Posted by Nealeb on 21/03/2022 16:58:58:

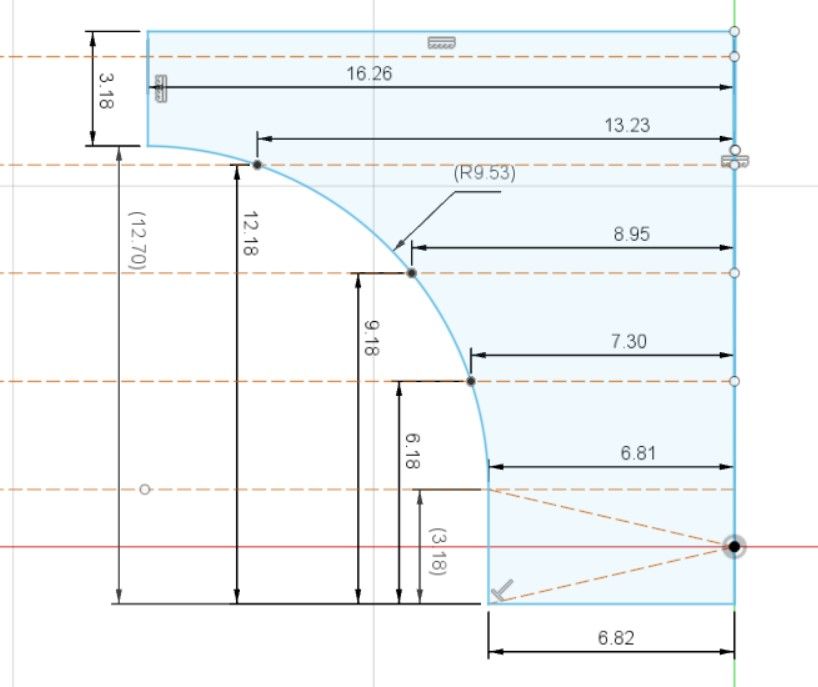

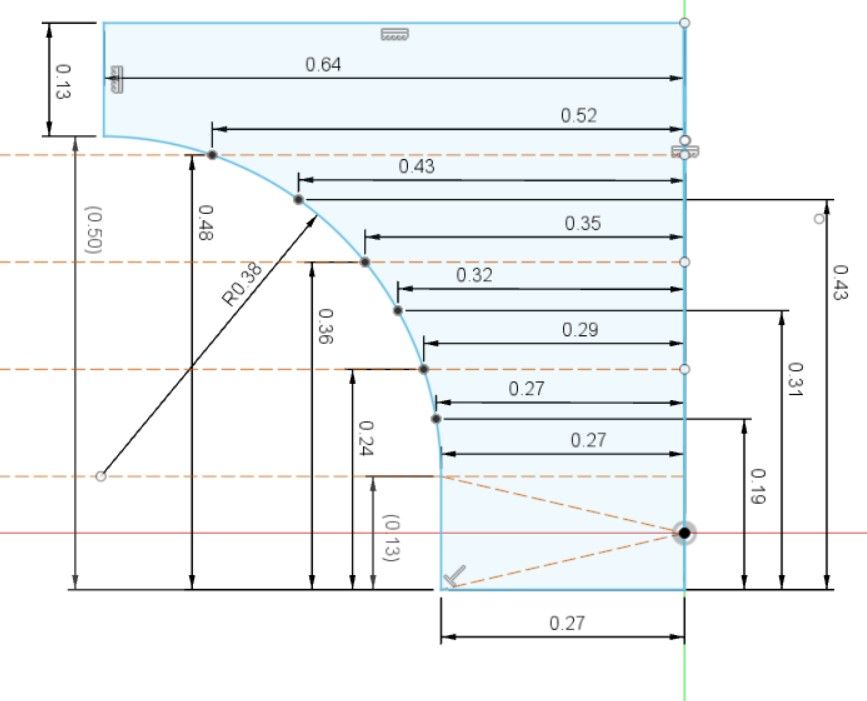

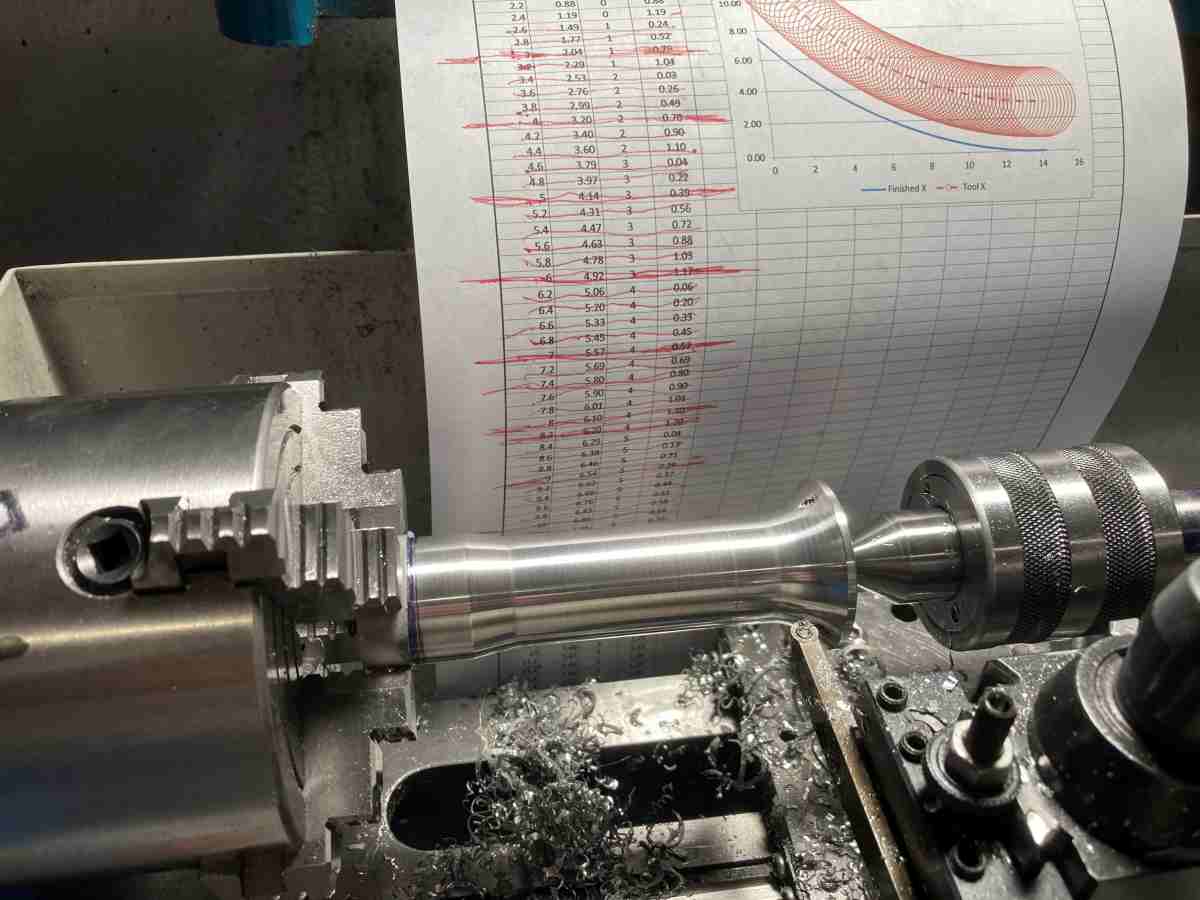

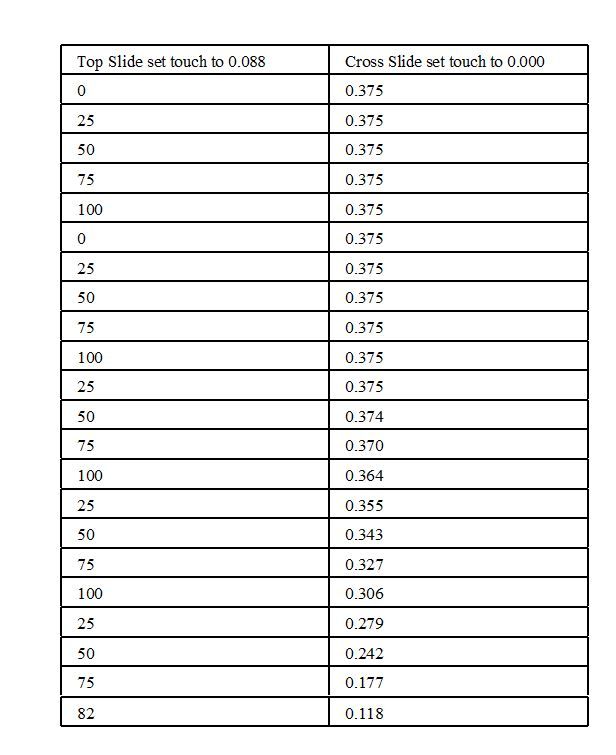

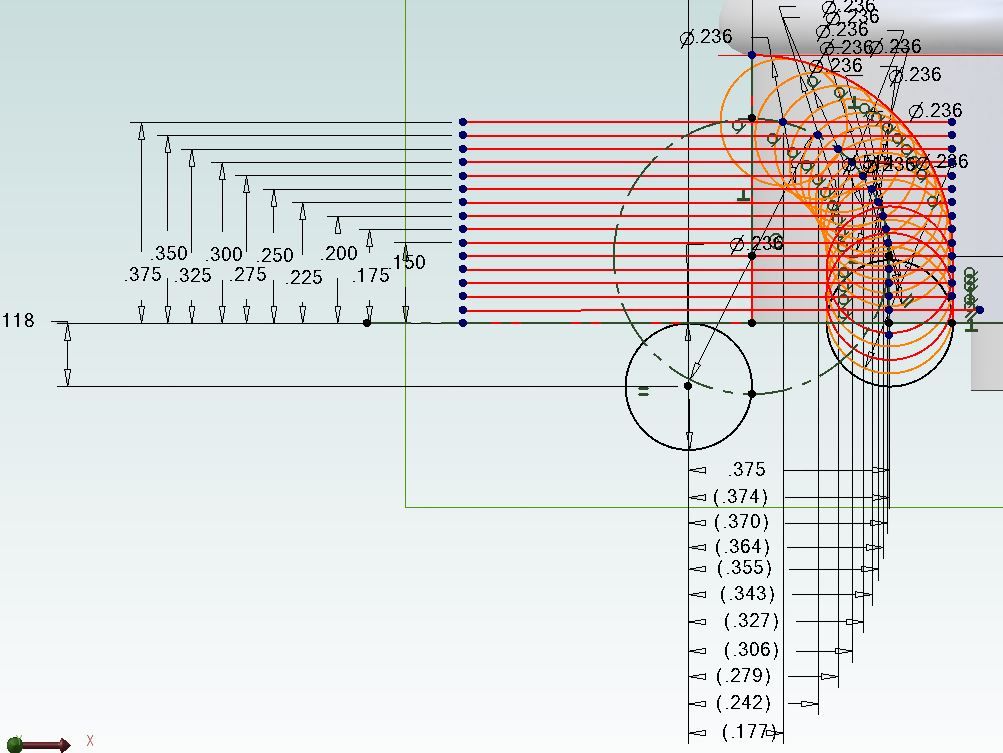

The reason is that in order to position the tool, assuming that you are using a circular button tool, you need the coords of the centre point of the tool. The actual contact point – where the cutting takes place – is a bit more difficult to calculate than just the curve itself as there is an offset of tool position from the curve that depends on the curvature of that curve at a given point.

With a circular arc and a circular tool, the XY coordinates of the tool centre point wrt the arc centre point are honestly just the XY coordinates of the arc multiplied or divided* by [arc radius] / ([Tool radius] + [arc radius])

The proof / derivation is via similar triangles. These coordinates (relative to the arc centre) then need to be translated into X,Y (or X,Z) tool movements relative to a datum position.

*Depending on whether the cut surface is concave or convex

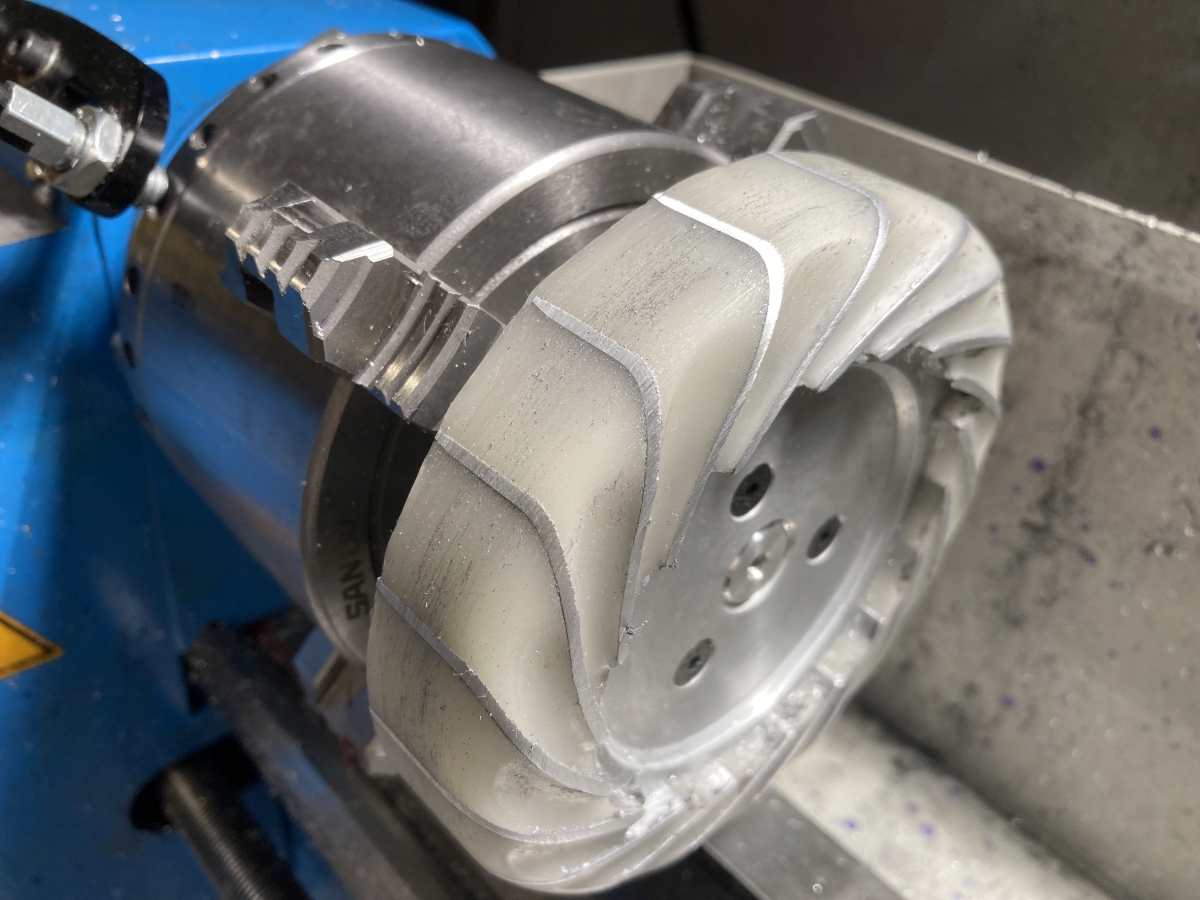

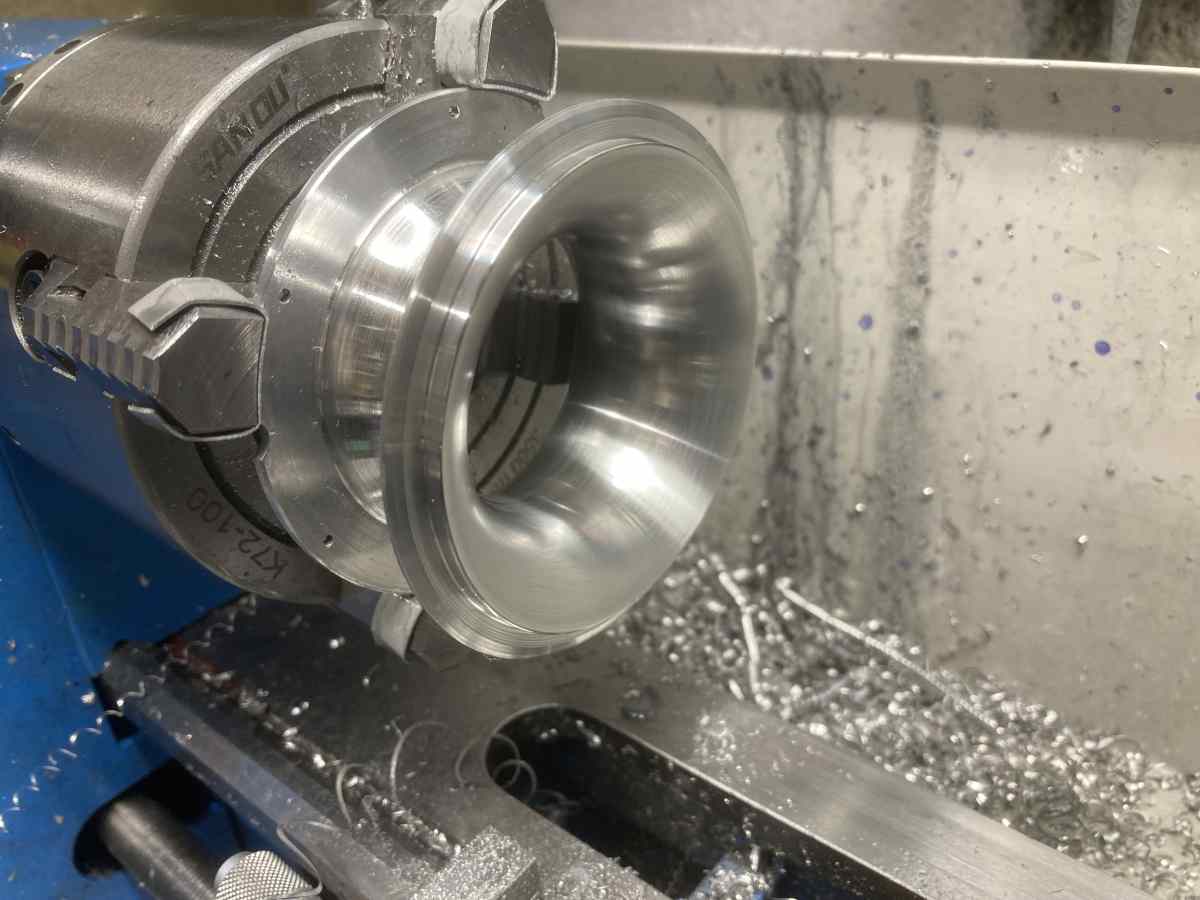

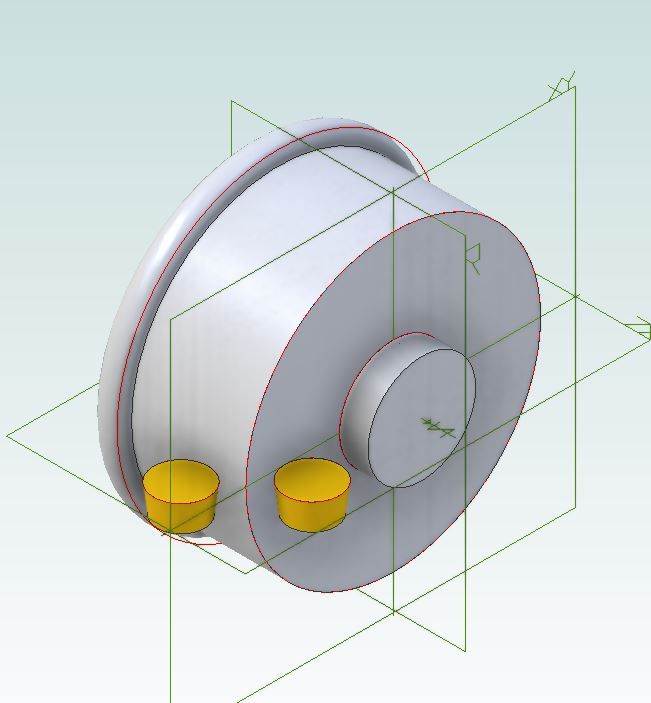

All the following were cut this way with 0.2mm step in X and a 6mm diameter button tool

8mm external convex radius:

20mm internal convex radius

External concave radius

8mm internal concave radius

17.85 mm internal convex radius

etc…

Edited By Andy_G on 21/03/2022 17:34:14

blowlamp.