Having an objectively excessive collection of Starrett hole saws I can generally find one quite close to the needed inside and outside sizes which minimises the amount of lathe work involved.

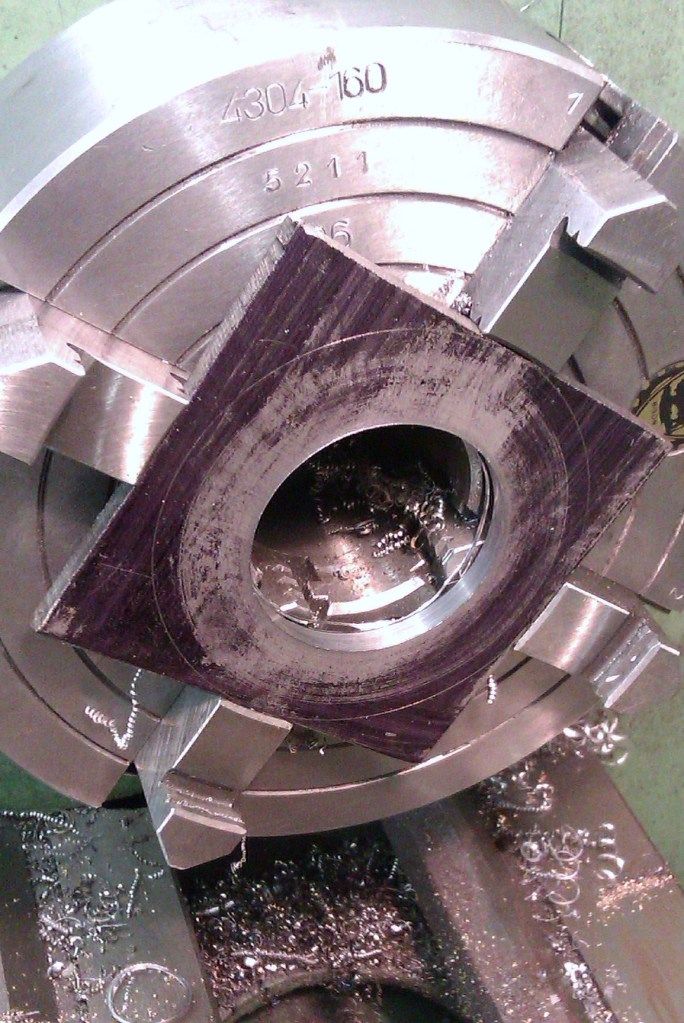

A certain care is needed when doing the lathe work to stop the nascent washer from twisting out of position in the chuck leading, at best, to misshapen inside and outside diameters. At worst the thing pretzelllises before self ejecting from the chuck.

Which is annoying.

The grooves in the jaws aren't guaranteed top hold the thin part in a secure and stable manner. The job is most at risk when taking the corners off the outside. The more sides you cut initially the lower the knock-knock-knock forces at each corner making it much easier for the chuck to hold properly. Clive Brown advises starting with an octagon rather than square which is what I used to do before getting into hole saw collecting.

Trapping a piece of suitably thick wood, MDF, particle board or similar between the embryo washer and the chuck jaws to act as a sacrificial support can help. No need to make it tight on the centre or terribly round. It just needs to sit under where the tool is cutting.

As with so many such jobs belt and braces set-up is frequently not needed. The job going fine when just held in the chuck. But taking that extra care costs little time when "thats the way you do it".

Clive

JasonB.

JasonB.