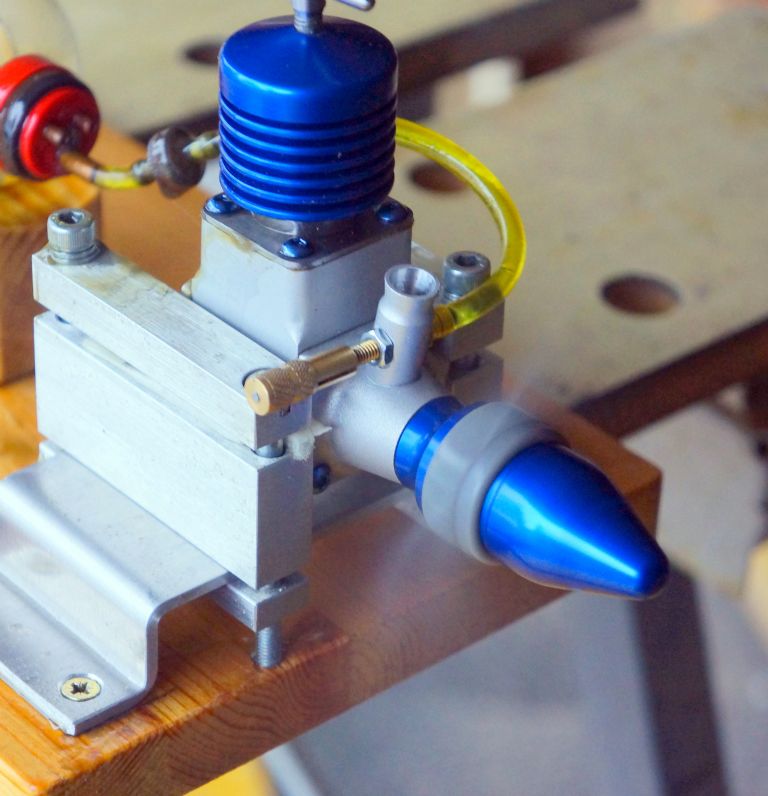

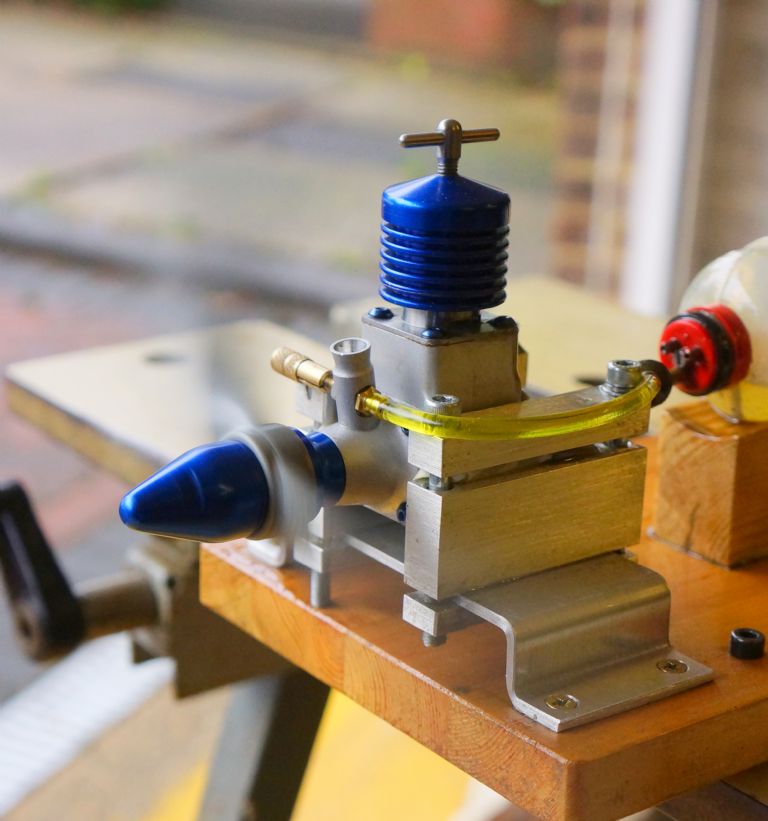

This is my latest engine recently completed. The design is by Aussie Ed Holly, who has made his drawings for it freely available. As drawn, it is a boxy, all bar-stock design. Eds intension being to encourage people to have a go at making an I/C engine. In his notes with the drawings he suggests that makers might like to alter things to make the engine unique to them and I have done just that..

This is my latest engine recently completed. The design is by Aussie Ed Holly, who has made his drawings for it freely available. As drawn, it is a boxy, all bar-stock design. Eds intension being to encourage people to have a go at making an I/C engine. In his notes with the drawings he suggests that makers might like to alter things to make the engine unique to them and I have done just that..

The Crankcase as drawn has a radial mounting, This has been changed to a beam mount I have lengthened the crankshaft to allow a spinner in place of the plain nut. Added a bronze bearing to the front housing that also has a single ball race. Also changed to a split collet for the prop driver in place of the fixed taper.. The Fins and Cylinder were held down by four long screws,but I have put a thread on the Cylinder to allow the fins to be screwed down. Cylinder height was increased by 0.375"as the Contra piston,as drawn is too shallow for the method I use to make them. I put about 0.005" taper to the outside,with a thin wall of about 0.020",.Diameter is then turned with a good finish to allow it to enter the cylinder for half its length. This will then push into the cylinder giving a gas tight fit with the Screw fitting.For the last three engines I have made this from EN1A,rather than C/.I . I smear copper loaded grease on it on assembly to avoid any chance of seize. Cosmetically I have tried to soften the appearance. The Fins , Prop Driver and Spinner are anodised and the crankcase has been bead blasted to give an overall smooth mat finish. To add to the "bling" I added blue S/S mush head screws.

It has proved to be an easy starter and to date it has had five runs of about two minutes each, running rich ,with a 10"x 4" nylon prop, RPM at this stage is around the 8000 mark. I have several props of other size to use on later runs.

Putting potos on here is a nightmare! Why do they end up in the reverse order that I click on them? I would expect to start at the top of the list, not the bottom.

Keith

Ramon Wilson.

Ramon Wilson.