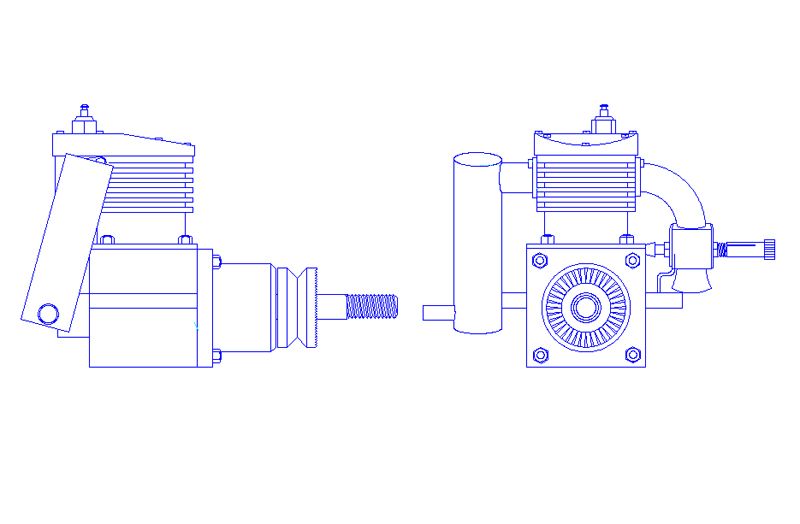

Nemetts 15cc engine

Nemetts 15cc engine

- This topic has 77 replies, 15 voices, and was last updated 7 January 2017 at 23:33 by

Emgee.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

I guess I was too focussed on the pics and text Is that a reasonable excuse?

I guess I was too focussed on the pics and text Is that a reasonable excuse?

and the cams,

and the cams,