Finally made a start on the engine, the short term plan is to get it through a steam test so I can take it to a local show at the end of May. I steamed the engine shortly after it arrived (December 2015) and I found that although it runs, the pump didn't seem to work, the injector didn't work and the hand pump was useless against the boiler pressure.

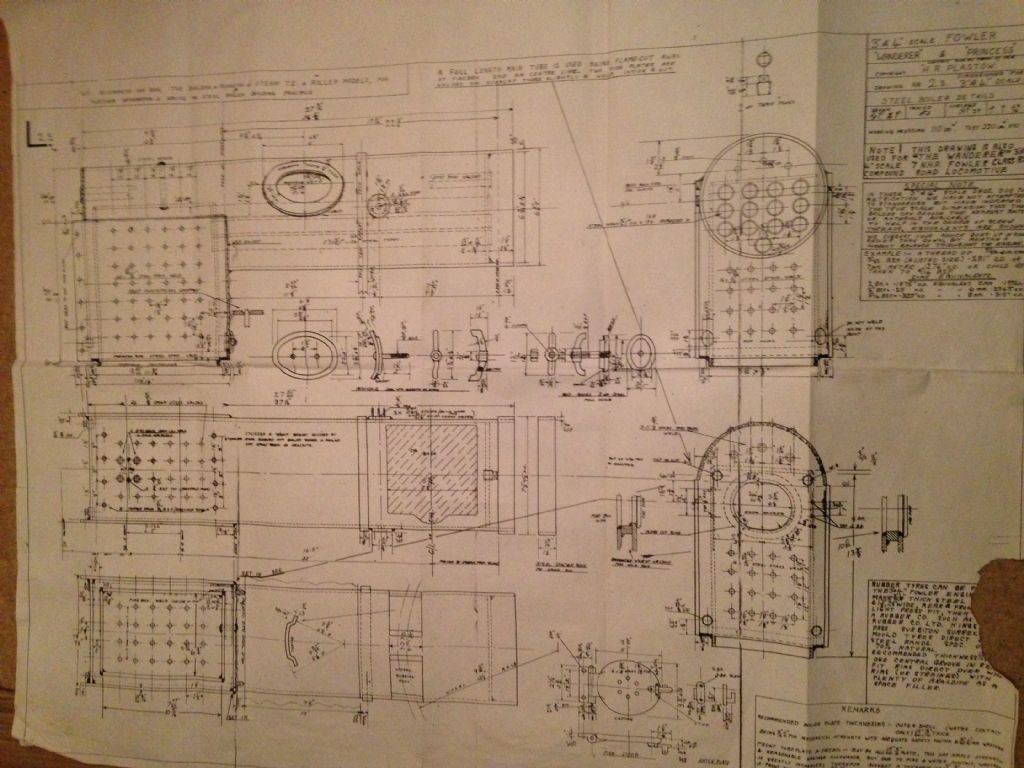

All of the pipe work is completely wrong for a Fowler so that is one of the things to be sorted out whilst getting the pump and injector to work. First I focussed on getting the pump to work; it hadn't had the bypass machines into it, instead it had an external quarter-turn valve in the pipe work to turn on/off the bypass. So I removed the clack body of the pump (where the bypass is supposed to be fitted) and set it up in the 4 jaw ready for facing and machining. The drawings for this engine are pretty poor in terms of detail and clarity (although they are double-dimensioned for 3" and 4" scale), so I had to do a small bit of design/guess work. For example, the gland nut is described as having a 9/16" Fine thread; I know I haven't got any 9/16" dies or taps so any near equivalent for this strange size was out of the question. Instead I used 1/2" x 20, still unusual but I had both tap and die and was close enough for my requirements.

Once I had turned and threaded the gland boss, I then had to bore a hole though it into the first clack chamber then into the wall between the first and second clack chamber. Before I could do this I had to design the valve spindle but this was a fairly straightforward task. After I had bored the hole, I then replaced the 4 jaw with the 3 jaw and turned the valve spindle until it fitted nicely into the pump where I then drilled the bypass hole through it. Next was to make the gland nut, also a fairly straight forward task. I filed a square onto the end of the valve spindle and fitted a handle which I made from 1/4" thick steel plate, which more or less completed the important part of the pump.

This afternoon I assembled the pump back in the engine and rebent the old pipe work to suit traditional Fowler looks; the holes need drilling in the footplate and the pipes dropping through. I also need to rebend the pipe from pump to clack valve which once done will mean I can steam up and give it a test!

Check out my 3" Fowler album to see progress pictures…

Cheers,

Dan.

Harry Wilkes.

Harry Wilkes.