I can remember when JasonB was not a 3D modeler believer (yes it is true; I speak the truth), but he has indeed crossed over to the 3D side.

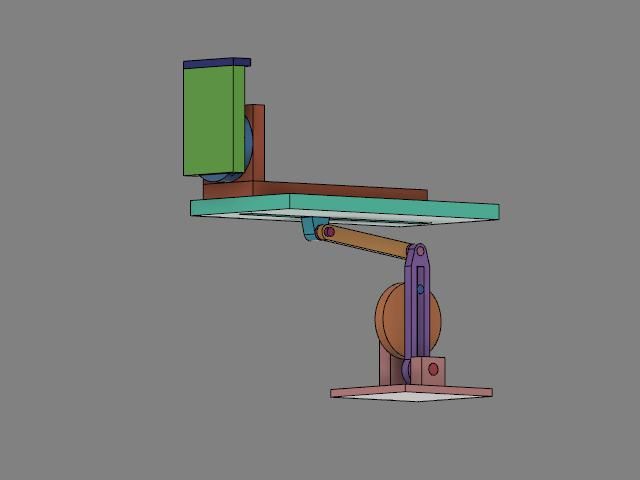

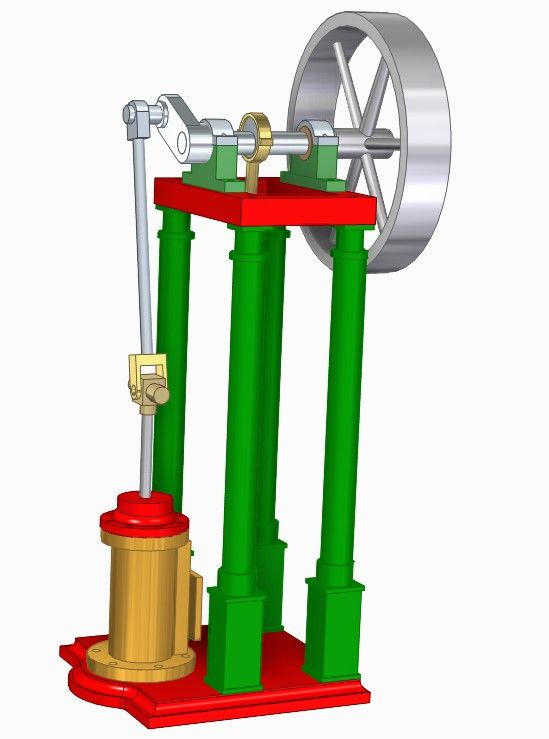

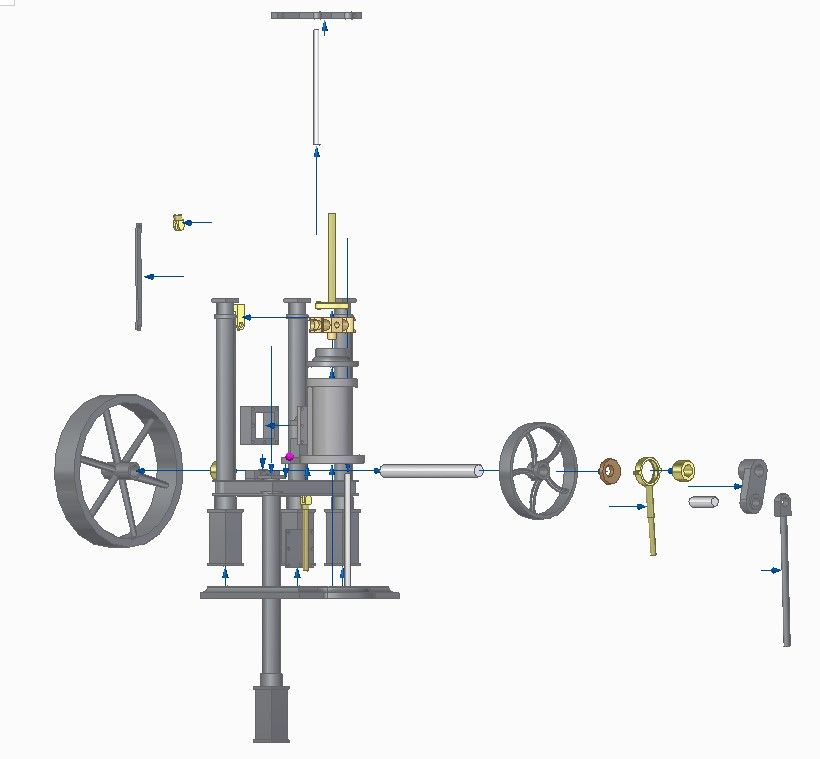

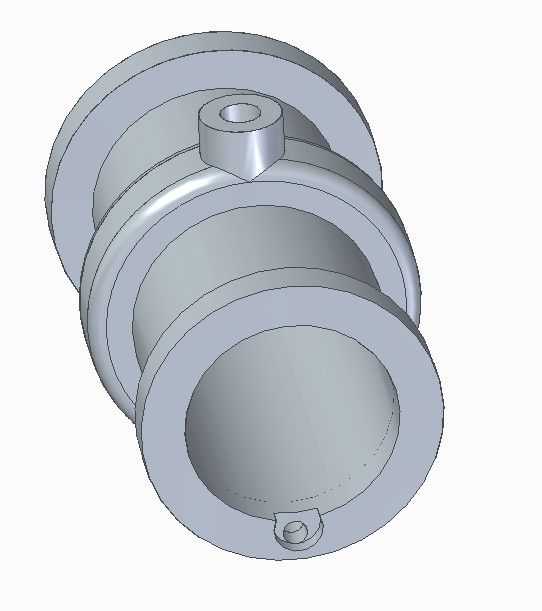

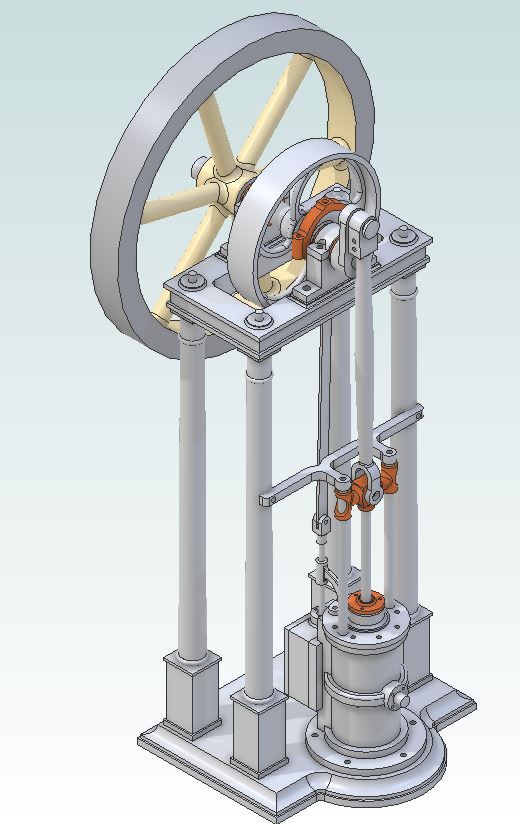

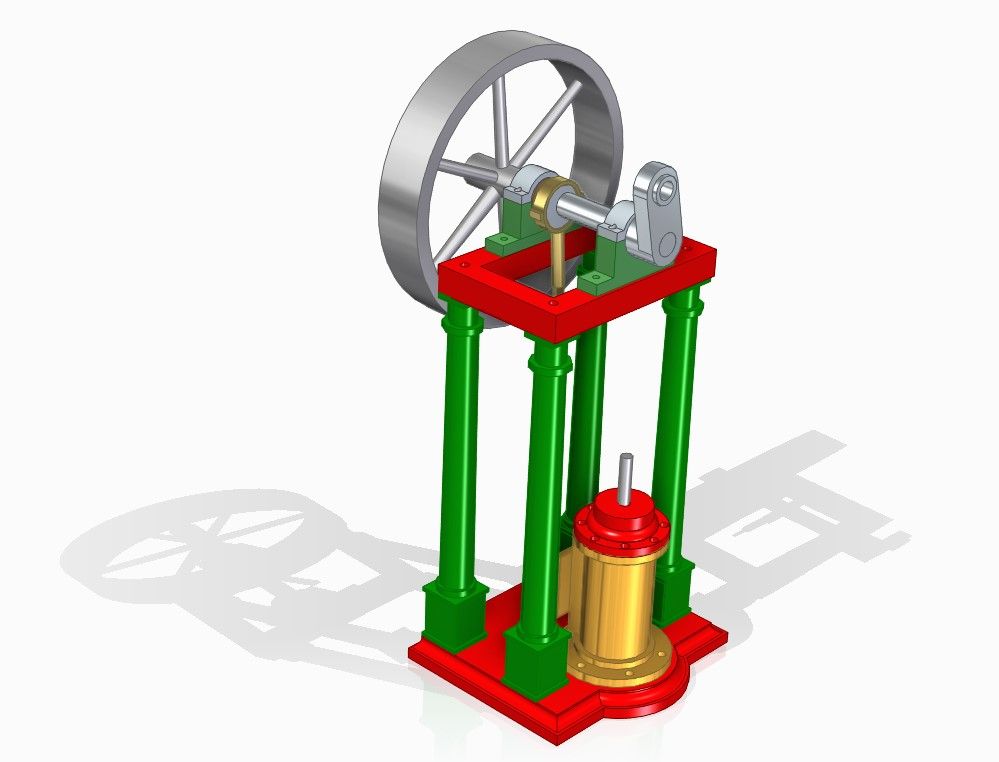

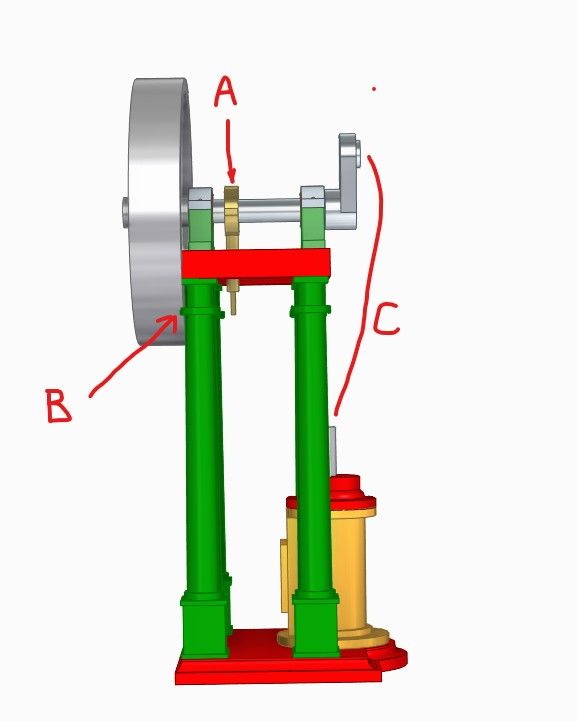

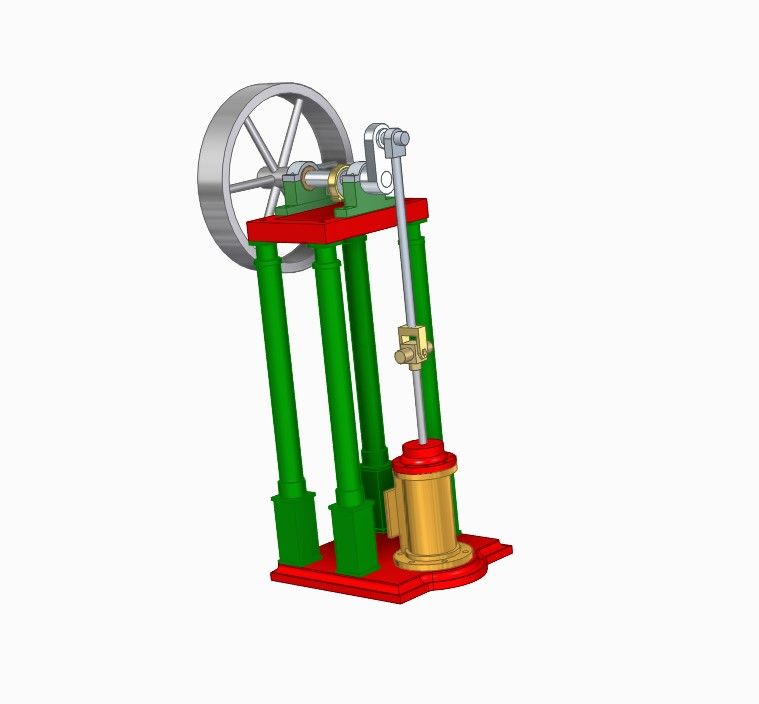

I have mentioned before, but it is worth repeating, 3D modeling is worth its weight in gold as a model engine design tool. For me, designing an engine without 3D would be like trying to build an engine without a lathe.

Sure, it could be done, but why not use a lathe?

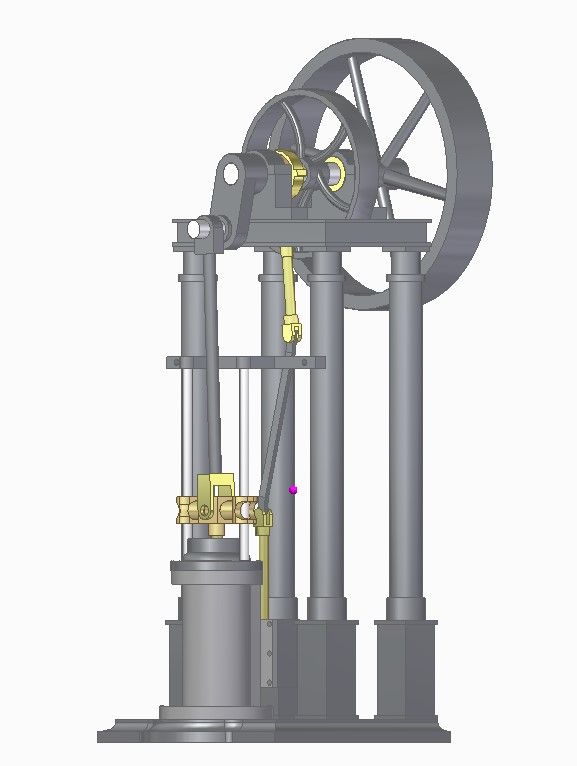

I am not sure about other programs, but Solidworks 2012 came with a rudimentary "Motion Study" part of the program. I was not sure about how to work the motion study part, but it has turned out to be very useful.

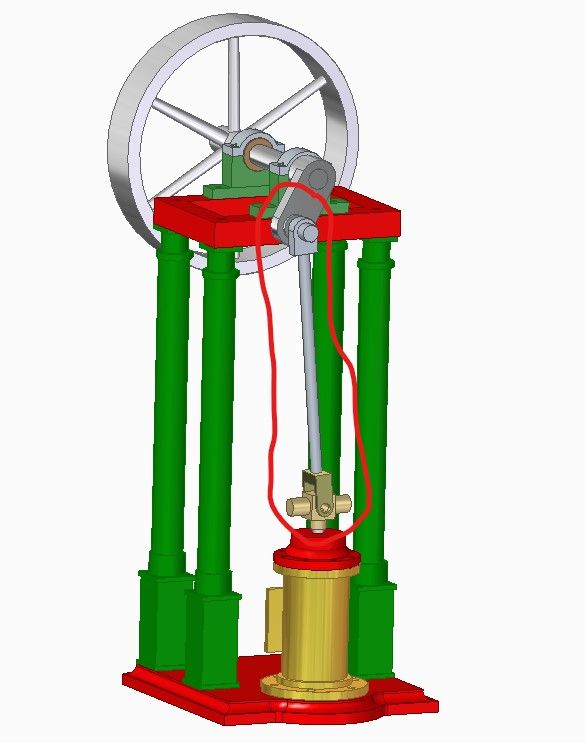

For SW motion study, you basically drag parts onto the page, and mate them one at a time.

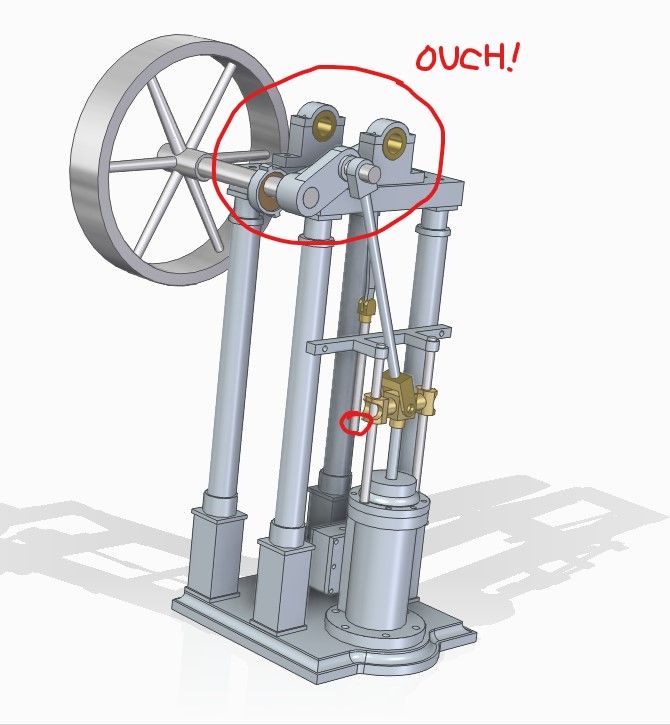

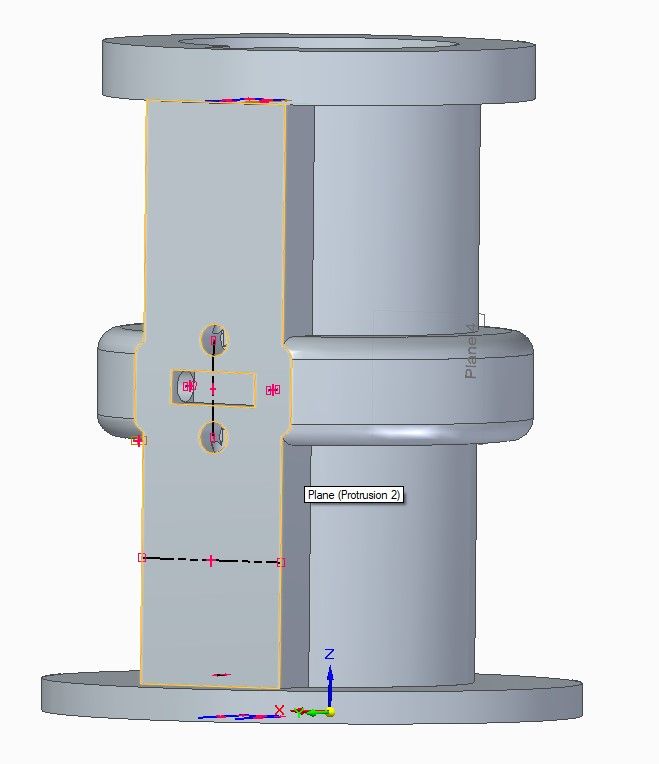

I discovered the hard way that you can mate things such that the parts bind when rotated, but learned this only after making a complete assembly, which then mysteriously would not run in simulation.

So now I drag in one part at a time, such as a crankshaft, and mate that to the bearings.

Then I rotate the crankshaft using the on-screen hand, where you can move things just as if you were using your hand to rotate something.

If the part will not rotate after you have assembled it, something is binding.

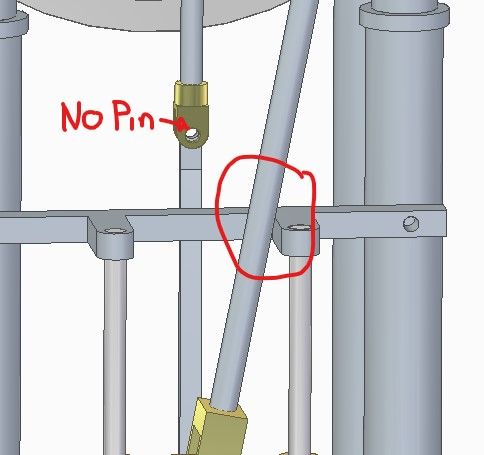

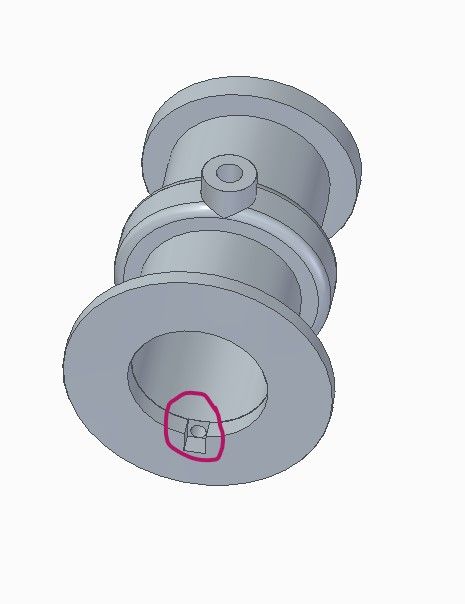

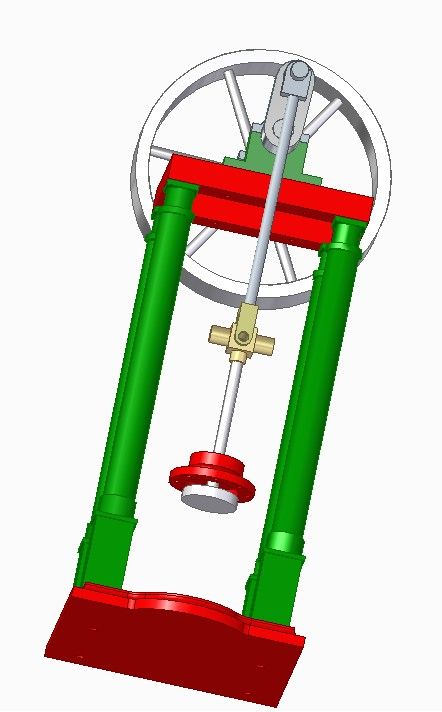

This is a very useful tool, since you can discover which parts don't fit right, because when you add them to the assembly, and mate them, all of a sudden the engine won't rotate. Remove the offending part, and the engine rotates virtually again, and so you can figure out what is binding.

Discovering alignment issues as shown above are another great example of how useful 3D modeling is.

.

Edited By PatJ on 24/05/2022 16:57:28

SillyOldDuffer.

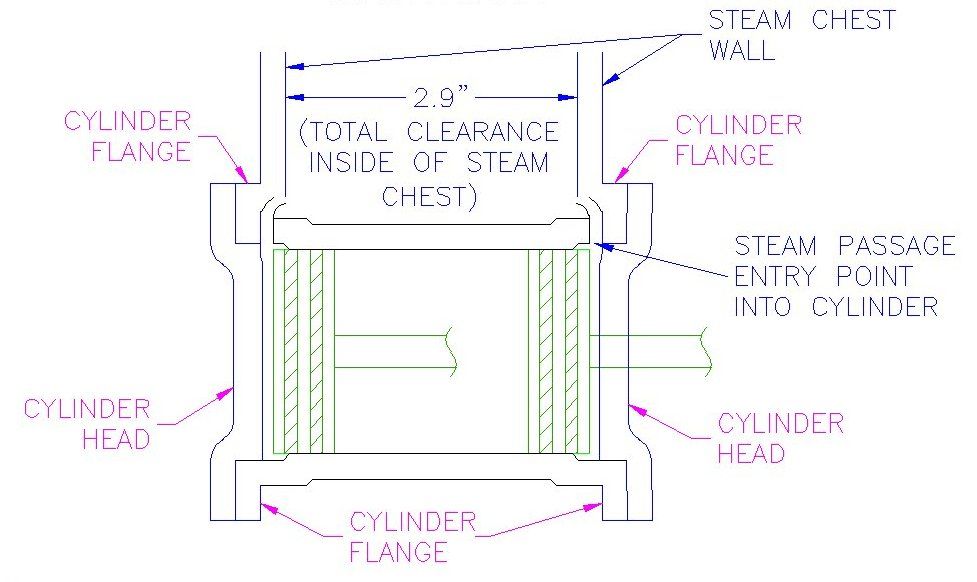

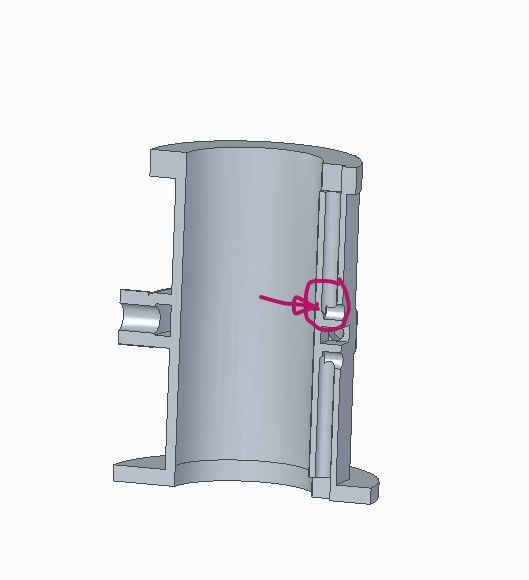

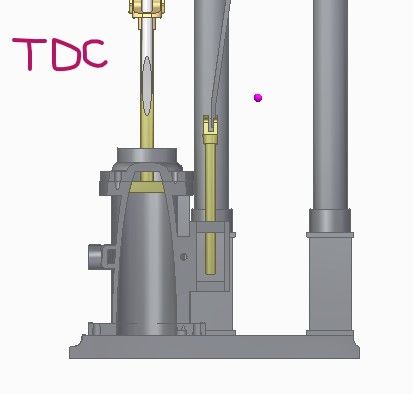

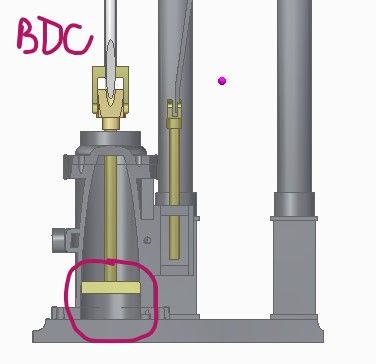

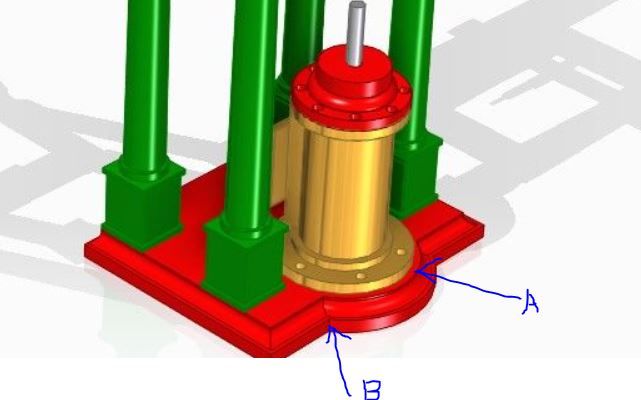

uggests shortening the conrod by 4mm will allow the piston to run full travel inside the cylinder without hitting the ends. Hope so because the other options are more complicated – changing the cylinder length, crank throw etc.

uggests shortening the conrod by 4mm will allow the piston to run full travel inside the cylinder without hitting the ends. Hope so because the other options are more complicated – changing the cylinder length, crank throw etc.