Posted by Steve Crow on 01/05/2020 18:29:21:

Posted by Graham Meek on 01/05/2020 17:29:59:

You could make your own for free and have the money for other things!

Regards

Gray,

That's nice! Does the dial work an eccentric cam for adjustment?

Would love to see plans for this.

Just by coincidence Neil has an article waiting a publication slot on this 36 mm diameter Boring & Facing head. The above boring head was made for a friend who has a Mannix MM 250S3 Milling machine, the taper is a BT 20, hence the 20 mm cutter.

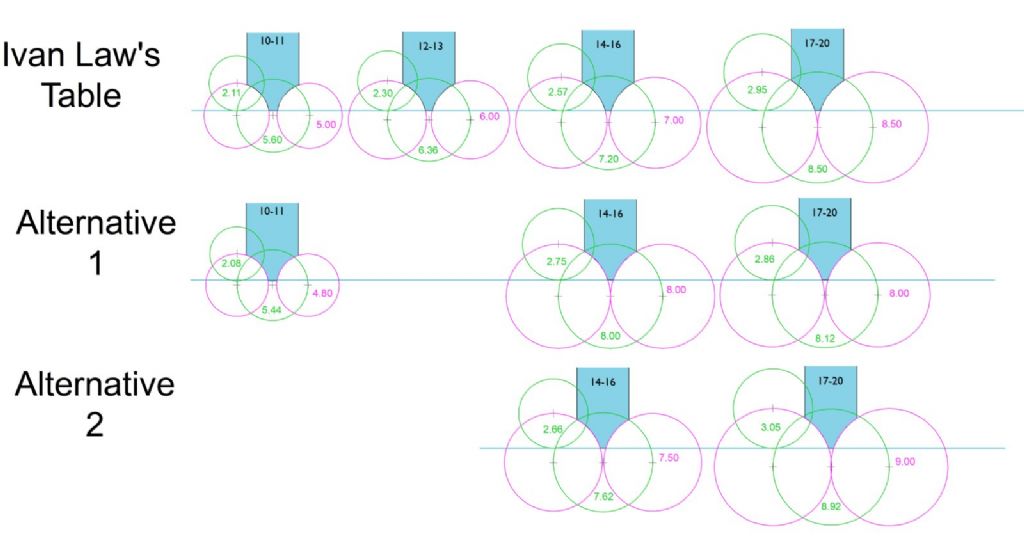

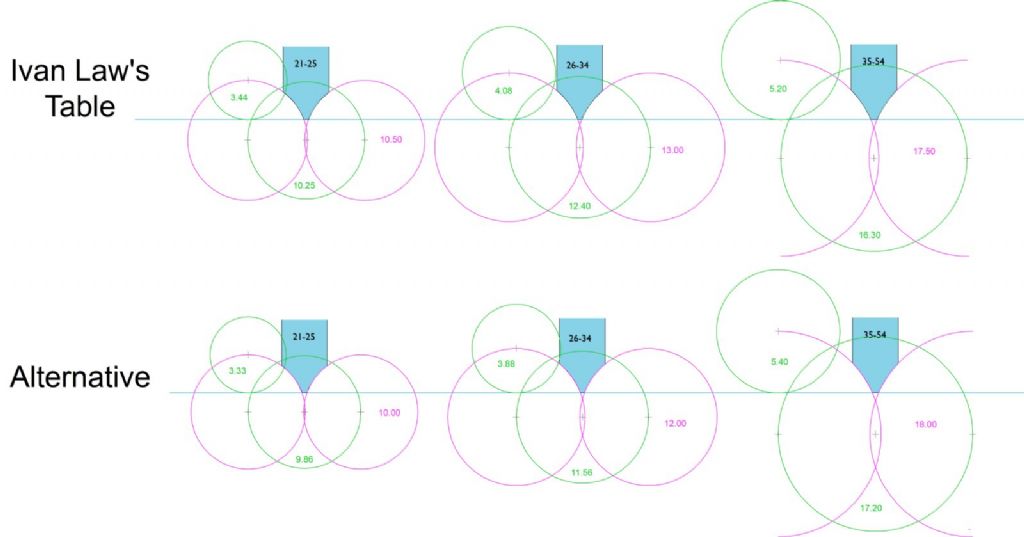

The feed of this concentric dial Boring Head to the feedscrew is by a single start worm and gearing to a conventional feedscrew. To keep the worm profile simple the Pressure Angle was chosen at 30 degrees. Thus the 10 tooth input gear has an Involute form with 30 degree PA. The feed works in two directions to meet the requirements of the two boring tool positions. There is a neutral provision in the gearing for manually setting the boring tool, so the operator does not have to wind the dial for this purpose. The dial can be set to zero, one full turn of the dial removes 0.1 mm from the bore, and two stops can be set to limit the travel when spotfacing. The feed is 0.05 mm per rev. A built in clutch in the feed ring allows the feed to stop once the limit stops are made.

With regards to forming the flanks of the single tooth cutters that I use. A series of photographs recently appeared in the thread on my design for the Myford Tailstock dial. Or you can find them in my album.

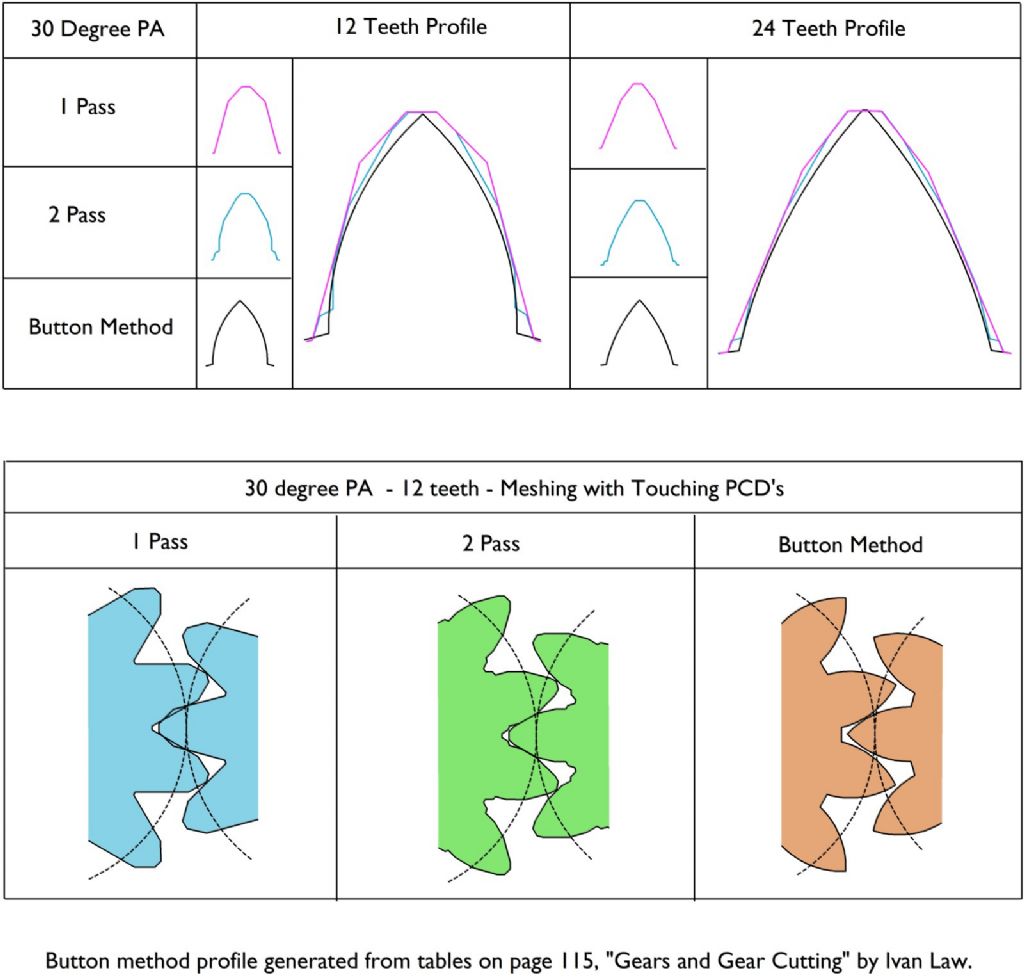

As regards the flank radius this is always going to be a compromise. B&S cutters cover a range of teeth per cutter. For obvious reasons the cutter will have to be made to cut the smallest number of gear teeth in that particular range. Thus those at the top of that gear cutters range are going to be a compromise.

I design my cutters to suit each gear used, that way the teeth are as close to a hobbed profile as I can get with a form cutter. These gears run extremely smoothly together because of this. While I draw and work exclusively in Metric very often an Imperial cutter is so close that it is not worth worrying about, so I use that.

I am currently working on the 66 mm diameter bodied version of this B&F Head following numerous requests for a larger version of the 36 mm baby of the family. (I built the 50 mm version some time back, see below).

Regards

Gray,

Edited By Graham Meek on 02/05/2020 11:40:19

Graham Meek.