1/3rd Scale “Ball Hopper” Monitor Build

1/3rd Scale “Ball Hopper” Monitor Build

Home › Forums › I/C Engines › 1/3rd Scale “Ball Hopper” Monitor Build

- This topic has 26 replies, 7 voices, and was last updated 19 September 2023 at 11:03 by

JasonB.

JasonB.

-

AuthorPosts

-

24 March 2014 at 17:30 #2399

JasonBModerator@jasonb

JasonBModerator@jasonbDetailed description of building a ball hopper monitor engine kit

24 March 2014 at 17:30 #147927 JasonBModerator@jasonb

JasonBModerator@jasonbAs a few people seemed to like the build thread that Allan did on his Victoria and I feel we could do with some more similar threads on here I'm going to post the more detailed build of the Monitor engine that I have been showing bits of in the What did you do thread. So here goes, its a bit picture heavy but as its not the mag I hope you won't feel its being padded out and want a refund

I had long fancied doing this engine and would often visit Pacific Model Designs website to eye it up. Unfortunately they went out of business so it looked like I would not get to make one, I did almost buy one of Lone Star's Engine Works similar style engines but the opertunity to make one of the PMD kits came up so how could I refuse.

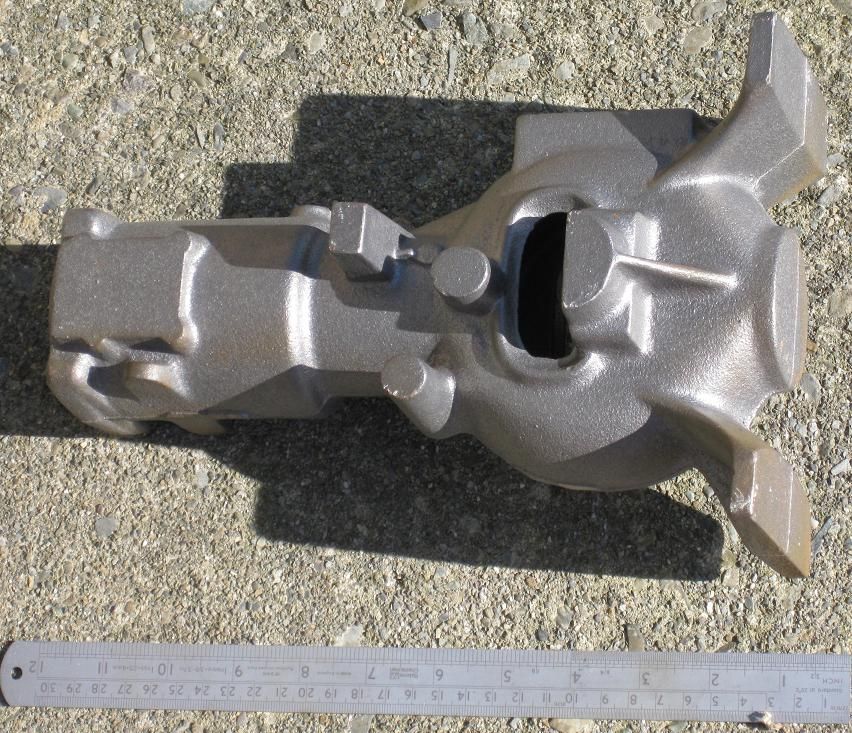

The engine is of the 4hp version and modeled in 1/3rd scale. All but one of the castings are supplied in cast iron, the exception being the carb body which is bronze. These are the castings with a 12" rule to give an idea of size, the plastic bag contains the two timing gears.

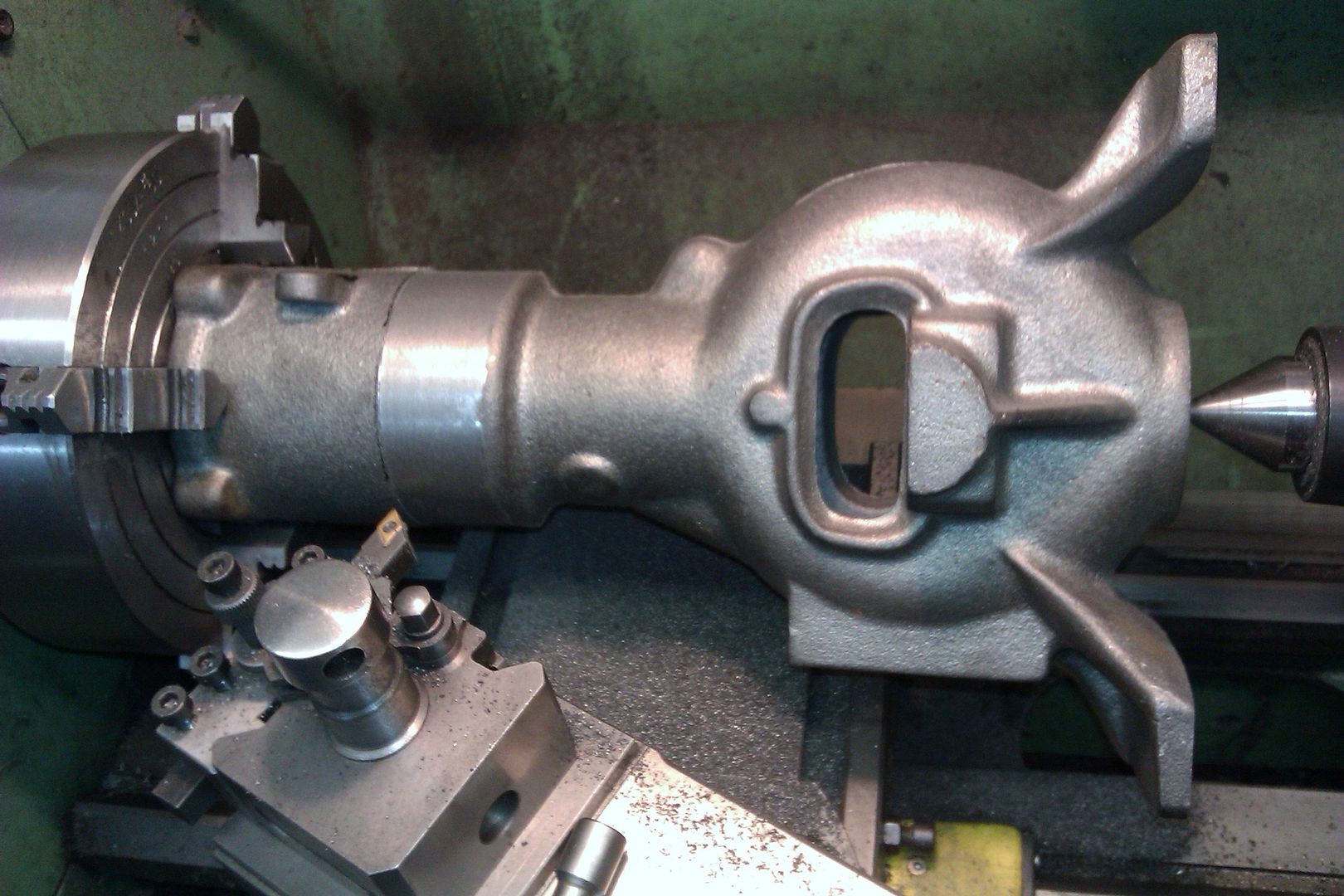

The logical place to start is with the crankcase which is quite a heafty lump at 11" tall

But before I could get going on that my fixed steady needed a little bit of surgery before it could be used for one of the suggested machining processes so I have included this picture especially for JS.

After a lot of careful measuring and marking out I decided on the position of the crank drain hole which was only centre drilled for now so that the casting could be supported by the tailstock while the head end was adjusted in the 4-jaw to get the outside of the cylinder to run as true as possible then the base was machined.

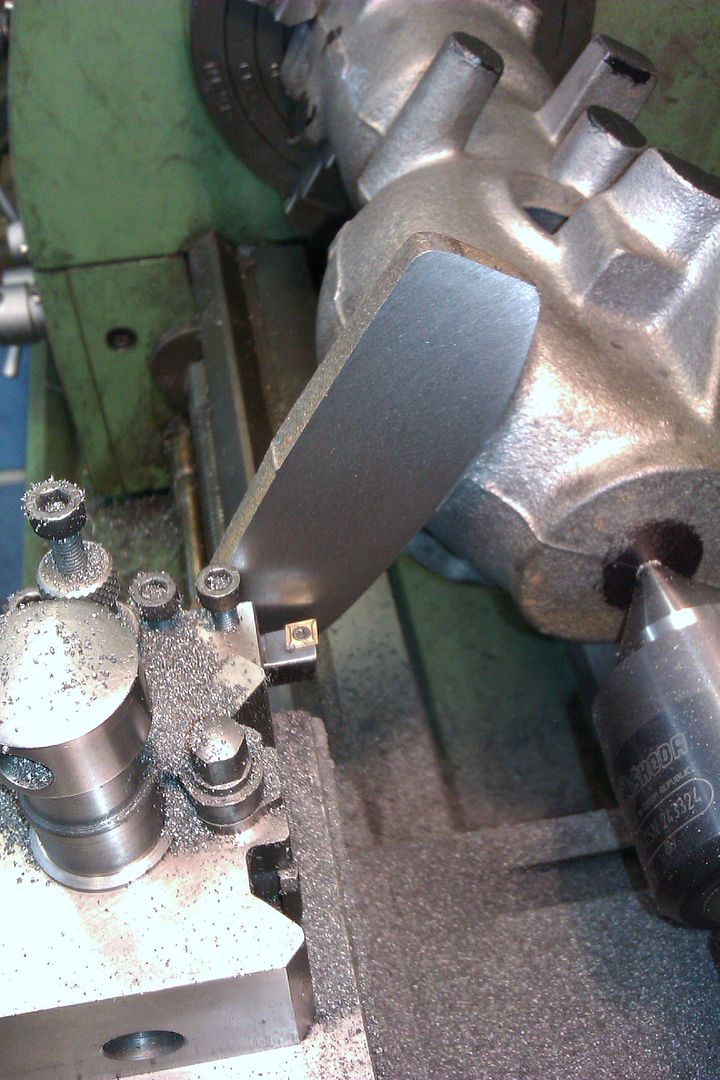

Who says carbide tooling does not like interupted cuts?

At this same setting a very light skim was taken off the lower part of the cylinder so the fixed steady would have a surface to run against.

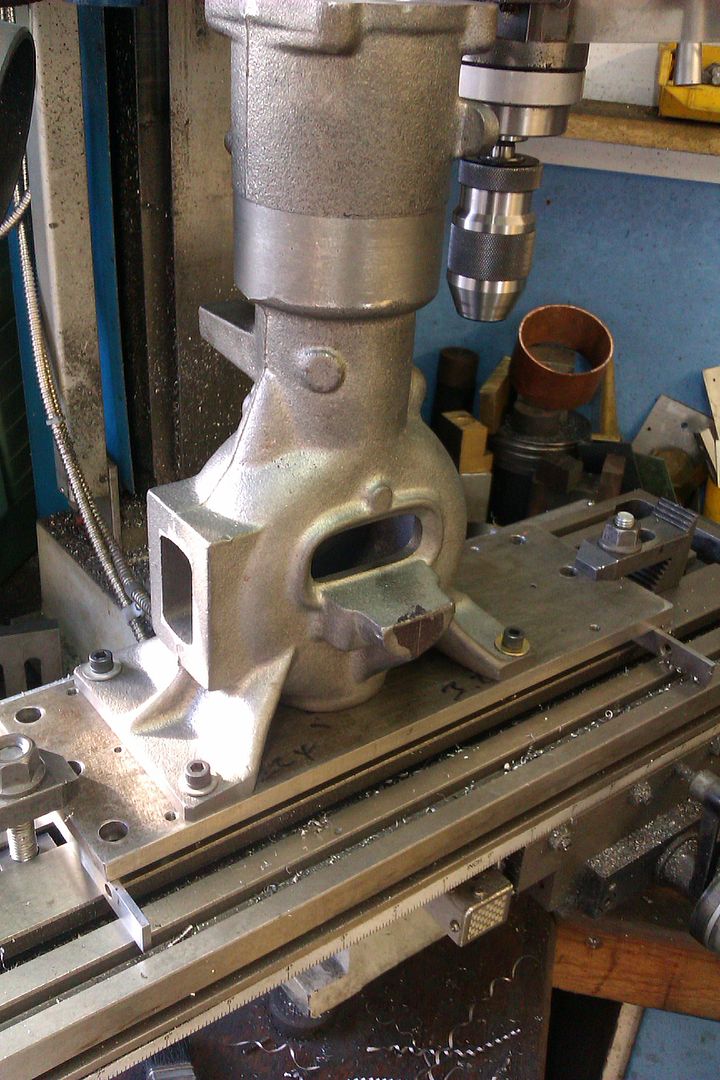

It was then over to the mill where the casting was shimmed up and a squaring cut taken across the base, this would be my datum for most of the other machining.

The opposite side and then the ends were squared to this first face

With the casting stood upside down the datum face was clocked true, centre located and the 4 mounting holes drilled a tight fit on some 1/4" Whit cap head screws. I had to resort to a keyed chuck here as I could not get the longer keyless on in the space available with the X3 head right at the top of the column

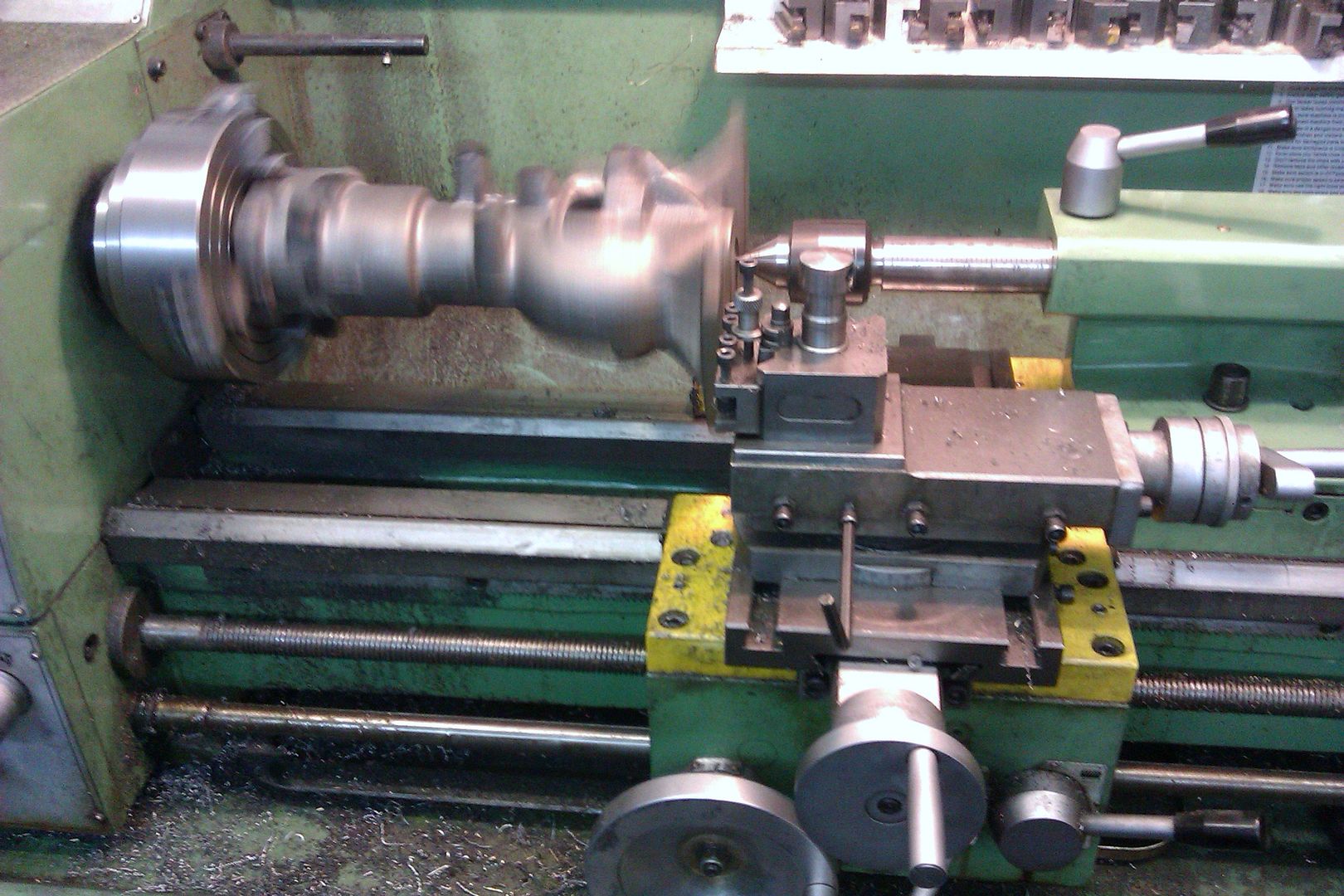

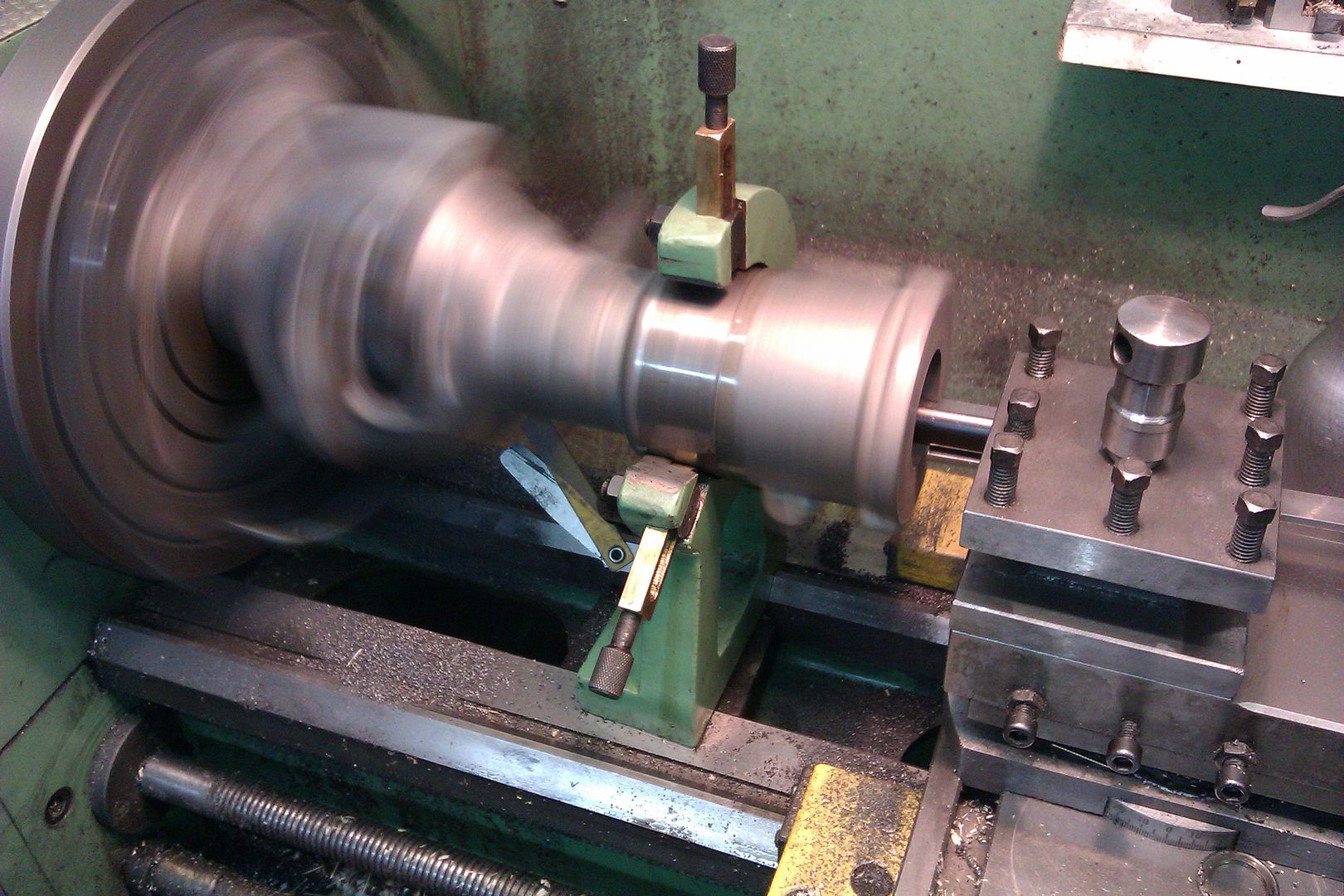

Back to the lathe and the crankcase was clamped to the faceplate and set to run true with a DTI against the previously turned portion. When true the fixed steady could now be positioned to add support while the casting was faced and bored, the bore for the liner needs to be about 6" long. I used the Warco supplied 4-way tool post as it takes larger tools than my usual Dickson QCTP

I'll stop there incase I loose the posting.

J

Edited By JasonB on 24/03/2014 17:34:49

24 March 2014 at 18:50 #147935Anonymous

Wot, ready made gears? That's no fun.

Andrew

24 March 2014 at 22:22 #147965Martin Cottrell

Participant@martincottrell21329A nice start Jason. That crankcase looks a bit of a beast! Nothing wrong with "picture heavy" when the pics are informative and relevant!

Regards, Martin.

6 April 2014 at 15:37 #149079 JasonBModerator@jasonb

JasonBModerator@jasonbTo help with setting the crankcase casting up for the forth comming milling operations I decided to mount it on a tooling plate. This was clocked true to the mill axis and 4 holes drilled and tapped 1/4Whit and the casting screwed down

I then wound the mill head upto the top of its travel and proceded to drill and tap the nine 2BA holes for the head (5) and hopper (4) studs as well as the dozen smaller holes that allow water to flow from hopper to the water space around the cylinder liner. All done using teh DROs PCD function.

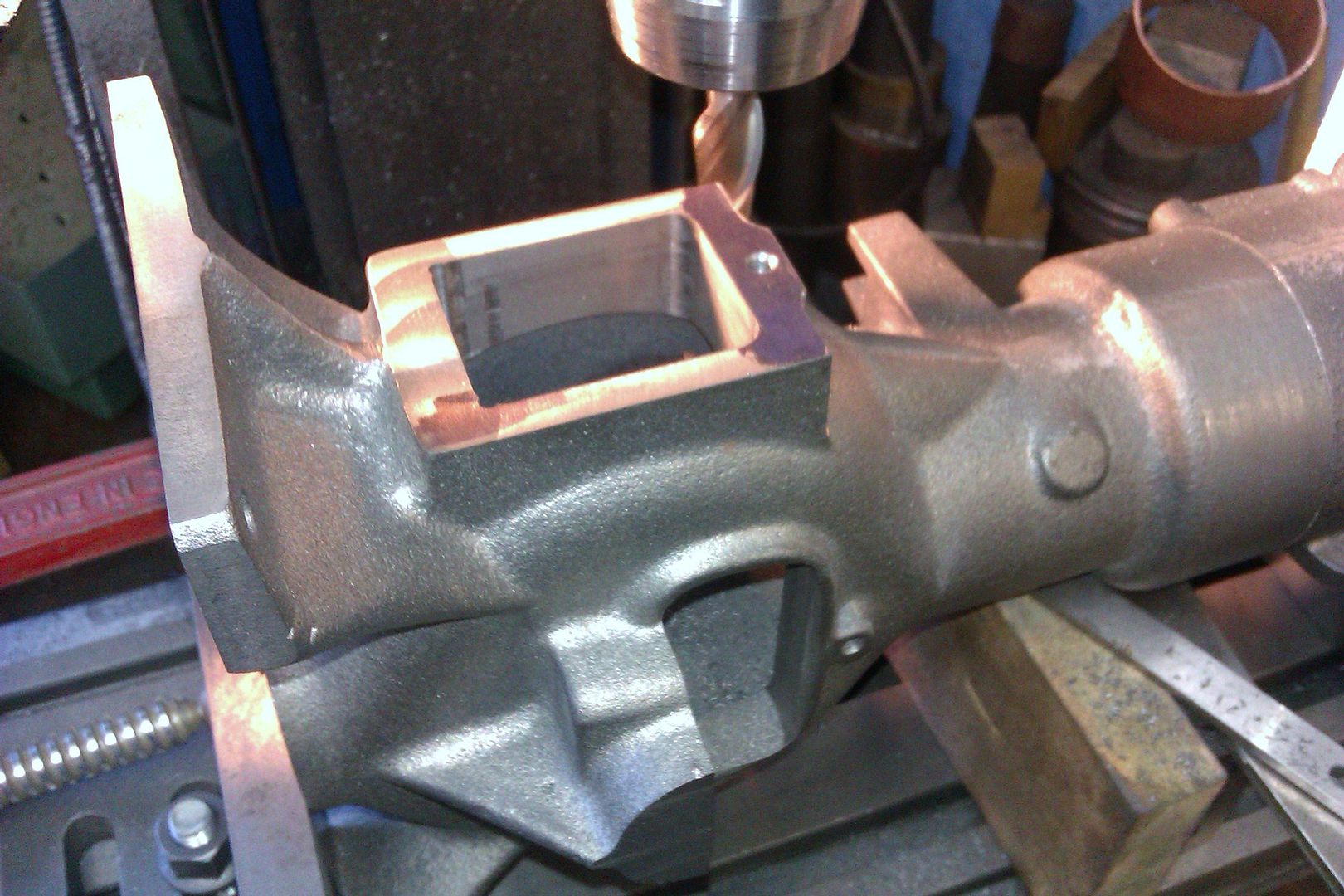

The casting was laid on its side with a parallel under the edge of the tooling plate to set it correctly in the horizontal plane and then clamped down using an angle plate at each end, the one at the base into tapped holes in the tooling plate, at the top I made use of some of the 2BA holes. I then used a "little Hogger" to machine all the surfaces back to the correct distance from the centre line.

A bit out of focus but the holes and slots were added at the same setting

Here you can see that the top of the bearing housing has been milled, I did these using the same set up but had to do each side separately as they are 5" end to end.

With the crankcase set at right angles the access hole on the side was faced back and opened upto final size.

I deviated from the drawings here. The pen mark shows where they put the stud hole which was a bit out of place if the cover was going to fit in the right place!

Due to the various overhanging brackets and proximity to the side of the casting I had to drill and tap the bearing cap stud holes from below.

J

18 April 2014 at 18:52 #150116 JasonBModerator@jasonb

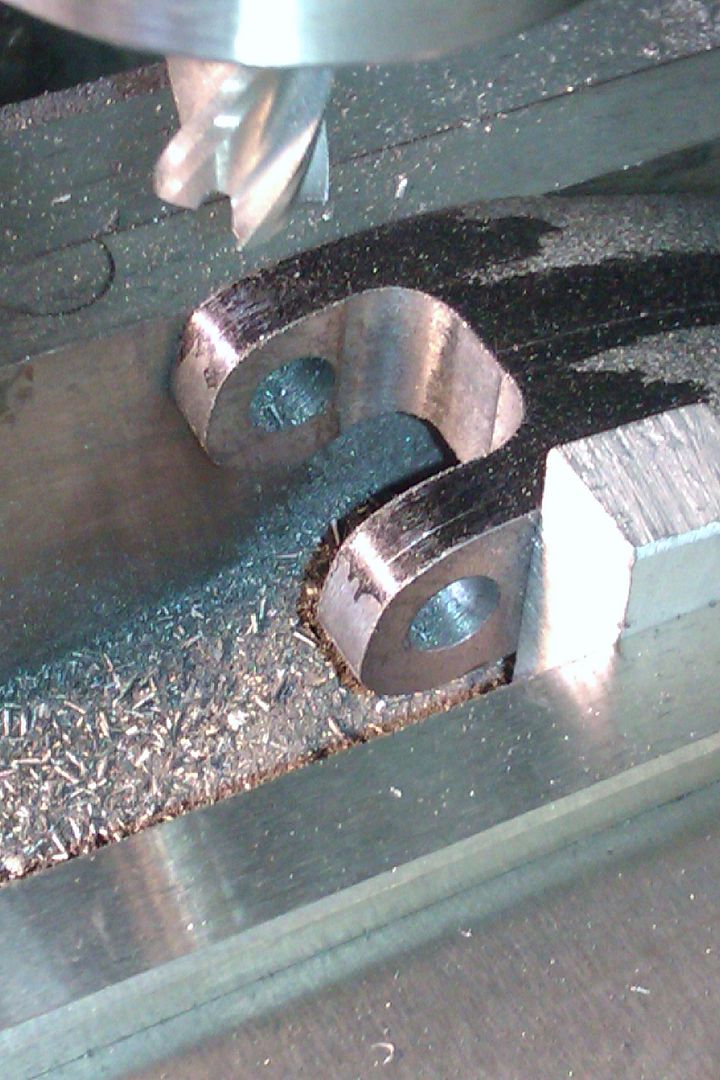

JasonBModerator@jasonbBefore the bearings housings could be bored I needed the bearing caps so these had their ends cleaned up but left over length and then the mating surface was milled down to size.

They were then flipped over and the stud holes drilled & spotfaced, the wick oiler tube hole drilled and a large counterbore cut to hold the oil.

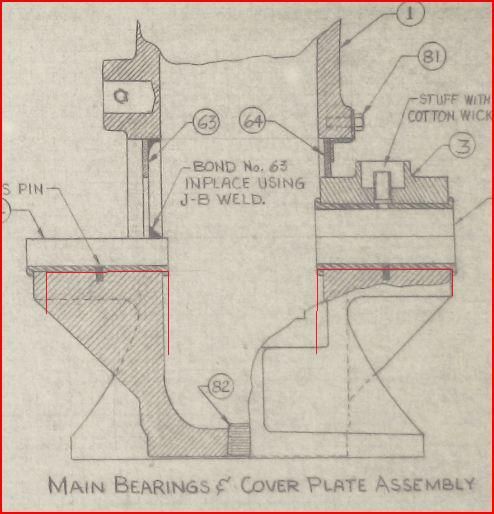

It was around this time that I confirmed my earlier suspicions that the whole casting was a bit narrow, 0.100" or there abouts. There was not enough room inside the crankcase for the crank to turn let alone the flanges of the bearings. This shows the cross section with what I actually had marked in red.

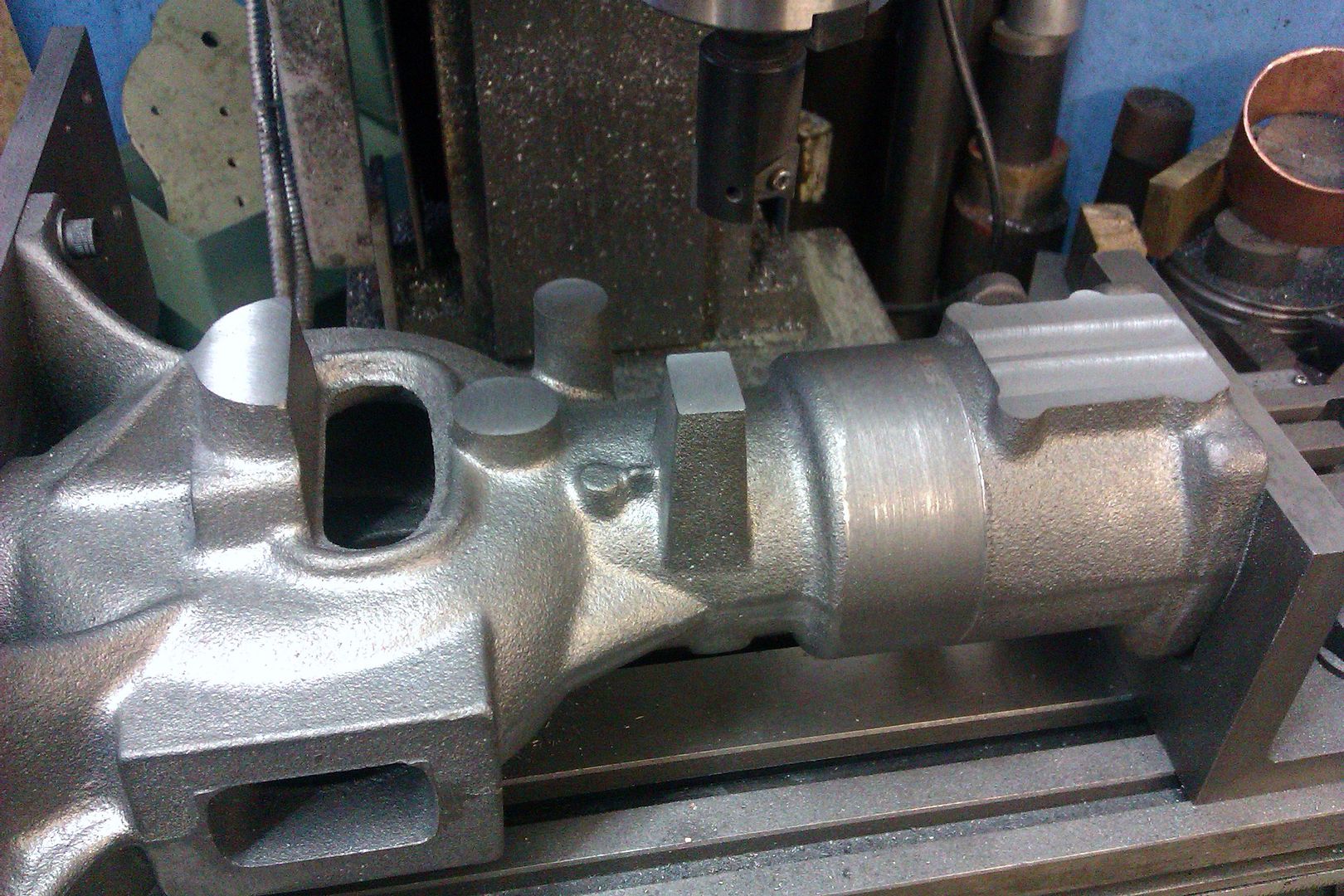

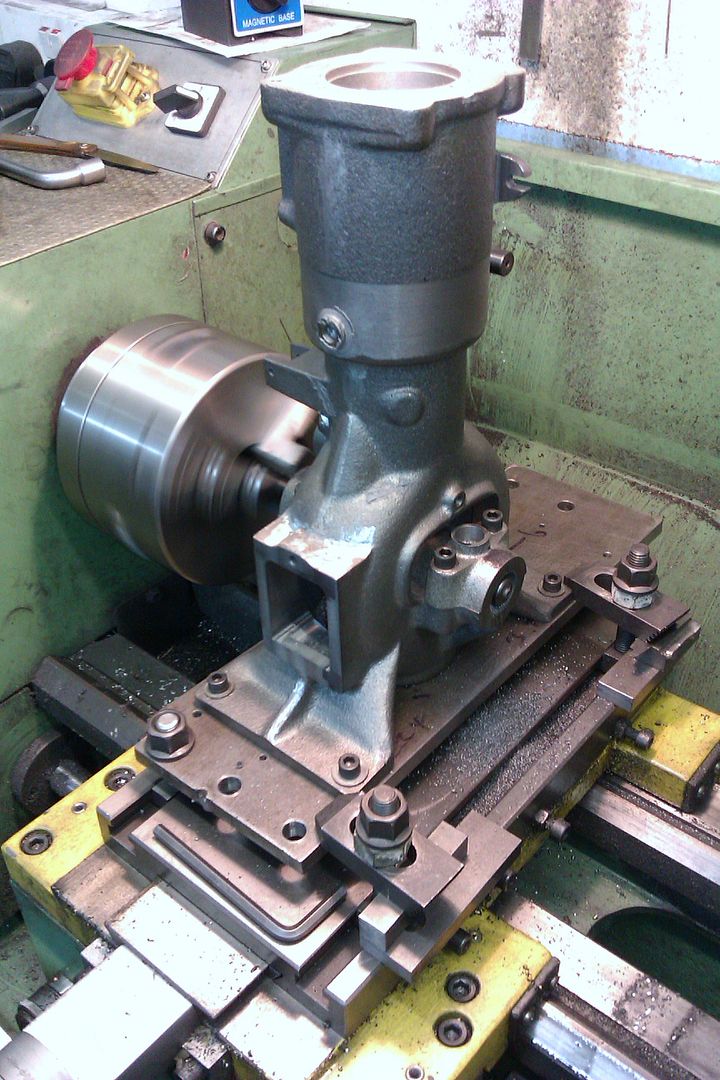

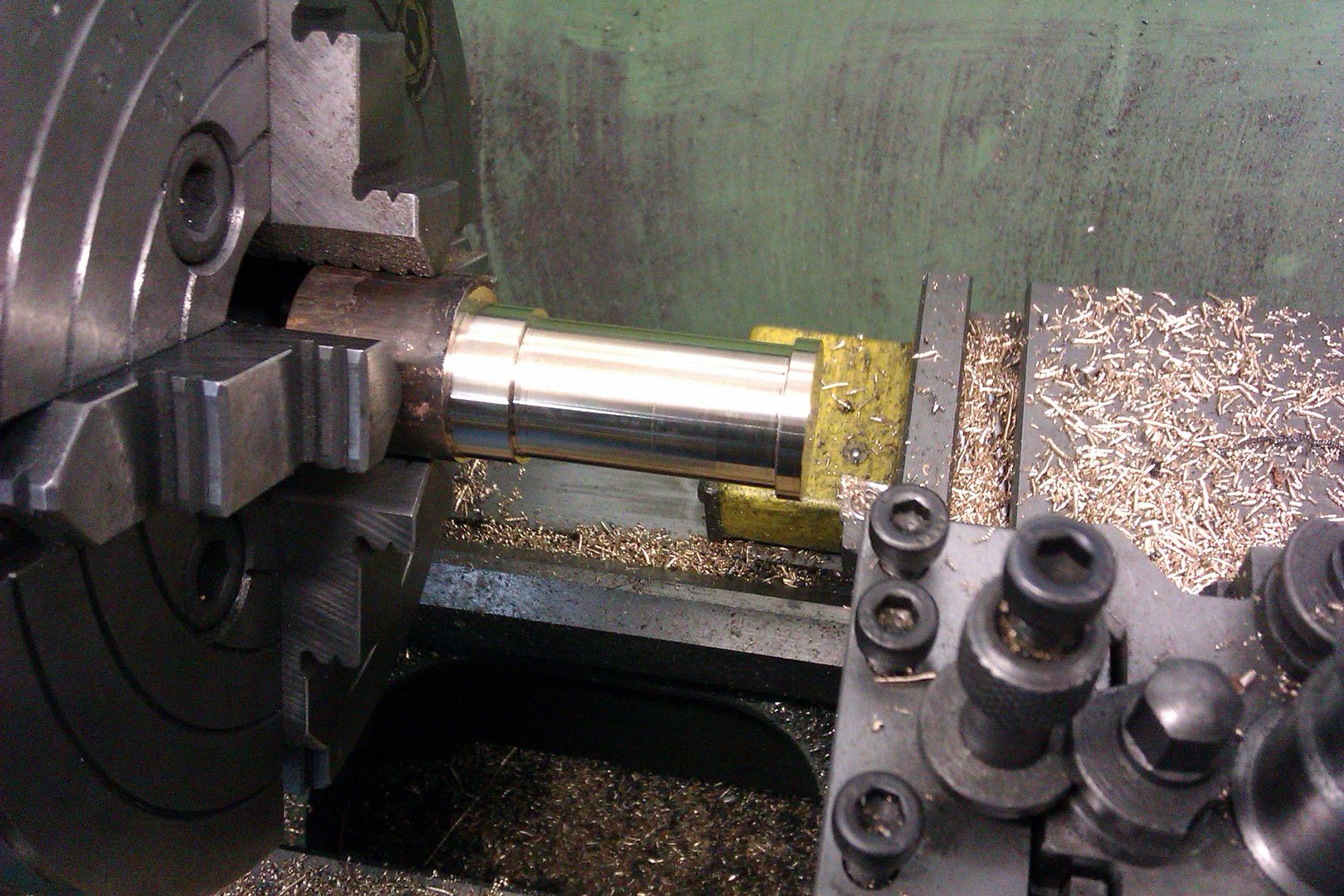

A plan of action was decided upon and the caps held in place with caphead screws for now. The casting was set up on the lathe cross slide and a long series 1/4" drill put through first. before opening upto 9/16 in a few steps.

A 1/2" boring bar was then used to take the bore upto just over 18mm

This allowed me to just sqeeze in a between ctrs bar to take the bores to the final 3/4"

I made use of the side access hole to change the bit to a side cutting one and counter bored the insides to take most of the bearing flanges so I could keep the crank as wide as possible.

The final job was to face back the bearing caps to match the narrow crankcase using a flycutter in the lathe, fit an angled bit and cut a decent chamfer – probably larger than needed looking at it now. I also marked the caps with punch marks

As you can see from above due to playing about with sizes and the position of the caps the fit was not ideal, so a bit of time with files soon had things looking better on the outside too.

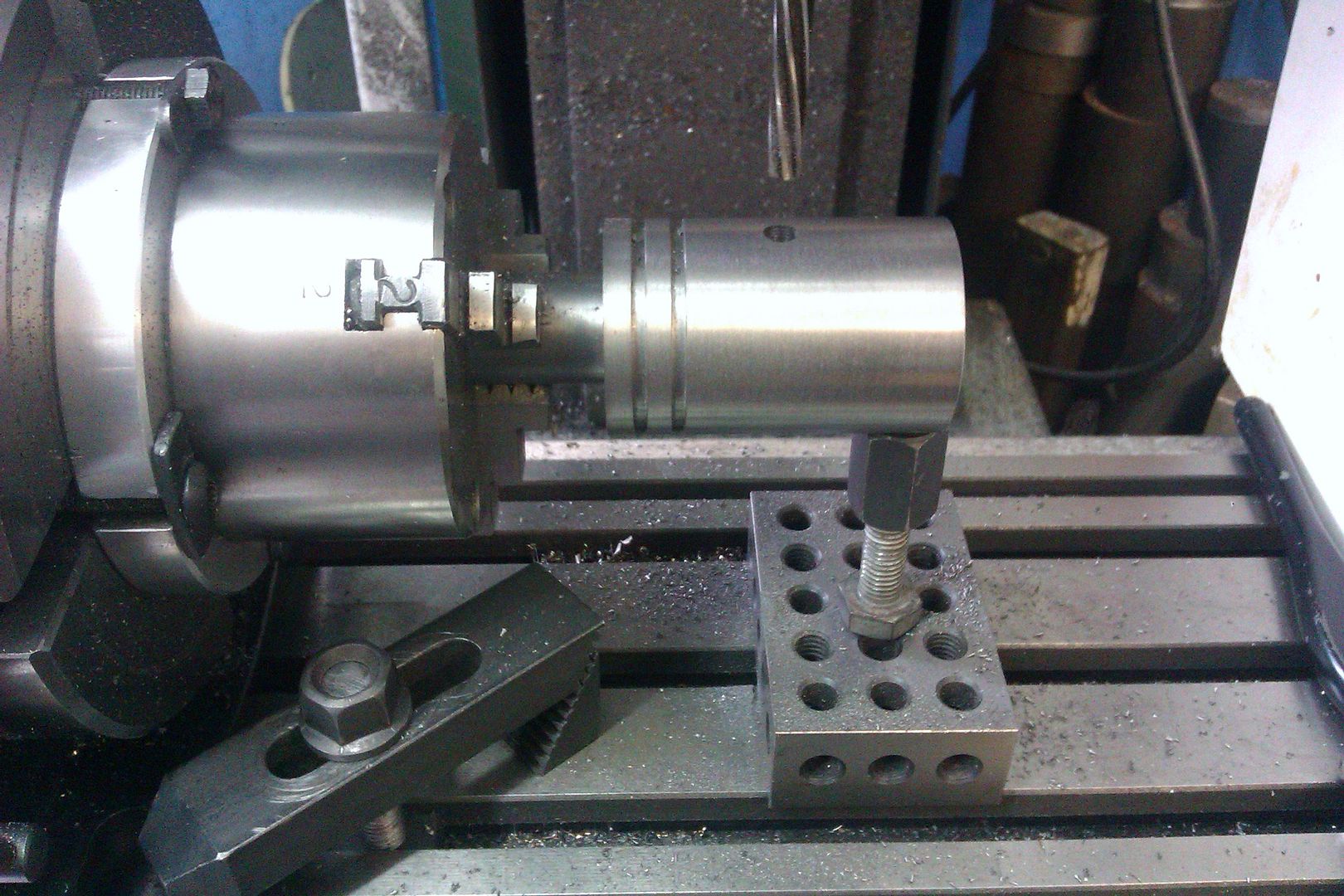

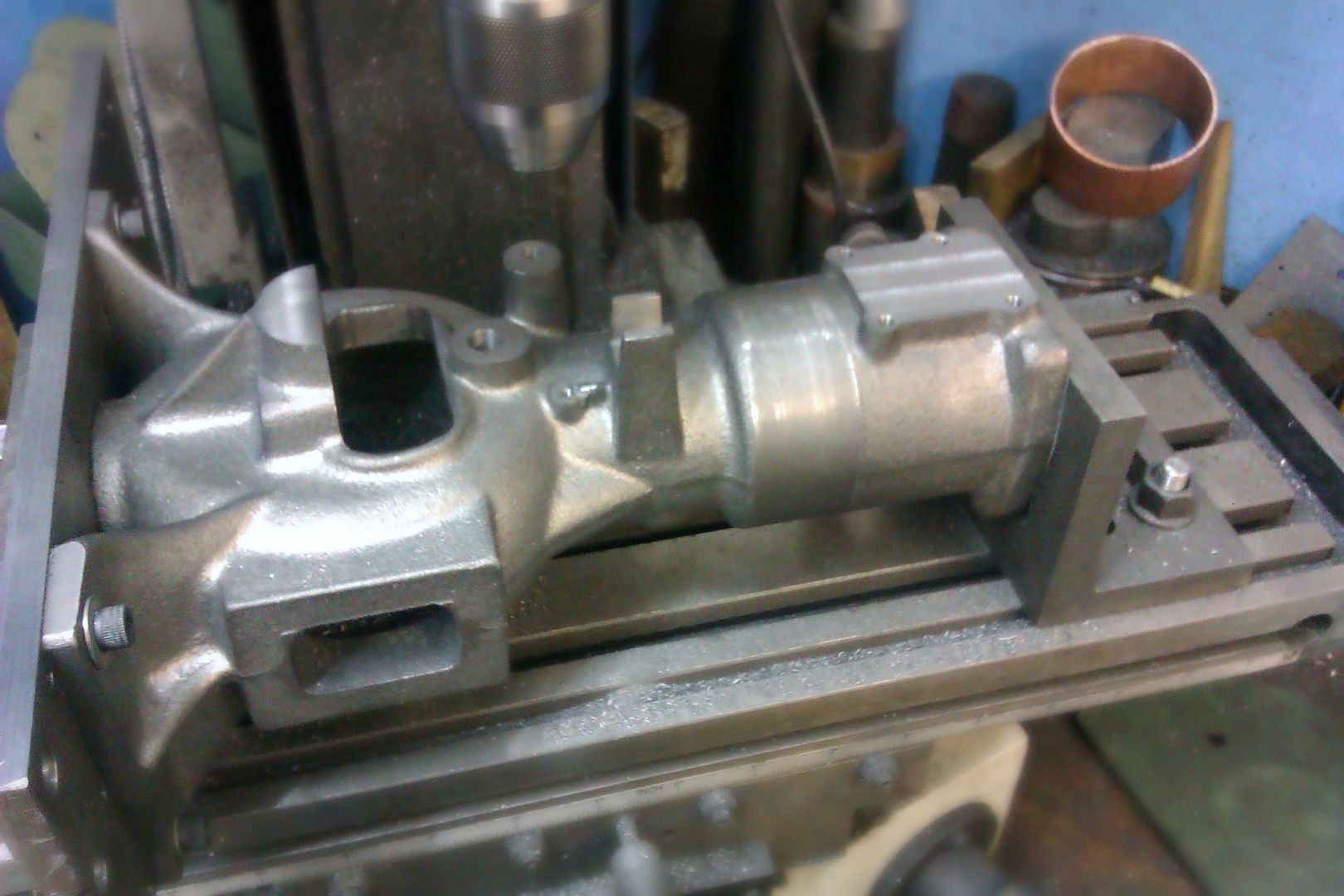

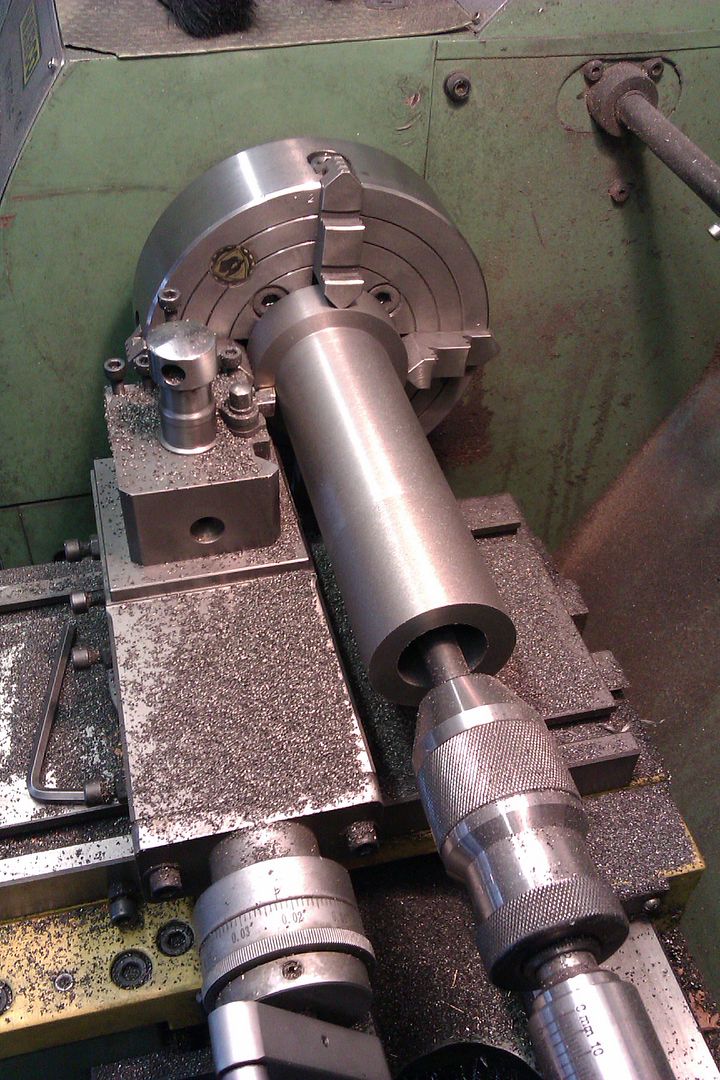

The cylinder liner had been roughed out a bit earlier and allowed to settle. The bar in the end is just incase it came loose as there was a lot sticking out the chuck and the bore was too large for my Ctr.

It was now finish bored and turned, you may be able to see a couple of changes in the pattern on the outside this is because the top nearest the chuck is a couple of thou larger than the bottom and the area between the two smaller still. This allows it to go most of the way into the crankcase before final pressing in with some Loctite for good measure.

J

27 April 2014 at 19:25 #150854 JasonBModerator@jasonb

JasonBModerator@jasonbThe crankshaft started life as a rusty lump that had been flame cut from a piece of 1" hot rolled plate, there was some hard scale on the surface particularly the cut edge and buy the time I had milled the 4 sides down to size I had three blunt corners on my 40mm indexable end mill.

With the 4 sides complete it was milled to length and some basic layout done, I then held it vertiacally on the mill by clamping to an angle plate and located the edges

From these datums the positions of the centre holes were located and drilled.

Using a 1/4" split point stub drill to save having to spot drill first the waste was stitch drilled away spacing the holes at 0.250" so they just joined together.

It just needed a small saw cut where I had kept shy of the vice and the waste dropped out.

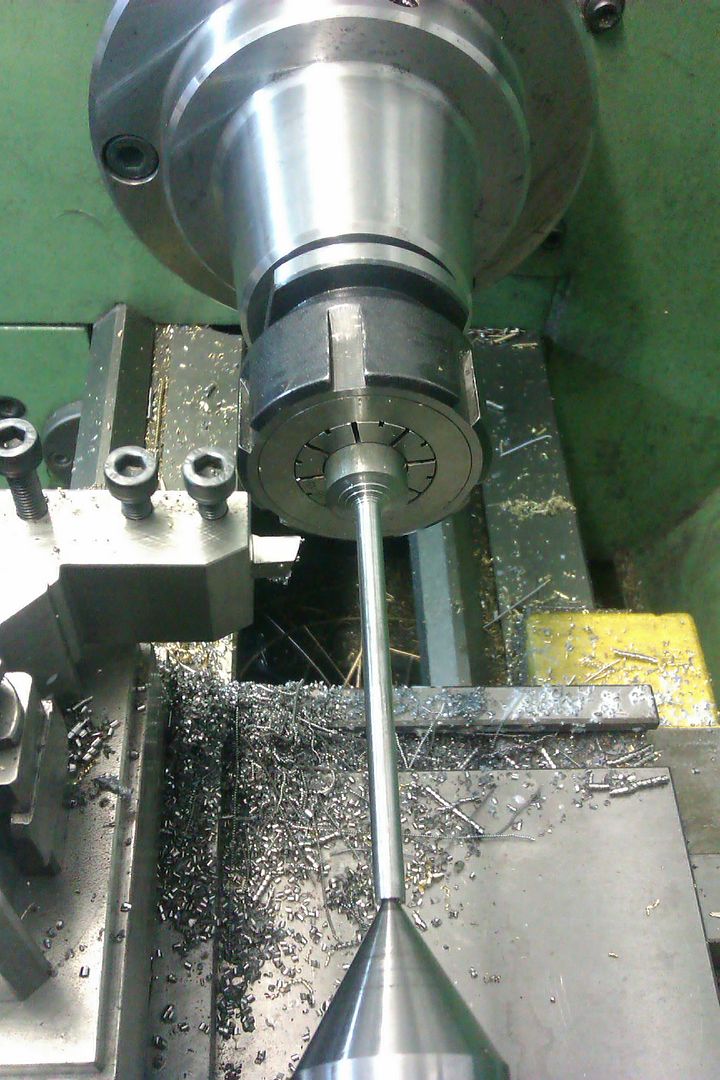

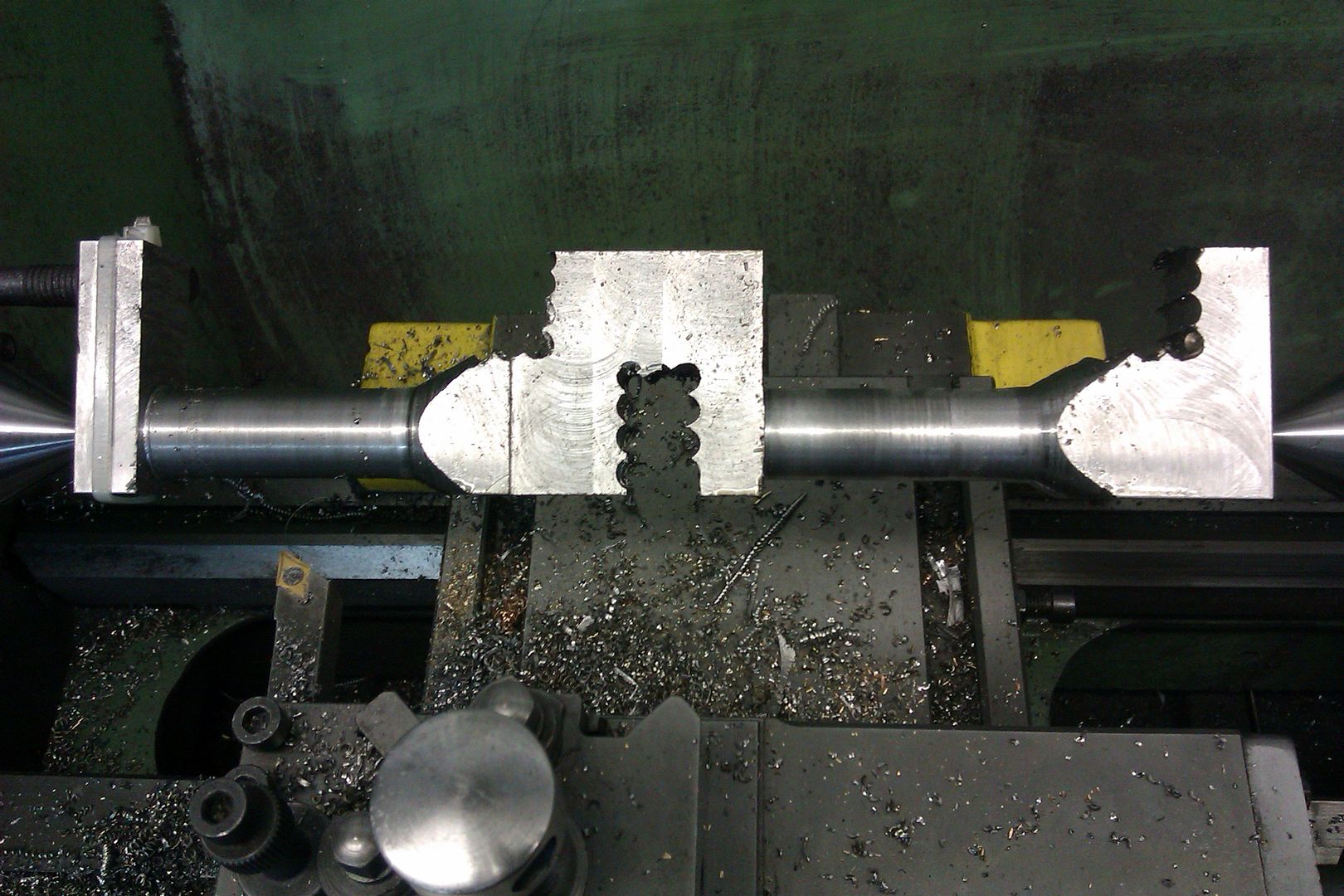

Before starting on the journal I like to rough out the rest of the shaft so it is a bit more balanced when cutting the journal

The tapers are to give the back of the tool clearance, these were then removed by turning the crankshaft end for end

Then using the other pair of ctr holes to turn the journal, inside faces of the webs and the small chamfer to the edge of the web

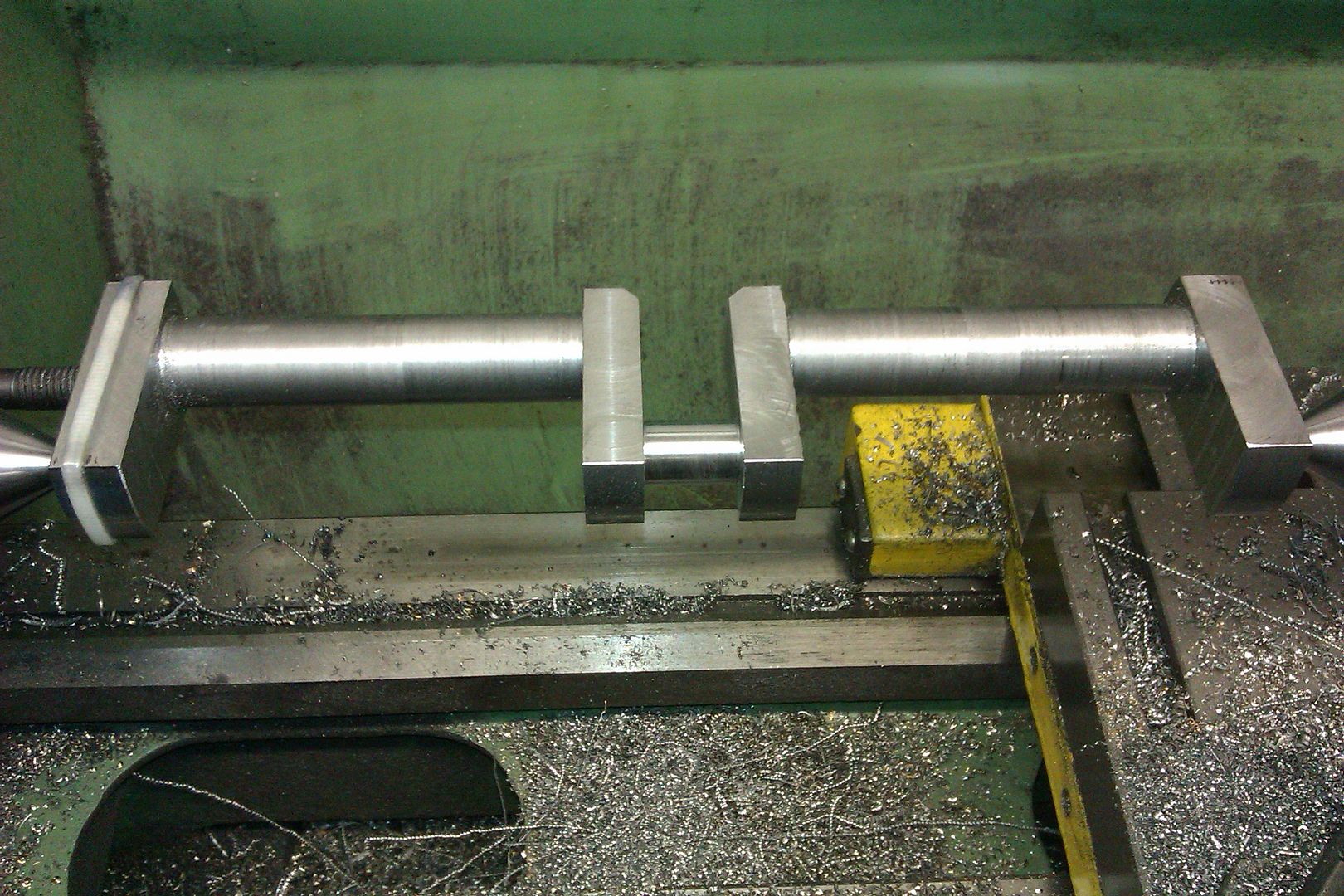

The excess material was sawn off the ends, a close fitting spacer wired and hot glued in between the webs to stop the tailstock pressure distorting things and the main shaft turned to 5/8" finished dia, final job was the other two chamfers on the outside of the webs.

Job done

J

27 April 2014 at 20:14 #150864GarryC

Participant@garrycHi Jason

This is great to see and going to be a great thread – for me, even though I couldn't follow it all there were already lots of interesting bits and pieces to see and think about there..

Looking forward to following..

Cheers.

Allan.

27 May 2014 at 17:29 #153699 JasonBModerator@jasonb

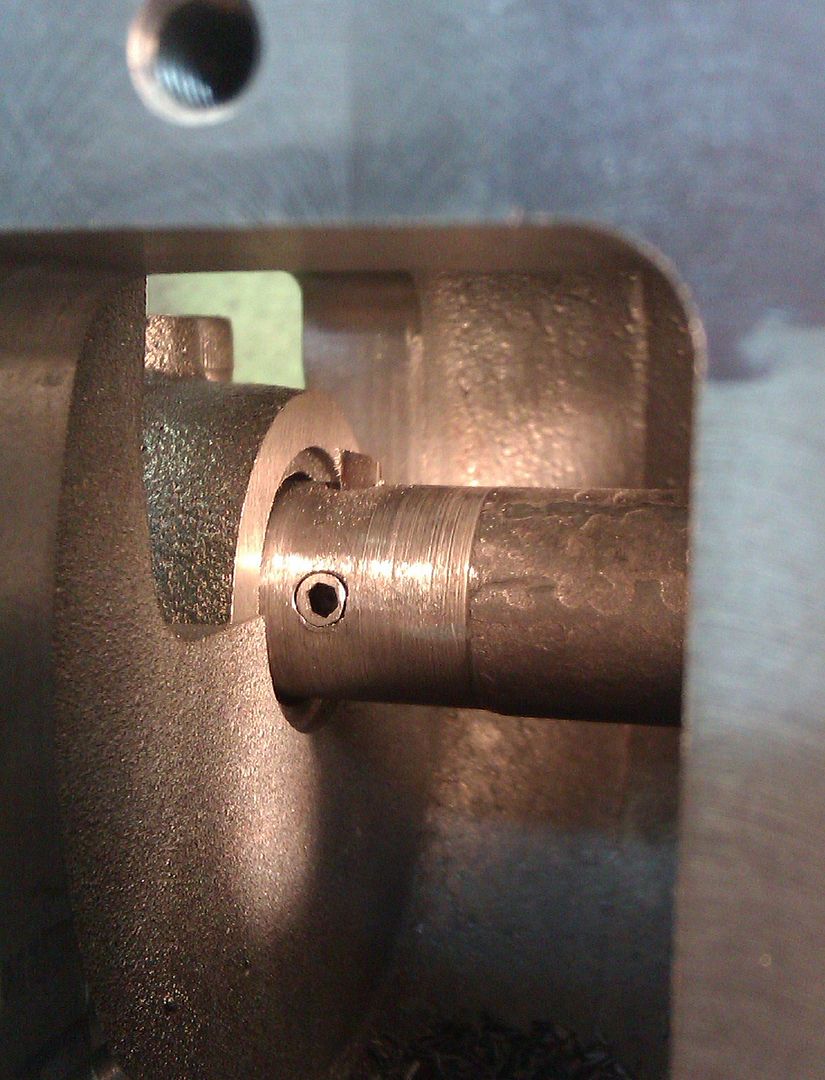

JasonBModerator@jasonbWith the crankshaft completed I could now make the bits that slip onto it to a known size. Starting with the split bearings a piece of 28mm bronze was sawn down the middle, the mating faces machined and then soft soldered together.

This was then held in the 4-jaw to get the joint on centre height and then the outside machined to fit the bearing blocks.

As the bearings only had a 1/32" wall I did not trust the solder to keep things together while they were bored so I made up a sleeve from scrap aluminium to slip over the main section but allow me to hold the whole thing in a 5C collet while it was drilled and then finally bored to fit the crankshaft.

And a couple of shots of them in place, on the second you can see how recessing the housing has allowed me to move the bearings outwards to help compensate for the undersize crankcase casting.

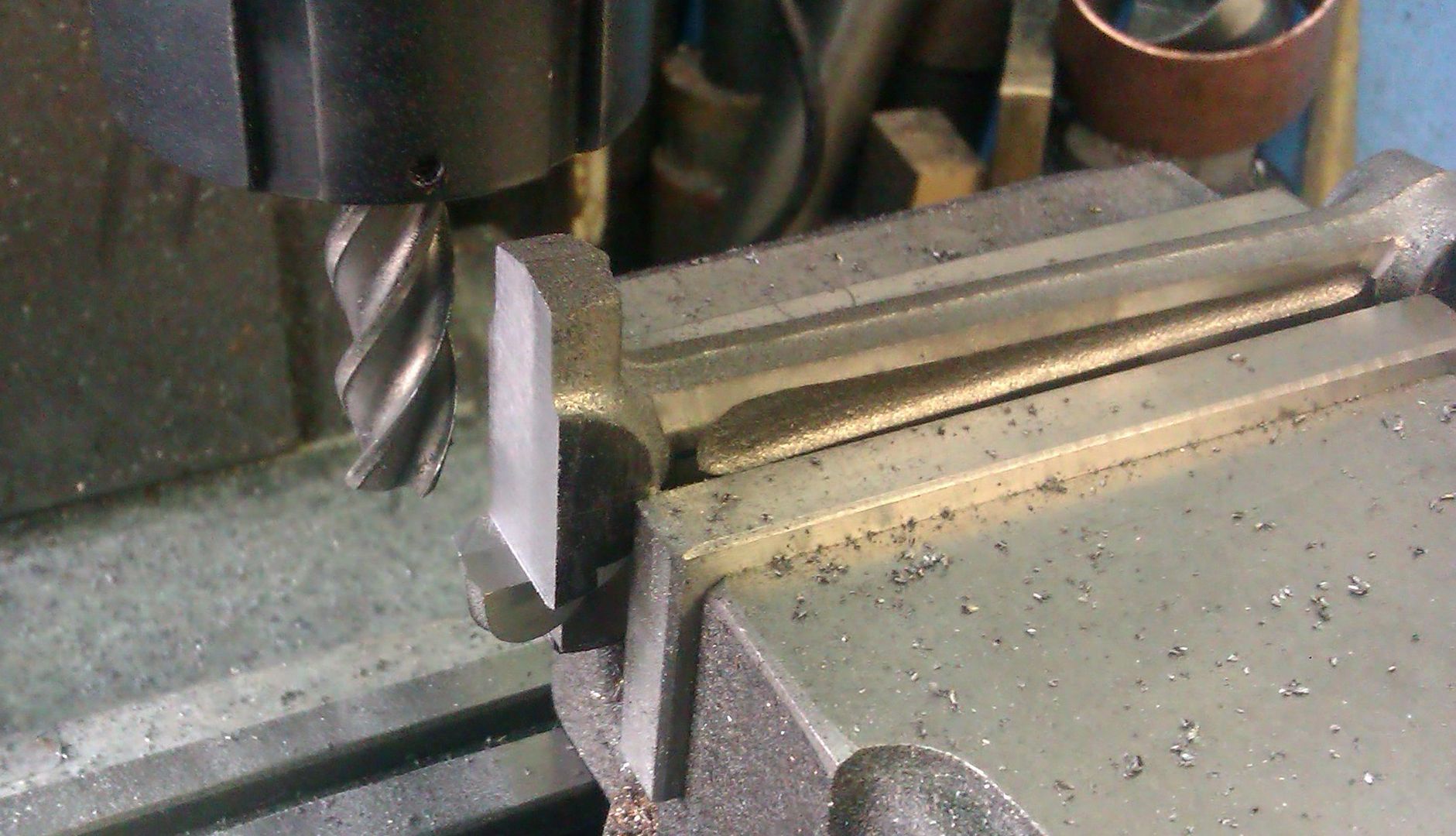

With everything in place I could now confirm the lengths of the keyways which were cut with a 1/8" two flute cutter

J

27 May 2014 at 18:31 #153705 JasonBModerator@jasonb

JasonBModerator@jasonbAs the inlet and exhaust valves are on the side of this engine the actual cylinder head was quite an easy job. The odd legs were used to swing a few arcs to get an average centre position and the casting then held in the 4-jaw to get this running true.

And the spigot turned to a nice fit in the top of the cylinder.

It was then just a case of reversing the part and facing off down size then turning the recess in the top. Final job was to drill the five 2BA clearance holes.

The hopper is quite a lump, weighing it at 2.5kg and measuring 5.5" diameter. To make sure I got the top and bottom holes in line I first machined a disc to fit snugly in the top opening and clocked that in on the mill table.

I could then slip the hopper over this disc and using a small height gauge get the central bead as horizontal as possible with the aid of some feeler gauges as packing. With a clamping bar inside it was then just a case of using the boring head to open out to the required 2.5". I do like these indexable bars from Glanze, they seem to work very well in all metals and will cut down to a 12mm dia hole.

I then skimmed the bottom surface back to the required size.

Before drilling another four 2BA clearance holes for the studs

Next it was over to the lathe so that the recessed hole for for the lid could be done, as its a fair size casting and the cut some 5" from the chuck I added a length of studding through the spindle just to be sure it would stay put.

The hopper lid was not the easiest to hold either so I put a bit of brass bar in teh tailstock chuck just to make sure it would not work its way forwards while the spigot was turned.

It was then easy enough to hold by this spigot while the rim was finished.

J

20 July 2014 at 19:26 #158326 JasonBModerator@jasonb

JasonBModerator@jasonbI think another installment is long overdue

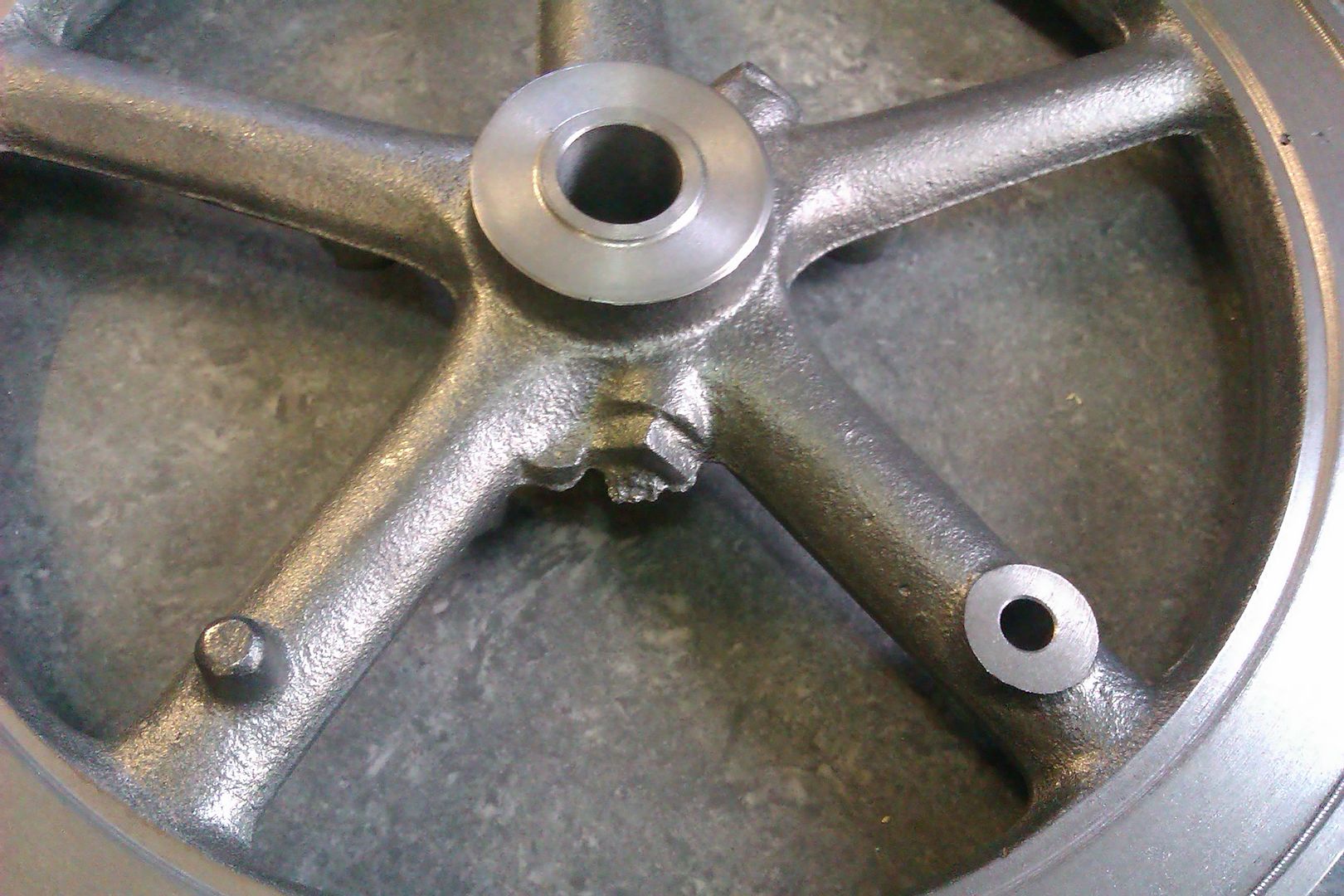

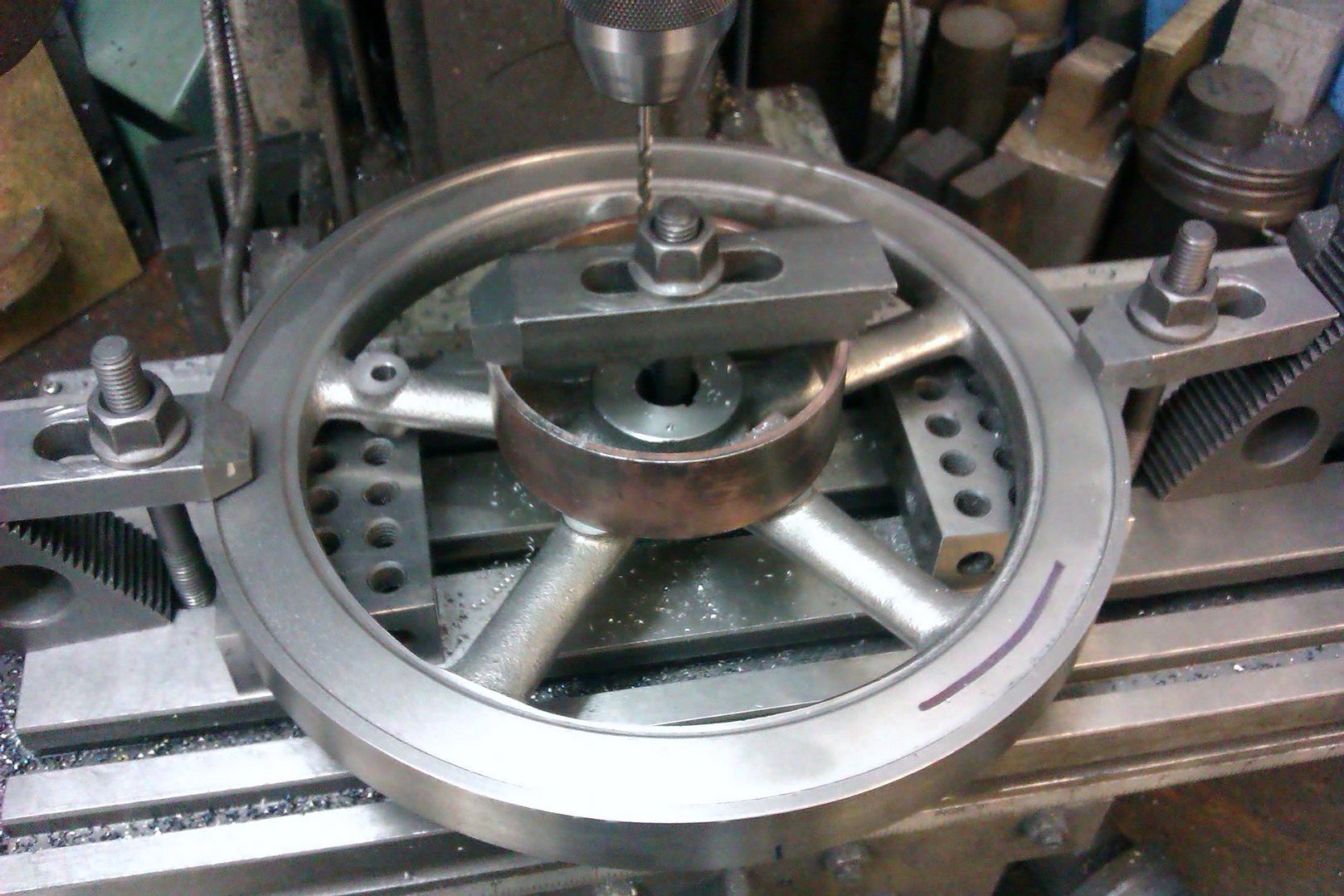

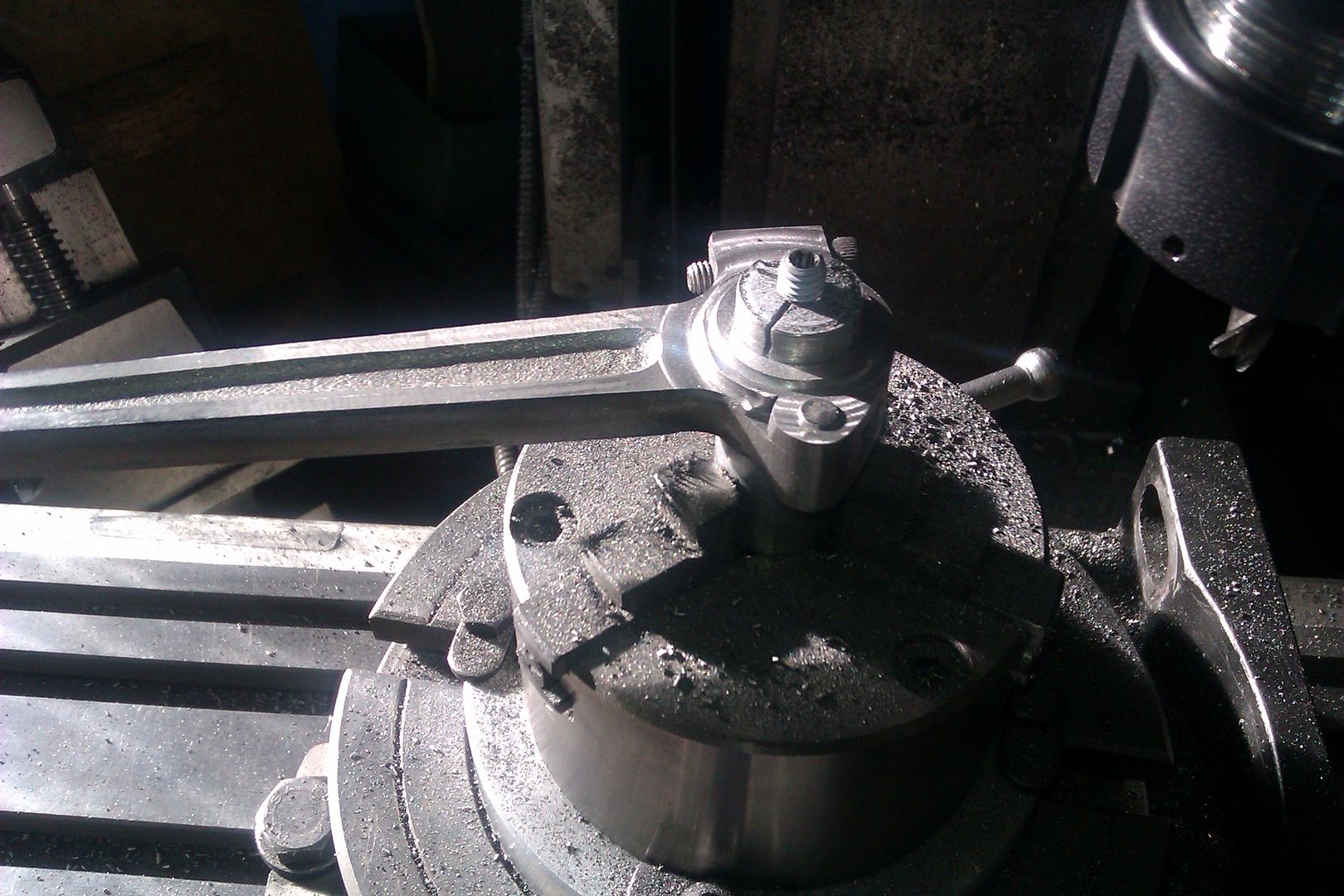

The flywheels on the Baker engines all had five spokes which makes them a bit hard to hold using my preferred method of the 4-jaw chuck bearing on the inside of the rim and the 3-jaw fits no better so I had to go with a faceplate. This is not quite so straight forward as there are a couple of protrusions on the spokes which are part of the governor workings so I had to use a disc of MDF between the faceplate and flywheel with suitable holes to clear these and the hold down bolts.

Here is the first side being done, firstly I lightly faced and centre drilled the waste in the middle where there was extra material. The live centre then gave a bit more support while the rim was machined.

I then bored the hole to a nice fit on the crankshaft and also skimmed down the outside of the waste before turning the flywheel over to do the other side

]

]Due to the hold down bolts I was only able to face back the three bosses that take the drive pully so had to hold the 3-jaw to cut the step that locates the pully rim, I knew that waste material would come in handy

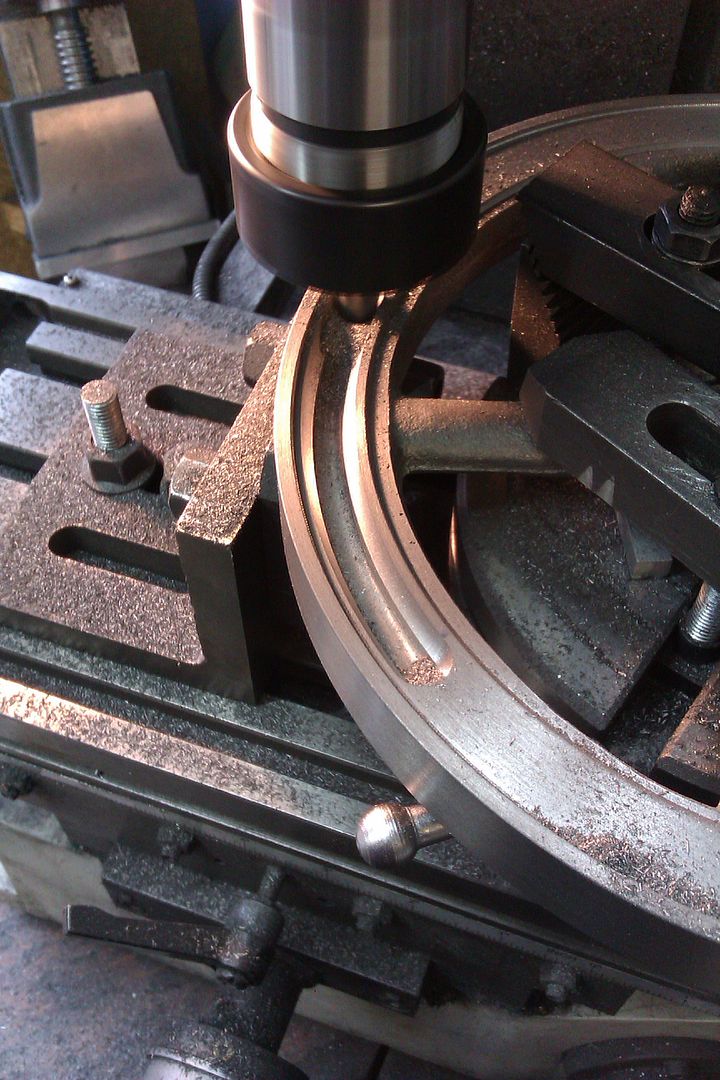

The engine is balanced by grooves cut on the inside of the rim with a 7/16 ball ended cutter, these are quite pricy in metrificated England so I went with an 11mm one at about 1/3rd the price and I doubt the 0.005" difference will matter. It was a bit hairy using my 6" rotary table with the 9.5" flywheels due to the ovehang and backlash but the cuts turned out OK in the end. The rim is just rubbing on that angle plate to stop it deflecting under the pressure of the cutter.

The castings have some rather rough nuts and bold heads cast into them, rather than try to clean these up I cut them off, filed the face flat and ground a shallow hole. Then I made up some dummy ones from steel with a short spigot on the undersides so they could be bonded into the hole with JB weld, looks like I also made the needle valve that day.

Unlike the Monitor kit that Maury sells this one did not come with a pully so I fabricated it. Starting with some ERW tube and a few off cuts of 1/8" steel suitably shaped (freehand on the belt sander) to the inside curve these were silver soldered together.

The holes were then drilled at the same setting as the ones in the flywheel so they would all line up OK

I then set the flywheel on an expanding mandrel and used that to hold the pully while it was trued up and the outer face crowned

The rotary table was centred on the mill spindle and then each mounting lug in turn centred to the mill and rounded over.

And the finished pully, I've left the inside a bit rough as its supposed to be a cast surface.

That will do for now, I'll try not to leave it so long until the next installment, J.

Edited By JasonB on 20/07/2014 19:27:19

17 August 2014 at 18:28 #160995 JasonBModerator@jasonb

JasonBModerator@jasonbWith that bits that go onto the ends of the crankshaft done I though the next logical parts should be what goes in the middle.

The conrod is supplied as an iron casting with another casting for the bearing cap, one unusual feature is that the cap is pivoted much like a hinge on one side with a single bolt to the other as there is only access into the crankcase from one side.

Making use of a step in the casting halves and the machining allowance at the other end the main rod was taken to width and a light skim taken along its length so I could hold it by the "I" section if needed.

Luckily the ends just fitted in the vice so held by them the central part of the hinge was milled to width, then the part reversed to take the face back to the joint line.

The bearing cap was machined in much the same way adjusting the hinge gap until it fitted snugly onto the conrod.

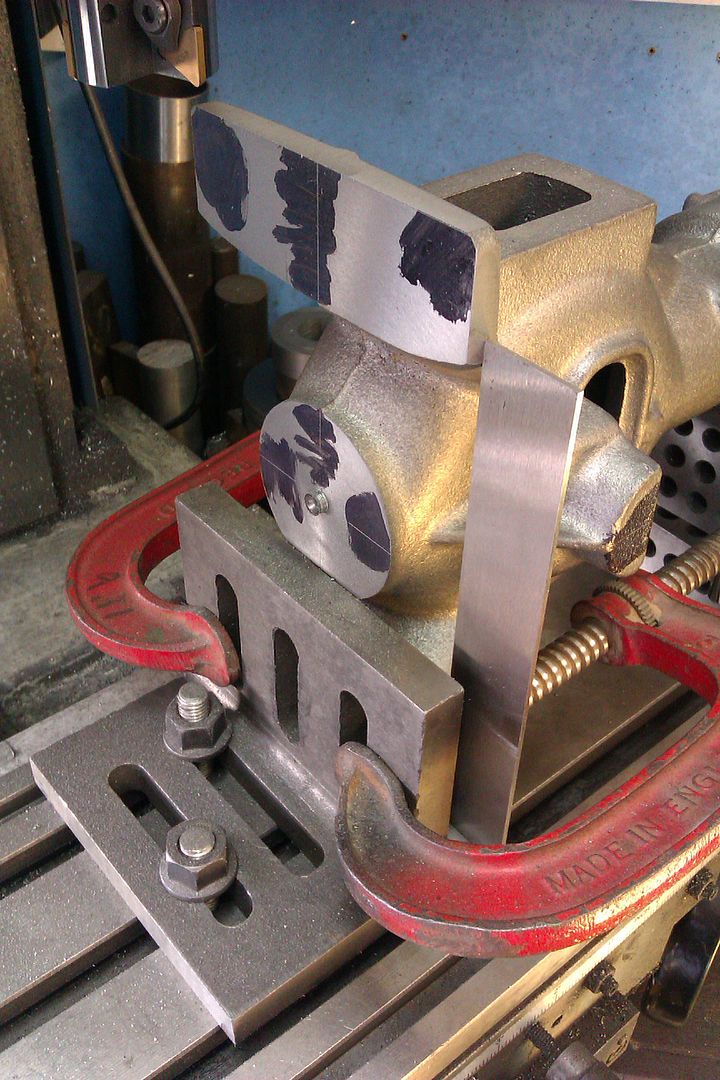

Then using a G clamp to hole the two halves together, the vice to stop it all moving about and some 1-2-3 blocks for support the hinge pivot hole was drilled and reamed.

With a length of silver steel (drill rod) as a temporary hinge pin the hole for the bolt was then drilled with the job held to an angleplate with assorted clamps.

Now I could make use of the skimmed side of the "I" beam to support the rod while the little end was drilled and reamed and at the same setting a boring head was used to open up the big end to 3/4"ready to take a bearing.

Finally a bit of hand filing to clean things up and a quick whizz around in the rotary table to make the big end look a bit more presentable.

The big end bearing was made in much the same way as the others, tin two bits of bronze, sweat together and then machine.

The small end bearing is just a simple turning gob and then pressed into the casting and thats another part ticked off the list

J

17 August 2014 at 21:45 #161020Martin Cottrell

Participant@martincottrell21329Hi Jason, nice to see more progress on this engine! Is it just me or have your photo postings gone horrendously out of sync?!

Regards, Martin.

17 August 2014 at 21:51 #161021 JasonBModerator@jasonb

JasonBModerator@jasonbThe ones on the "What have you done today" are upto date but there are just a few odd ones, these cover the whole build in a lot more detail and are not so upto date.

J

21 September 2014 at 14:17 #164191 JasonBModerator@jasonb

JasonBModerator@jasonbThe next logical part was the piston, this is supplied as an iron casting and the first job was to get it running as true as possible in the 4-jaw and clean up the holding spigot.

Then holding it by the spigot in a 5C collet I could machine the end, OD, skirt and put in the two groves for the piston rings.

It was then transfered to the mill and held by the spigot in a 3-jaw mounted to the rotary table to clean up the rectangular hole for the little end and also drill and tap for the screws which retain the wrist pin.

Without rotating the table it was reset in vertical mode and the hole for the 3/8" wrist pin drilled and reamed, I added a simple jack to reduce any risk of the piston sagging under pressure from the drill.

The spigot was then sawn off and the piston returned to the lathe with protection between the jaws and taken back to finished length.

The rings were just turned from CI bar, parted off and then treated as I have covered before

While the cast iron dust was spread around the workshop I decided to do the fuel tank, first job was to clean up the two mounting lugs, as you can see by the shiny edges they were a bit chilled.

Luckily the middle was soft enough to allow them to be drilled and tapped, the fuel pipe connection was also done at the same setting.

The same could not be said for the filler hole, this was chilled all over and although the indexable milling cutter cleaned up the face to show the extent of the chilling there was no way it could be tapped like that.

The solution was heat, I used the propane torch to get the filler boss upto red heat and kept it there for about 15mins then let it cool very slowly.

That did the trick and a brass cap finished off the tank

J

18 October 2014 at 20:21 #166908 JasonBModerator@jasonb

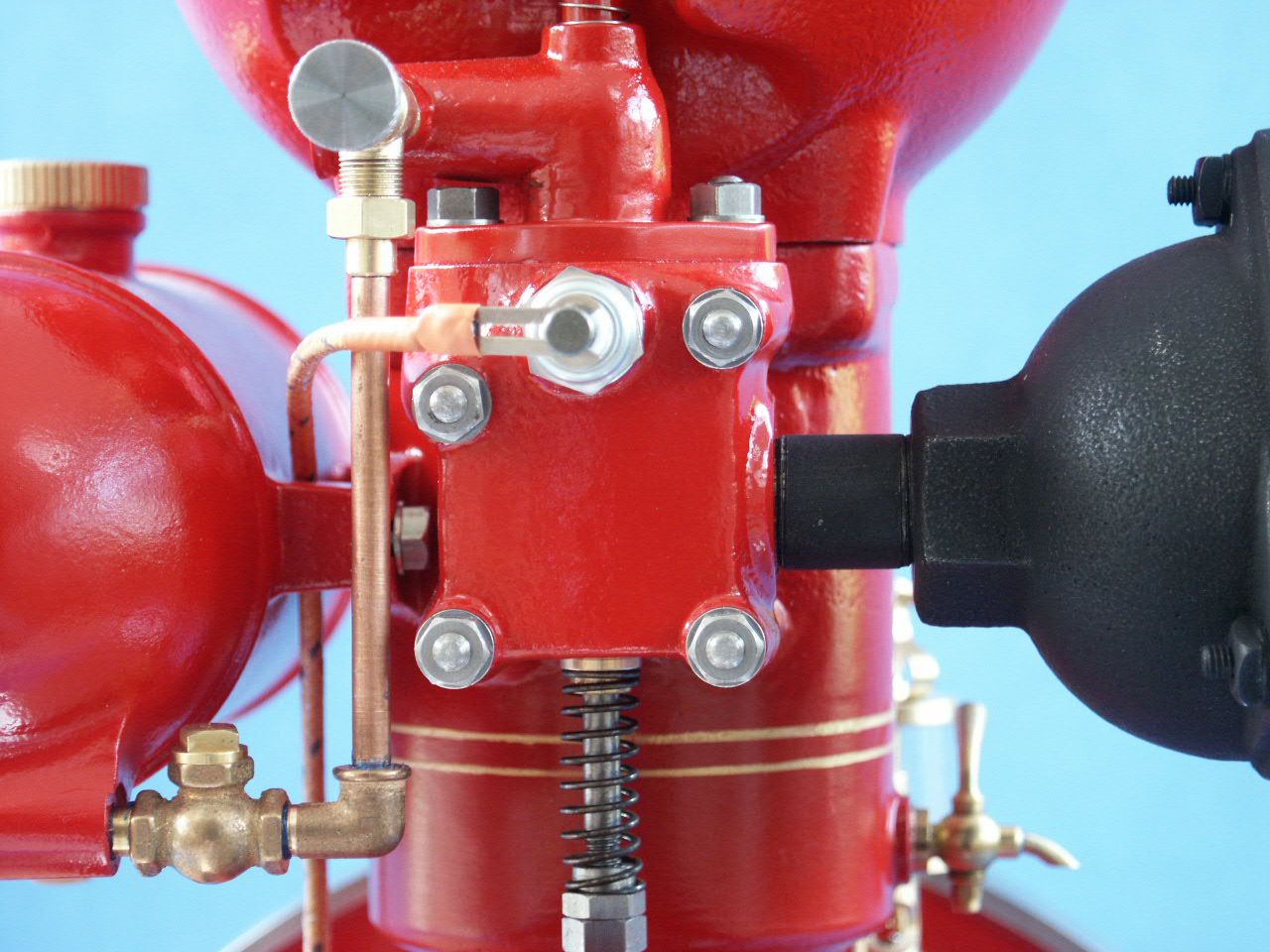

JasonBModerator@jasonbDue to the cooling hopper being on the top end of the cylinder there is not the normal cylinder head arrangement on this engine, instead the valves, plug and carb fit into a block on the side of the cylinder and there is a slot from that into the combustion chamber.

First job was to shim up the casting and get the surface that mates to the cylinder nice and flat, due to the previous chilled spots I used a carbide tipped "littel hogger" to do this

This flat surface was then placed against the vices fixed jaw and the top machined flat.

Followed by drilling and tapping the carb mounting holes and the larger hole which will create a space below the inlet valve where the fuel/air mixture is ignited (plug goes into the dark central boss on the front) The bottom of this hole has the seat for the exhaust valve and a hole right through for its stem.

The casting was then turned 90degrees keeping the same face against the vice and the hole for the exhaust pipe drilled & tapped 3/8" BSP. using a pointed rod in the drill chuck to guide the tap, I find tapping like this better than a separate tapping guide/tool as you can always ensure the work is directly below the axis.

The last thing to do on this was to spot face the four mounting holes and spark plug hole, drill 3/16" for the 2BA studs and tap M10x1mm for the CM-6 plug.

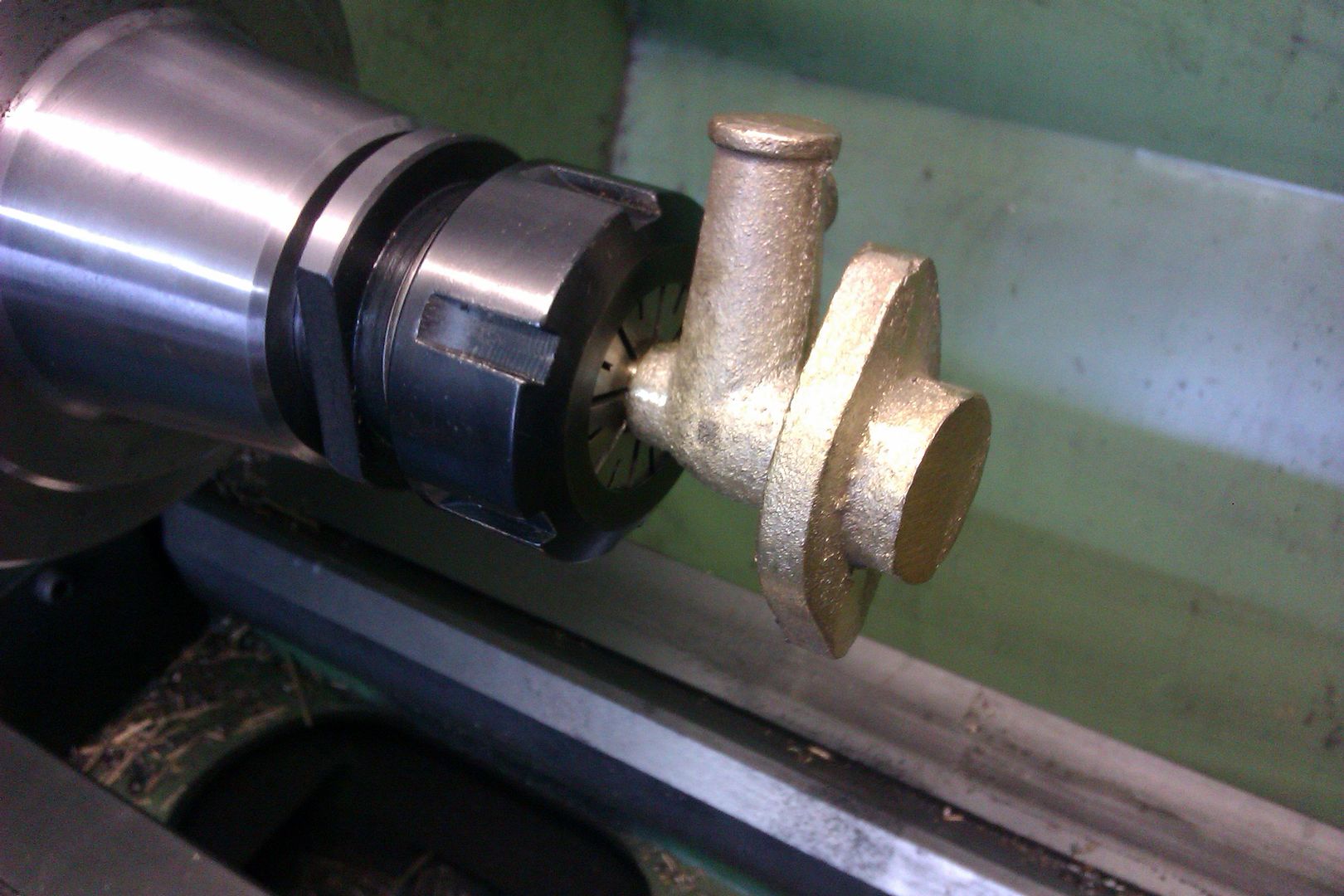

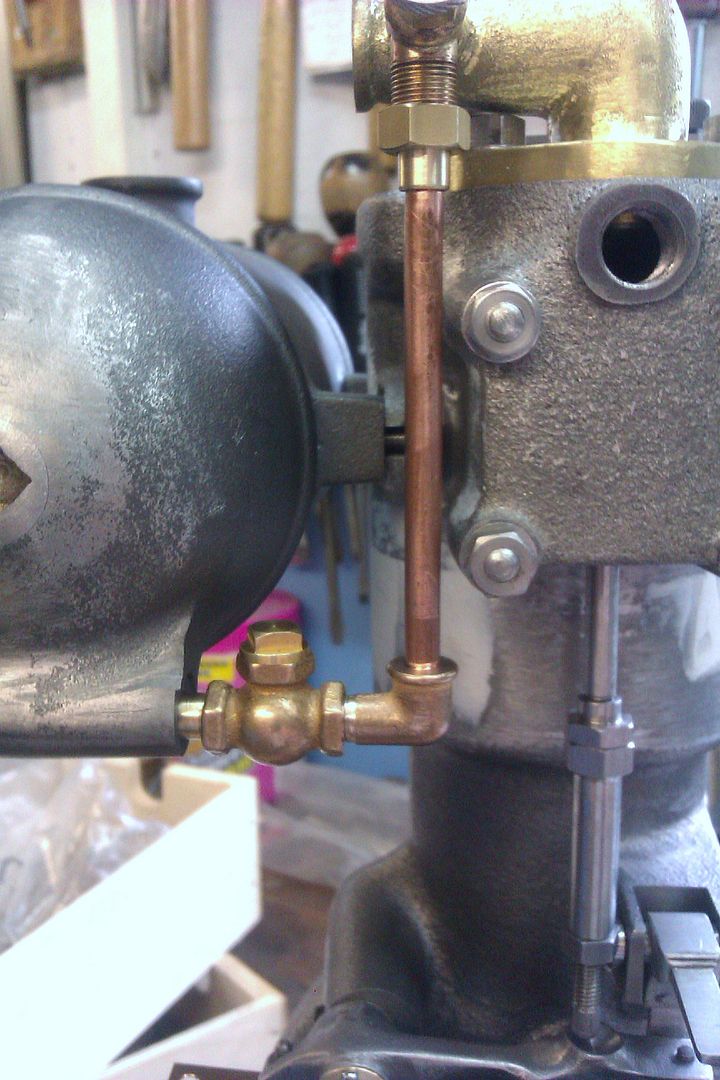

The "carb" also houses the inlet valve, A chucking spigot is provided and was lightly cleaned up with a file so it could be held in a collet, the end lightly faced and centre drilled so that the tailstock could give support while the boss and flange were turned.

I also cleaned up the top face of the flange at the same time which needed to be done with a parting tool to clear the elbow.

I then held it by the spigot to machine the outside of the valve guide

Flipping it back around again and held more firmly on the now turned guide the spigot and flange were given a final skim before drilling and reaming the hole for the valve stem, counter boring and machining the valve seating.

Then over to the mill in a collet block to firstly drill the mounting holes

bore the intake at right angles to this

And then drill and tap for the needle valve body at right angles to the other two holes

Finished part, save for a bit of cleaning up.

J

18 October 2014 at 20:56 #166913Jeff Dayman

Participant@jeffdayman43397Nice job as usual Jason, well done. JD

2 November 2014 at 17:49 #168431 JasonBModerator@jasonb

JasonBModerator@jasonbThanks Jeff.

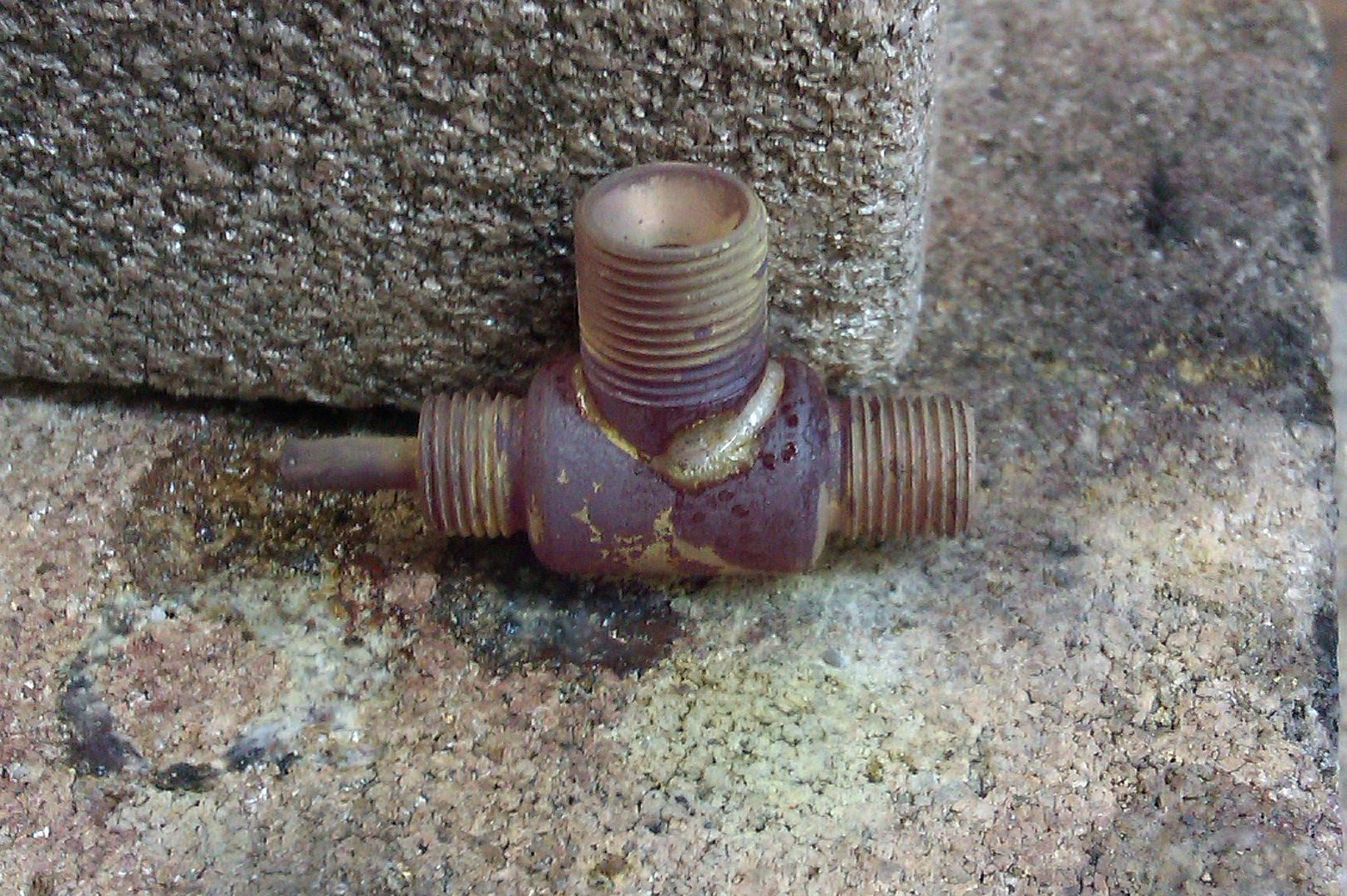

The needle valve body screws into the side of the carb, this is just a brass turning with a threaded spigot at right angles. After turning a pocket is machined into the body with a 2-fluted cutter

The two are then silver soldered together

Nothing too special about the needle valve though I did put a slightly more tapered point onto it. (The square nuts are for the flywheels which have already been covered)

I deviated slightly from the plumbing shown on the drawing as it was a bit tight to get things in and not as the full size seem to have things. The non return valve is from P M Research as is the street elbow.

There is a venturi that is inserted into the carb intake but I did not take a photo of that. What I like about this carb position is that you can see a burst of fuel being sucked in on each "hit" stroke but thats getting a bit ahead of outselves

The valves were cut from 16mm stainless bar for a 5/8" finished dia, I made the stems a bit over length so a centre hole could be used for support while turning the shaft.

The back of the head was then machined to profile and unusually for a valve the end of the stem was threaded.

While the valve was still on the parent bar I used that as a handle to grind the valves into their seats with some 1000g SiC powder and a drop of oil, you can see the matt area where the valve head has been ground.

Once sawn off the bar the heads were cleaned up and given a slightly convex surface

And the finished pair, the exhaust is slightly larger than the inlet.

J

16 November 2014 at 20:20 #169801 JasonBModerator@jasonb

JasonBModerator@jasonbThe governor latch started life as a short slice off some 2.5" angle iron as I wanted to take advantage of the radiused internal corner.

This was cut down and then held in the 4-jaw to bore the pivot hole and turn the raised boss before reversing to do the other side.

Then over to the mill so that the arms could be bought down to profile

The "hooked" end was then case hardened and the spring loop silver soldered on, the latch plate was cut from ground flat stock and the notch cut with a flycutter

The latch is activated by a weight that pivots from a boss on one of the flywheel spokes, first job was to clean up the outer faces and drill & ream a hole for the pivot pin

Then mill a slot so it would fit around the spoke boss.

And finally drill & tap for the spring tension adjuster.

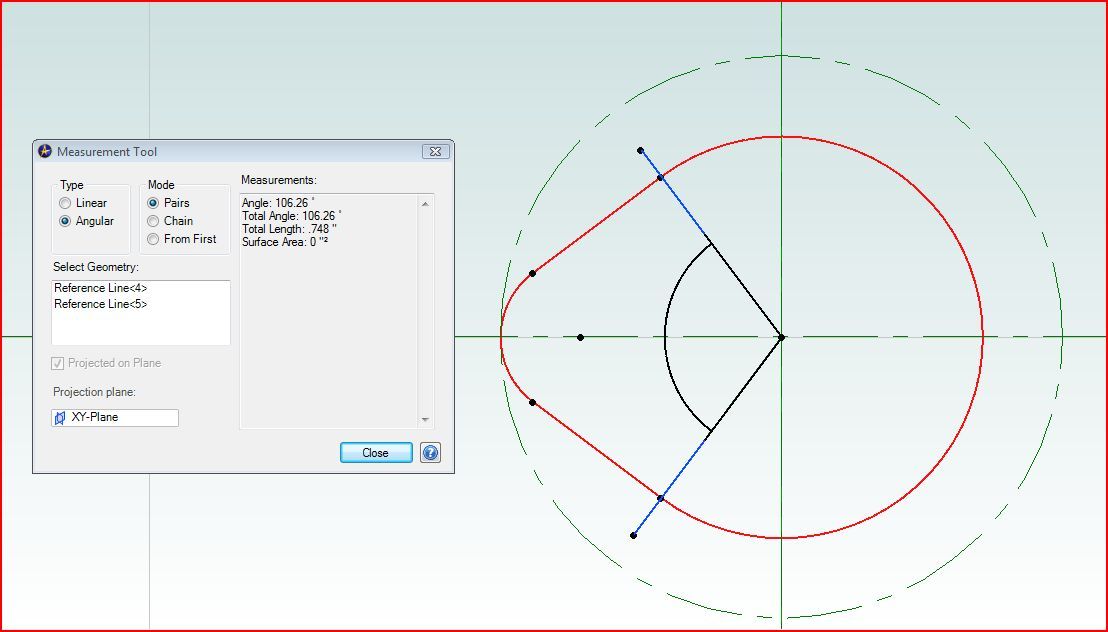

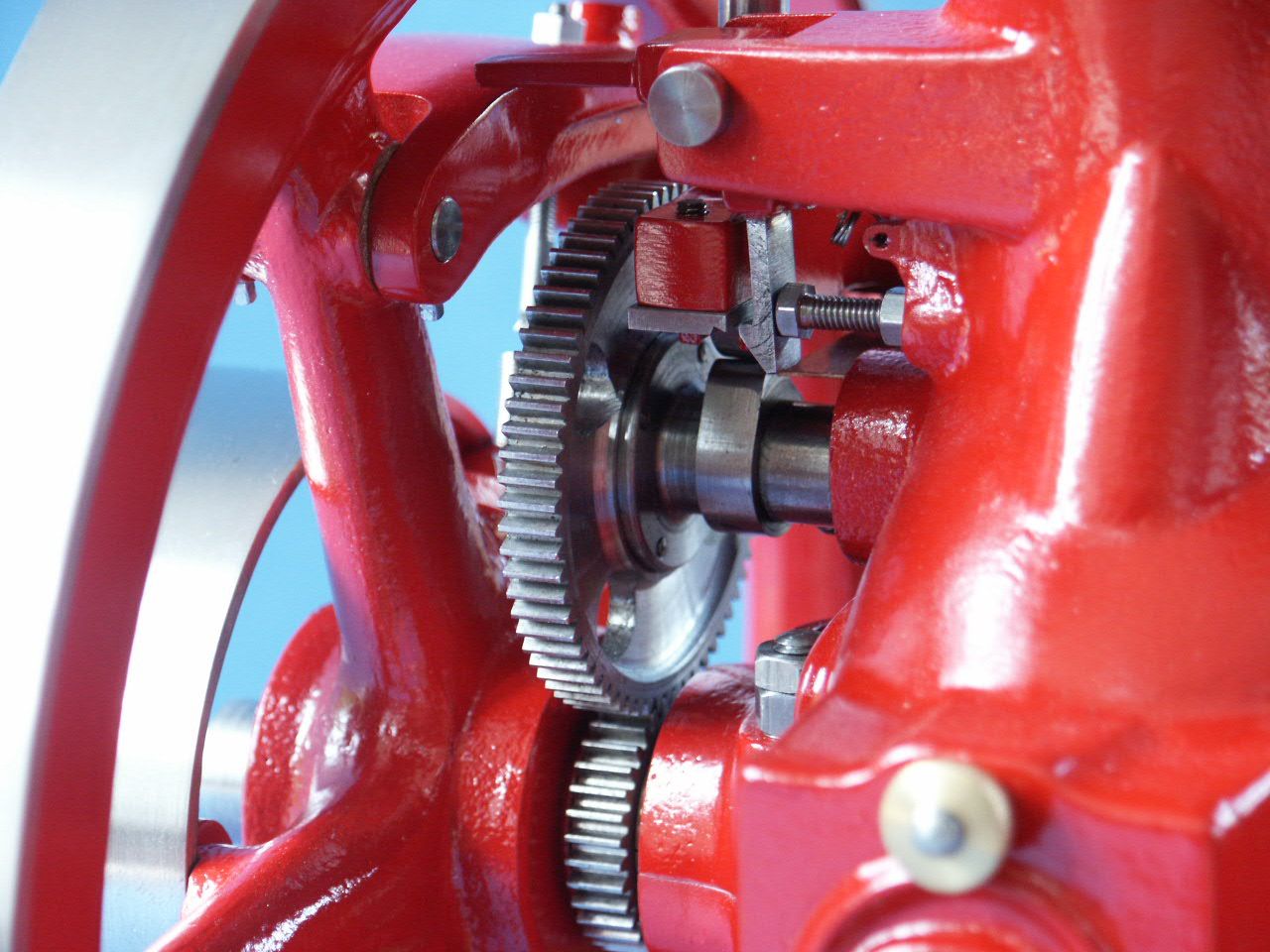

The exhaust cam is machined as part of the timing gear boss. The drawings give base & nose radius and total height so I drew it out in Alibre to work out the angles.

The boss was turned and the cam cut on the rotary able

Here is the finished cam together with the shaft it turns on and the two bronze bearings that are pressed in. The timing gears are supplied in the casting kit and just need a recess machined and some tapped holes.

Looking at photos of full size engines they all seem to have four holes in the timing gear so I added these as well as thinning down the main disc

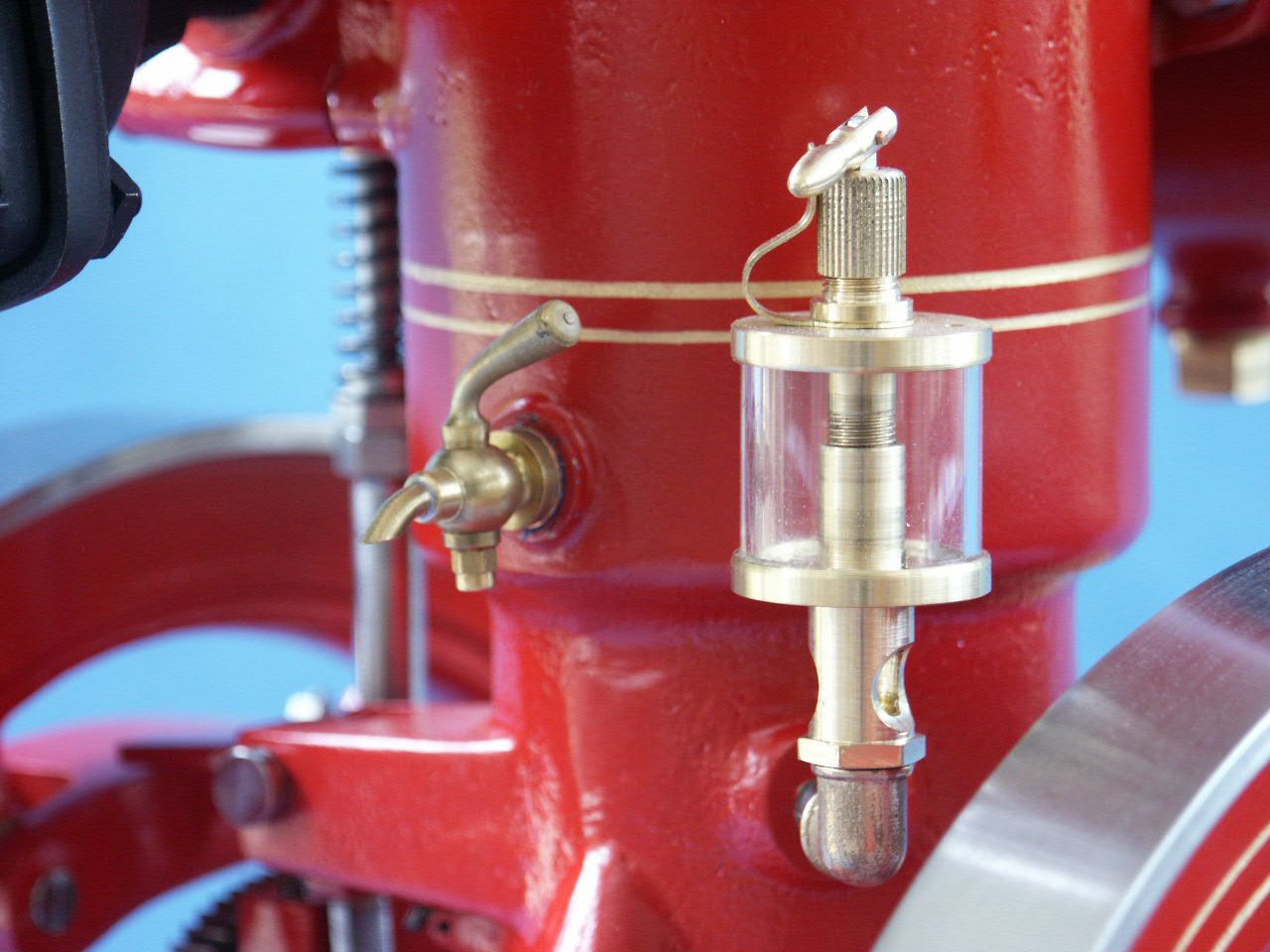

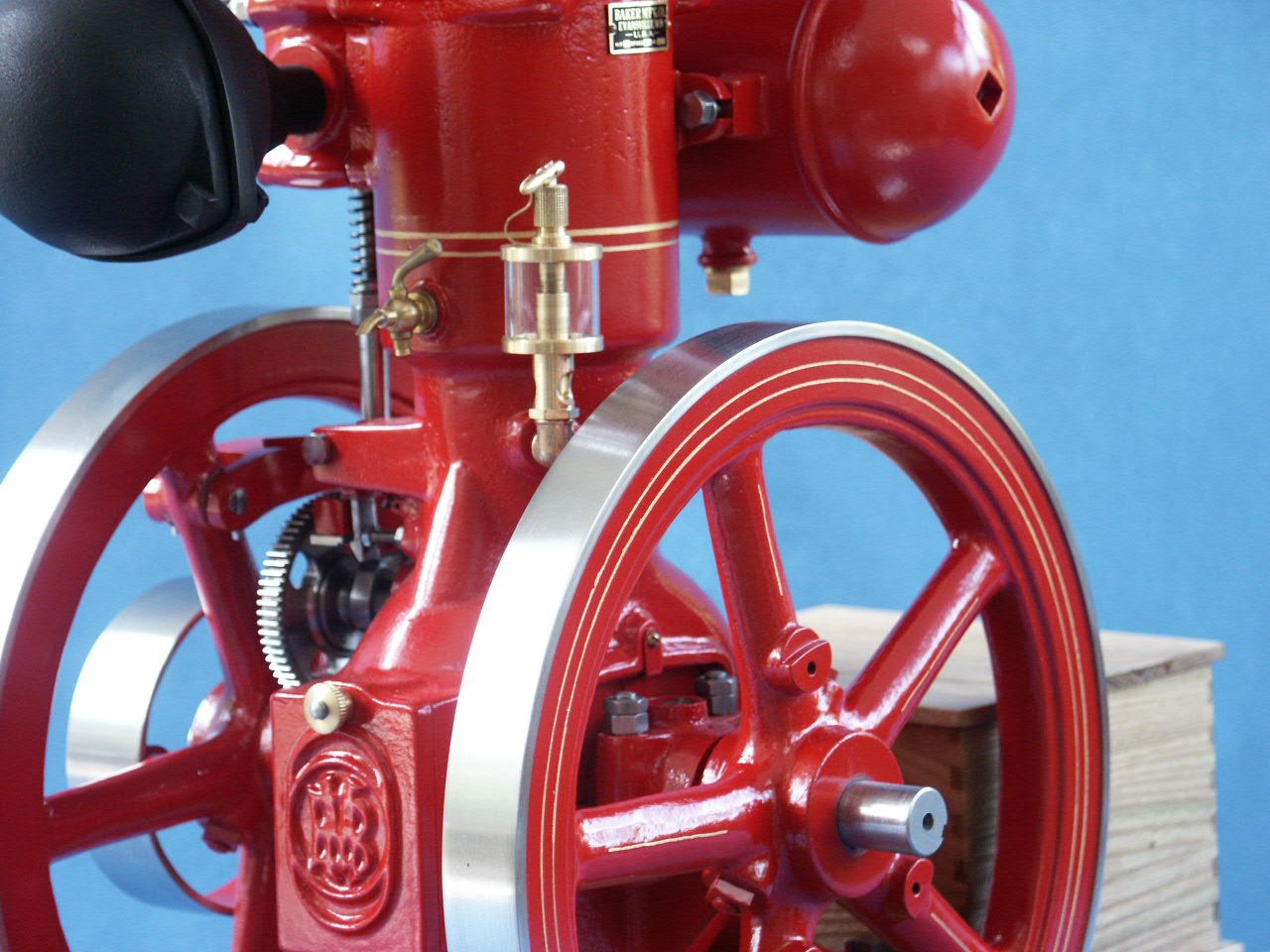

I also knocked up an oiler to keep the piston moving

Finally a few pics of most of the bits put together

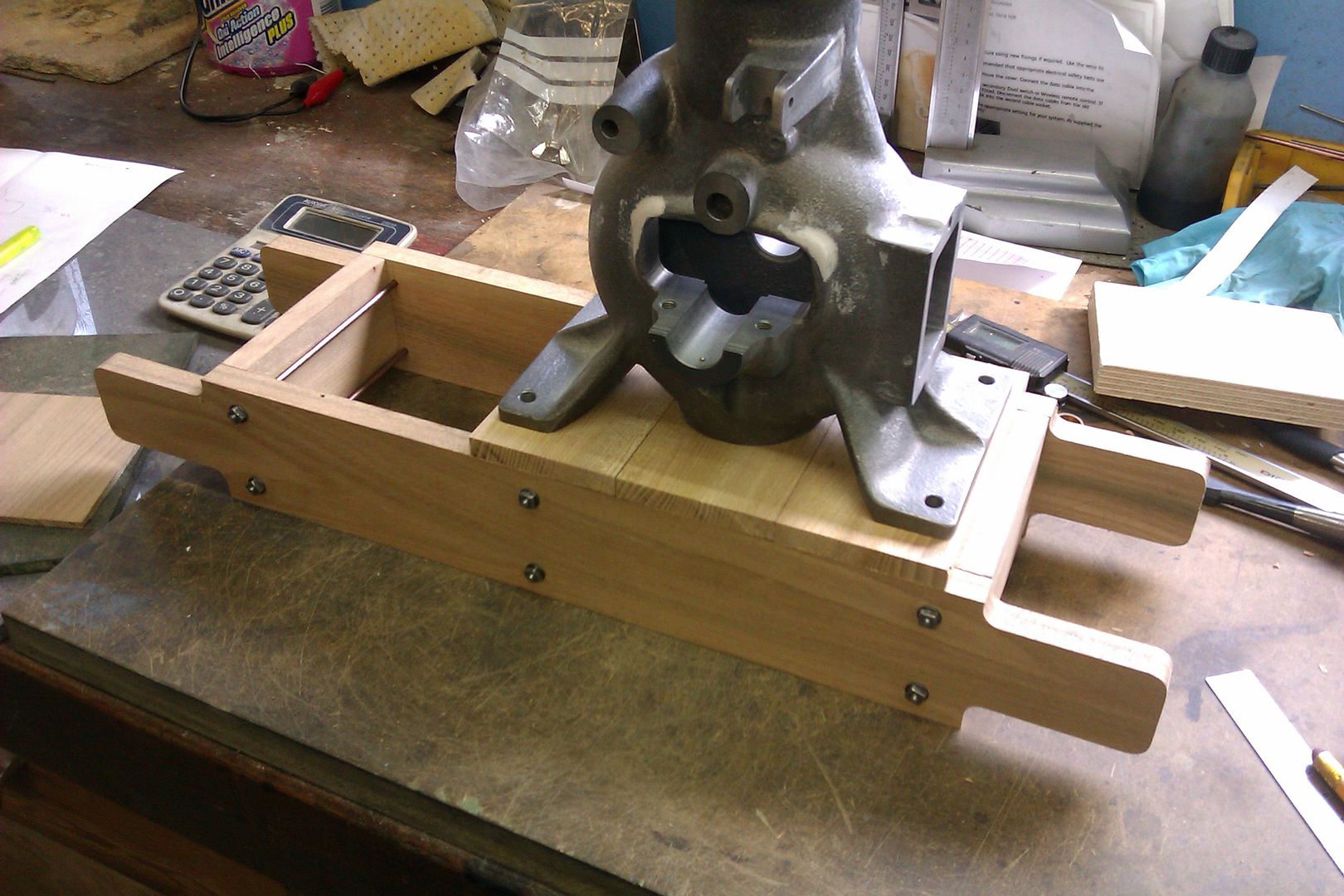

The base was made from some recycled chestnut which has quite a nice grain & colour. This is slightly different from the drawings and more closely resembles some old illustrations I found in some old catalogues (thanks Pat)

J

7 December 2014 at 17:31 #171844 JasonBModerator@jasonb

JasonBModerator@jasonbSo with all the machining done its time to start the finishing touches. First up is to go through all the parts and clean off any remaining casting flaws which are mostly where the two parts of the casting boxes may have been a little out of line and also I like to run over the cast surfaces with a grinding stone in the Dremel to knock off any small lumps. This was followed by a wipe down with thinners and then body filler applied where needed. The main areas where to blend in where I had to turn a surface around the cylinder for the steady to run on and also reprofile the corners of the crankcase side holes. Then a good rubdown, I'm not aiming for a dead smooth finish as I want the parts to still look like they are castings

Following another wipe over with thinners I sprayed on some high build primer (etch on the bronze castings) which tends to show any blemishes that can be attended to. Being a light colour it showed up quite a few pin holes that were not obvious to the eye, compare this shot of the bearing caps to the painted one and the one that has been second filled behind it.

Once all the blemishes were sorted and the primer touched up it was on with a coat of red. You can see that the machined mating surfaces have been masked and holes pluged with whatever seemed to fit.

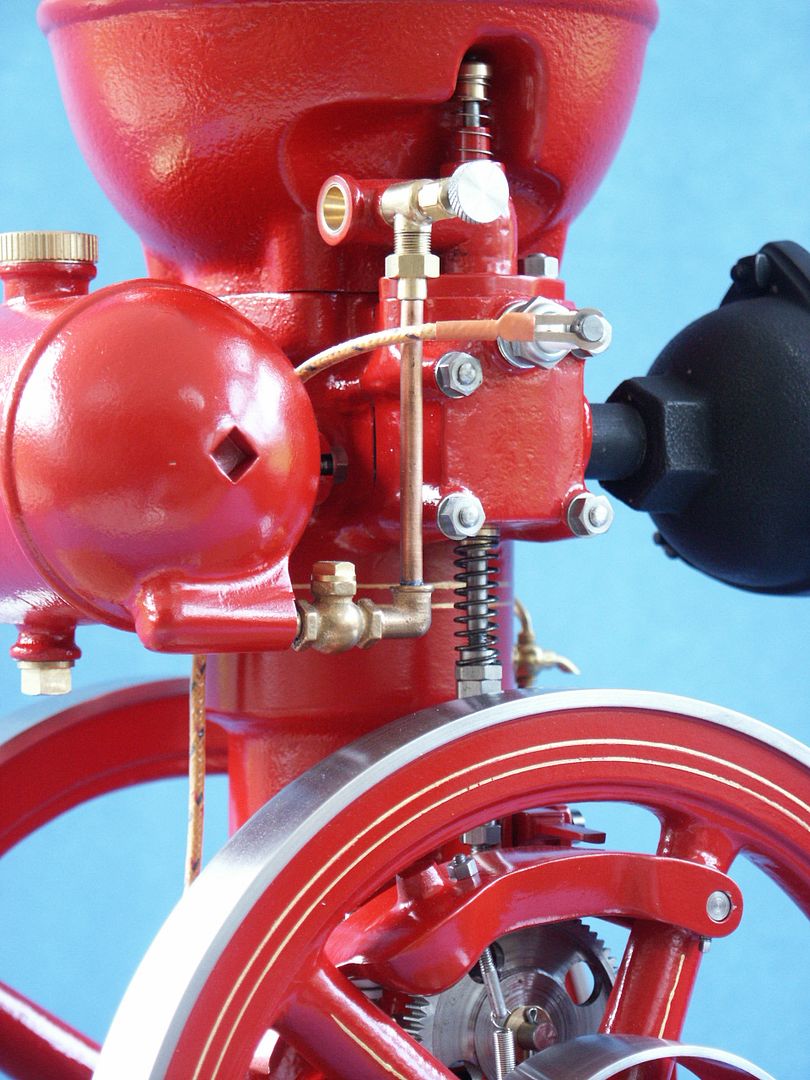

Once the paint had been allowed to harden for a few days it was out with the paint brushes and ruling pen to add a few pinstripes and pick out the "Monitor" logo on the fuel tank. I used a gold acrylic for this as the pigment is quite fine and diluted it slightly with an airbrush extender medium as this works better than water. The acrylic is also not affected by the fuel proof clear coat that went on next.

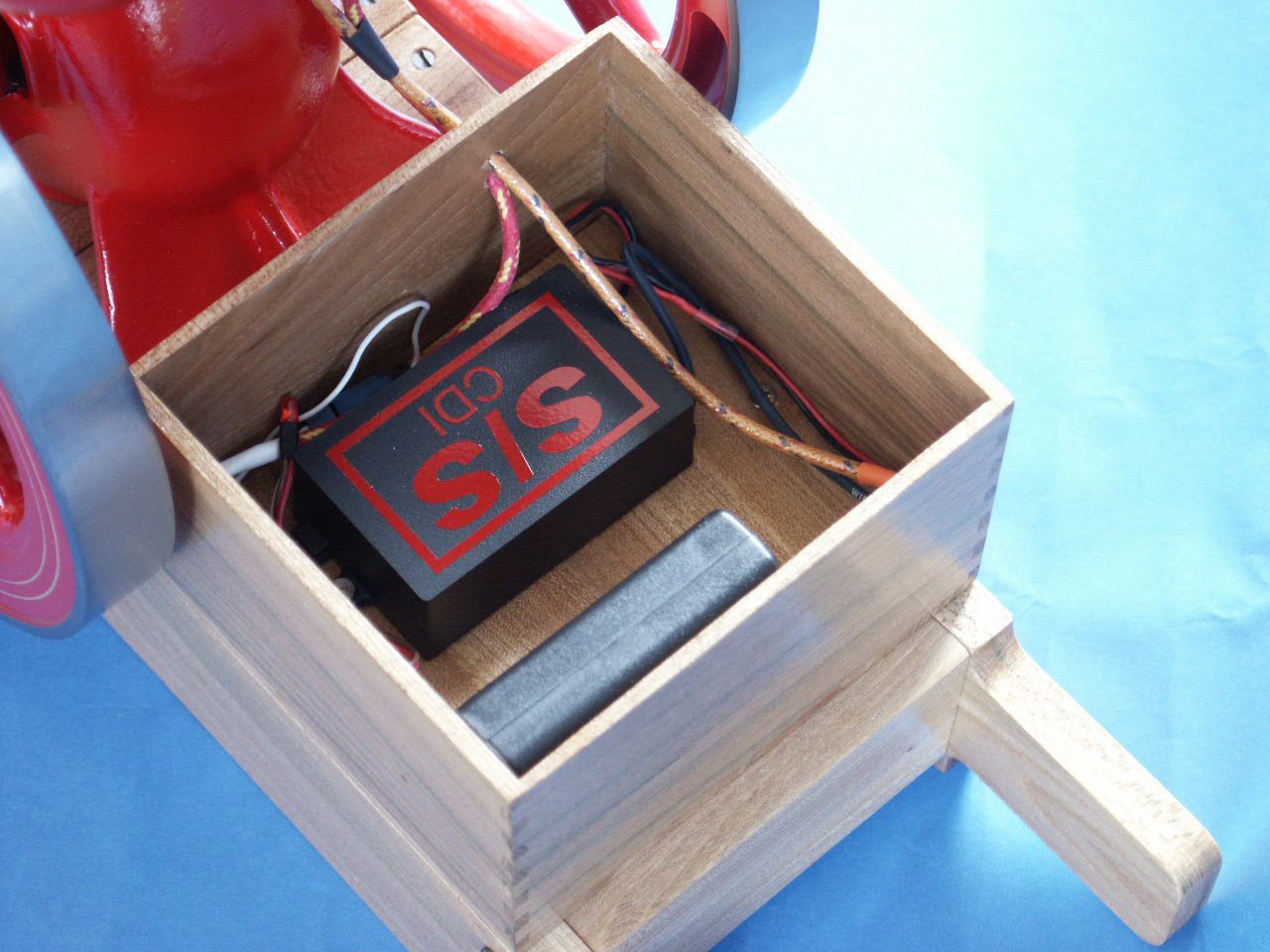

It was then assembled on the base. I went with an ignition from S/S which easily fitted inside together with a battery box for 4 AA size batteries. The wires that are visible were done in old style cotton covered wire complete with a flat sparkplug clip not an unsightly steel braided wire and big metal cap.

And thats about it, so a few pics of the finished engine.

Thanks to all who have commented throughout the thread and a big thanks to Dave for giving me the chance to build this one.

J

Edited By JasonB on 07/12/2014 17:33:19

Edited By JasonB on 07/12/2014 18:26:52

7 December 2014 at 17:38 #171846 JasonBModerator@jasonb

JasonBModerator@jasonbIt took about 1/2hr of adjustments until it would run consistantly, mainly to the needle which needed far less of an opening than the build notes suggested. It now just needs a couple of turns with a finger over the intake to suck up some fuel when starting from cold and then starts on the first wind of the starting handle.

First video is of it inside, the flywheel looks white as I had some masking tape on it to save marking the paint with the starter handle. The metalic clicking that you can hear is the governor weight hitting the latch each time it goes round not something to worry about.

And the second is on a bit of a bouncy garden table I'm affraid but it does show the governor latch working.

J

7 December 2014 at 17:55 #171851nigel jones 5

Participant@nigeljones5JB – That's good even by my standards

. Seriously good! I thought the crankcase had oil in the bottom to lubricate big end etc?7 December 2014 at 18:22 #171857

. Seriously good! I thought the crankcase had oil in the bottom to lubricate big end etc?7 December 2014 at 18:22 #171857Jeff Dayman

Participant@jeffdayman43397Beautiful engine Jason, great work. Does it get hot enough running to need water in the hopper? JD

7 December 2014 at 18:31 #171860 JasonBModerator@jasonb

JasonBModerator@jasonbThanks Chaps

Fizzy you are right the bottom end uses splash lubrication. I just added a few drops of oil to the big end for the test runs which were only a few minuits long as if it had needed a strip down things would be a lot cleaner. Once I got it running right there it was filled with oil, I also fitted the two plates that close in the open areas around the bearing caps and sealed with a small bead of clear silicon, again not something I wanted to remove if possible.

Jeff the longest I have let it run is about 5mins and by then it is starting to get about as warm as I would want it too so any longer runs would best be done with the hopper filled.

J

19 September 2023 at 09:05 #660538Bruce Weir-Smith 2

Participant@bruceweir-smith2Jason

This is a long shot so to speak however, I am trying to source some information on the Baker Ball Hopper Monitor engine 1/3 scale. I tried to up load a photo of the engine however, I wasn't able to work out how.

The engine was purchased just over five years ago from someone who purchased it from the original builder long since gone. So the finished engine is approx fifteen years old.

A good friend of mine has given it to me to see if I can get it going – easier said than done. I have had it running for half an hour or so only to die and refused to restart. The engine run did highlight a few problems most of which can be fixed with a little care. My problem is the air intake and fuel mix. Just looking at what the original builder has done, just doesn't look right in the way he machined what could be called the venturi. What I am looking for is someone who has a set of plans and if they would take a photo or similar of that part of the drawing of the air intake venturi and fuel jet. I am trying to avoid re inventing the wheel so to speak.

If you can help, it would be very much appreciated.

Thanking you in advance

Bruce W-S

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › I/C Engines › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Flattening brass plates

Started by:

t1krt in: Workshop Techniques

- 2

- 2

-

5 April 2025 at 15:34

Bazyle

Bazyle

-

Problem getting the right parameters on a VFD

Started by:

Robert Graham in: Electronics in the Workshop

- 5

- 6

-

5 April 2025 at 15:24

David Jupp

-

Myford S7 Taistock Adjustment

Started by:

Harry Wilkes

in: General Questions

Harry Wilkes

in: General Questions

- 9

- 12

-

5 April 2025 at 15:17

Harry Wilkes

Harry Wilkes

-

How to wire up 3 phase motor and 3 phase converter?

Started by:

ell81 in: Beginners questions

- 7

- 13

-

5 April 2025 at 12:35

Robert Atkinson 2

Robert Atkinson 2

-

Morse Key

Started by:

Steve Withnell in: Work In Progress and completed items

- 2

- 2

-

5 April 2025 at 11:43

SillyOldDuffer

-

James Coombes Drawing Error (or mine?)

Started by:

Steve Withnell in: Drawing Errors and Corrections

- 4

- 5

-

5 April 2025 at 10:51

Steve Withnell

-

Measuring increments on boring head

Started by:

Bill Phinn in: Workshop Techniques

- 15

- 18

-

5 April 2025 at 08:48

Bo’sun

-

Flexispeed Meteor 2

Started by:

ferroequinologist in: Manual machine tools

- 11

- 19

-

5 April 2025 at 07:01

ferroequinologist

-

What Did You Do Today 2025

1

2

3

4

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 23

- 78

-

4 April 2025 at 20:57

Nigel Graham 2

-

Powered hacksaw – blade lift for the return stroke

Started by:

Sonic Escape

in: General Questions

Sonic Escape

in: General Questions

- 8

- 17

-

4 April 2025 at 20:00

Nicholas Farr

Nicholas Farr

-

Damp proofing concrete floors

Started by:

Duff Machinist in: General Questions

- 13

- 13

-

4 April 2025 at 19:57

Bazyle

Bazyle

-

New member old lathe

Started by:

t1krt in: Introduce Yourself – New members start here!

- 8

- 16

-

4 April 2025 at 19:52

t1krt

-

Elliott Omnimill Quill Clamp

Started by:

dangermouse in: Manual machine tools

- 3

- 3

-

4 April 2025 at 19:23

Bazyle

Bazyle

-

Tangential tooling

1

2

Started by:

Keith Matheson in: Workshop Tools and Tooling

- 13

- 29

-

4 April 2025 at 18:14

Howard Lewis

-

Which lathes have drawbars in the headstock?

1

2

Started by:

ell81 in: Beginners questions

- 17

- 26

-

4 April 2025 at 18:04

Howard Lewis

-

Stripped aluminum threads. Now what?

1

2

Started by:

brucemc777 in: Beginners questions

- 19

- 33

-

4 April 2025 at 16:34

old mart

-

gear cutting with the shaper

Started by:

jacques maurel in: Workshop Techniques

- 5

- 6

-

4 April 2025 at 15:15

Andrew Tinsley

-

Machinery Handbook

1

2

Started by:

Dalboy in: Books

- 30

- 37

-

4 April 2025 at 12:27

SillyOldDuffer

-

Electric motor vibrations

Started by:

Sonic Escape

in: General Questions

Sonic Escape

in: General Questions

- 8

- 12

-

4 April 2025 at 07:38

JasonB

JasonB

-

Build Your Own Metal Working Shop From Scrap (7 book series)

Started by:

Dr_GMJN in: Books

- 6

- 7

-

4 April 2025 at 06:39

Pete

-

Scraping

Started by:

ryan.carter848 in: Books

- 7

- 10

-

4 April 2025 at 05:11

Pete

-

Ml10

Started by:

keel in: Beginners questions

- 5

- 7

-

3 April 2025 at 23:06

duncan webster 1

-

Warrington Model Engineering Developments

1

2

Started by:

colin wilkinson in: General Questions

- 14

- 41

-

3 April 2025 at 20:26

keel

-

Vice as Broaching Press

1

2

Started by:

James Hall 3 in: Beginners questions

- 16

- 37

-

3 April 2025 at 20:00

JasonB

JasonB

-

UK consumer protection laws?

Started by:

Fulmen

in: General Questions

Fulmen

in: General Questions

- 8

- 10

-

3 April 2025 at 19:07

Fulmen

Fulmen

-

Flattening brass plates

-

Latest Issue

Newsletter Sign-up

Latest Replies

- Flattening brass plates

- Problem getting the right parameters on a VFD

- Myford S7 Taistock Adjustment

- How to wire up 3 phase motor and 3 phase converter?

- Morse Key

- James Coombes Drawing Error (or mine?)

- Measuring increments on boring head

- Flexispeed Meteor 2

- What Did You Do Today 2025

- Powered hacksaw – blade lift for the return stroke

]

]