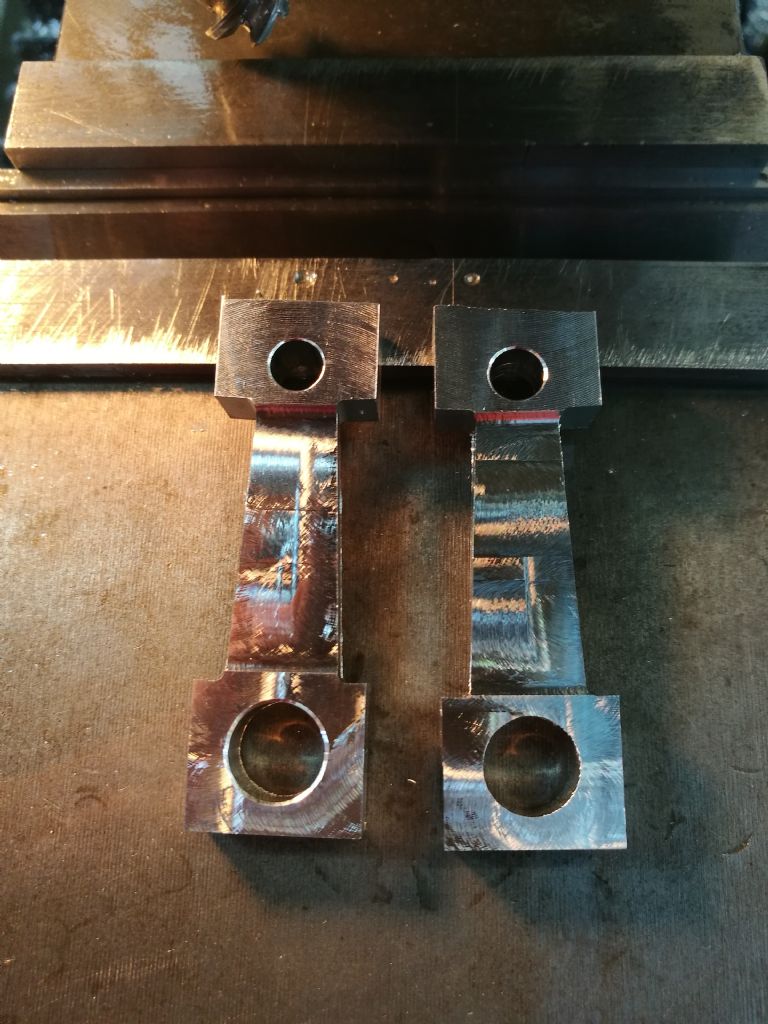

Introducing some pedantry, IDEALLY when the rods are fitted, the big ends should be tightened to the same torque as that used when they were machined. Taken as read that the caps will be assembled oriented as they were whilst being machined.

In this size, difficult to measure to measure the torque, without rather special torque spanners for low torques, or you could use a spring balance on an arm of known length.

In an ideal world, even after machining the bores, they could be measured with a bore set, or something of that nature and torqued in stages until as round as possible, and the figures noted. During assembly, the fixings are then tightened to the figures noted for each fixing. (That's what i did for an engine for a sports/racing car)

The reason for this procedure is that if the torque applied during assembly differs from that when the bore was machined, the resulting bore will be oval. The plane of the major axis of the oval will depend on whether the fixings have been under or over torqued compared to that applied before machining.

The devil is in the detail, but it does make a difference to output and life expectancy!

Howard

Fernando Giaccaglia.