So I was looking for something on one of my external HDD's and happened across the 3d model of the main body of something I made as a gift for a friend years ago (there are some other parts which turn it into a little bird).

I've just produced a little drawing of it as it's a really interesting part, which produces lots of challenges:

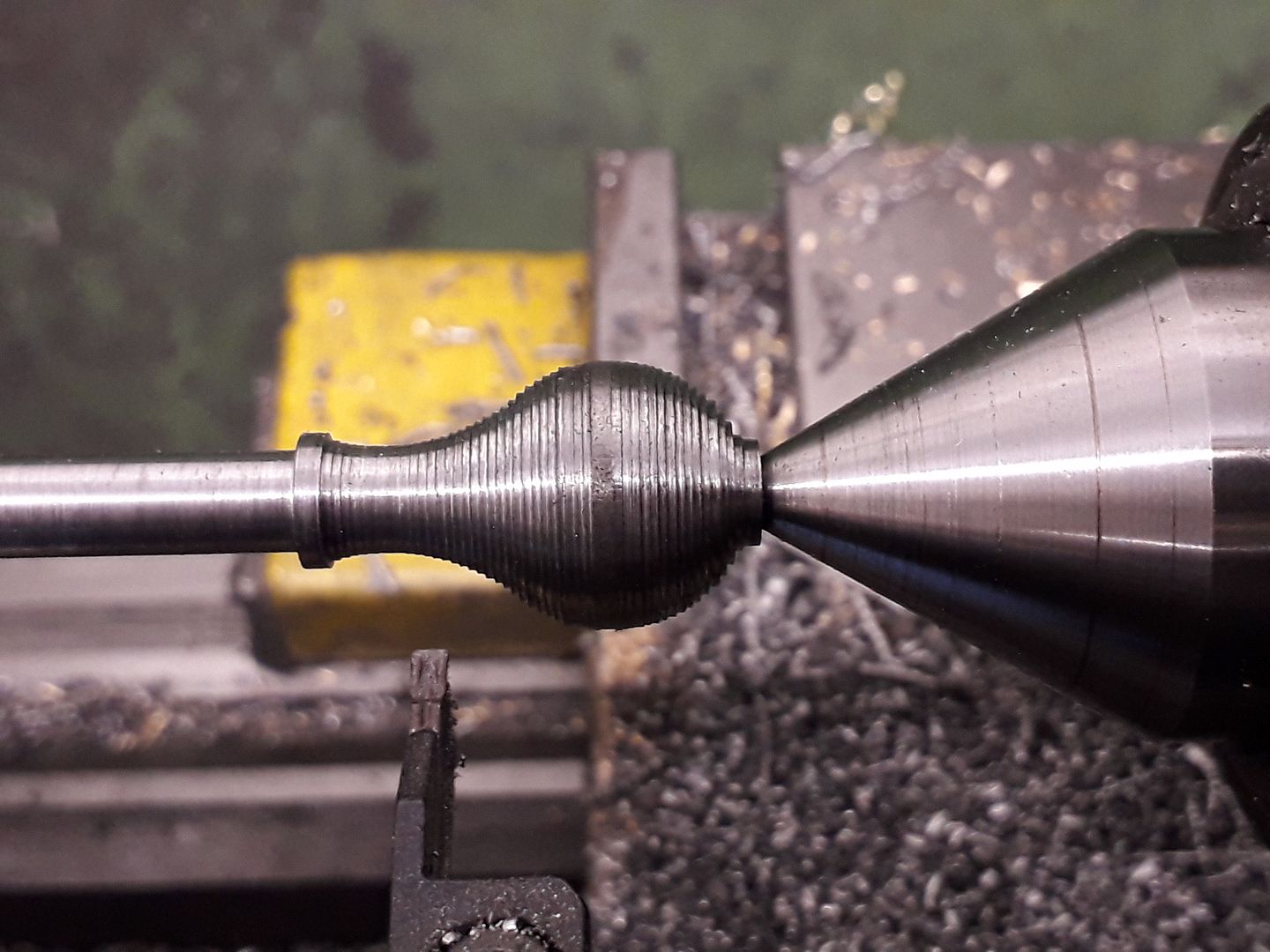

The one I made was actually ½ scale, and turned from a cylindrical piece of brass on a M6 threaded arbour, the curves roughed in with chamfers, and the final shape generated with a (gigantic) carbon steel form tool shaped to produce the full profile.

That very direct approach was easy on the work-holding front, but an absolutely bonkers way to go about it in just about every way…

Something which I came to fully appreciate as the process resulted in innumerable scrapped parts, several snapped arbours and at least one malformed brass bird being launched bodily across the workshop.

I quite fancy making another full-size one for myself, but learning from the previous failures, I can recognise that there's a risk of having a 1kg hunk of brass launched at me, which I'm not really up for.

Thankfully in the intervening years since I made the last one, I have also become slightly more imaginative (to go with the risk aversion) and have been able to come up with a few different approaches using to try which I think would result in a decent outcome, all of which involve making a jig/chuck which can hold onto a sphere securely, and pose their own problems in terms of driving the workpiece and/or marring the surface of a finished part due to clamping pressure

I am however curious how others would approach this, because on first inspection it's far from simple to even hold on to the thing.

Howard Lewis.