I had thought I might be able to assist with these, as I have a box of similar shape collets that came from a scrapped automatic capstan lathe.

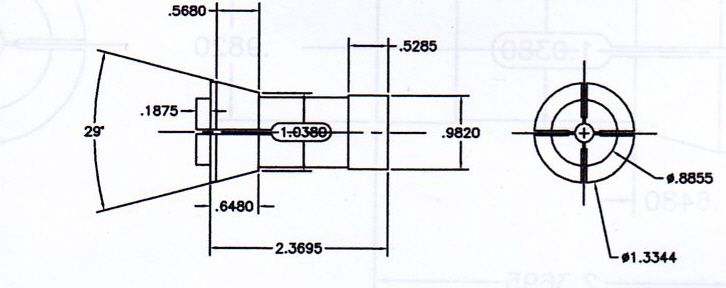

But when I dug them out today, while they are the same nominal shape they are different dimensions – overall length is 2.531″, the ground end opposite the taper is 0.471″ , the parallel section ahead of the taper 0.498″, taper max dia. 0.734″, taper min dia. approx 0.485″, taper length approx. 0.451″.

I cannot recall the make of lathe, but seem to recall that the collets were refered to as “dead length collets” – i don’t think that the length of material protruding changes as the collet is tightend. The collet chuck on this machine was either pneumatically or hydraulically actuated & there was a bar feed fitted.

It seemed a shame for all the tooling that accompanied the machine to follow it into a skip, so the collets & few other bits were “rescued” – but a suitable holder / clamping arrangement for my S7 has yet to be designed.

Nigel B.

Ian S C.