Posted by Bazyle on 06/05/2022 17:34:28:

Why don't these tools just let you 'pick up' item one, twiddle it round to be upside down, and push it down onto roughly the right place on item two. Then press a special button "use your megadoodles of computing power that cost me and arm and a leg and join these bits". Like a drag and drop …

Fusion360 and SE both work like that. FreeCAD is still primitive in this department, but getting better.

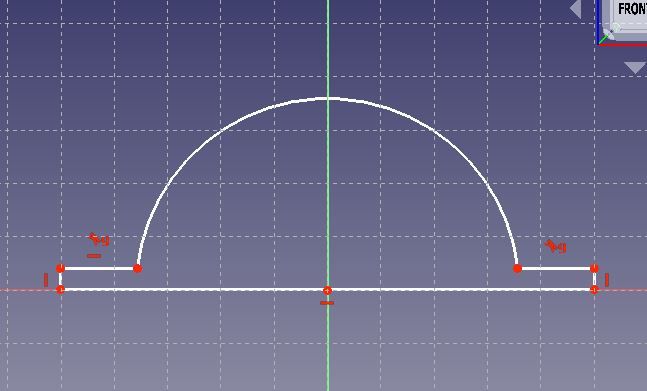

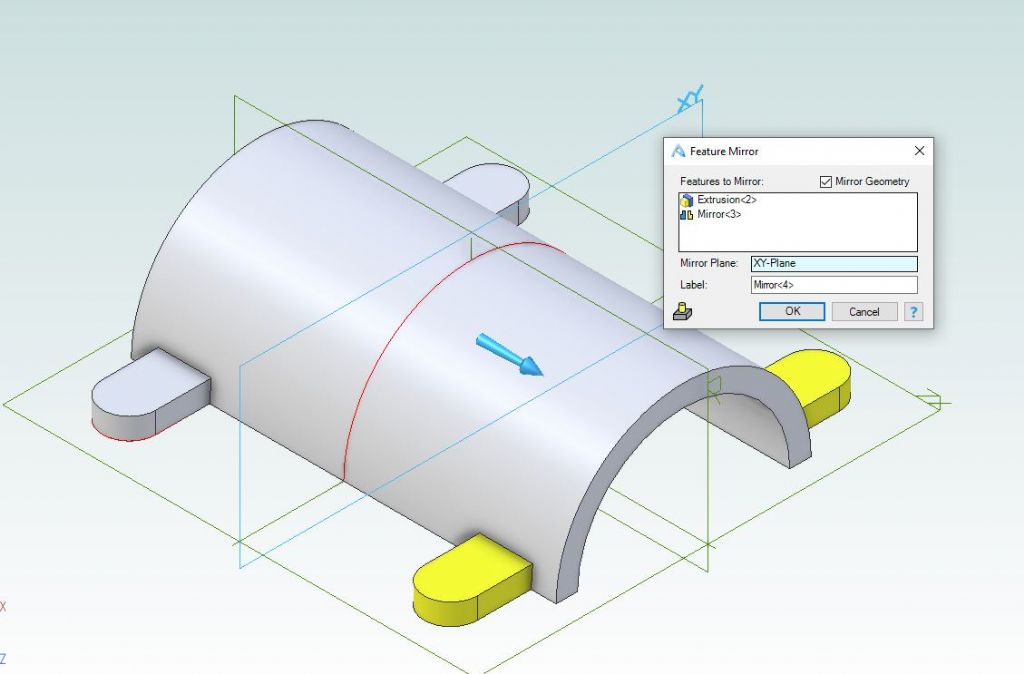

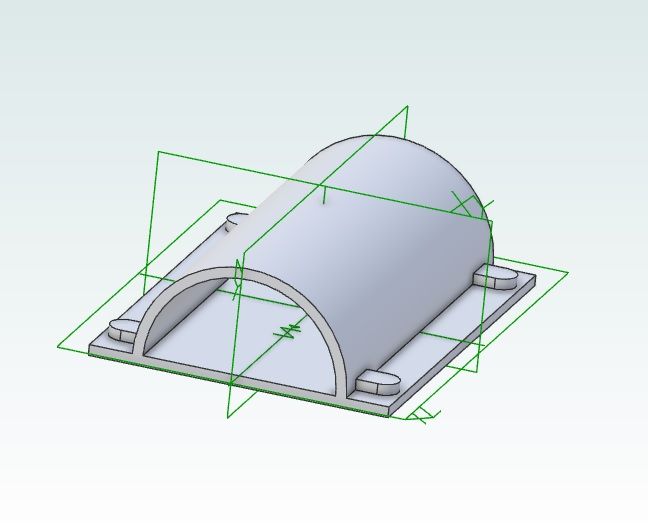

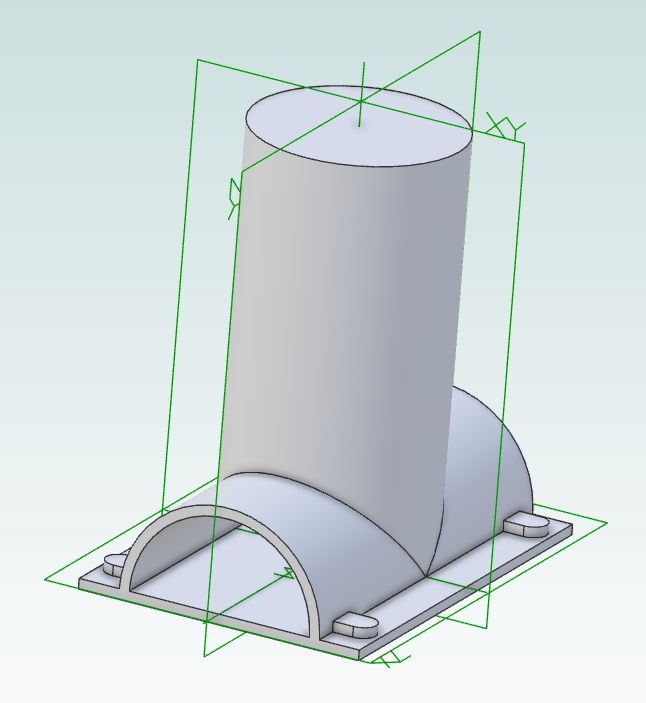

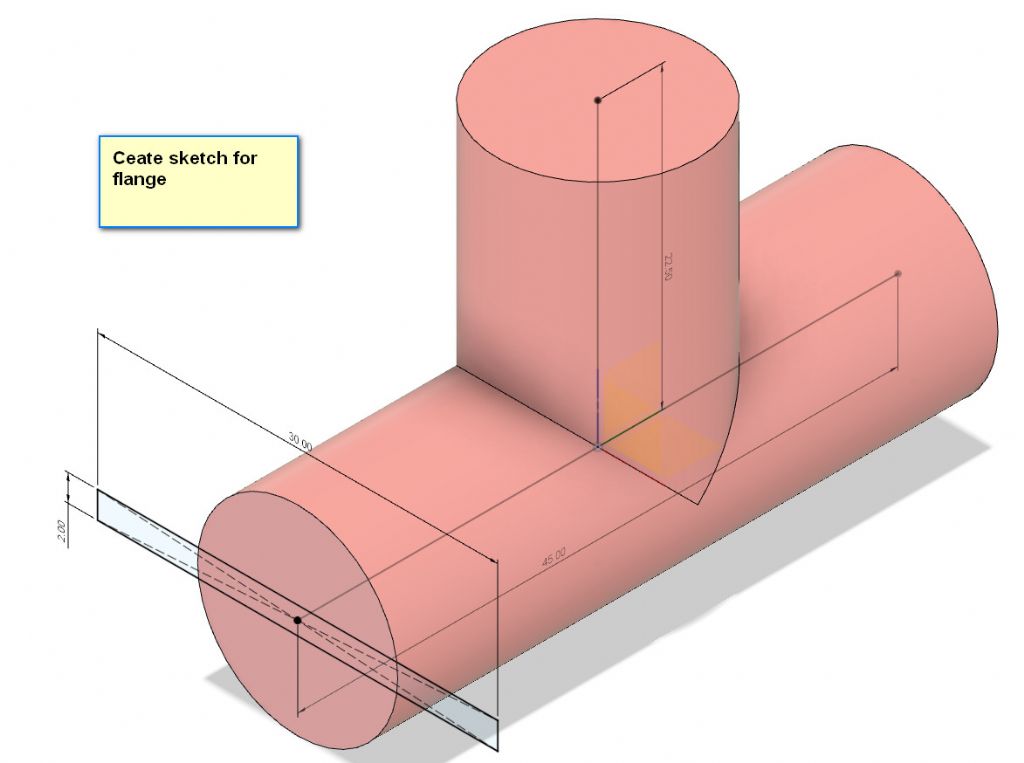

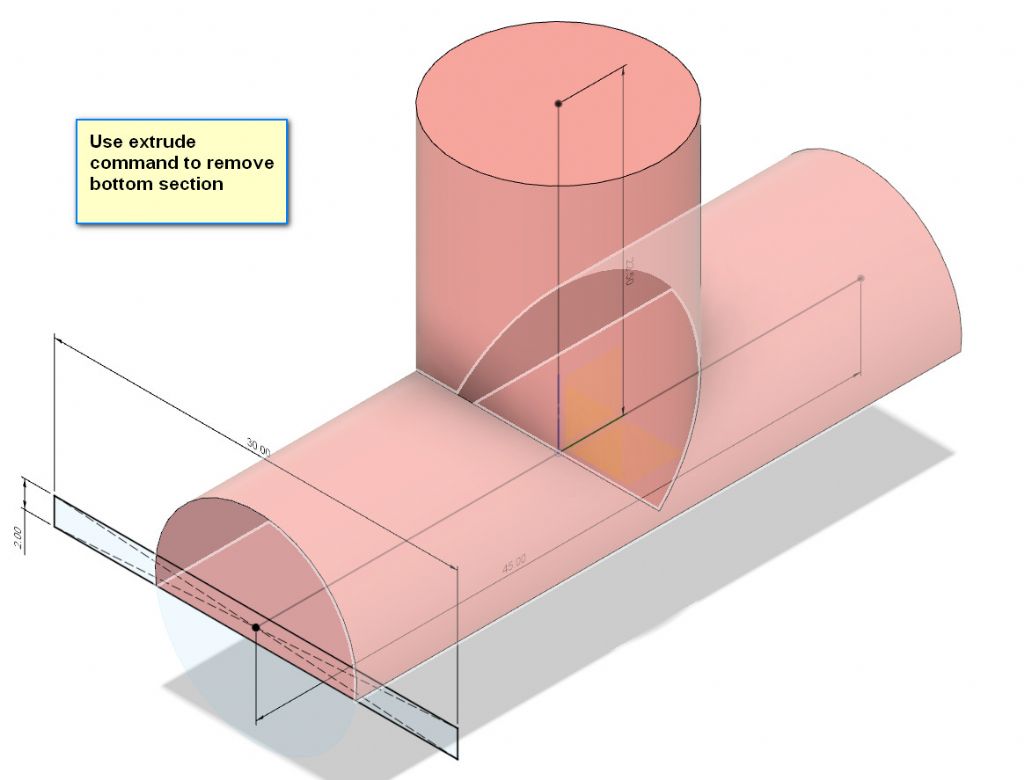

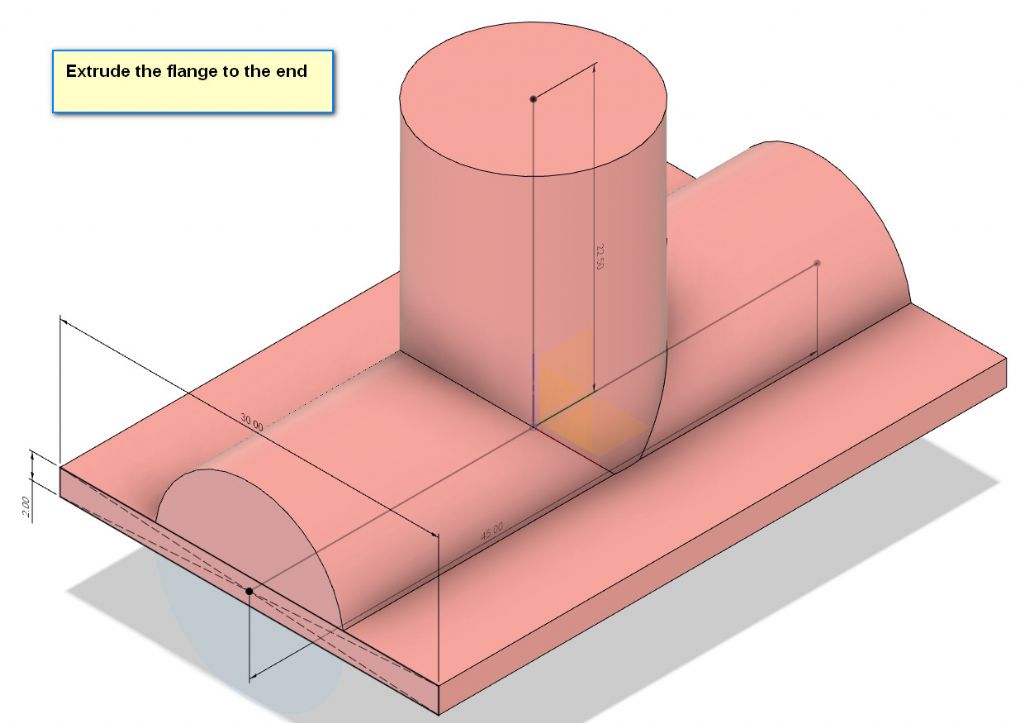

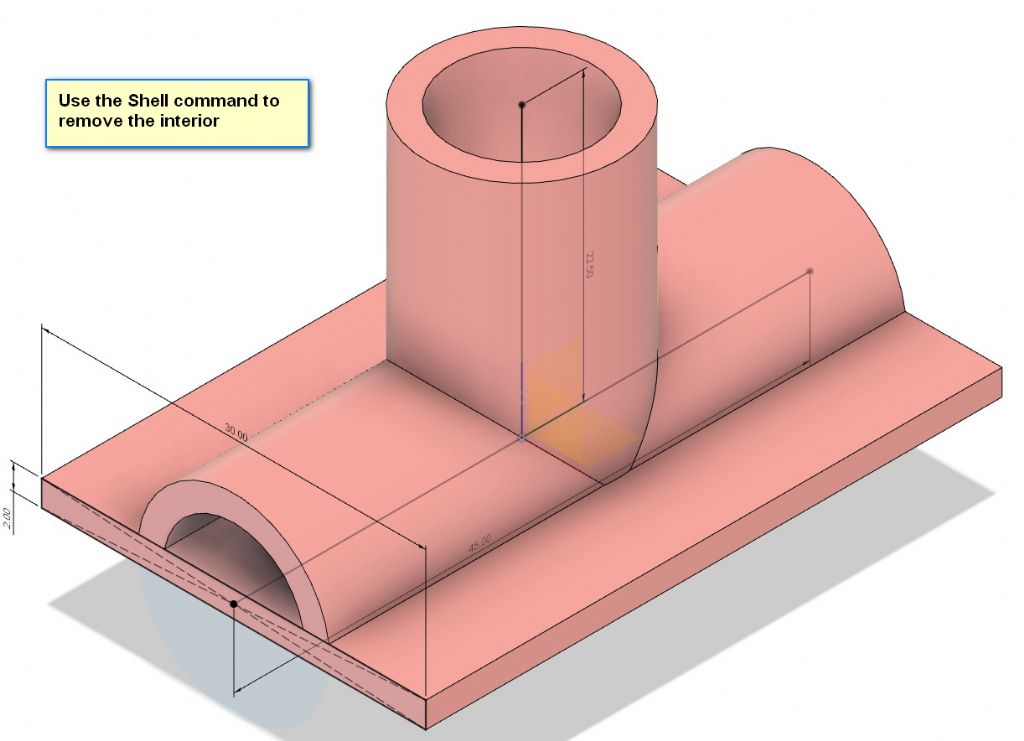

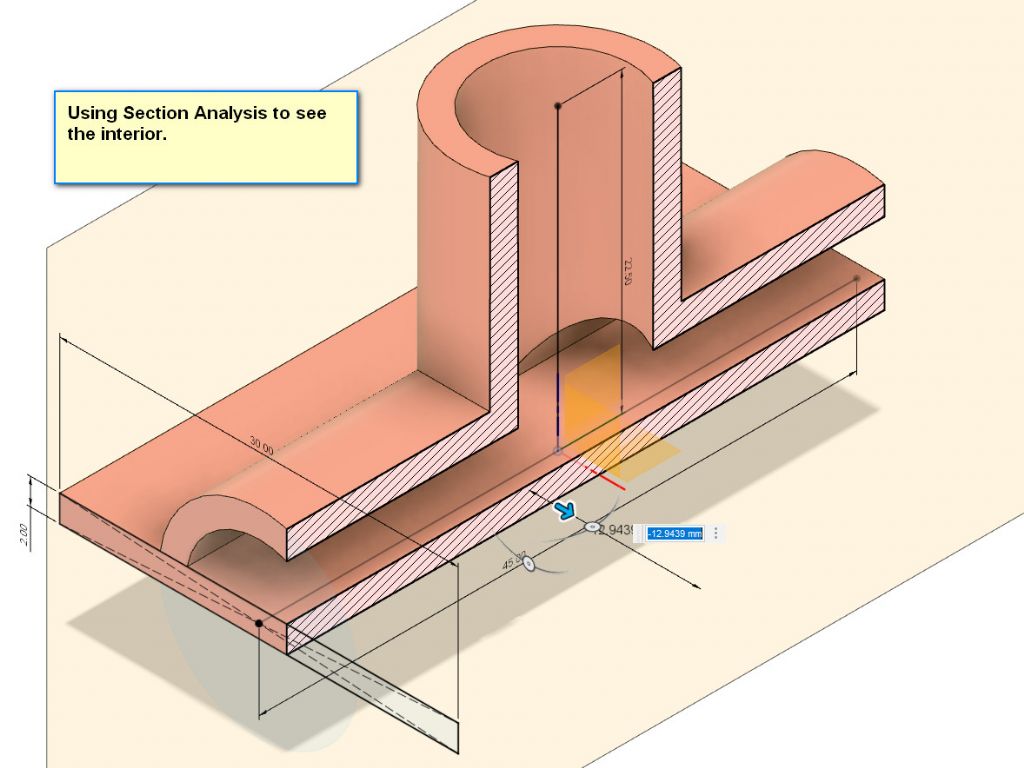

This example is Solid Edge. I designed a door bolt, which although based on the domestic item, is original : my dimensions, not a copy.

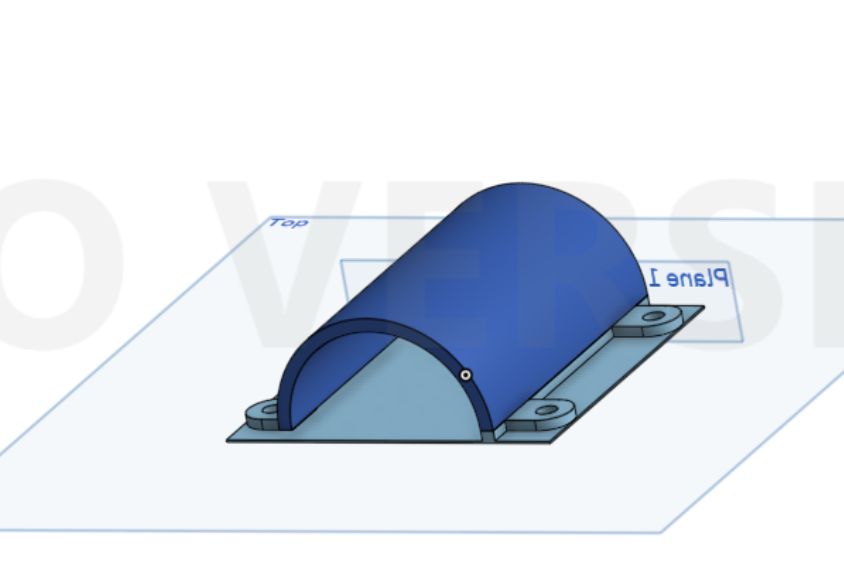

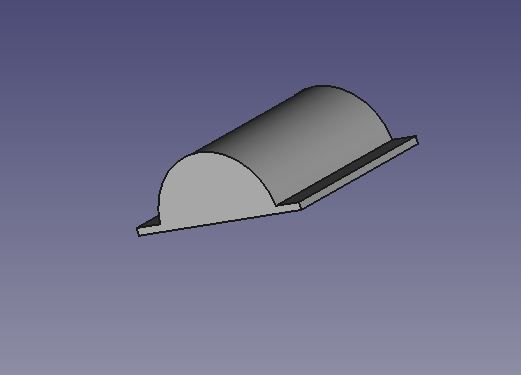

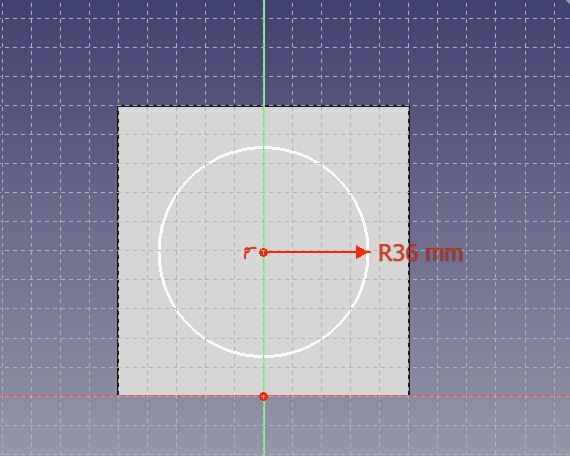

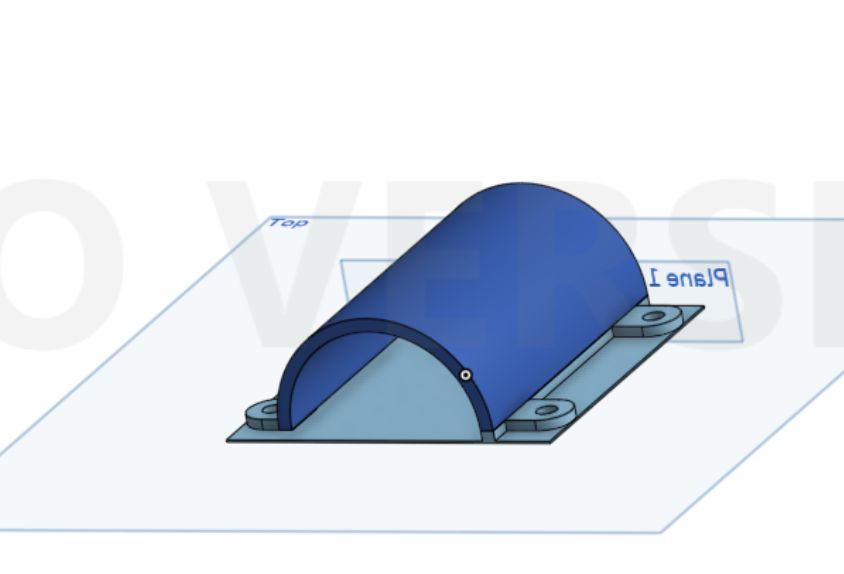

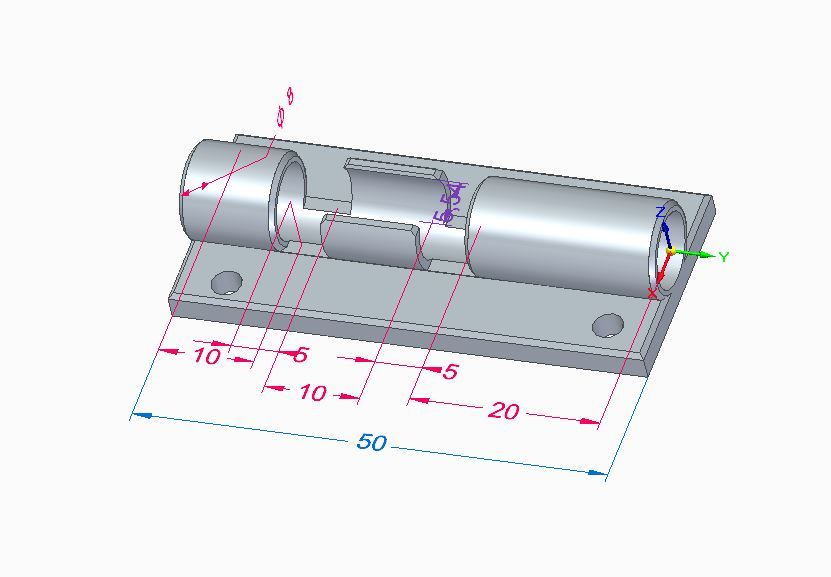

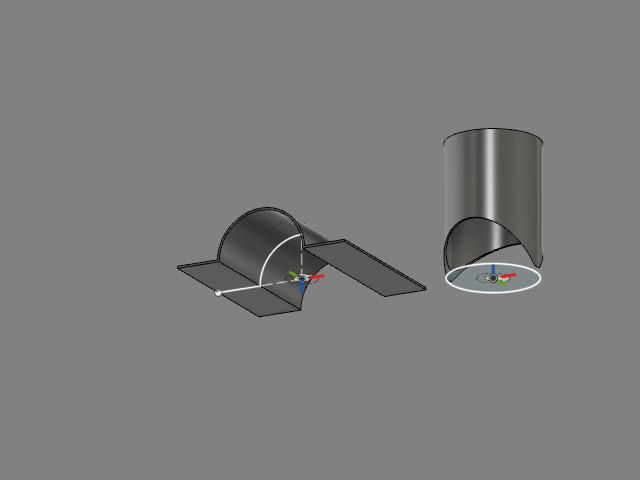

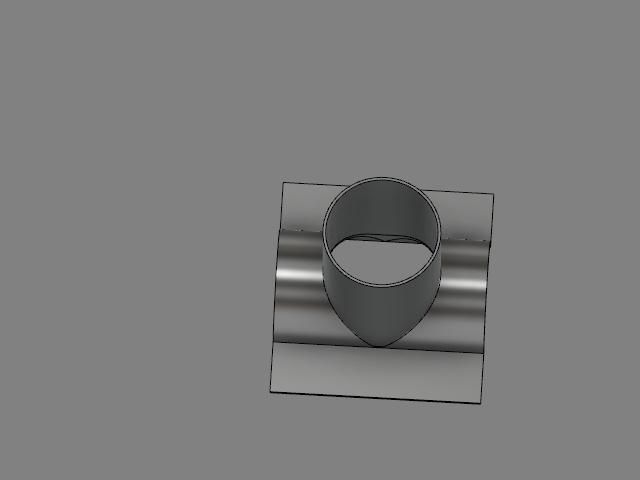

First part is the bolt body:

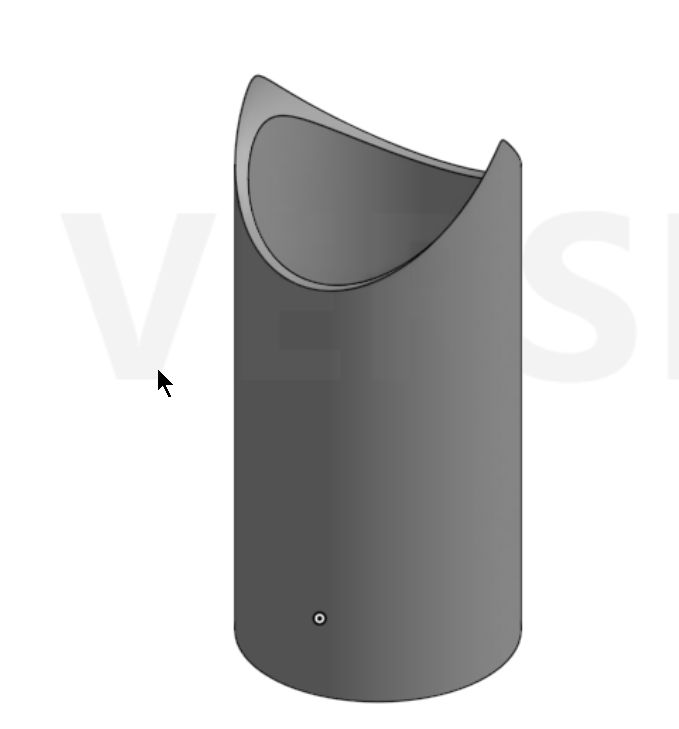

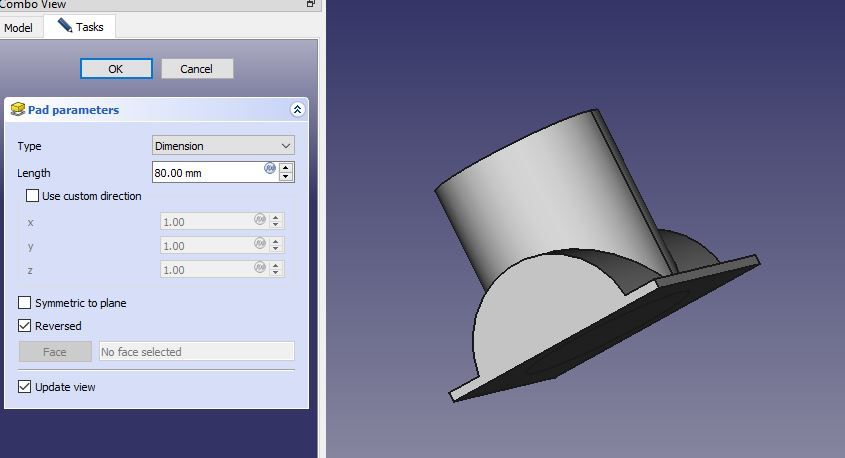

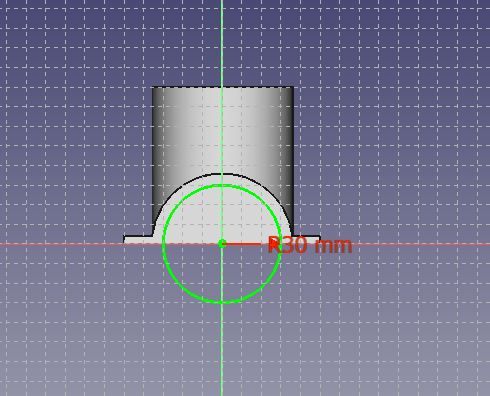

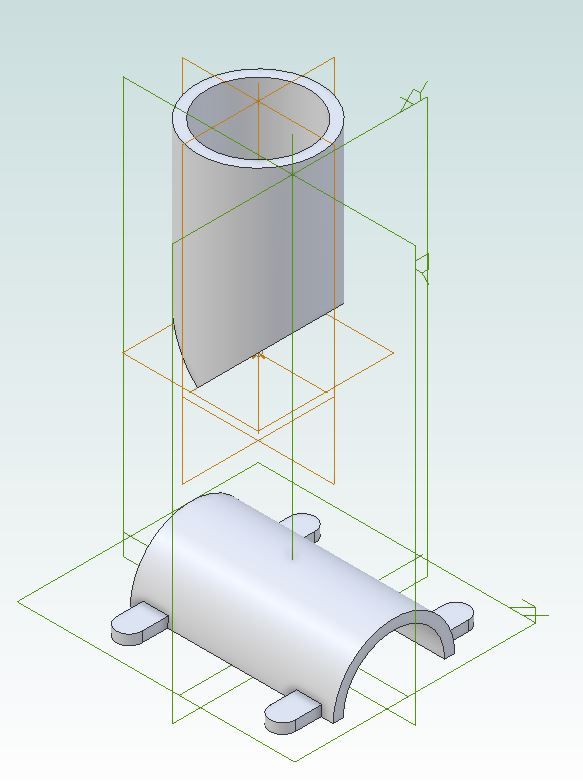

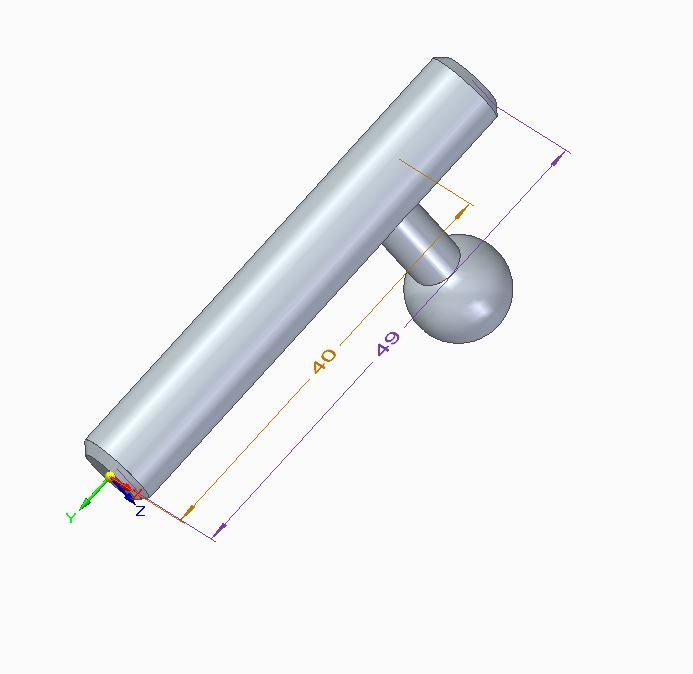

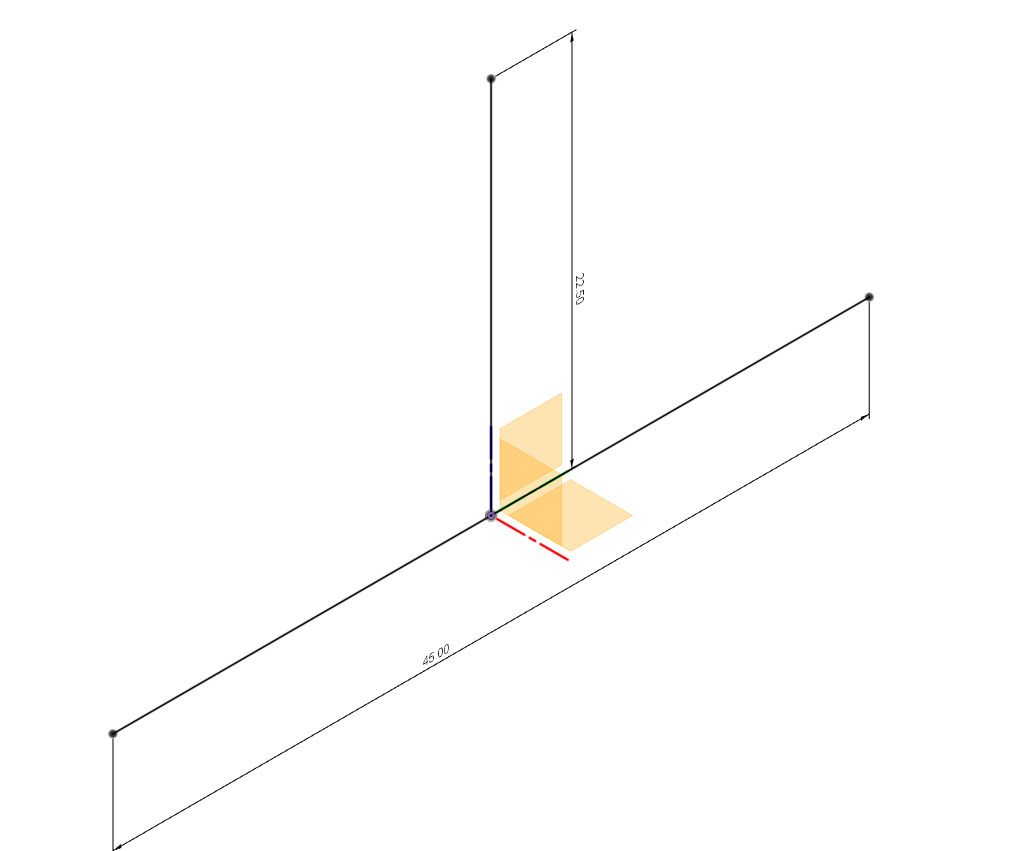

Created separately is the bolt. It has to fit into the body, correct diameter, length, handle to fit the slots etc.

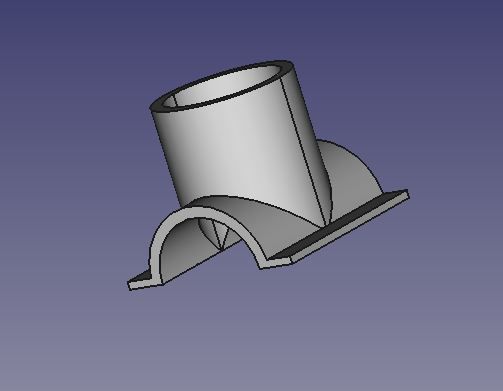

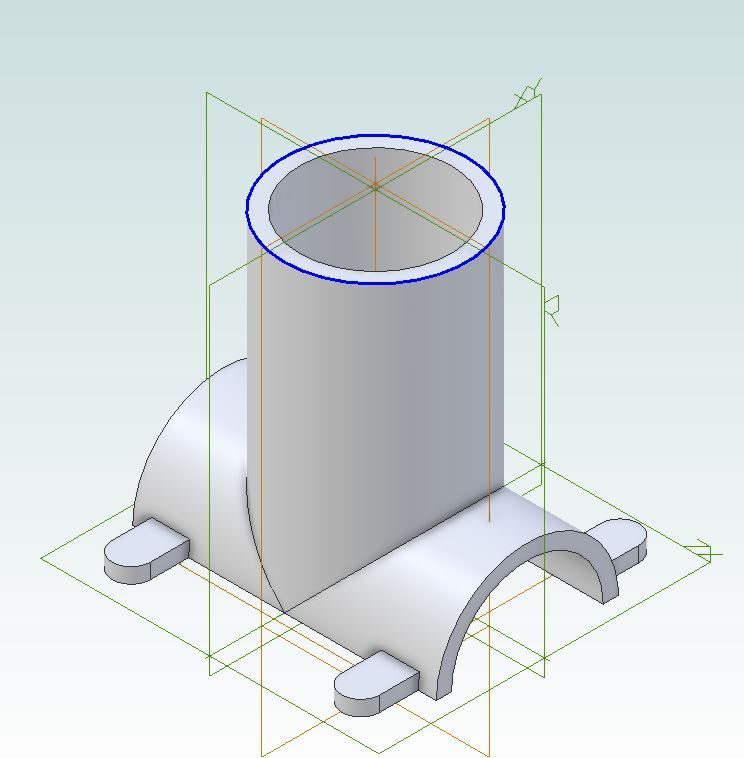

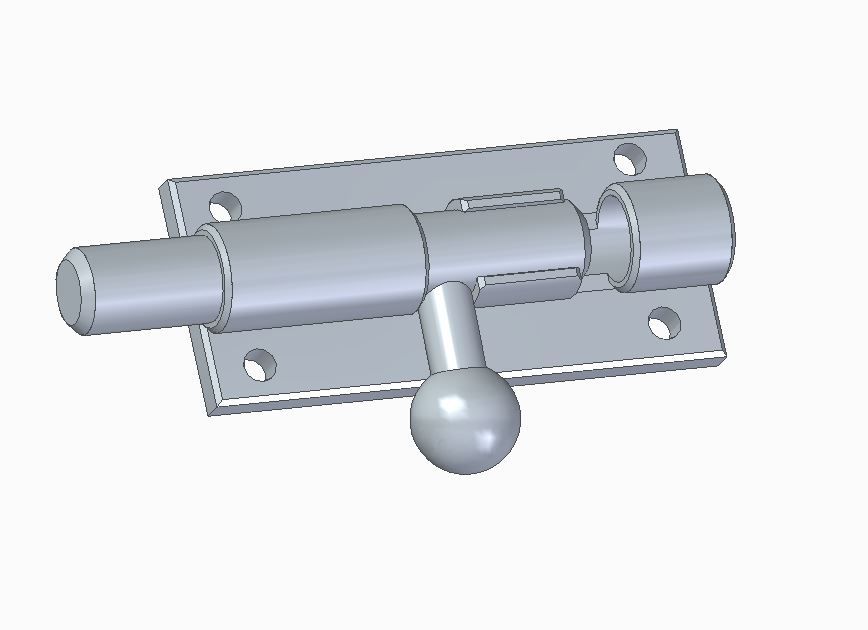

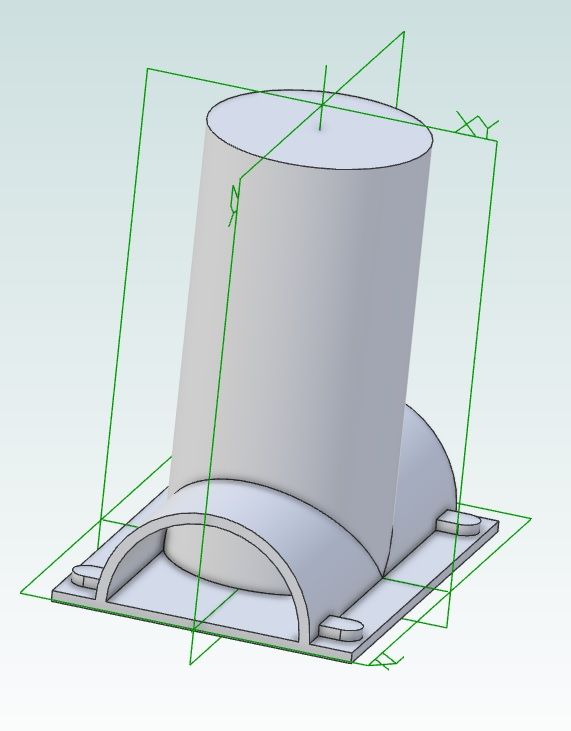

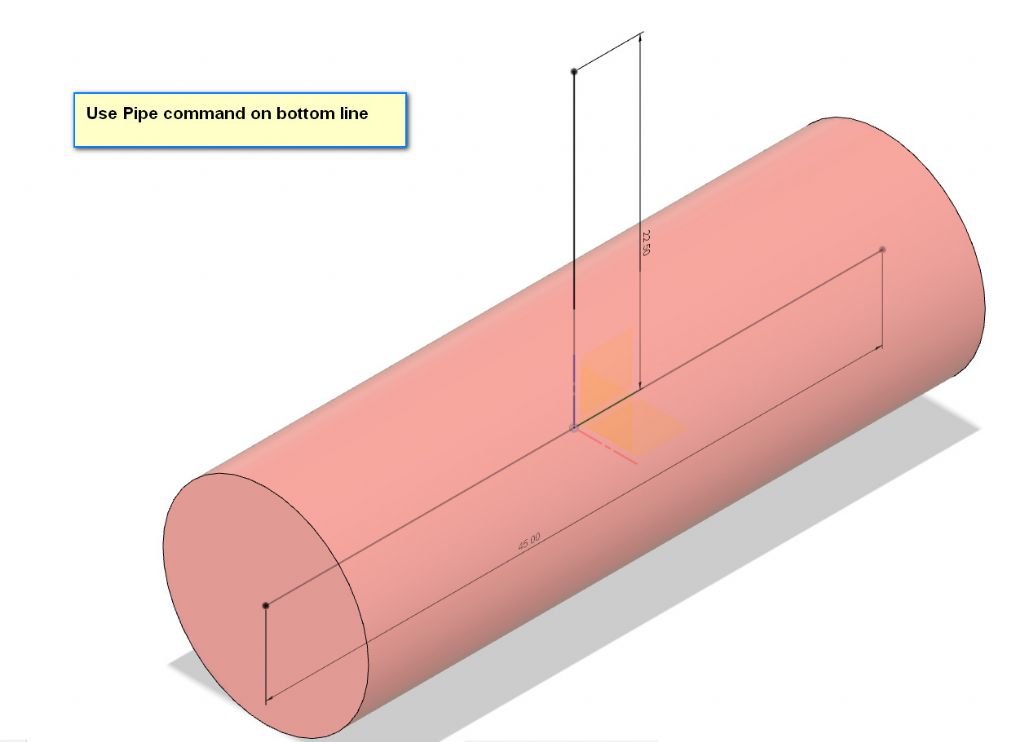

SE (and similar CAD packages) allow two or more parts to be combined as an Assembly, which achieved by drag and drop plus intents – axial, rotation allowed or not etc. The result is two parts working together.

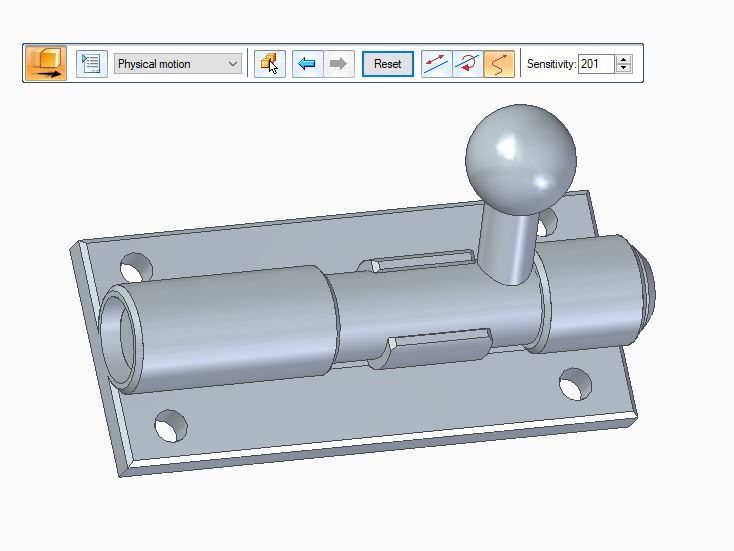

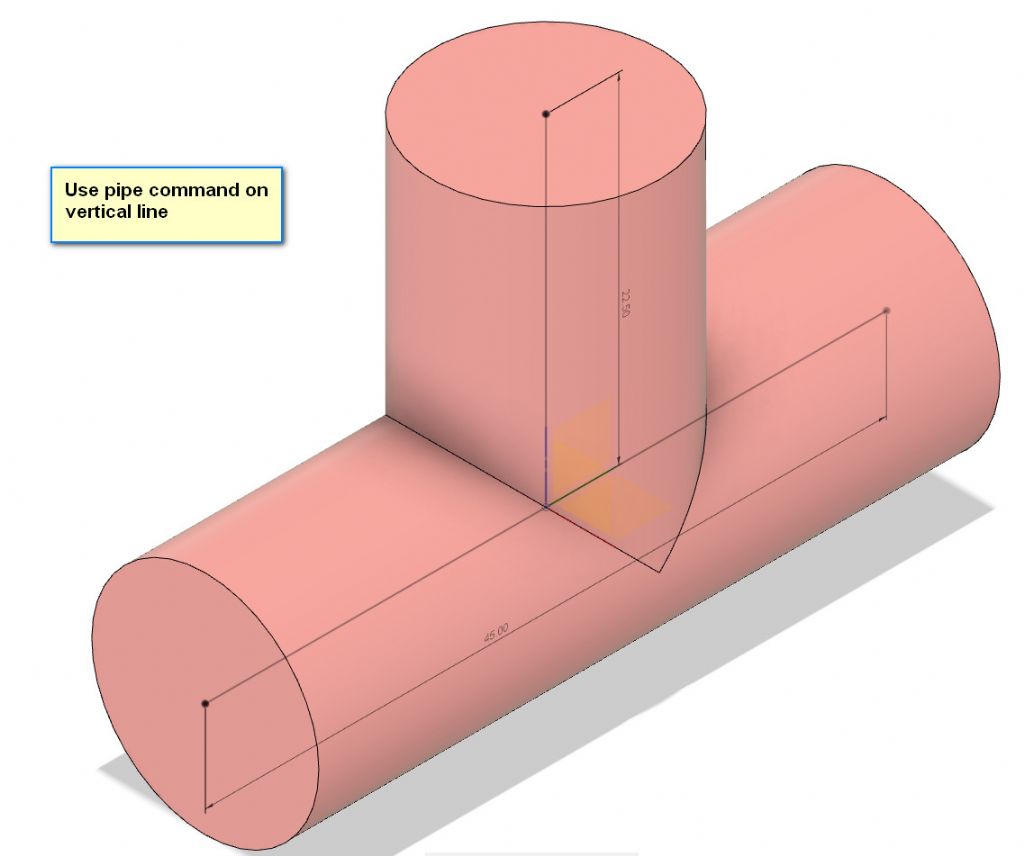

The software understands the bolt slides in the body, and detects collisions and interferences. When the design is correct, the bolt can be moved realistically on screen to prove all is well:

Mildly useful for designing a simple door bolt, but highly valuable when developing a multi-part object like an engine, where pistons must fit into cylinders without smacking into the head or valves, whilst the conrods turn the crankshaft without jambing. At the same time, the valve gear is driven from the crankshaft by a chain, and valve events delivered with cams. Saves an enormous amount of time when fits of all these different parts can be confirmed in a model, rather than painfully made for real, only to find they crunch expensively together inside the prototype!

Challenging enough to build an engine from someone else's plan, but much harder to reverse engineer an old engine from pictures or to develop a working engine from scratch. These tools are primarily for creating original work, not copying what went before.

Dave

Gary Wooding.

Gary Wooding.