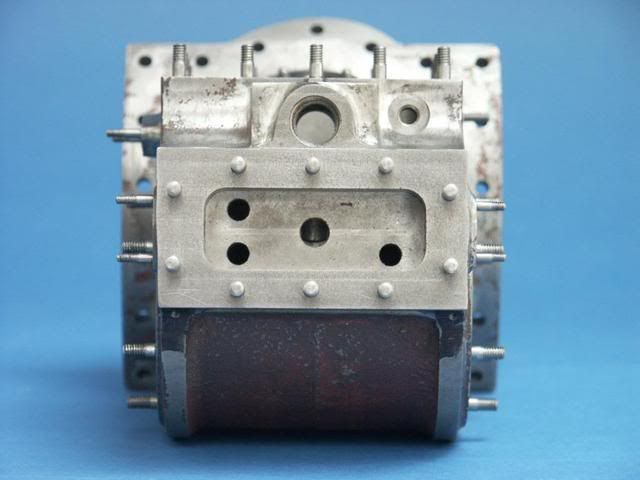

Eric is asking about ways to do it without removing the Block from the boiler. Its also a flat surface at the bottom of a rectangular recess not a round loco type regulator, something like this which is actually my Fowler.

I am lead to believe there is a recess front and back of the port face.

Back in the day the full size engines were done in situe with a planing machine that bolted to the cover studs and was hand cranked back an forth, the recess either end giving the tool something to run out into. Something could probably be knocked up to form guide rails and a tool holder run along these by hand, samething similar to a hand router using a HSS toolbit

Another way if there is not much to come off would be to make a holder for a dremel or die grinder so you could run back and forth using a small grinding stone at a constant depth, bit like cutting a mortice with an electric router.

You would want to blue the mating parts after either method and hand scrape to a final finish or lap them in with Timesaver

Edited By JasonB on 16/10/2013 17:44:17

Ian S C.