Good evening all,

I’m new here, but a regular on various other fora. I was prompted to respond as I have, some Smart & Brown lathes and a fairly intimate experience of messing about with them. Firstly you may like to consider the Yahoo Smart & Brown group dedicated to these lathes. It is friendly and active and an Operators Manual and Parts Lists are available for free download once you have subscribed, although the details of the feedscrew nut are not very explicit.

You might also consider talking to Bracehand Ltd near Hitchin (Google it), Chris, the proprietor, was an employee of S&B’s and he bought the S&B name and remaining spares and all their old drawings when they went under. It is not inconceivable he may have a new or ‘good used’ nut and/or feedscrew.

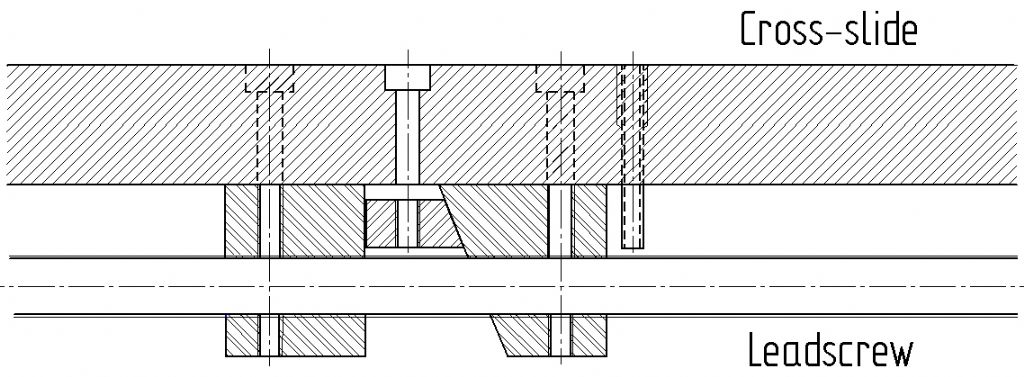

Brian, you have correctly deduced the backlash adjustment on the Mdl A, the taper tipped screw opens the split to reduce the clearance. Make sure that you adjust the nut on an unworn part of the screw or it will bind when you do move to an unworn area. It is probable that most of the backlash can be adjusted out, but any remaining will be due to wear in the scew, not the nut. This will manifest itself as a variation in the backlash over the range of movement. If this is unacceptable, it is the screw more than the nut that needs replacement.

You are pretty much committed to the 8 TPI when you consider the 0~125 graduations on the handwheel. It has caught me out and my chum who’s Mdl A I serviced last year, but unless you change the handwheel as well you are in for some major confusion!

The two part nut that Steve described is used in the top compound slide of both the Mdl A and 1024 as well as some of their other machines. I agree that I prefer either of the two part nut arrangements to the tortured nut on the MdlA, but the original has lasted 60 odd years so it can’t be too bad.

Backlash would not normally give rise to the carriage floating about in use, have you checked the gibb strips for correct adjustment? It might be worth a look.

Rgds

Richard

Brian Davies.