I should mention what the benefits of 3D modeling are, and why it can be worth the trouble to learn 3D modeling, and use it instead of 2D CAD or manual drafting.

There are those who will be better served by using either manual drafting or 2D CAD, but for those who have the time, take the deep dive into the world of 3D modeling.

As with building model engines, 3D modeling can be addictive, and one seems to have to want to build those ever more challenging models/engines.

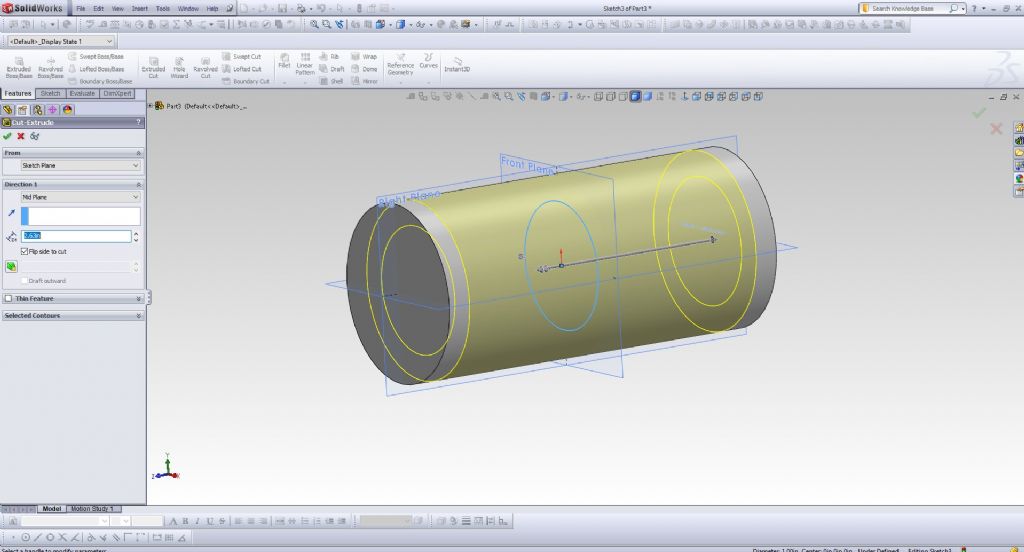

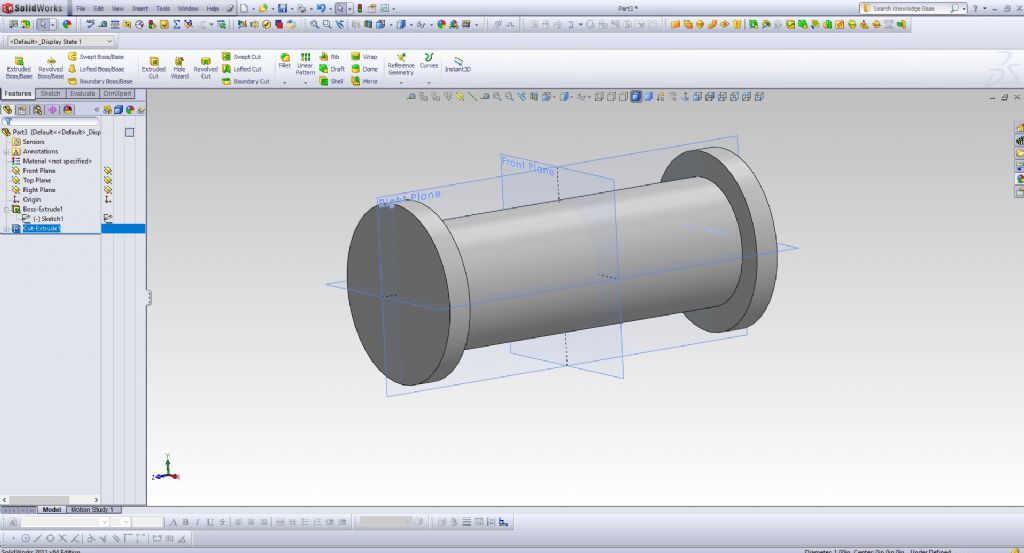

Some of the benefits of 3D modeling are:

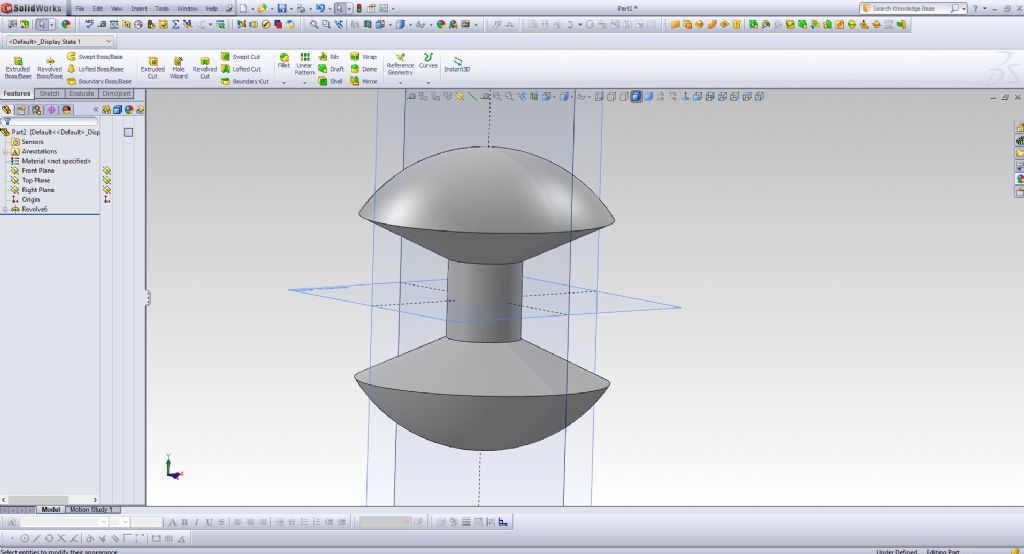

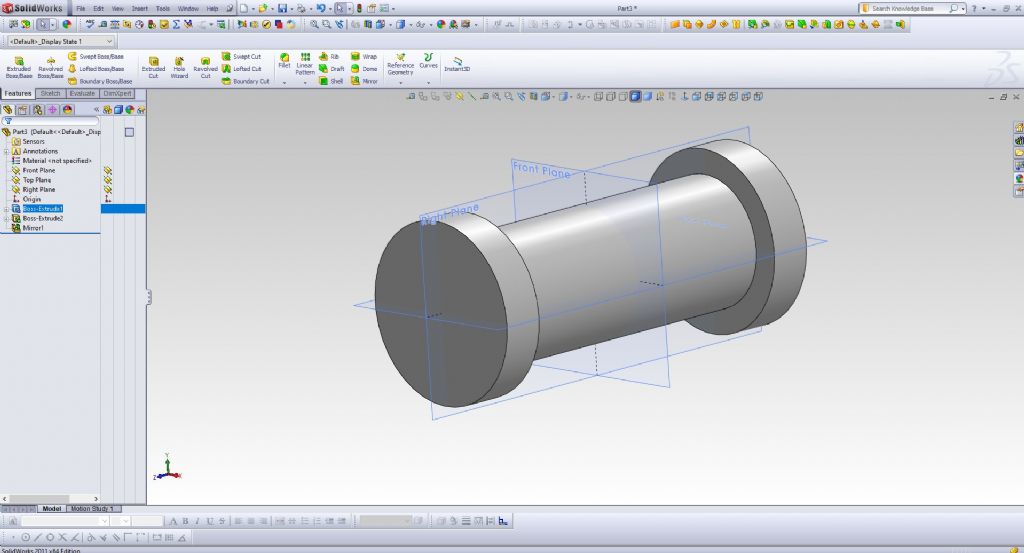

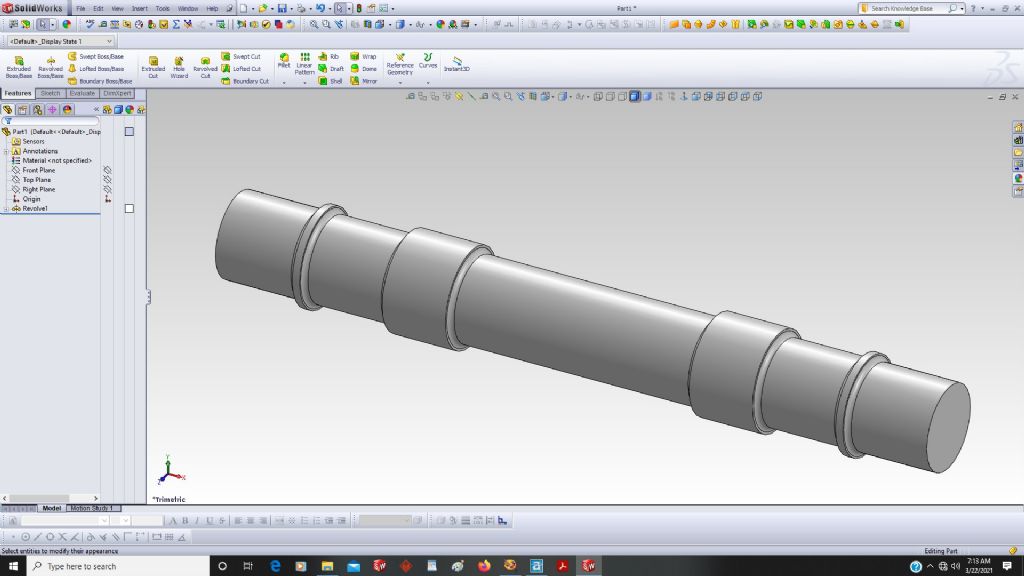

1. You can create an assembly, and assemble the parts together, and verify if the parts actually fit, verify that things such as the holes in the cylinder head and the studs on the cylinder actually align, etc.

2. When you create an assembly, you run a motion study, and actually run your engine virtually (not all programs have this option).

If the parts do not fit, the engine will not run.

It is best to test each part for rotation as they are added, in case there is a misalignment.

Otherwise if you assemble all the parts before attempting a motion study, and you have a problem, you will not know which part is causing the problem.

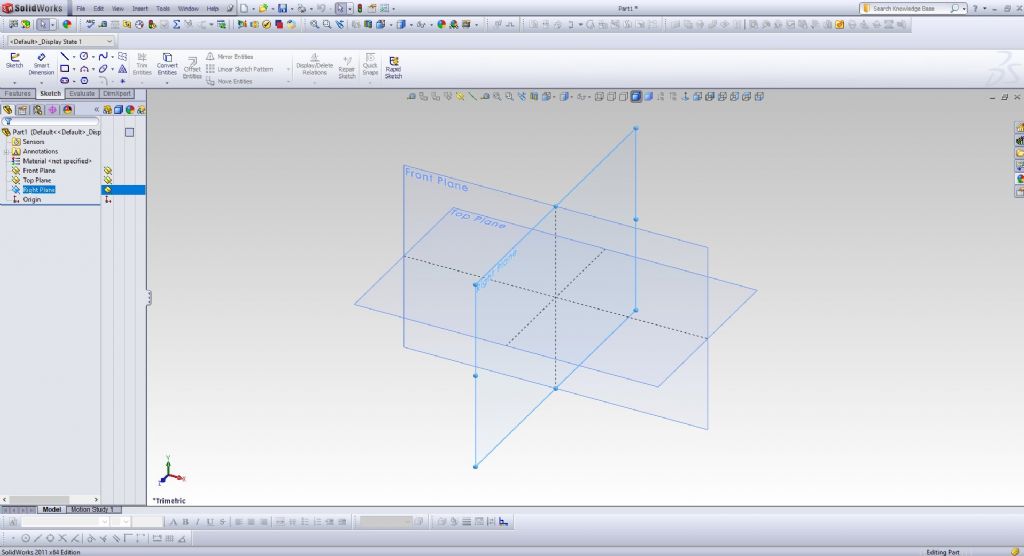

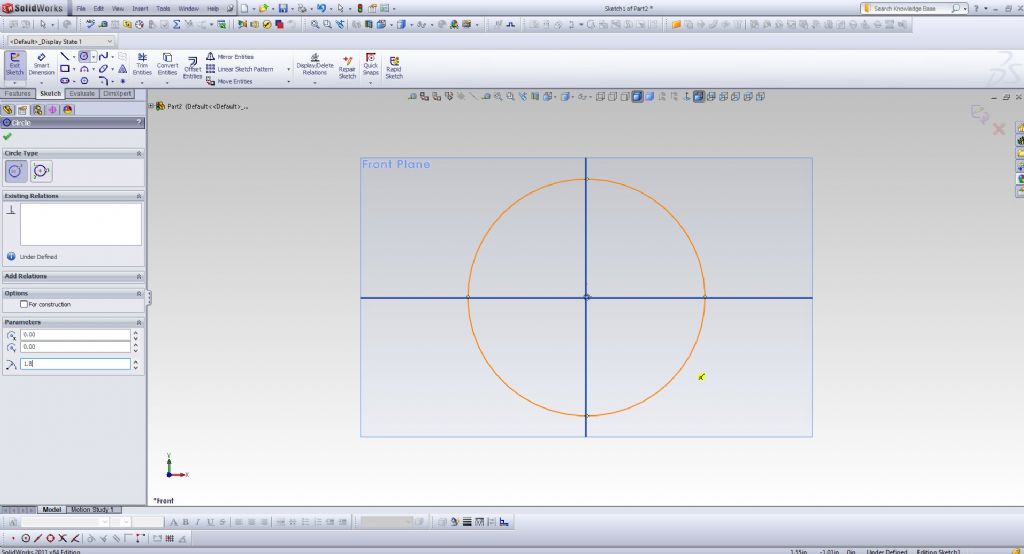

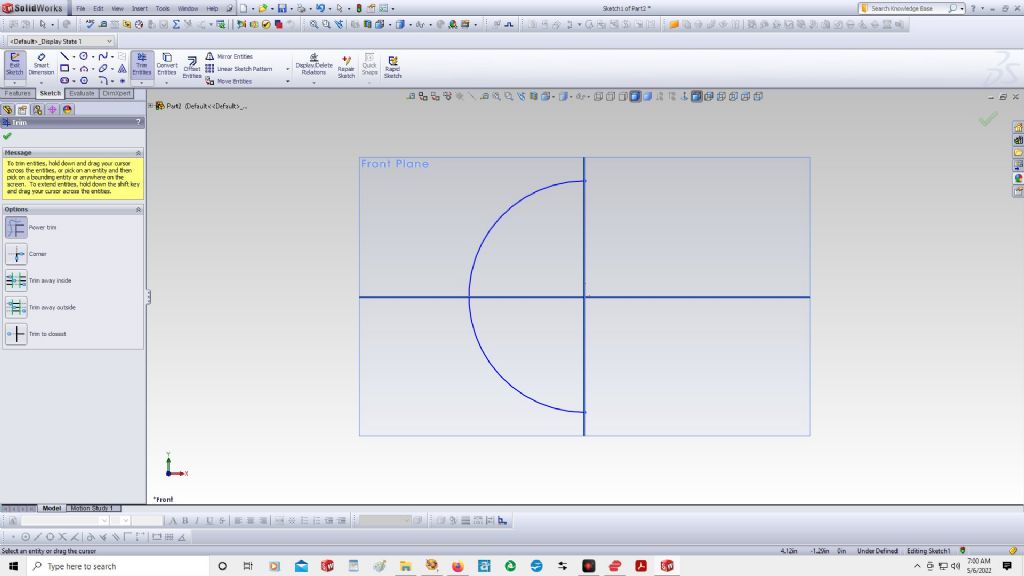

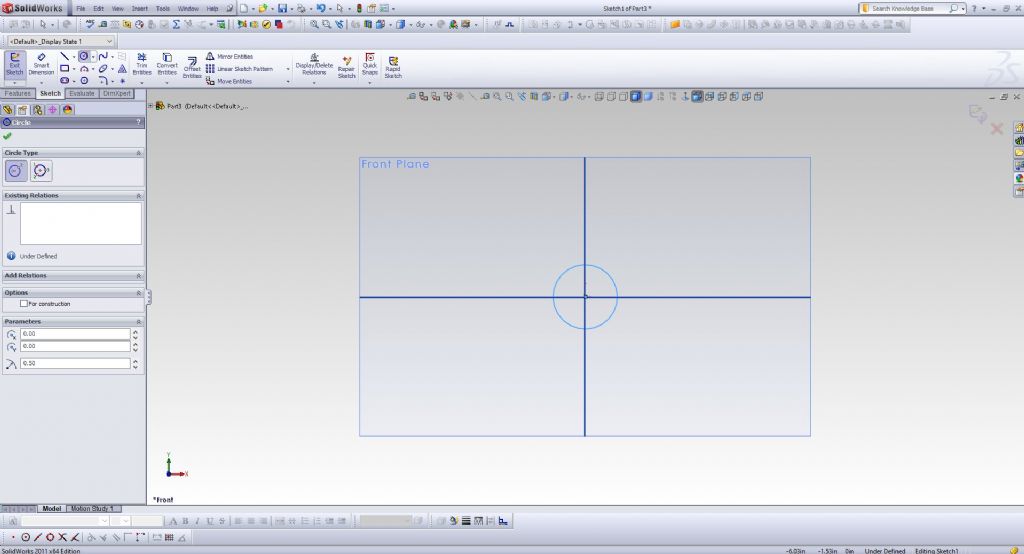

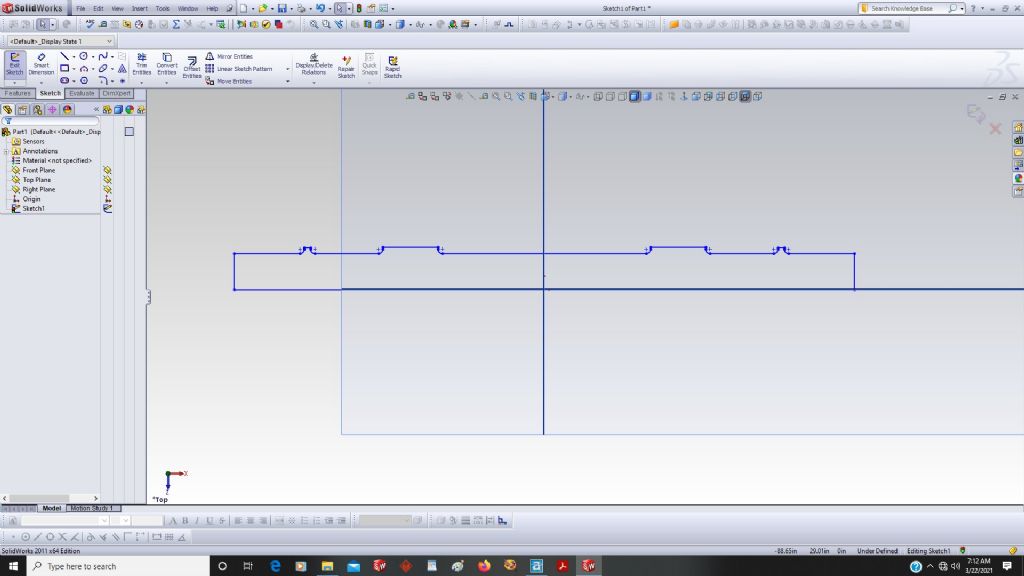

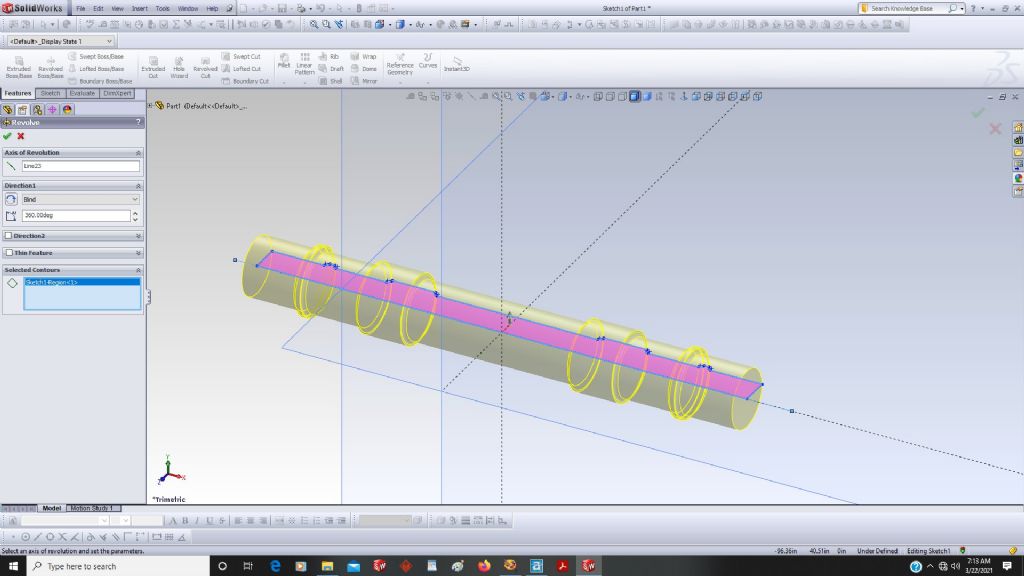

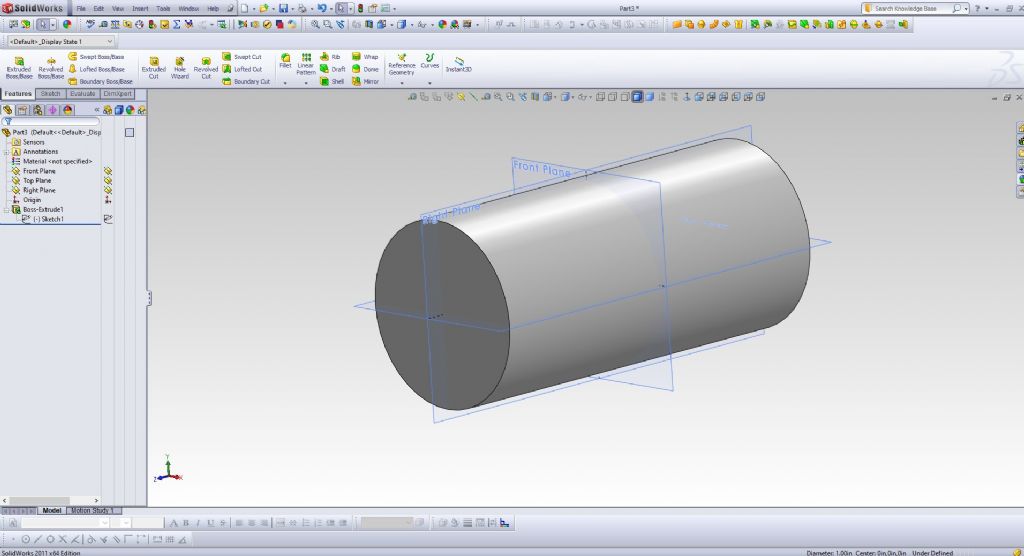

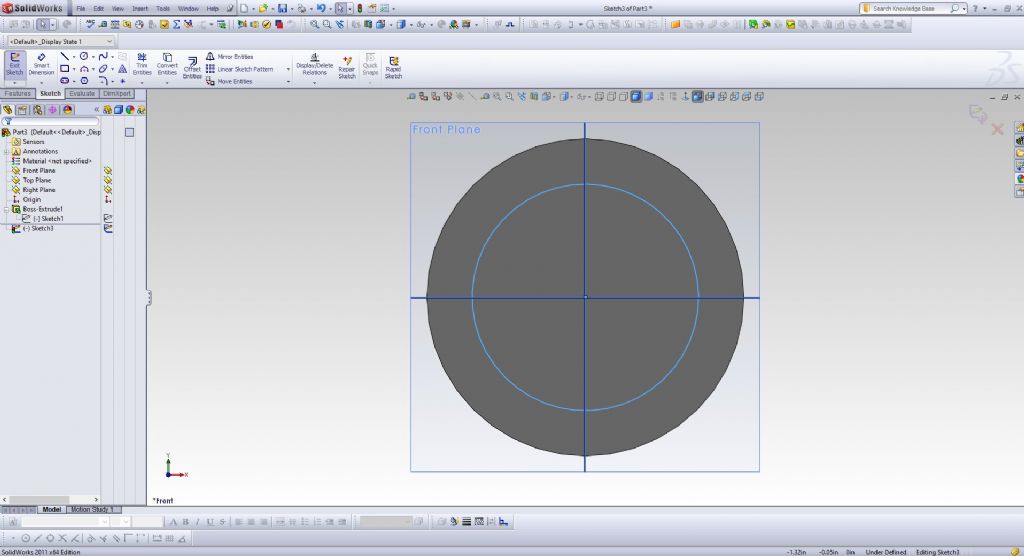

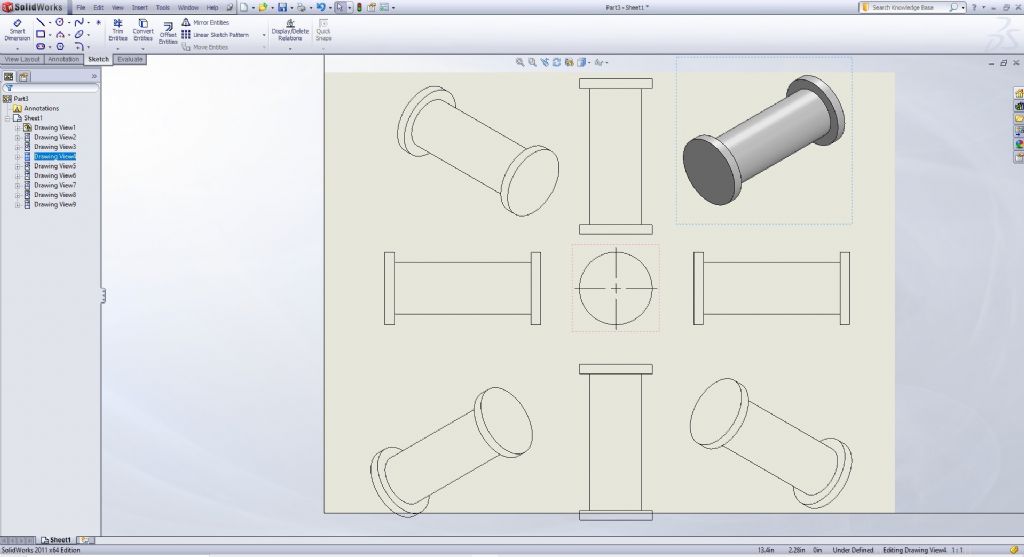

3. Once you have created a 3D model, you can derive the 2D drawing from that model by creating a drawing file, and dragging and dropping the model onto a virtual sheet of paper.

You can drag the model left, right, up, down, and at angles, to automatically create, front, top, side, bottom, isometric, etc. views.

The views can be line drawings, or solids.

You can dimension the views, and if you change your models, the dimensions automatically update to reflect the new dimensions of the part.

Edited By PatJ on 06/05/2022 21:05:16

PatJ.

PatJ.