Hi All

As an alternative if you have a precision ground bar

25 – 40mm is ideal, of constant diameter say to

within ten thou and as well you have a tenth

accuracy dial indicator you can use these to check

the axis of your machine.

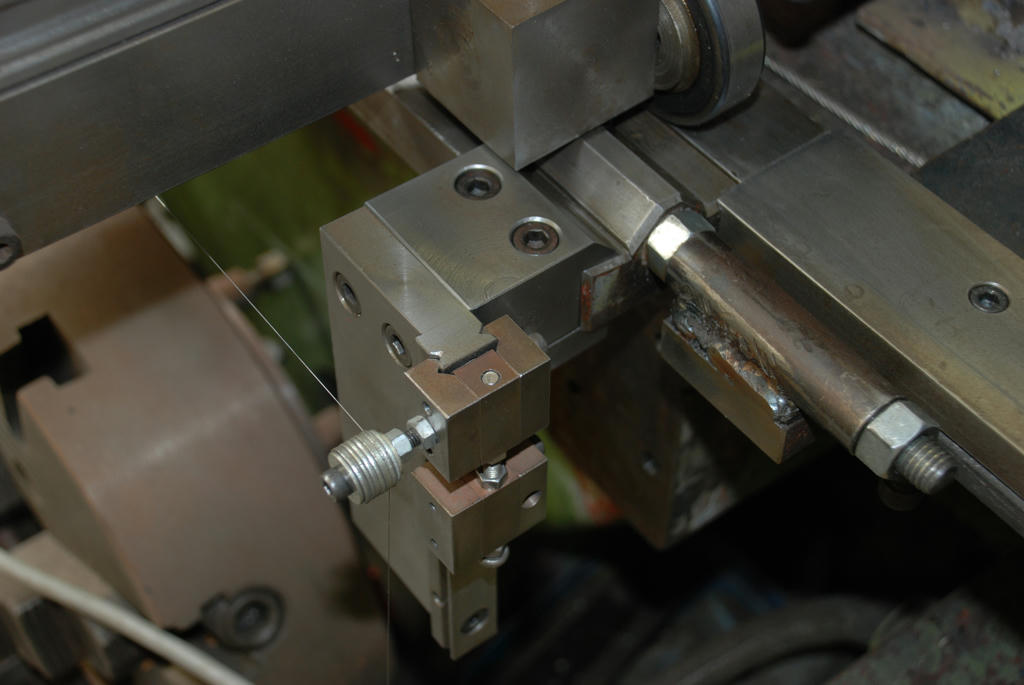

Just set the bar up in your chuck a 3 will do but

better a 4 jaw. Use the dial indicator to centre it. If

you have a 4 jaw chuck.

After cantering one point unless you are very lucky

the bar will not be in line with the machine axis at all

points. Also your precision ground bar may not be

perfectly straight, it does not matter! The dial

indicator is going to sort out any wobble in the bar.

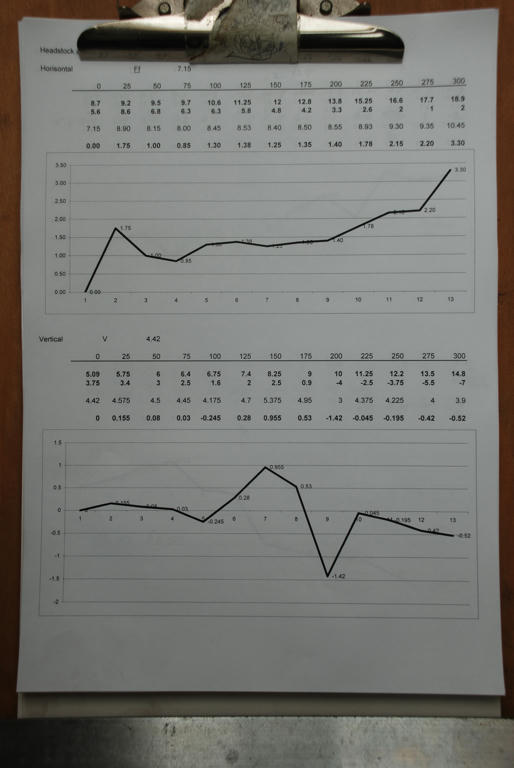

We are going to take several measurements along

the bar, if it is say 300mm long maybe measuring it

ever 2cm would be a good start.

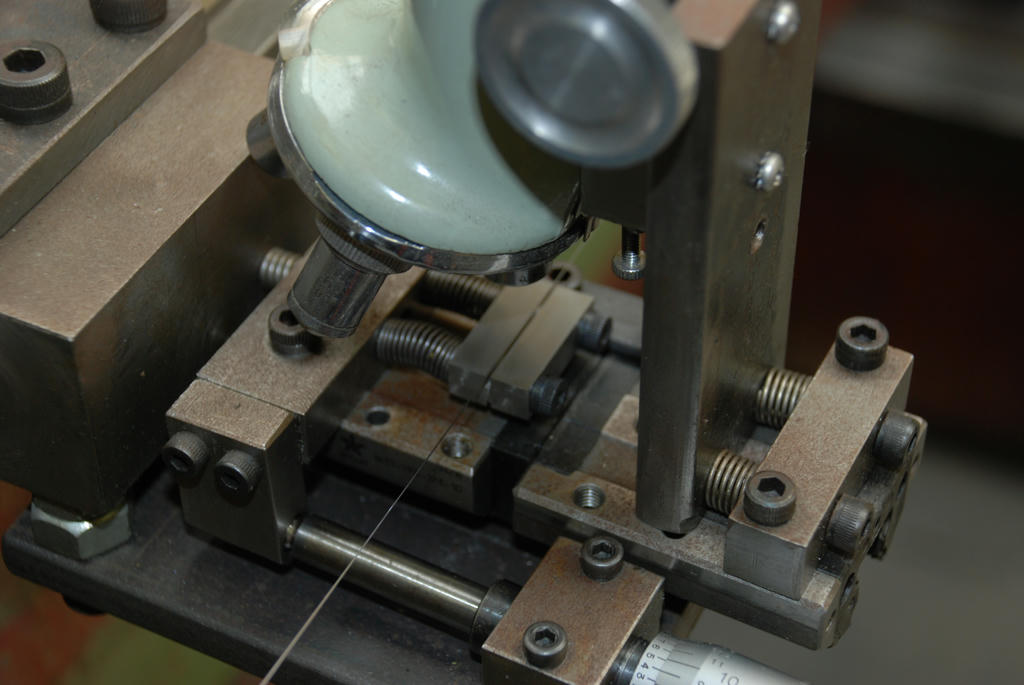

After setting up your dial indicator on the saddle and

moving it to the start point of your measurements

say near the chuck, and checking it is on centre you

are ready.

You will also need a ruler or other means to move

the carriage to the next measuring point.

Rule off rule off a piece of paper it will need 4

columns and as many rows as you have measuring

points. Mark the 4 columns; position, High, Low,

High minus Low

Now we are ready to find if there is any alignment

error between the axis of our lathe spindle and the

path travelled by a cutting tool at the diameter of our

test bar.

Before starting check again that the tip of your

indicator is on centre, and you are at the first

reading position 0.

Then rotate the spindle until the indicator reads

highest and note the reading on your paper in the

high column.

Then rotate the spindle until the indicator reads

lowest and note the reading on your paper in the

low column.

Repeat this for all the other positions.

At this point you have all the other highs and lows,

we can now calculate the error! Subtract the low

from the high and note the result in the last column.

You may get positive and negative numbers.

Repeat this for all the other measurements the

results will either be all the same (very unlikely), or

they will differ hopefully progressively, a straight line

error, you have a straight bed and saddle travel. But

the alignment to the spindle is out.

Alternatively the result will describe a curve this

indicates a straightness error in the alignment of the

saddle and bed as well as any overall error between

the alignment of the saddle and bed. On older

lathes there is often some error detected a dip in

the bed near the spindle is very common.

If you can use Excel you can do all this on a

spreadsheet and graph it.

This method does not check the alignment of the

taper in your spindle to the axis of rotation. However

this is easily done with a finger type dial indicator.

This method is a very good indicator of the

condition of any machine slide to spindle alignment.

To speed this process up fewer measuring points

can be used. Or for extreme accuracy more points.

Regards

John

John McNamara.