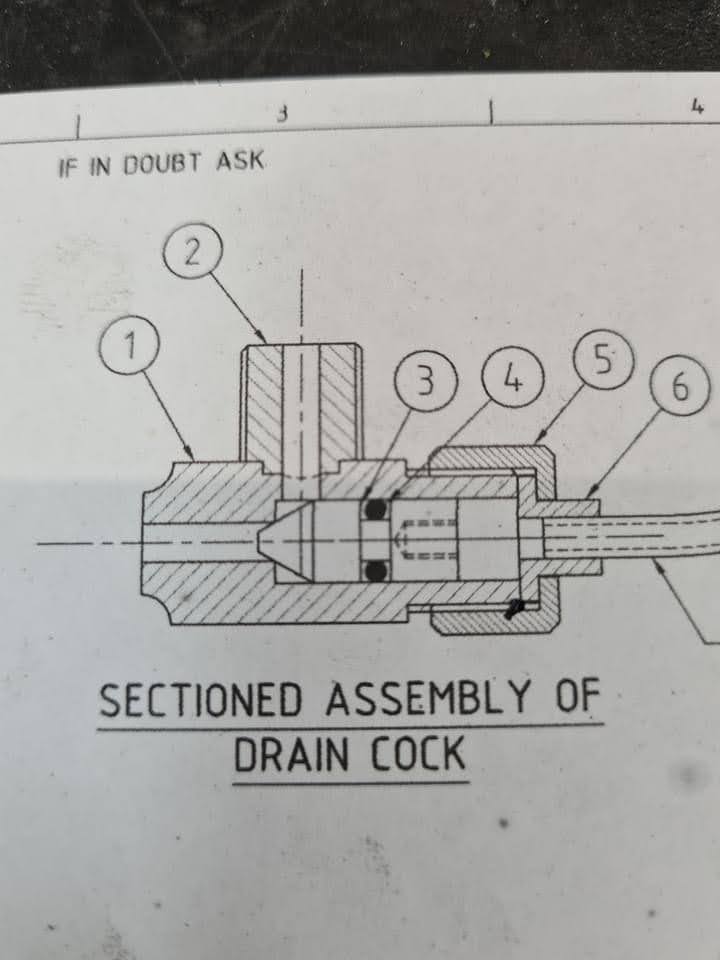

Sorry Duncan, 1 is the end that should connect to the cylinder. The pressure from the steam on the other end holds the valve on the seat. When there is no pressure there, any pressure in the cylinder can open the valve, allowing it to drain. The ones on my steam launch are just like the one shown, and they work fine. If the pressure in the cylinder gets high enough, say from trying to compress water, it can overcome the steam pressure on the other end and vent anyway, so they act as a relief valve, although I have also provided separate relief valves as well. The operating valve should be a changeover type, so that in one position it connects live steam to the valve, and in the other it connects the cylinder end of the valve to atmosphere.

The operating cylinder part needs to be big enough to hold the valve on its seat, but not so much bigger that it won't act as a relief valve. The ratio of the areas will approximately determine the pressure at which it opens.

I don't have drawings of mine, they were made by eye from a sketch, and they would be a bit big for all but the largest of model locos.

John

Baz.