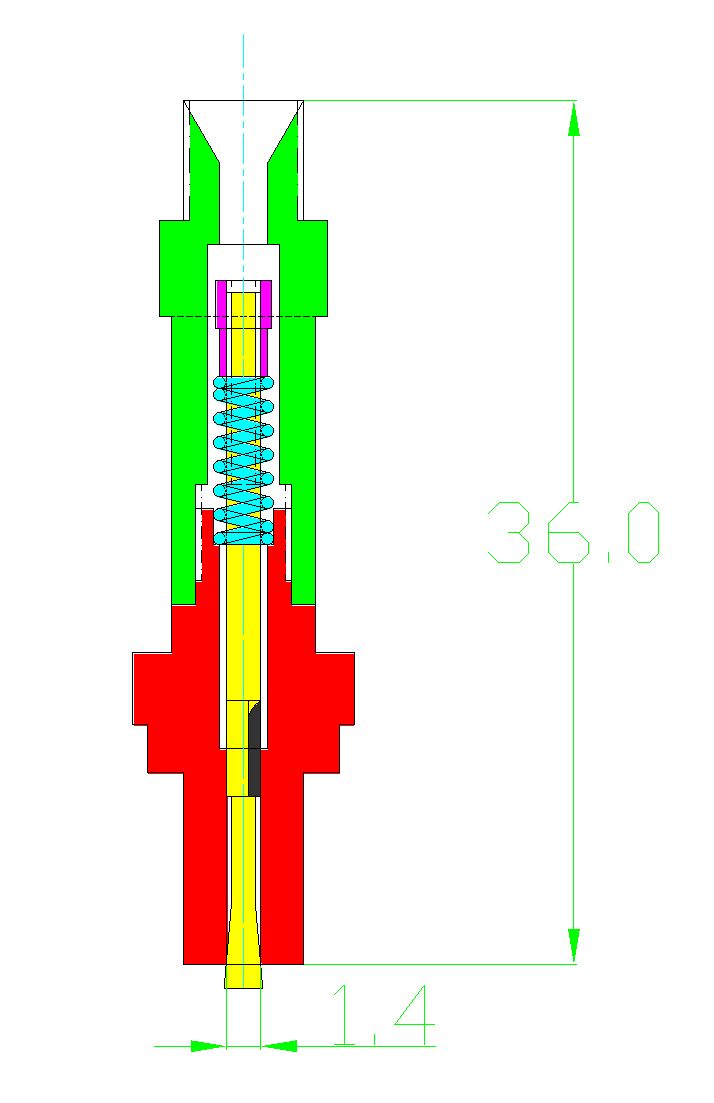

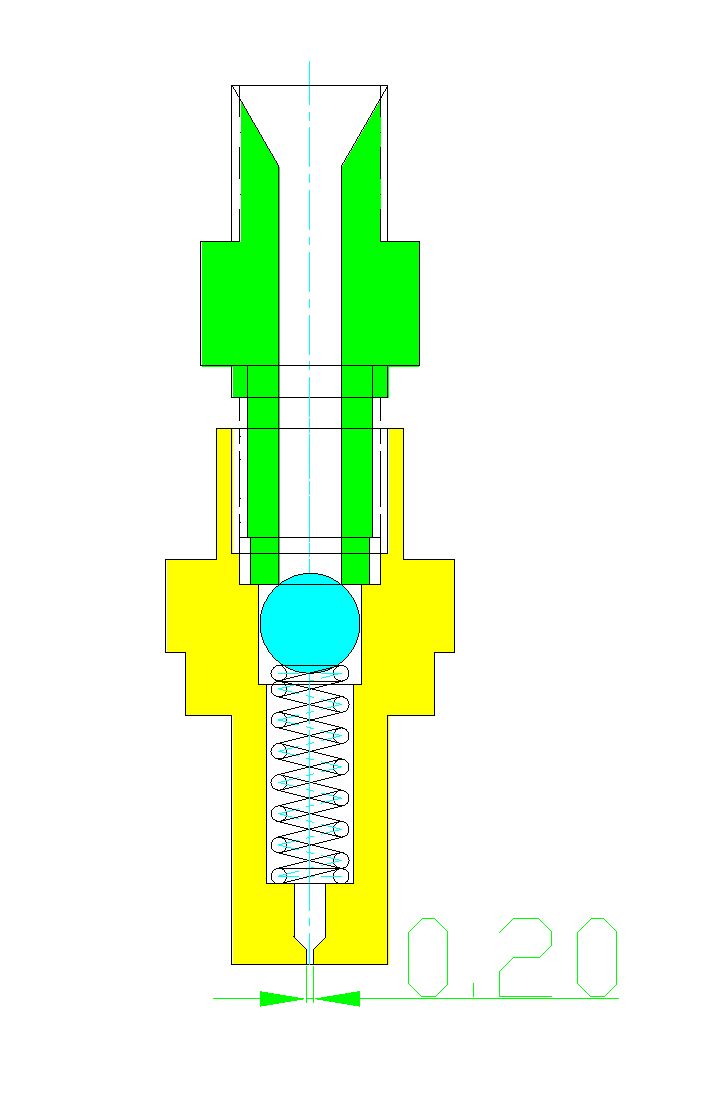

I restored and ran a 3 1/2 Hornsby oil engine for a long time,a big lump around 15 cwt, with twin flywheels ,the second flywheel was specified for electrical generation to smooth out the power strokes and improve governing. The Hornsby is not a diesel,the fuel is squirted at low pressure into the hotbulb on the induction stroke,the jet of fuel hits the far side of the bulb and cooks and vapourises,the subsequent compression and the heat in the hot bulb causes ignition.the governor arm controls the amount of fuel injected by increasing or decreasing the amount of travel of the needle valve in the injector,surplus oil flws back to the fuel tank. I saw Graham Corys engine running many years ago at the 1000 engine rally and was quite impressive,from memory i believe that the gas burner used to preheat the hot bulb had to be kept alight as the hot bulb could not retain it heat. Hornsby hot bulbs do vary internally some are plain others have ribs no doubt to suit various types of fuel (paraffin also known as lamp oil) Hornsbys also found that the small passage between the hot bulb and the cylinder was critical in its diameter, as this passage retained the rich mixture in the bulb until it mixed with fresh air on the compression stroke, and ignited before or around top dead centre there is no fixed timing,I think a lot of experimentation would be required to get the proportions of injector ,the hot bulb restriction know known as the Hornsby neck,compession which is very low in a full size engine, The Blackstone hot bulb engine used a timed disc in a tube mechanically timed to control when the fresh air on the compression stroke mixed with the rich mixture in the hot bulb, Blackstones did not use an injector they had a small oil resevoir adjacent to the hot bulb and sucked the fuel on the induction stroke into the hot bulb via a fixed jet, the disc valve stopped the subsequent rich fuel mixture getting into the cylinder,both Hornsby end Blackstone engines had timed air valves to allow fresh air to enter the cylinder on induction, now indicate how these engines can be difficult at times, after my Hornsby had run after about 3 days rallying carbon would build up on the injector jet and eventually deflect the jet of fuel so that it just dribbled into the hot bulb and did not hit the far side of the hot bulb and it would go sloer and stop,possibly due to running at slow dem speed and no work to do, now on my small Blackstones the timing valve can be critical or not needed, a friend demonstrated on his Blackstone that he could hold the the valve open and it would still run ok, I tried it and on one of mine it ran better with valve open and on another one I found that it was critical and if the adjuster on the valve was turned more than two flats of the nut it would stop within a few minutes. A lot of patience is requied with these early types of engines, and I think I would reluctant to go too small ,

Nigel McBurney 1.