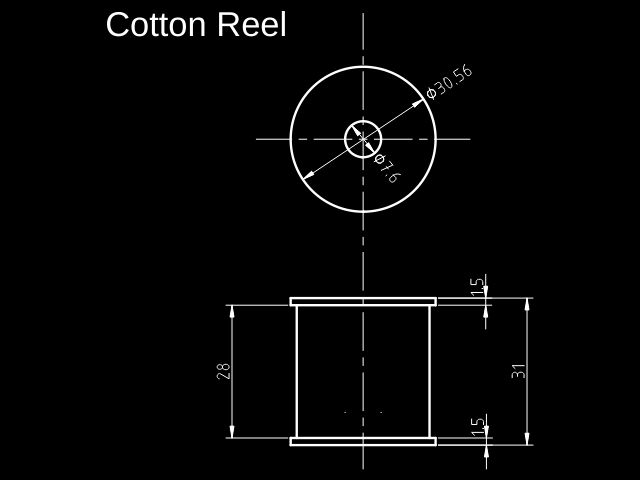

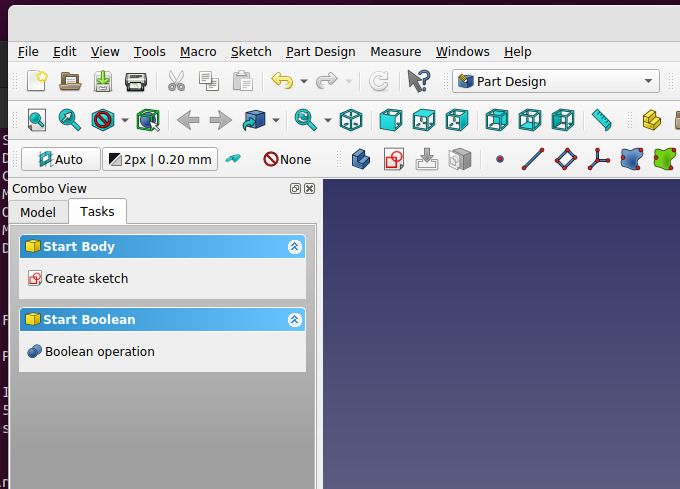

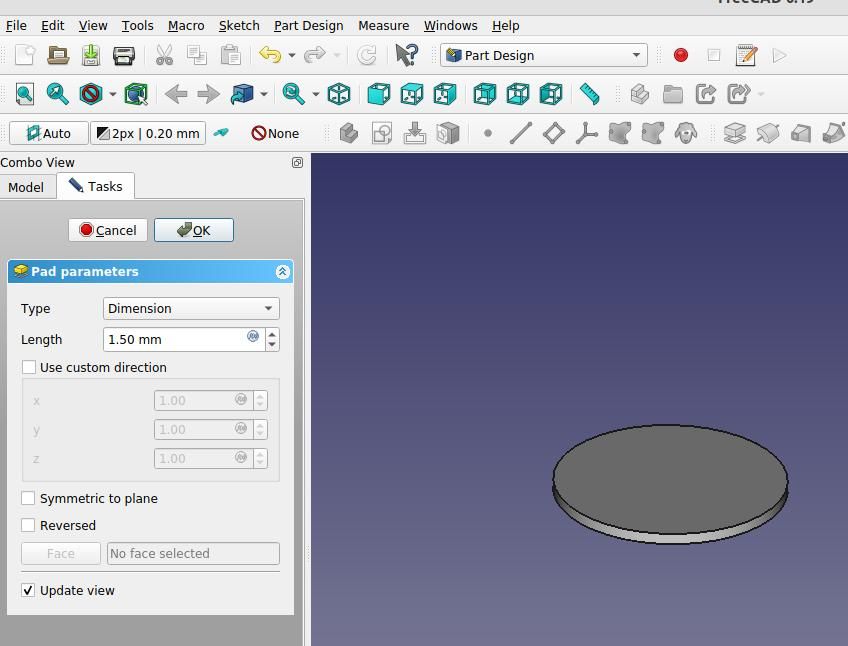

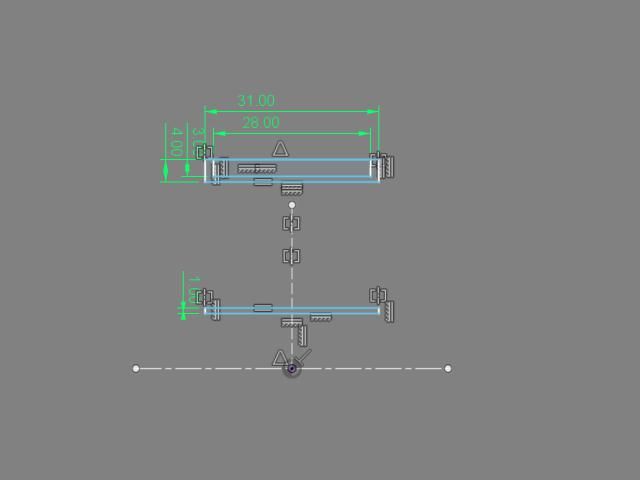

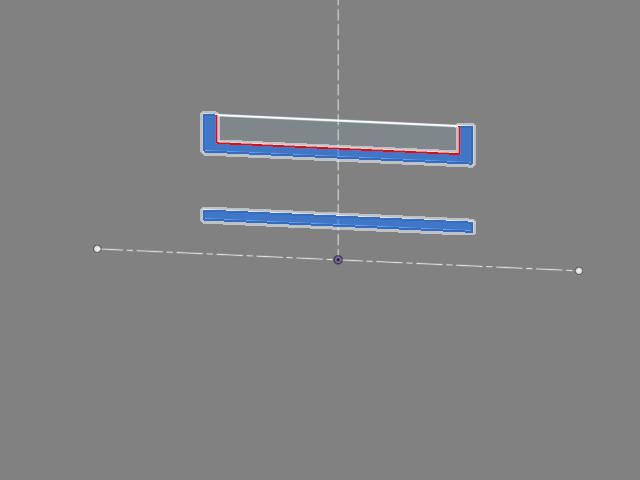

Click Pad and set the pad dimension to 1.5mm. Click to update the screen This pad creates the bottom of the cotton reel.

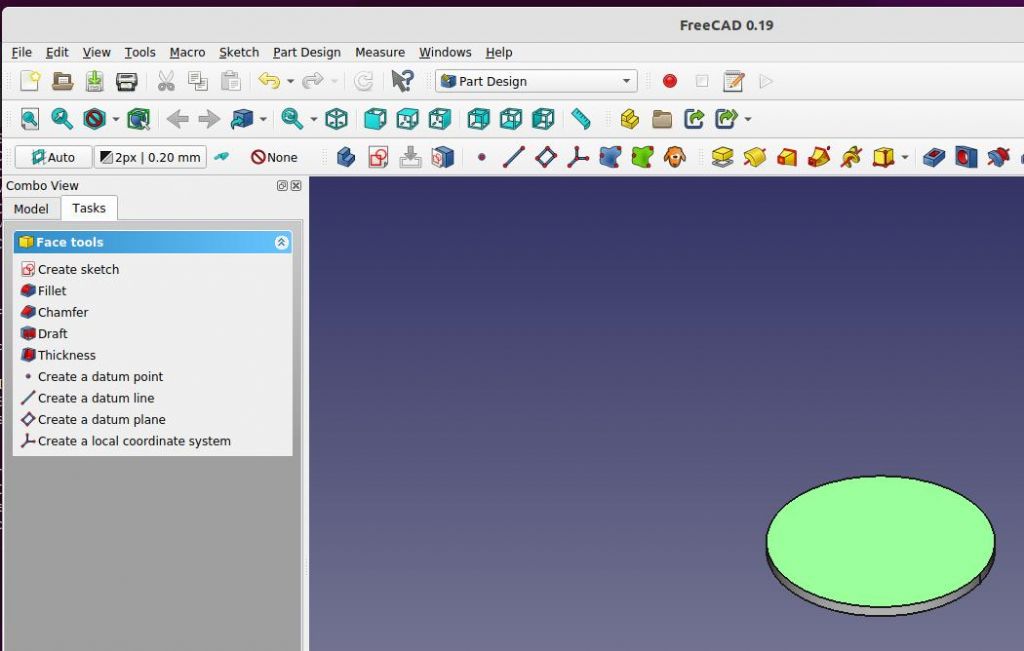

Click OK to close the Pad dialog, then select the top face of the cotton reel to select it. Should change colour:

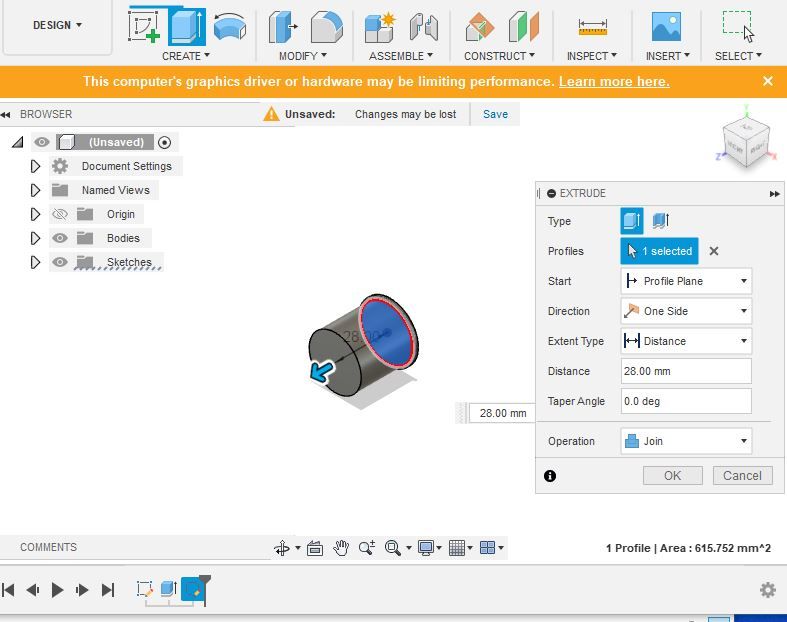

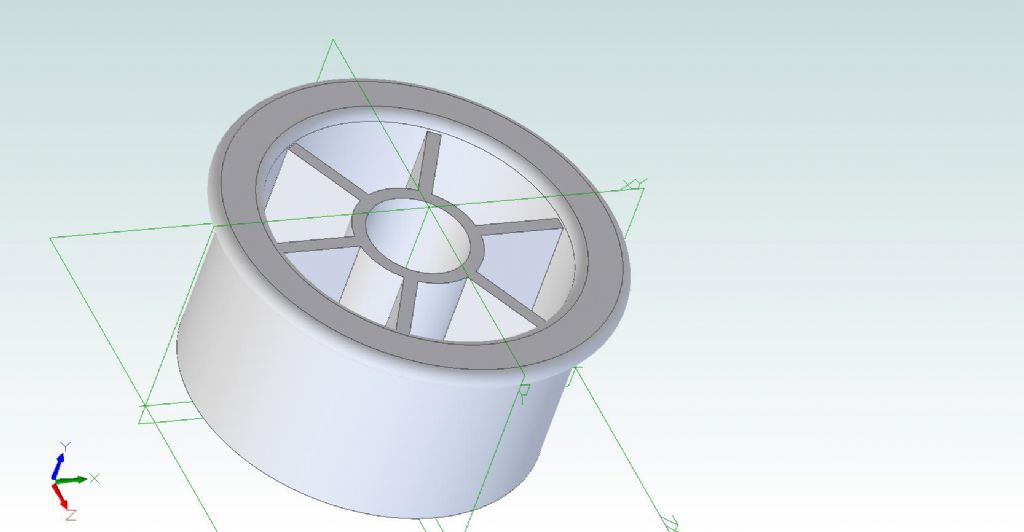

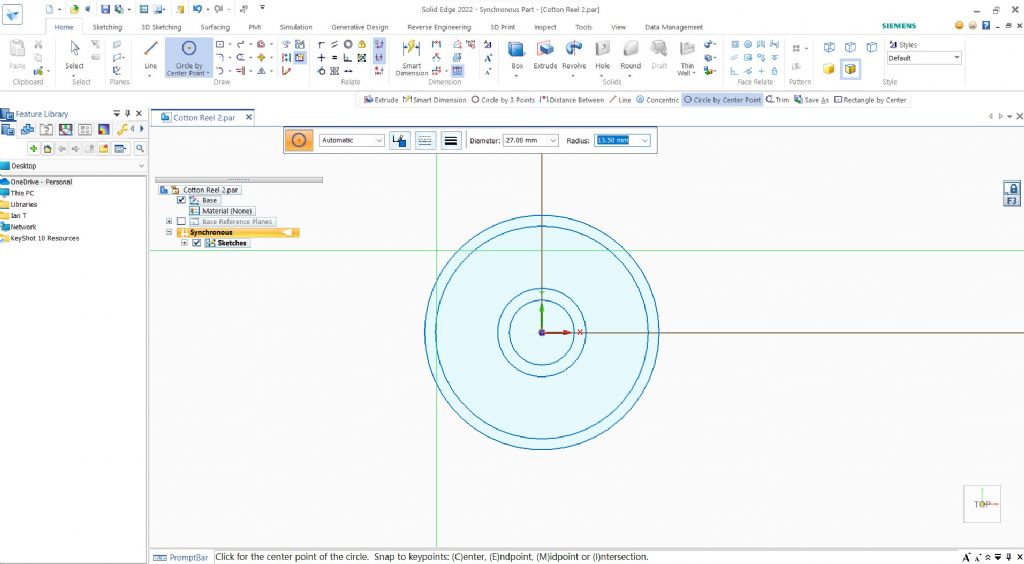

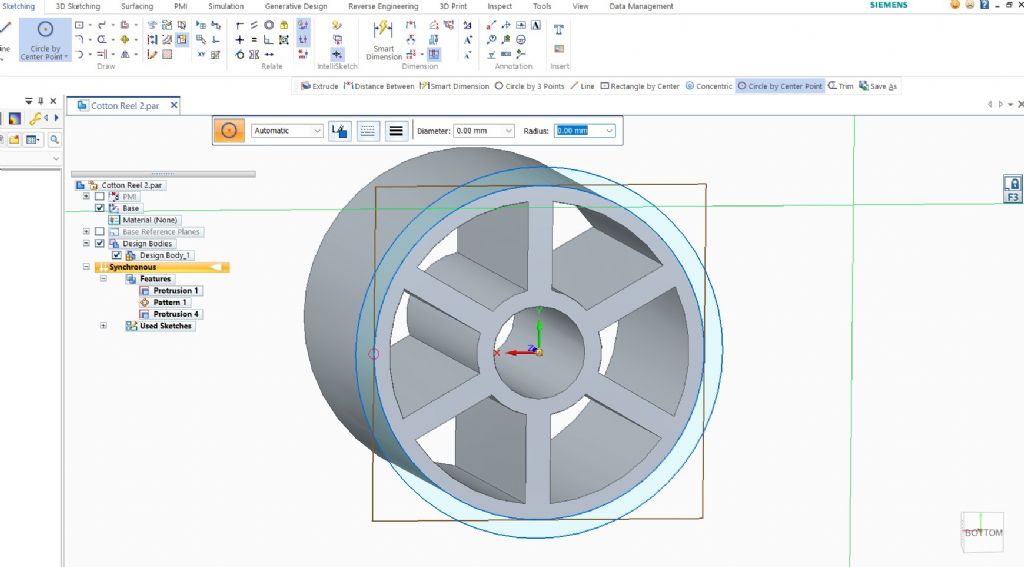

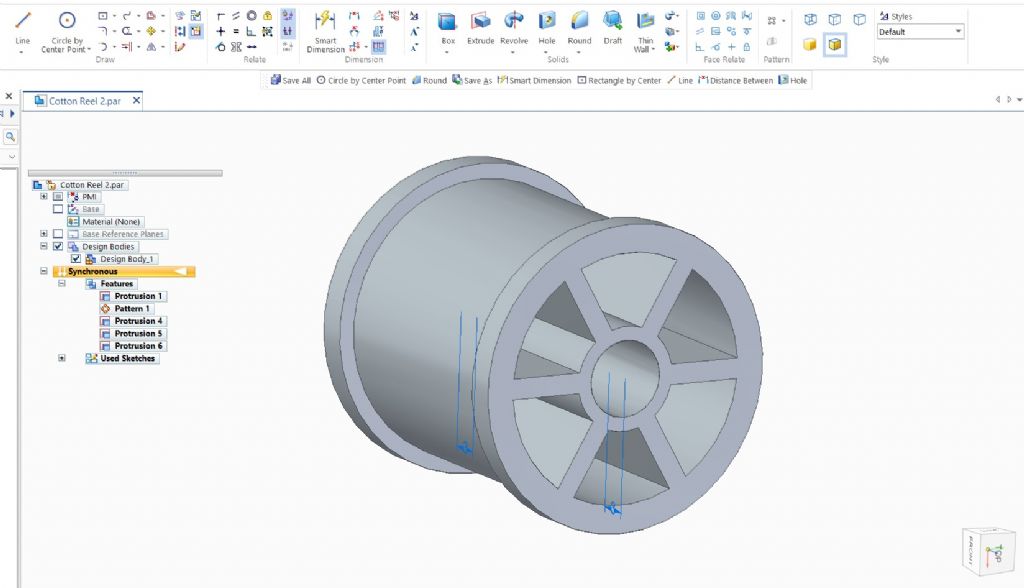

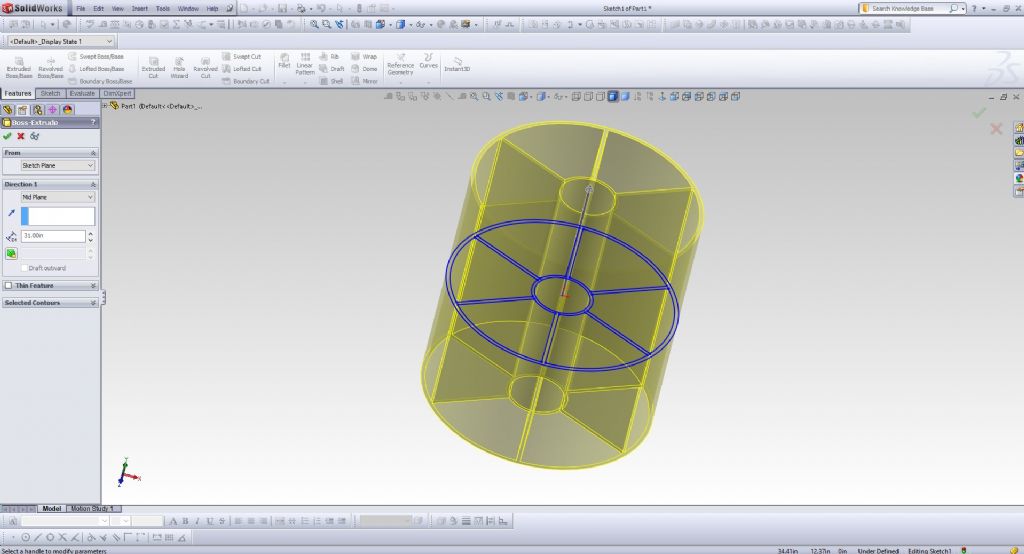

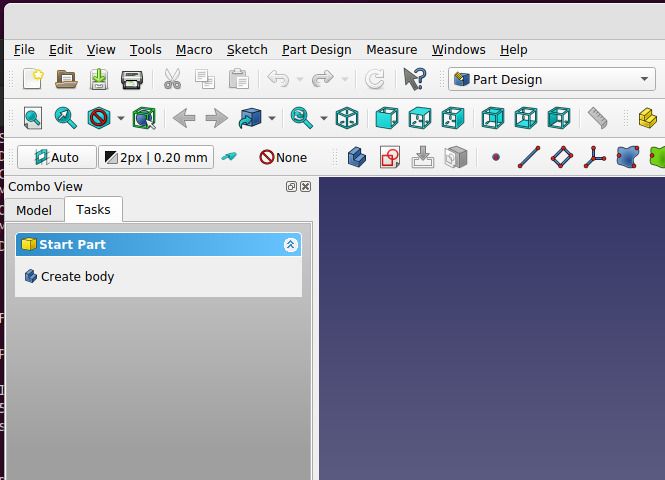

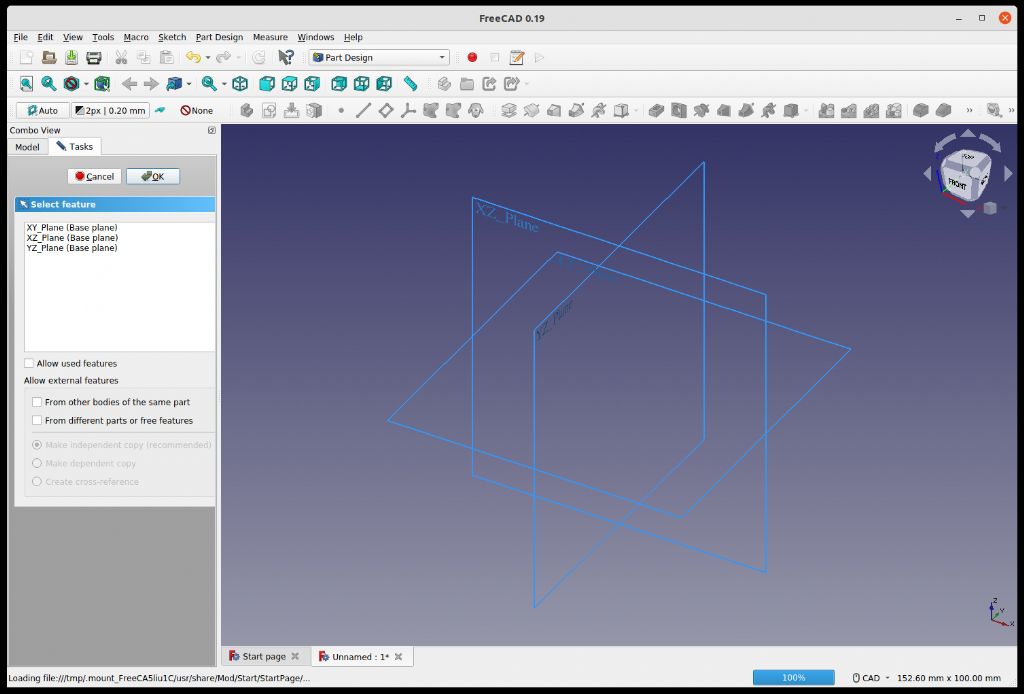

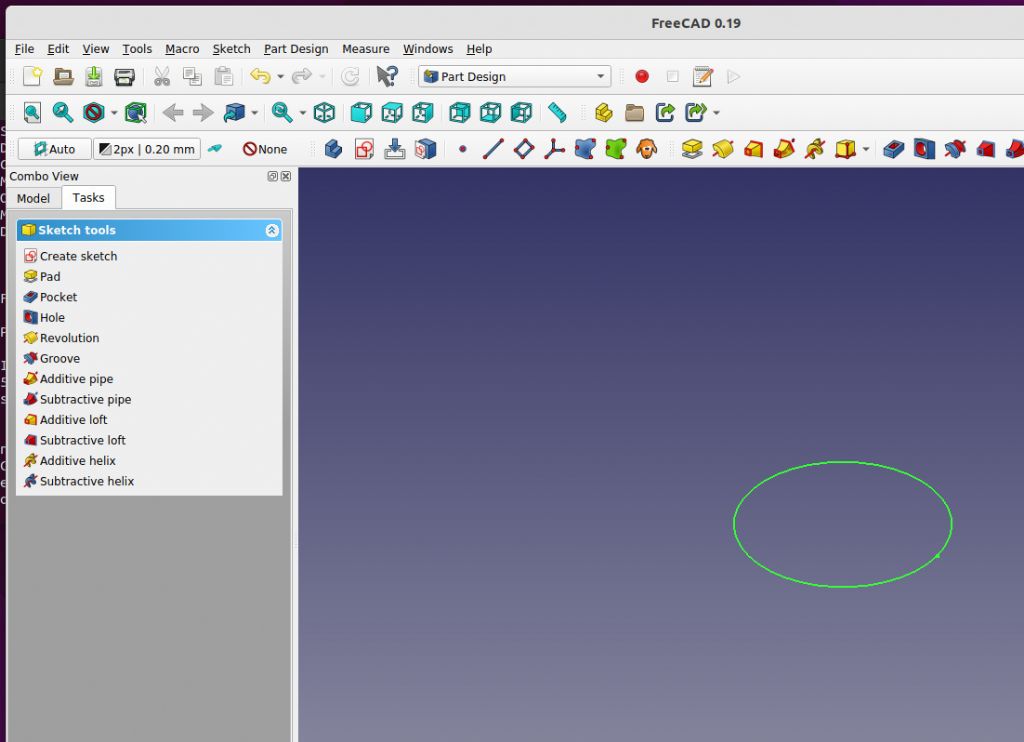

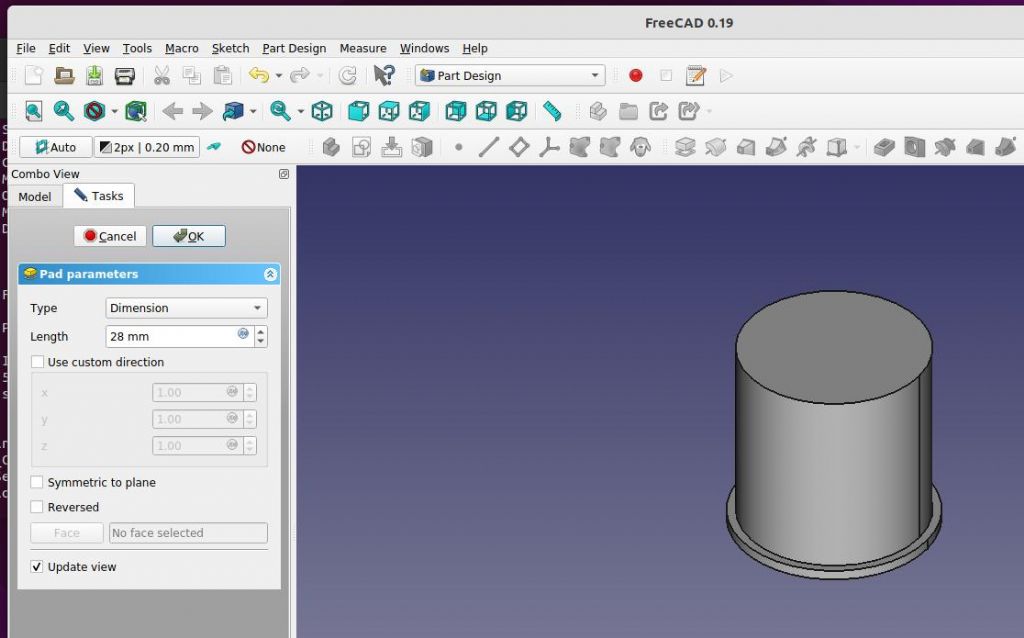

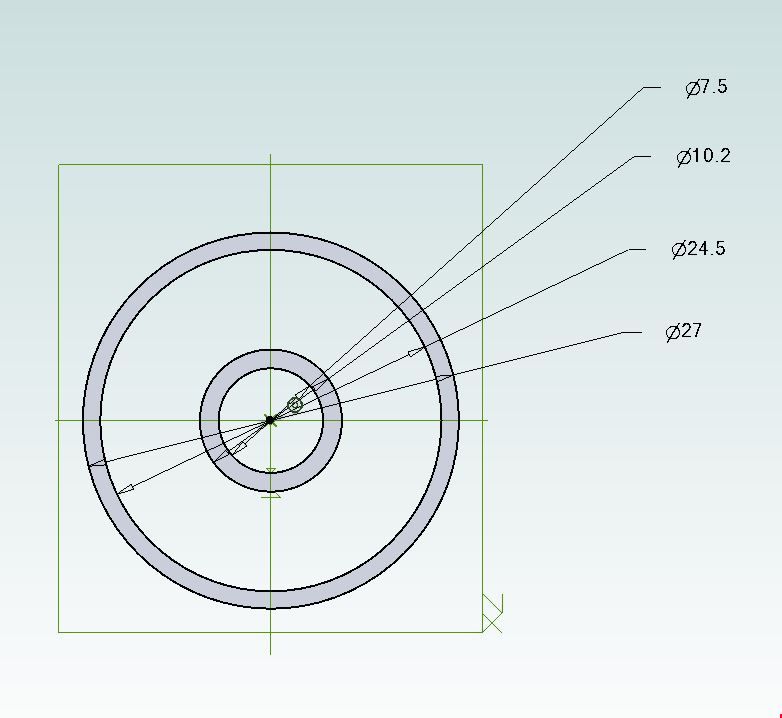

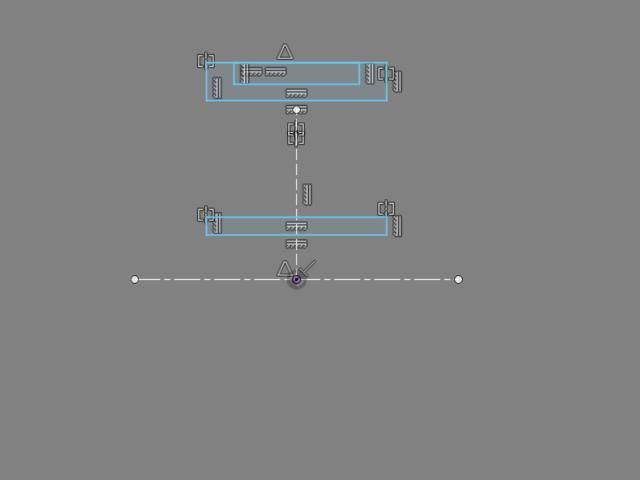

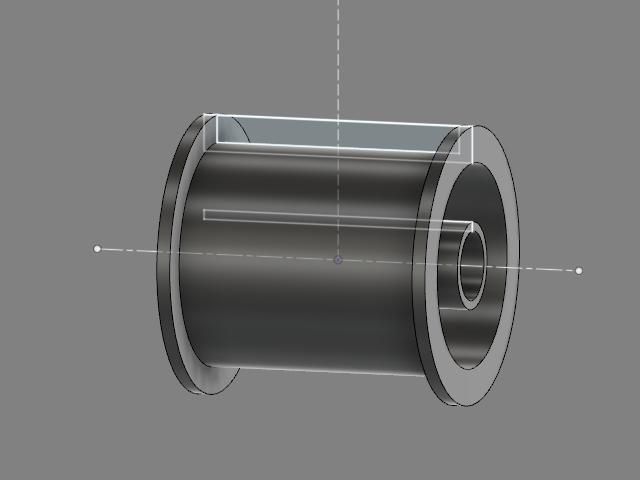

The option to Create Sketch has reappeared, so click on it allowing allowing a new sketch to be added to the object. Draw another circle and constrain it to 28.00mm Closing the sketch allows this one to be padded as well. Press pad and set the dimension to 28mm as well. OK the Pad, to reveal:

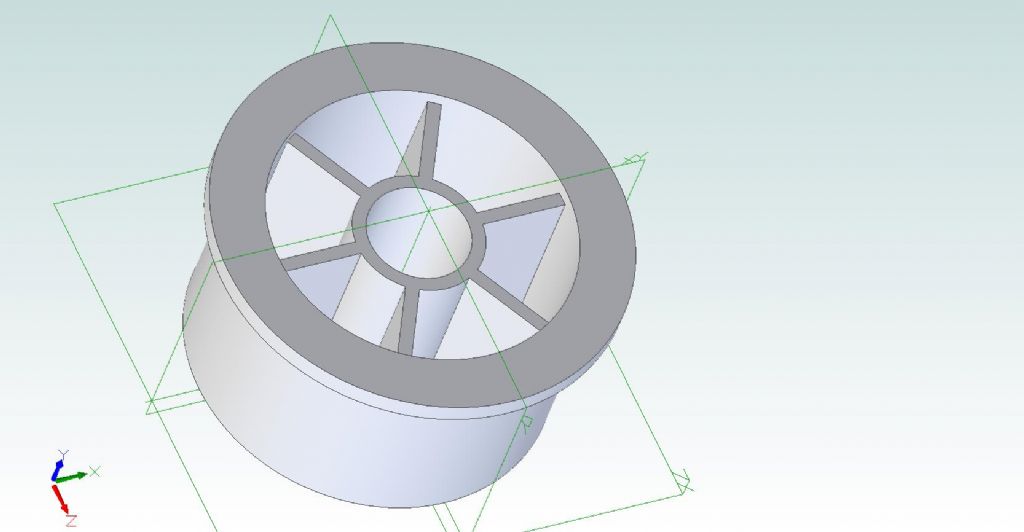

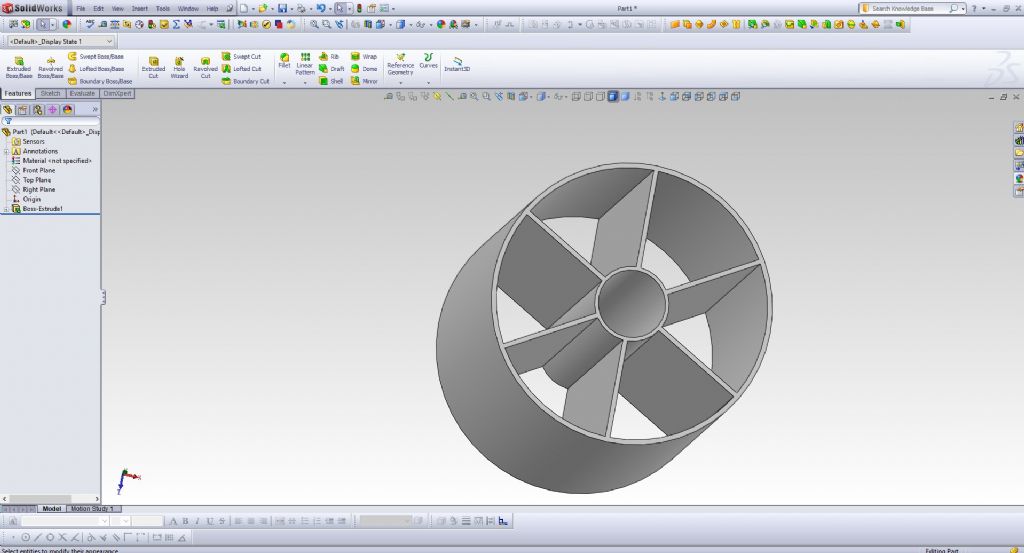

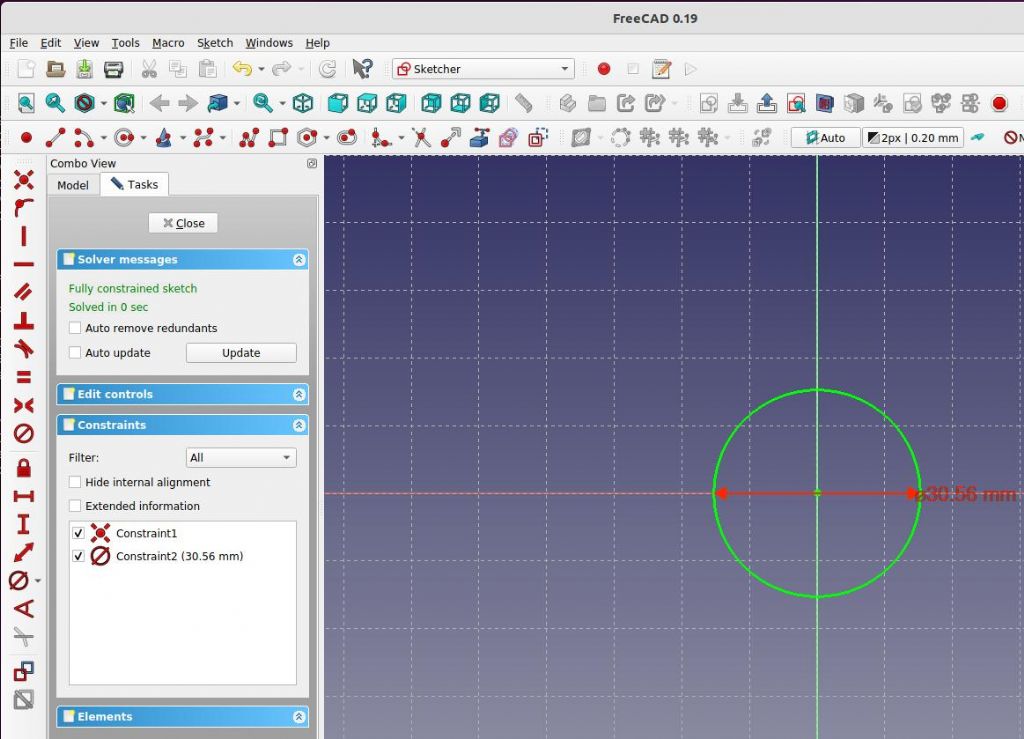

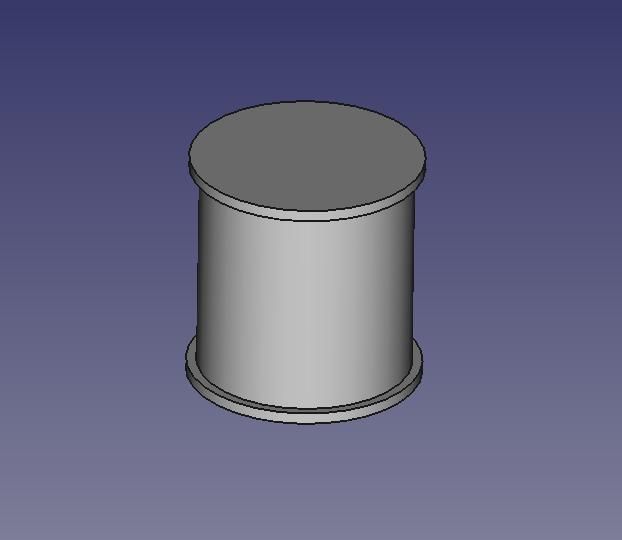

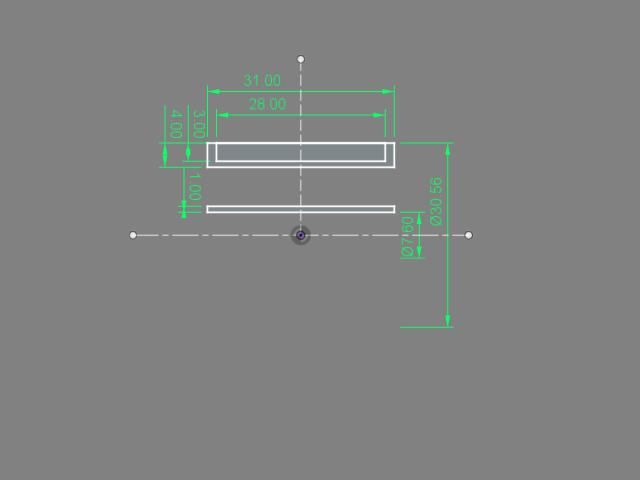

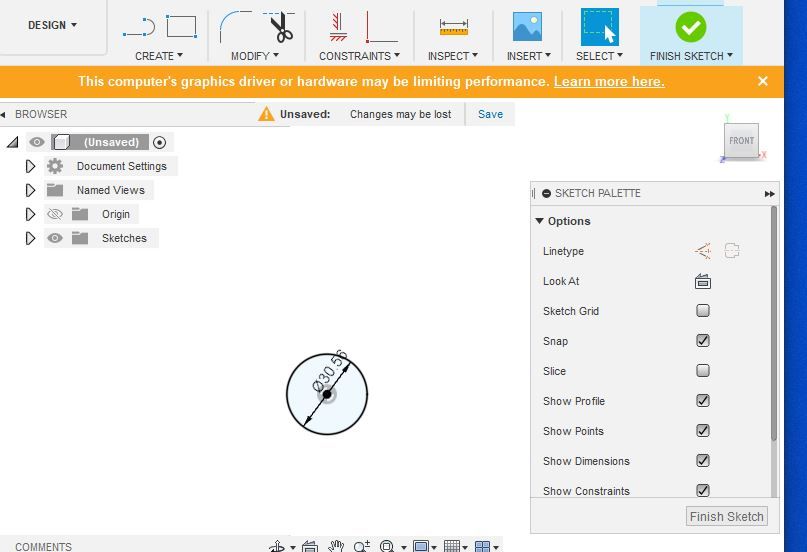

In the same way, select the top face again by clicking it, create a new sketch with a circle diameter of 30.56mm, close the sketch, and Pad to 1.5mm:

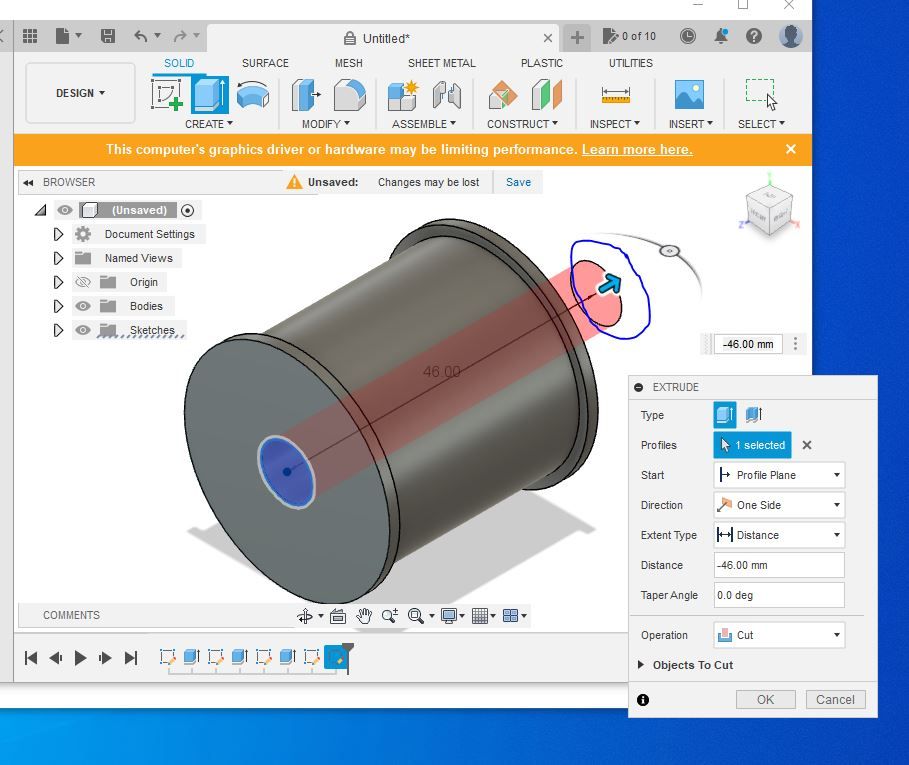

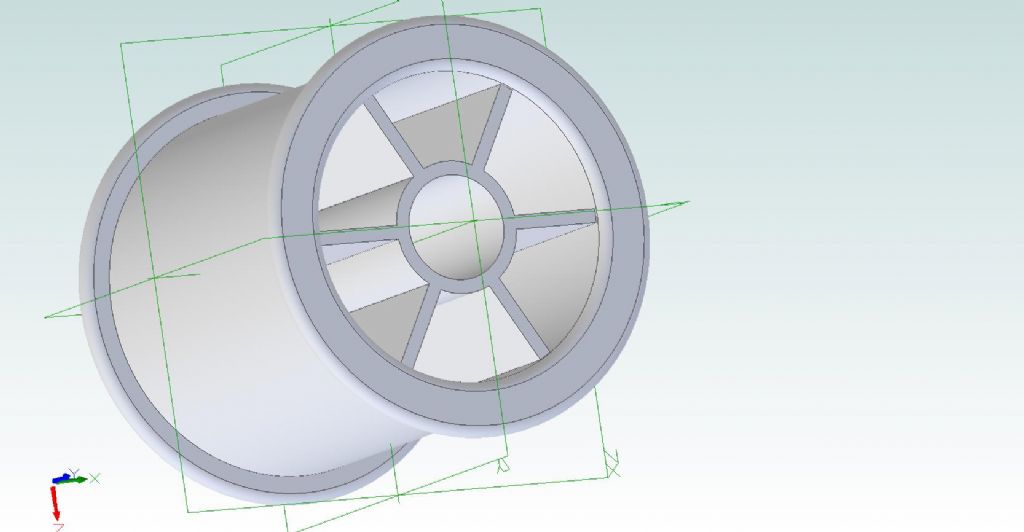

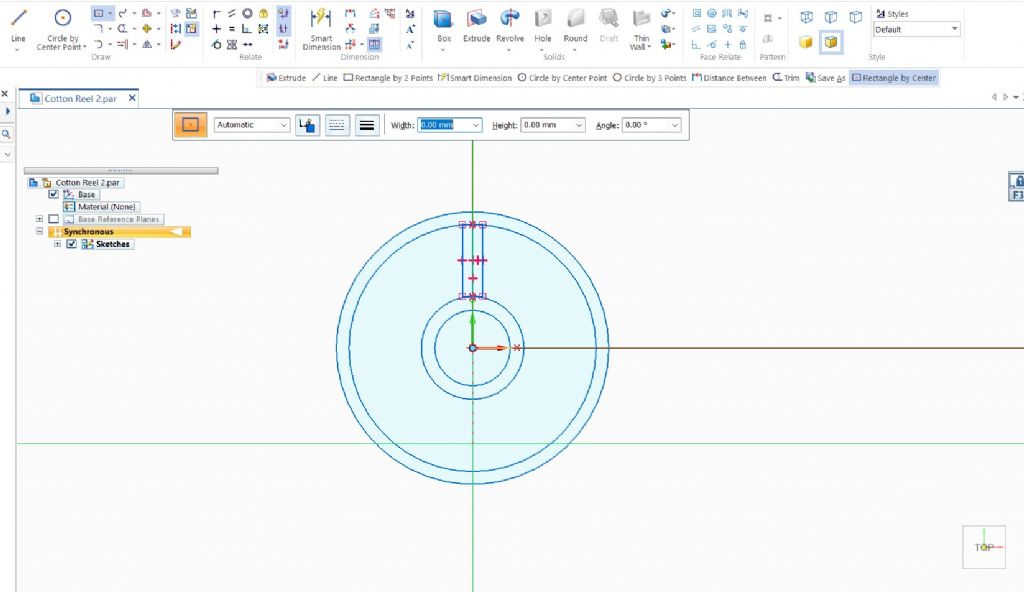

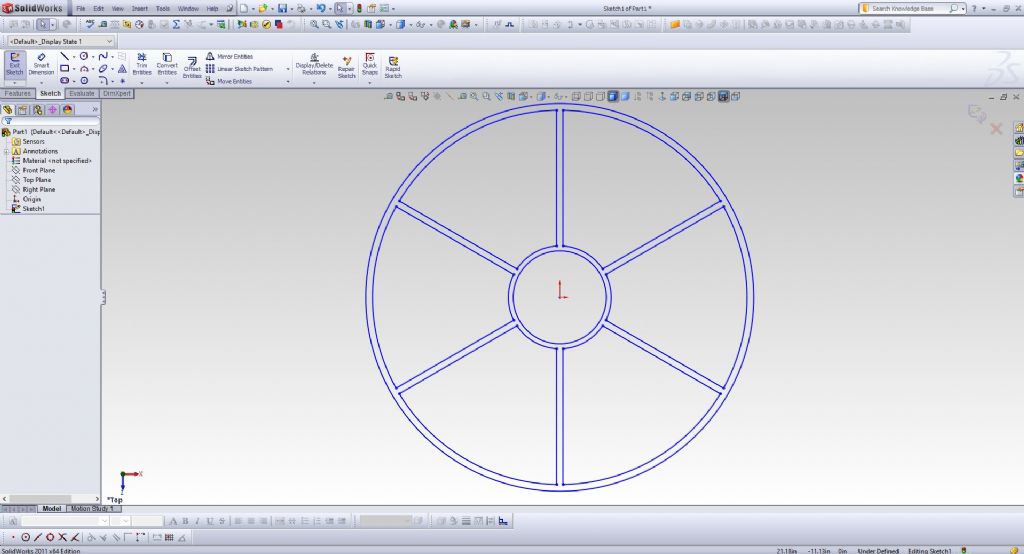

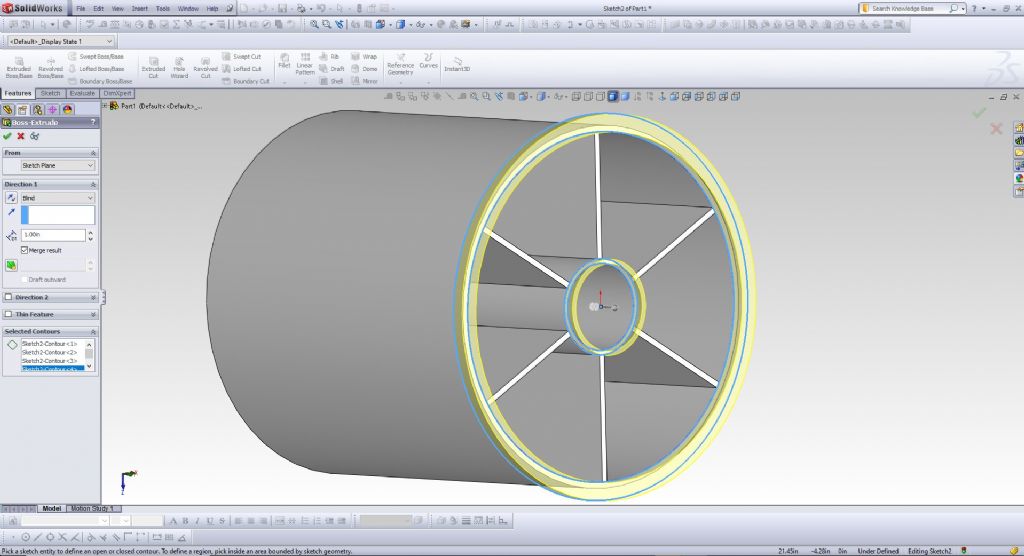

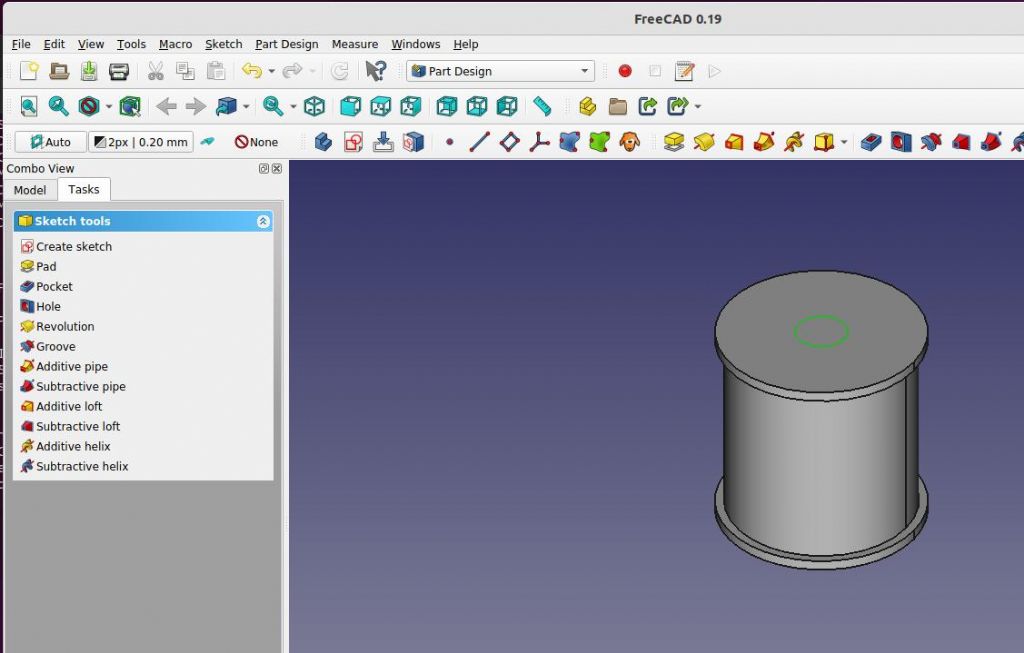

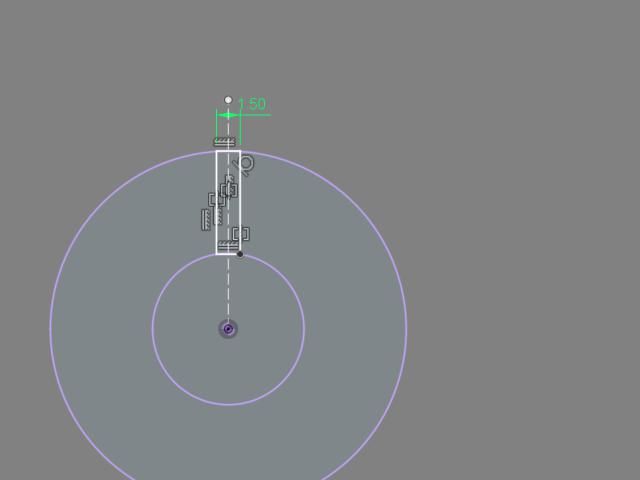

To add the hole, select the top face and create another sketch, this time making it 7.6mm diameter. Close the sketch:

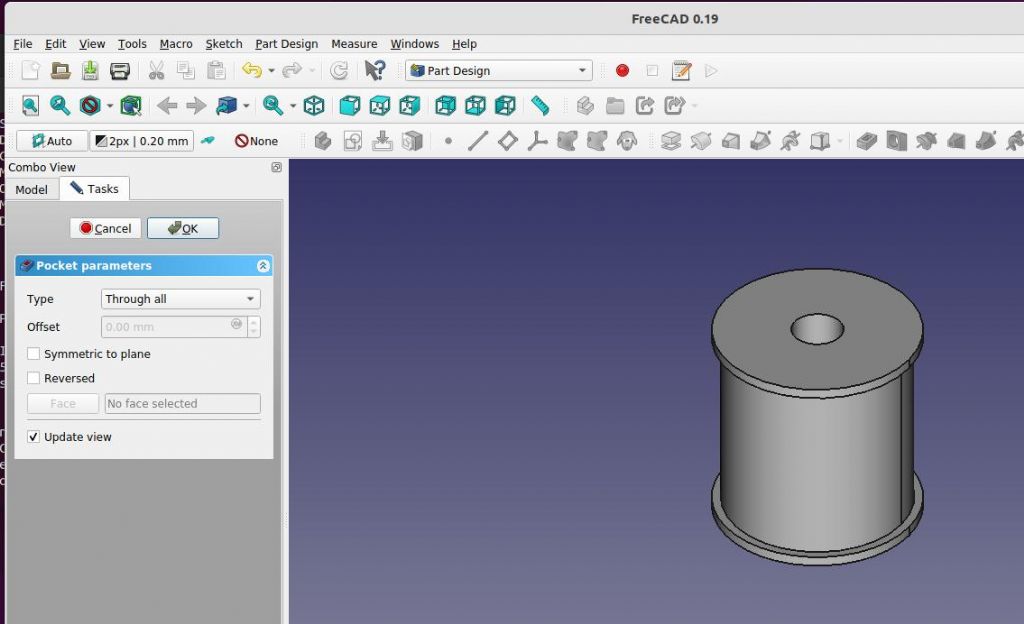

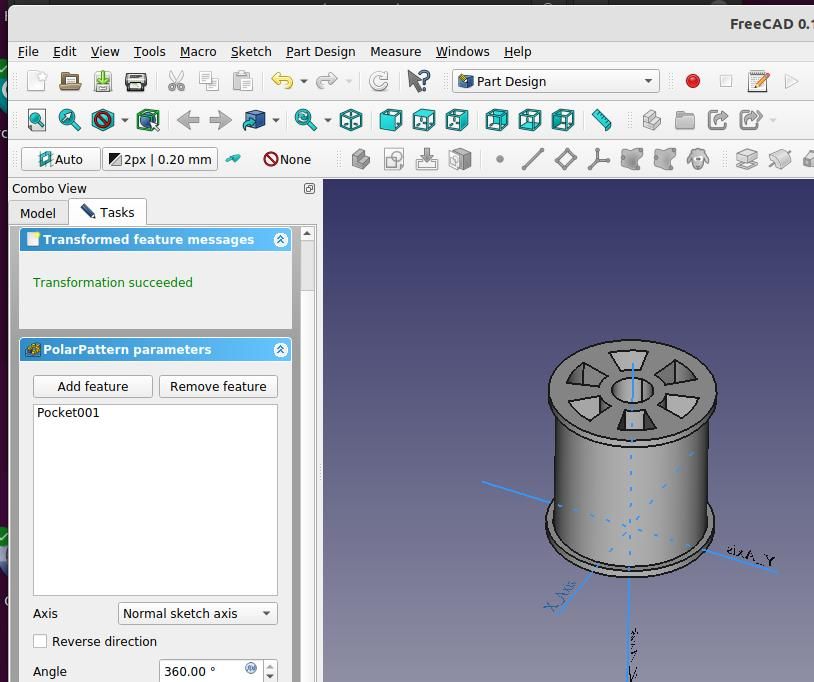

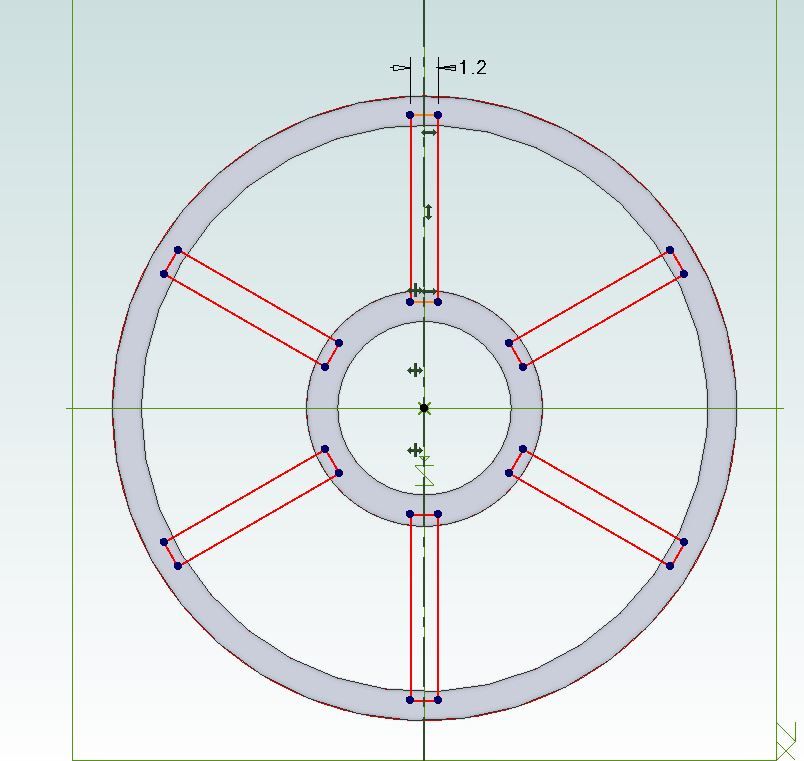

This time select the Pocket tool (Pad adds, Pocket subtracts). Set Type to 'Through All' and the hole is drilled.

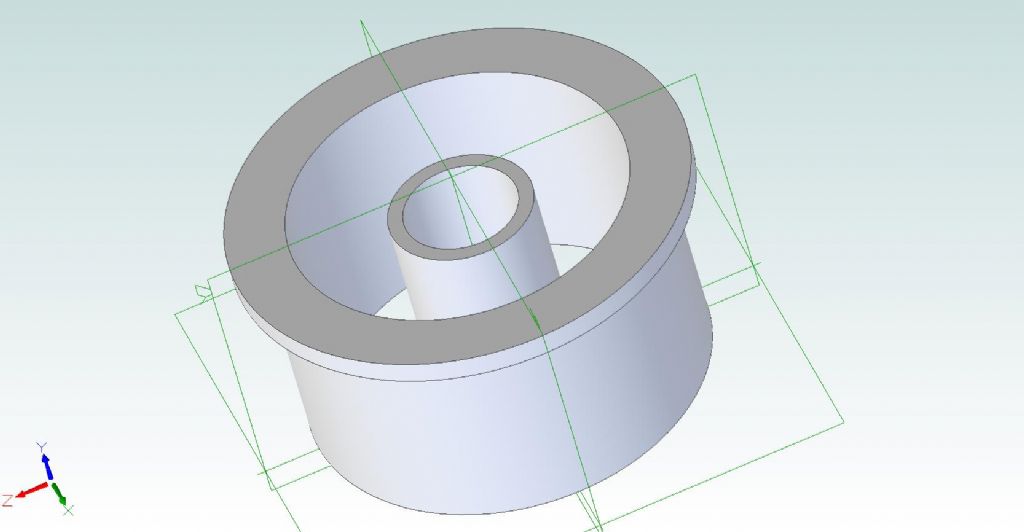

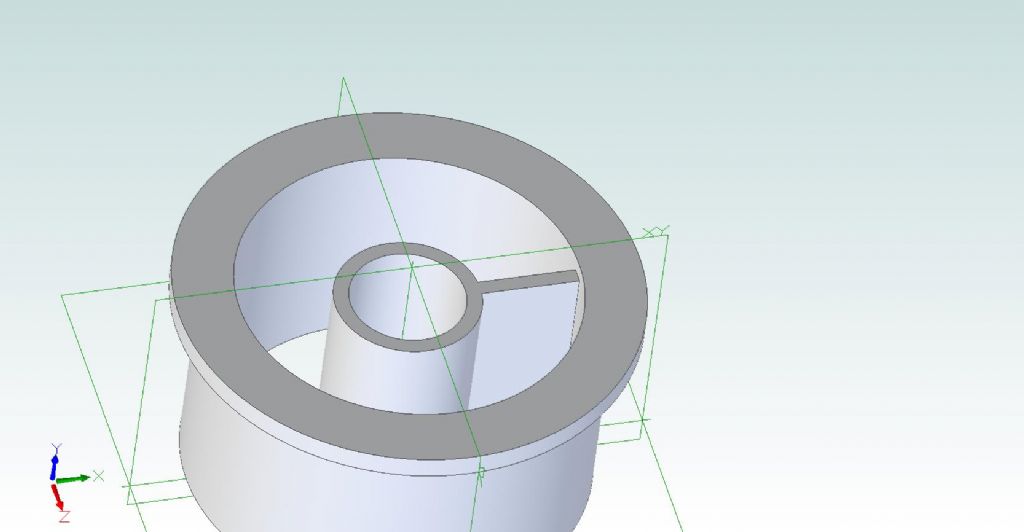

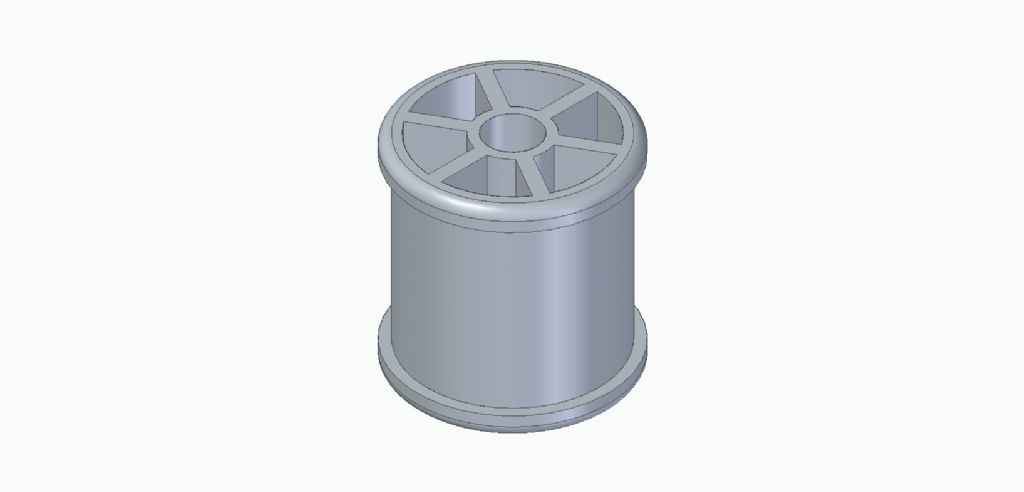

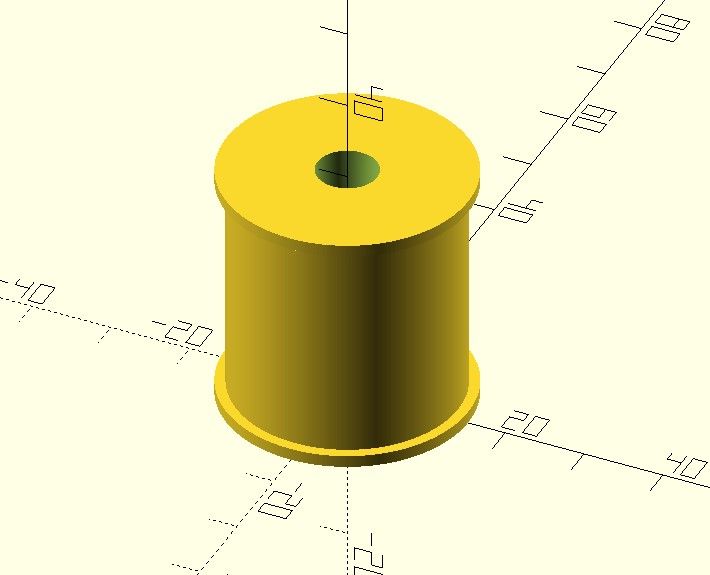

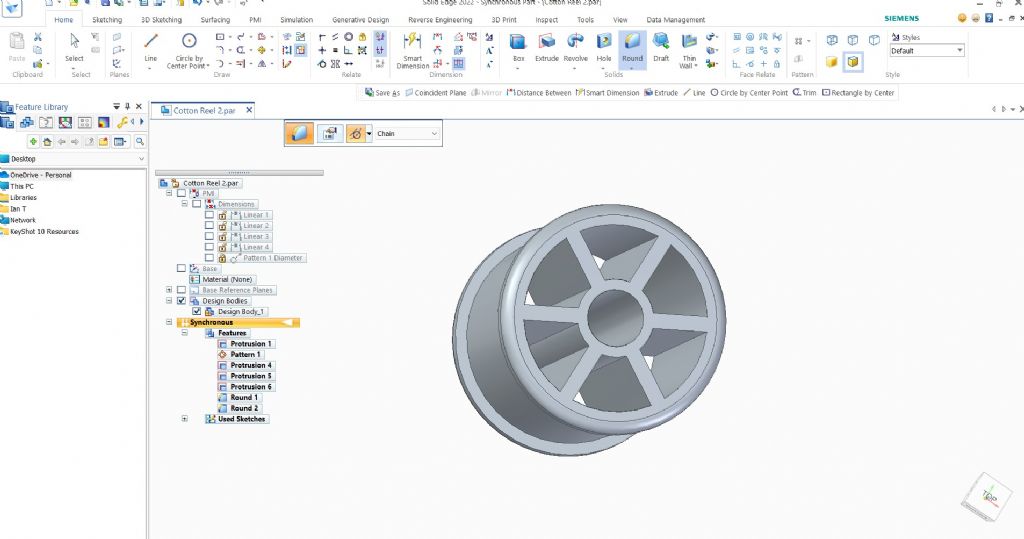

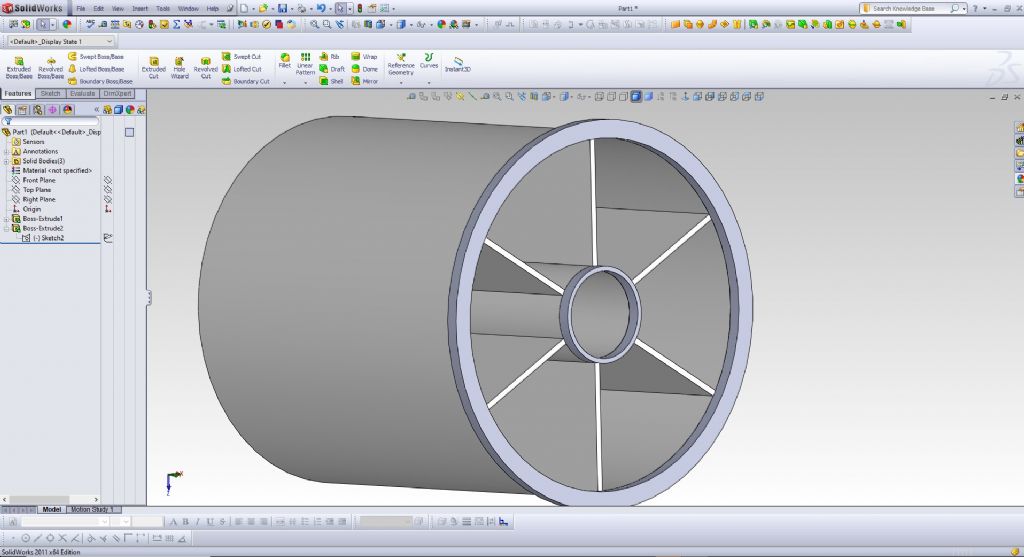

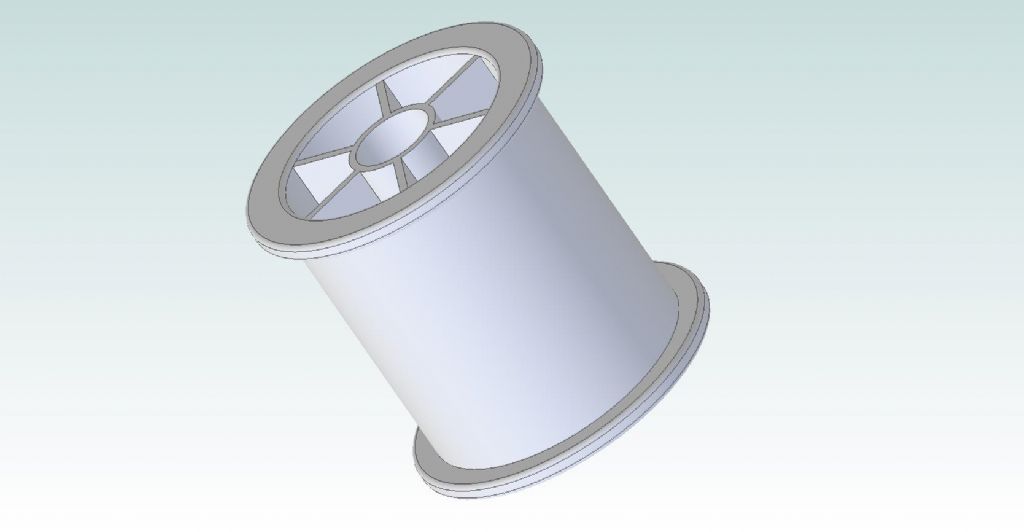

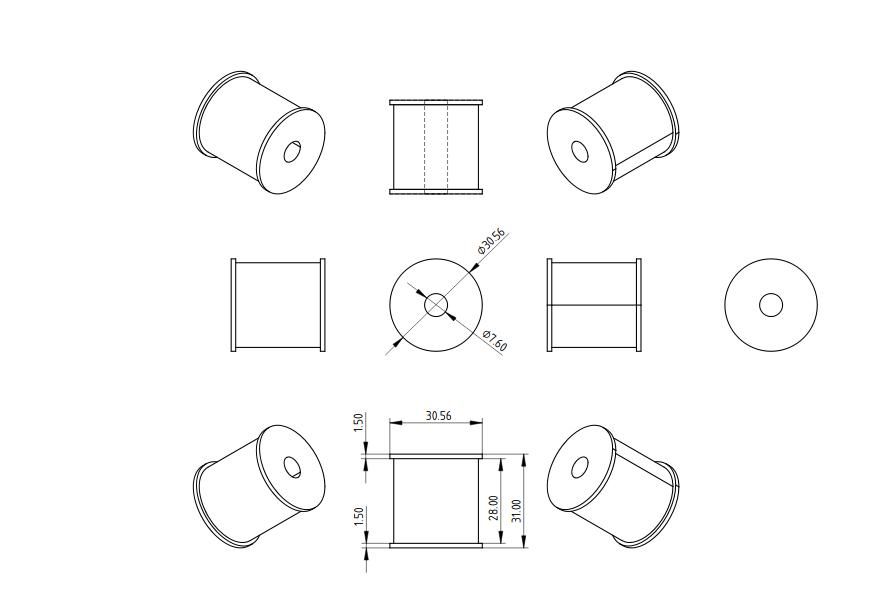

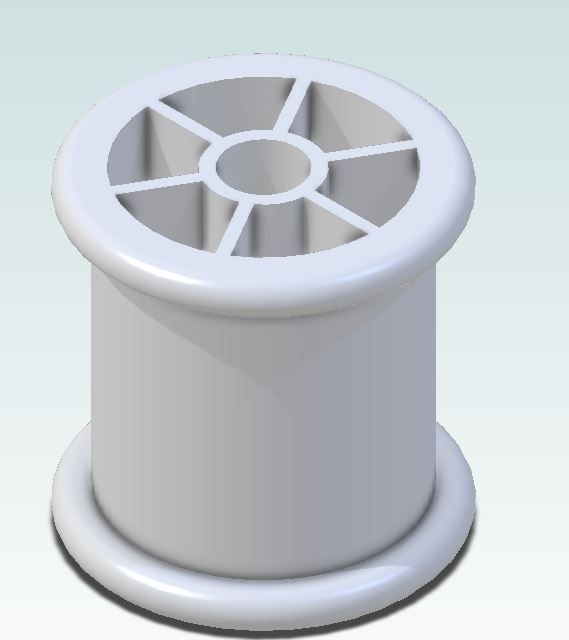

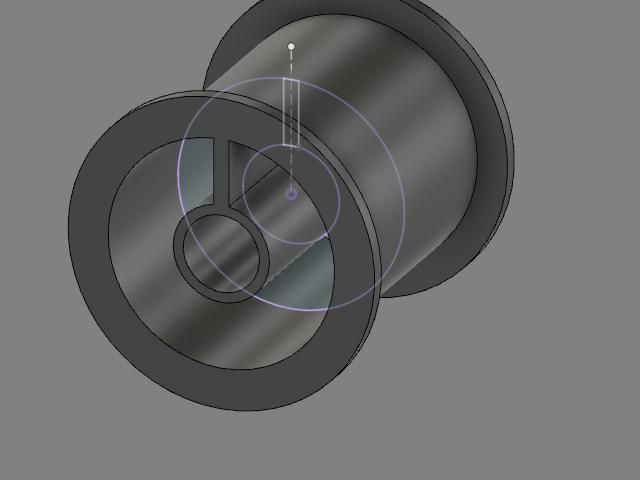

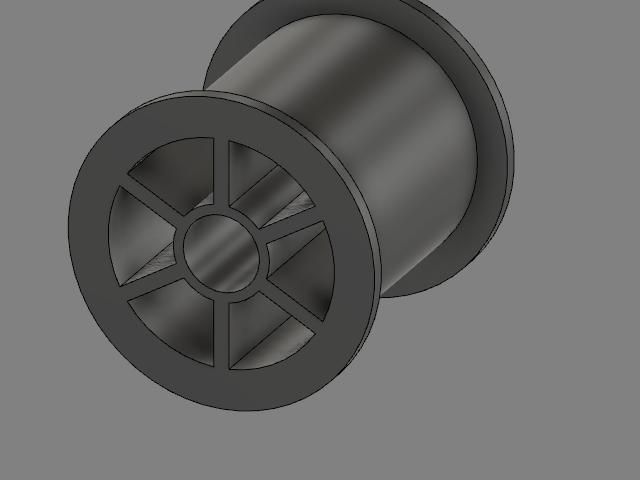

Closing Pocket leaves us with a completed model cotton reel. FreeCAD understands it to represent a solid and can use it to generate the usual 2D projections, to which the user can add dimensions, notes and sections:

Or to export the object as a mesh or STL. These define the outer envelope of the solid and are used by other software to generate the additive g-code needed by a printer or the subtractive g-code needed by a CNC machine to cut metal.

Takes much longer to describe than do.

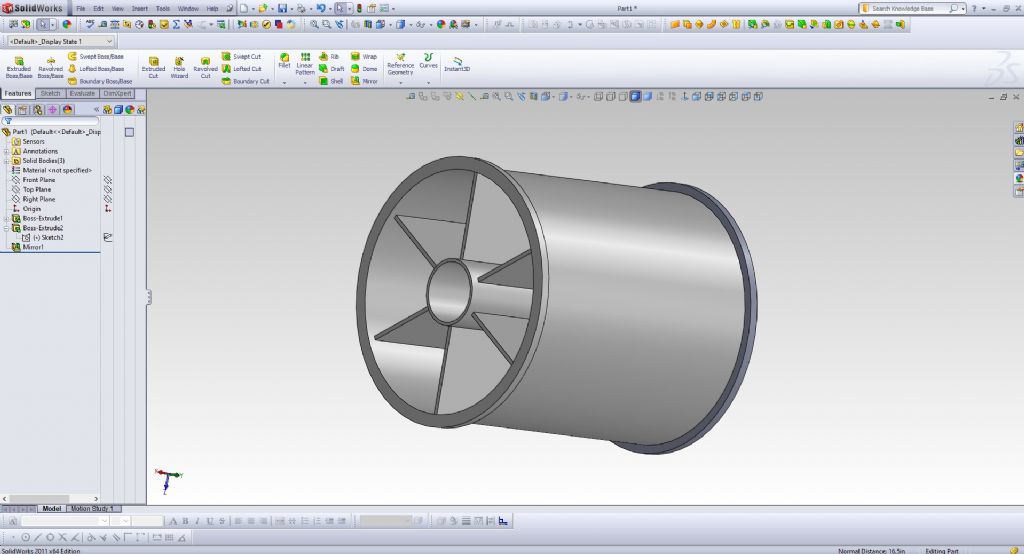

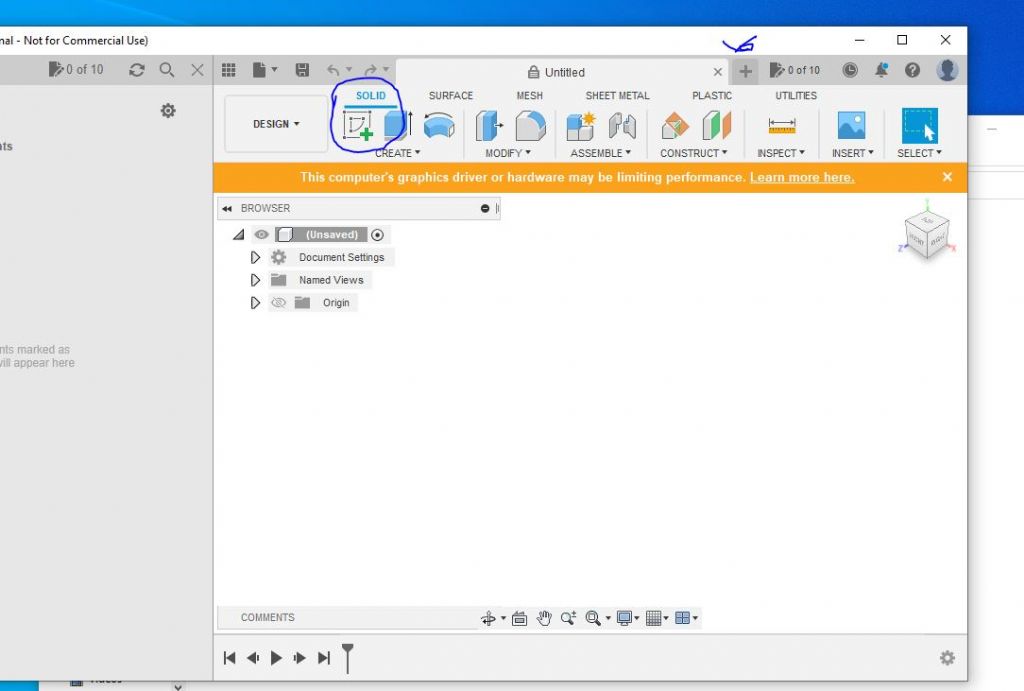

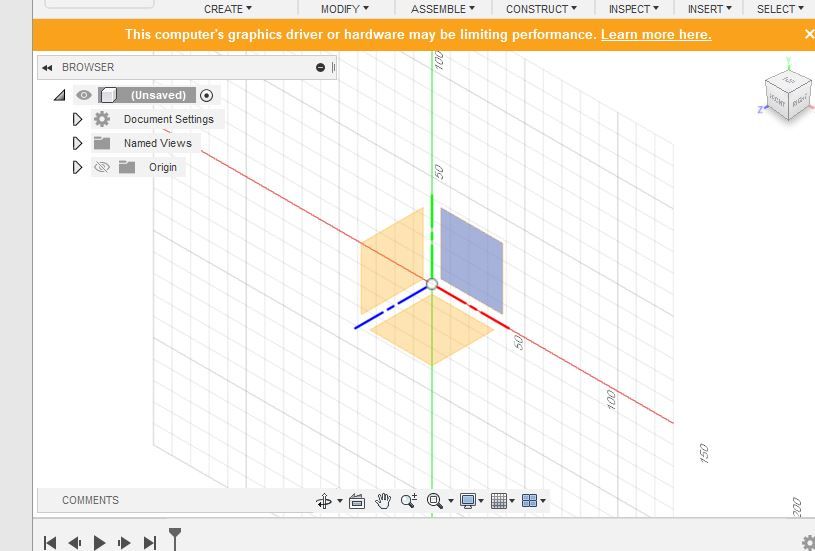

Fusion 360 next, after a nap and strong coffee. Delighted to see others submit the same job in Alibre, TurboCAD, MOI, Draftsight, Solidworks or any other favourite. Please don't cheat by doing it with one sketch and a rotate: I want to show how pad/extrude work with a succession of sketches.

Dave

David Jupp.

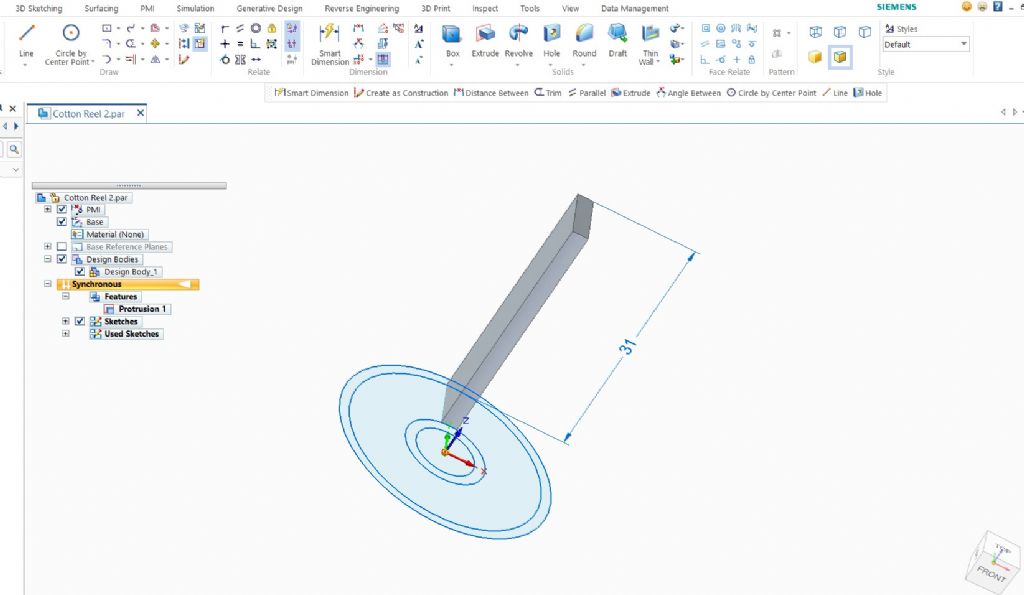

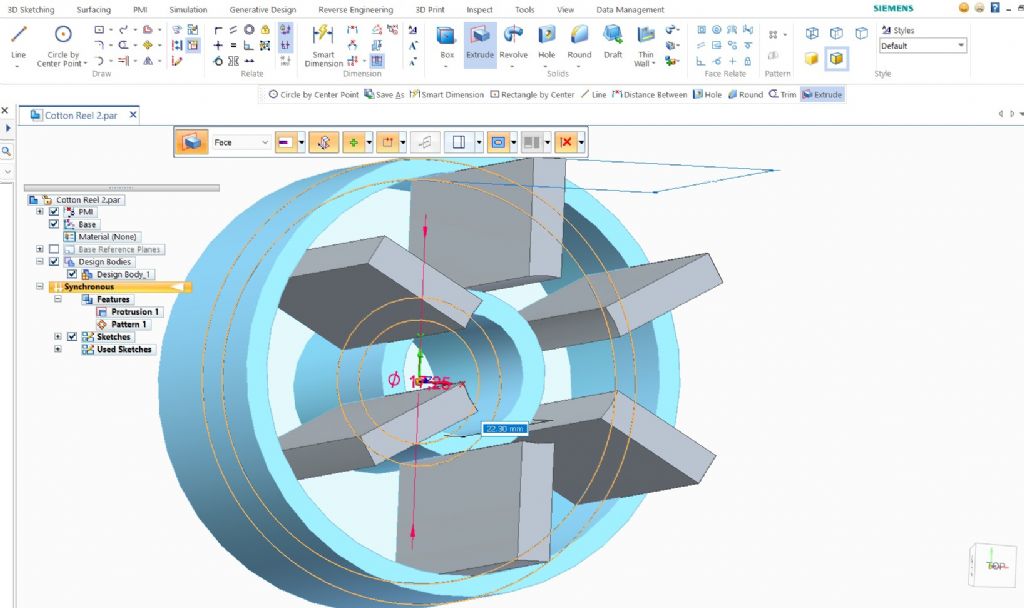

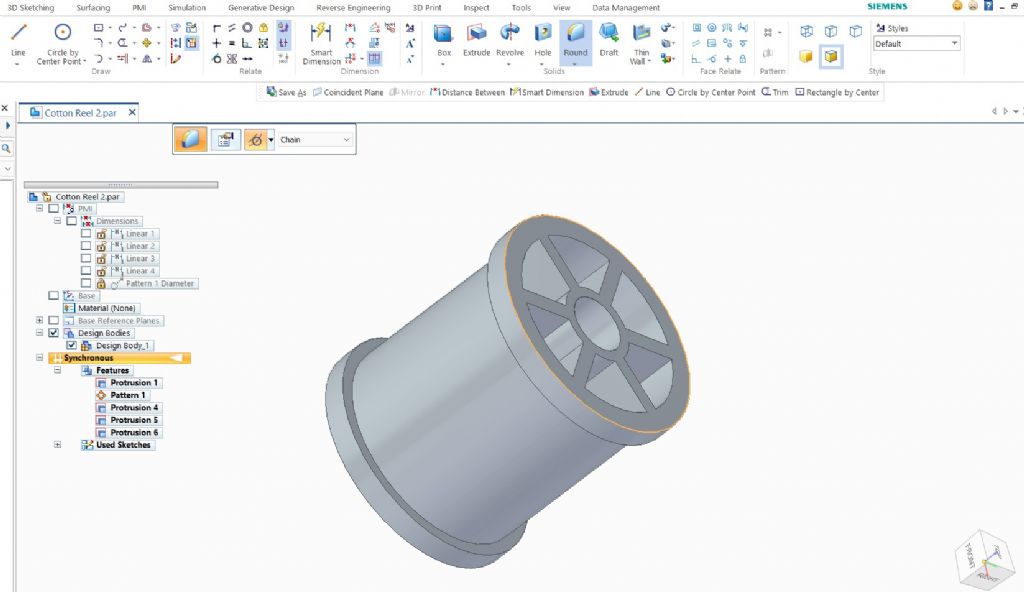

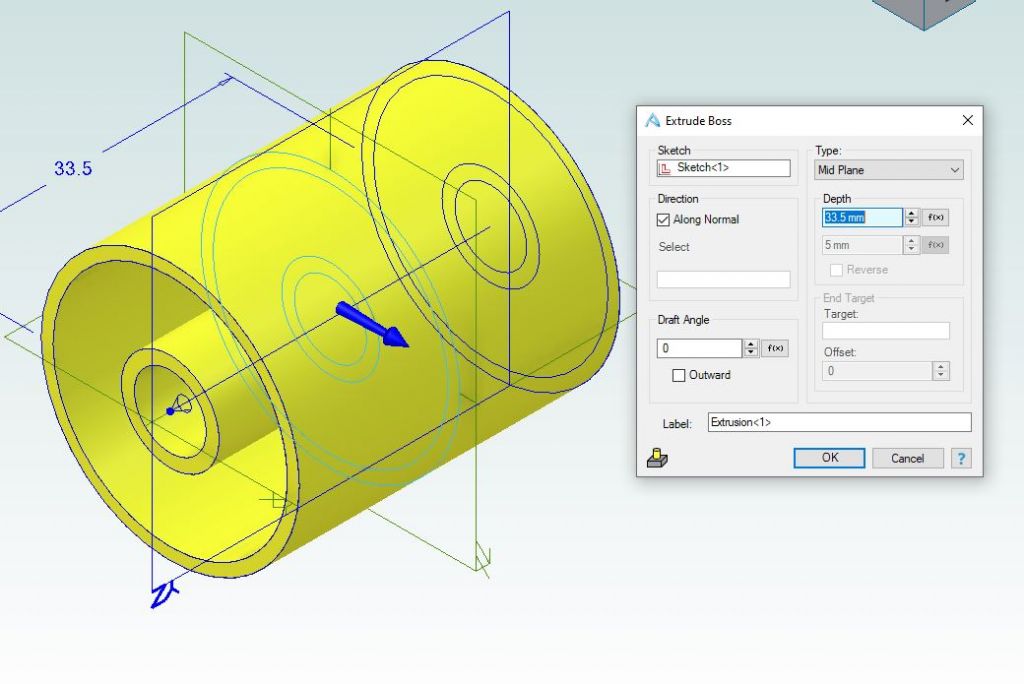

, or make a negative hole. Pull positively and make the dimension 28mm:

, or make a negative hole. Pull positively and make the dimension 28mm: