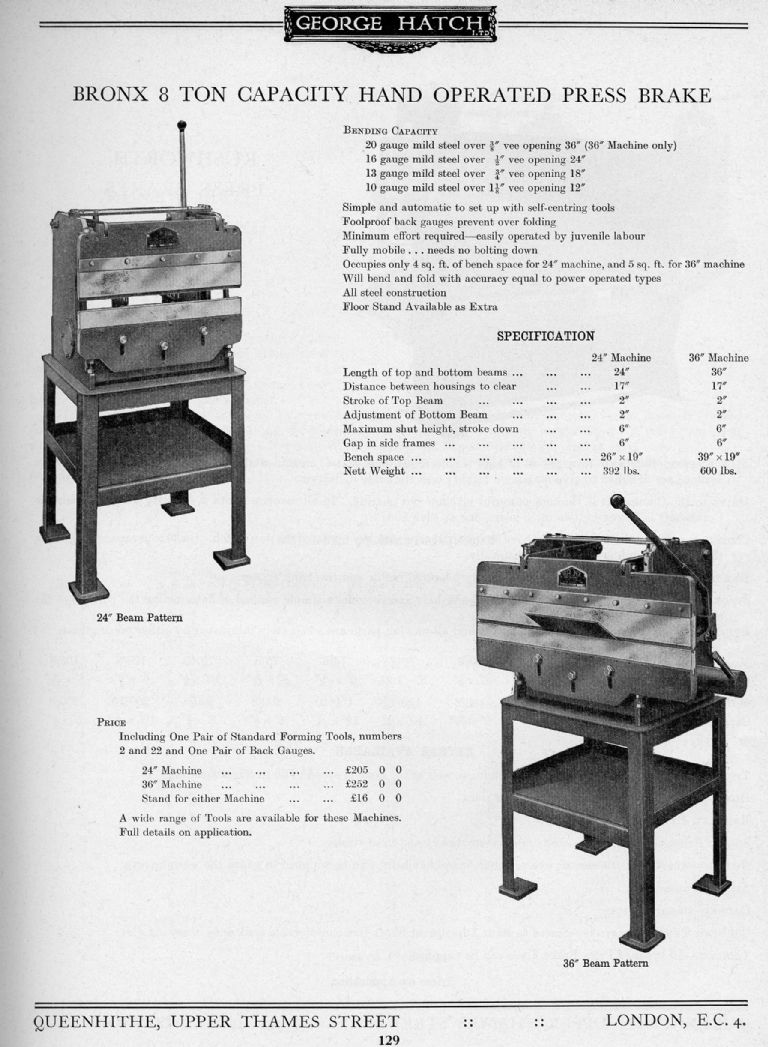

Hi Sean, as has been said, 1/8" (3mm) much over 6" wide will take a fair bit of effort to bend in a hand sheet metal bender. You would need a moderate size machine like a press brake, the one in this advert below would only do 12" wide for 10g steel, approx. 1/8".

I was given the job of making a small bench hand folder at work some time ago now. The base plate is a piece of 200mm wide by 30mm thick flat bar, welded on top of a piece heavy channel and the top beam is a piece of 100 x 100mm x 10mm thick angle iron which was stiffened up and the folding part is 150 x 75 x 10mm thick angle iron with channel iron gussets, this will accept 1M wide sheet, but 2mm thick steel is its limit and that takes some grunt for that width, I could take a photo it if you like, but not until Tuesday next week. If you have a workshop hydraulic press, you could always get or make a "V" block and a forming tool.

Regards Nick.

P.S. here's a photo of my make-shift press I cobbled together to bend a couple of pieces of 6mm chequered plate.

Edited By Nicholas Farr on 29/11/2018 22:27:35

sean logie.