Posted by Ian Phillips on 17/07/2016 22:42:07:

In theory a simple compression spring is something I should be able to make myself but commercially made springs would be much better because they have closed ends that are ground flat.

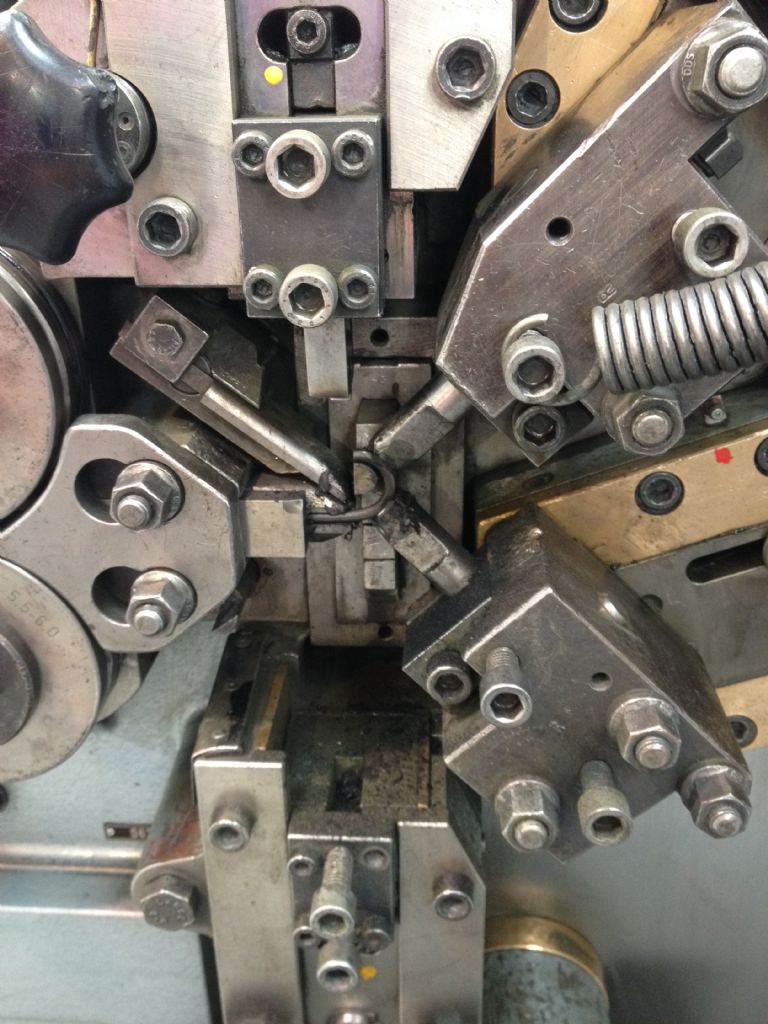

Closing and grinding the ends isn't difficult. I posted this a couple of years ago:

Choose the gauge of spring (music/piano) wire and the i.d. of the spring. Find a bit of MS steel to act as the mandrel and drill a cross hole to anchor the wire. Mount a bit of bar in the lathe toolpost so that the top of the bar is at centre height and file a V groove into the bar top surface.

Set the lathe up for screw turning to the desired pitch. Without engaging the lead screw turn a couple of close turns.

Then engage the lead screw and turn the spring to the required length

Now disengage the lead screw and add a couple more turns

Snip off the wire at both ends and you have a spring with closed ends

Now touch each end of the spring on a grindstone and you have a completed spring

I turn the mandrel by hand for this process and you might need to do a little experimentation with the spring mandrel diameter. I've used this method on 3 engines now and the springs have fulfilled their purpose admirably. Spring/Music/Piano wire is available from the usual ME suppliers.

Hope this helps,

Rod

Neil Wyatt.

Neil Wyatt.

, so making one-offs wouldn't be quick.

, so making one-offs wouldn't be quick.