Hi Calum,

A while ago I made my version of the MLA toolpost and this is the reply I got from the MLA membership. So as long as you credit the originators I do not see any problem with copyright.

Alan

JACKARY,

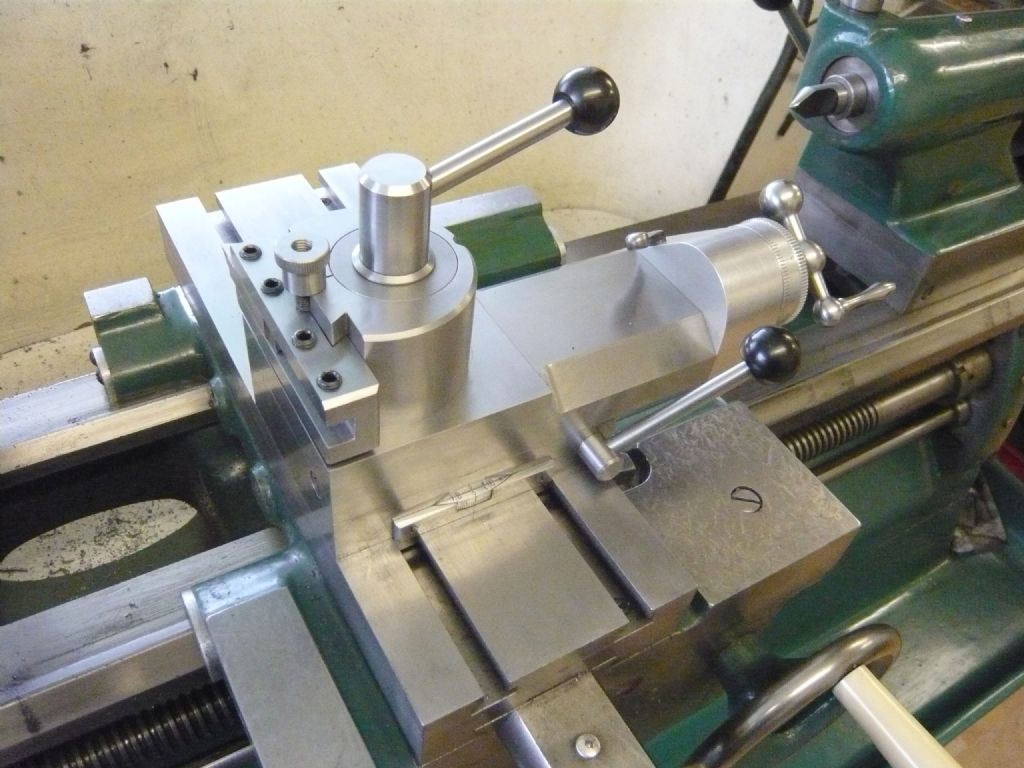

compliments on your nice looking version of the MLA toolpost. Also, the topslide compound it's mounted on is sheer elegance.

I would just like to bring up one thing, that with the original, prototype version of the toolpost it was found that the dovetail clearances in the relaxed position should be around four or five thou., ideally, if I remember correctly, and not to exceed about seven thou. Those tolerances were easily accomplished by gauging with the toolpost body when milling the toolholder dovetails. I now have seventeen toolholders of various types, and presently there is no urgency to make more. When there is, should there be access to a milling machine, I would consider pre-milling the dovetail in a long slab of steel and, as needed, sawing off from it toolholder blanks like slices from a loaf of bread. The key would be in milling the dovetail with reasonable accuracy, so that the toolholder blanks would all fit equally well, rather than equally poorly.

A friend and I, using his milling machine, made a pair of larger versions of the original, prototype toolpost, with the intent that one of them would be used on his South Bend heavy ten lathe, using the large collection of Aloris and knock-off Aloris toolholders he already had, as well as some he had made.

During that project we decided to measure the dimensional variation, or "allowance" among them, and found the variation to be too great to be accommodated by the MLA toolpost without alteration. I forget what the variation was–I think I could look it up–but it was quite significant. Which does point to one advantage of the wedge type toolpost, in that it is fairly tolerant of dovetail dimensions. That can be seen, if I recall from my friend's lathe, in the various positions the Aloris locking handle assumes depending on the toolholder mounted.

That is certainly not to discourage the choice of the MLA toolpost in favor of the wedge and plunger types. The MLA is more easily made by the amateur machinist than the others, and in my opinion is more rigid, having full dovetail engagement with no interposed pieces. I mention it to point out that the cheap knock-off toolholders might not be suitable for the MLA toolpost, as suggested in a comment a while back.

JACKARY, it might be interesting finding out if you have measured the dimensional variations, or "allowances," among the dovetails of the toolholders you've made so far. Though I have to say, just from a feeling I get looking at the photo of your toolpost, that yours appears more flexible, and capable of greater expansion, than the prototype, and so more capable of accommodating greater variations in the toolholders. Again, compliments on a nice looking job.

Edited By Alan Jackson on 02/04/2022 10:34:14

Edited By Alan Jackson on 02/04/2022 10:36:00

Edited By Alan Jackson on 02/04/2022 10:37:21

Nick Clarke 3.