My dimension question came up during an excursion into 3D printing, and I've been distracted by a USB cabling problem, still unsolved.

Many thanks for the help and observations, all much appreciated. It's been underlined to me that producing good drawings is a mixture of art and science. Science does an excellent job of the geometry and correct drawings, but making clear to a human needs intelligence!

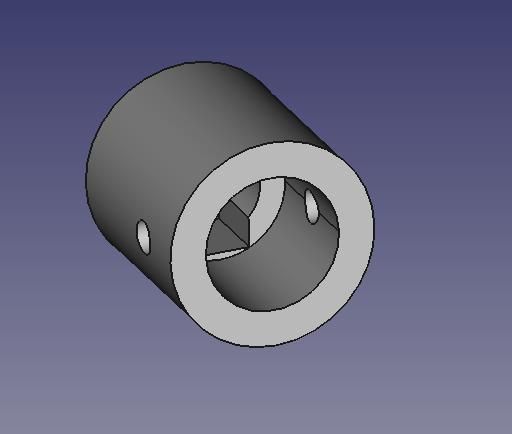

The Coupler is modelled in 3D with a Pad and 3 pockets, 4 simple sketches total. The sketches make perfect sense to the CAD package, but not in a workshop. Though the rendered object gives a good idea of the shape and how it might be machined, it's not dimensioned.

3D printing is easy enough because the CAD model contains all the information needed to create the shape. Ditto CNC. For strength I need to make the coupler in Aluminium or Mild-steel, and I only have manual machines. Proper 2D Technical Drawings are needed.

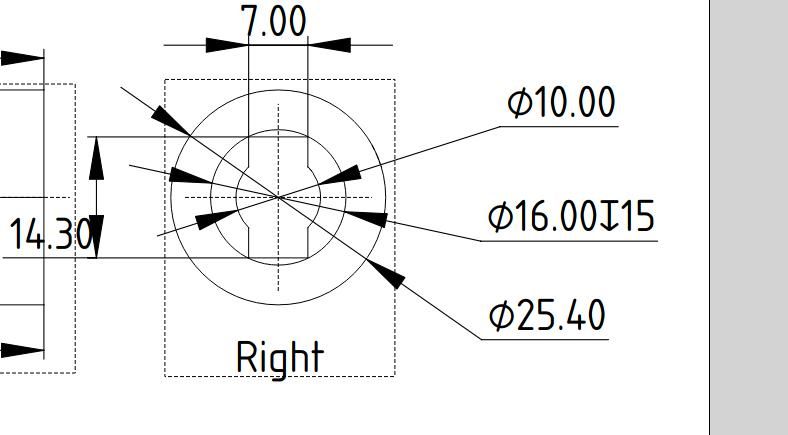

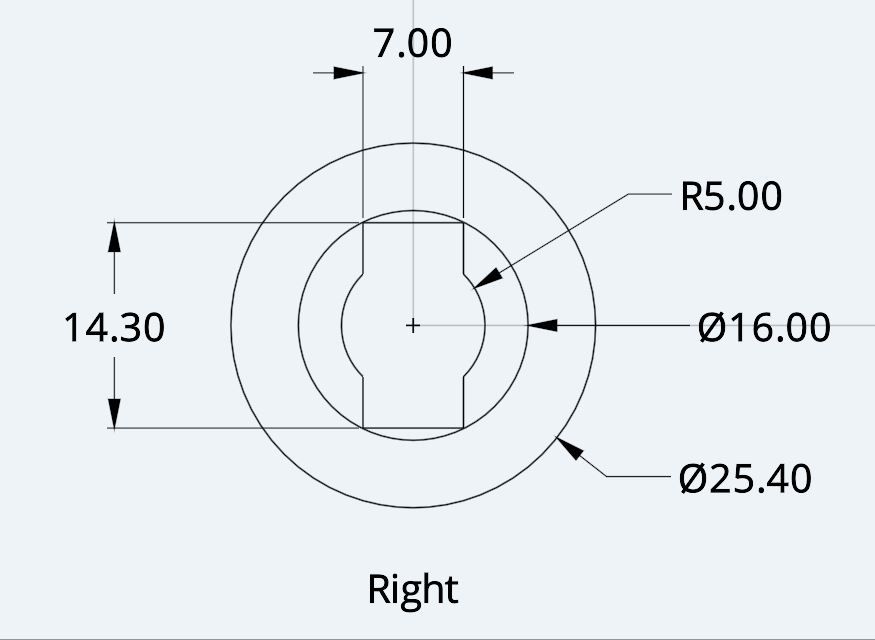

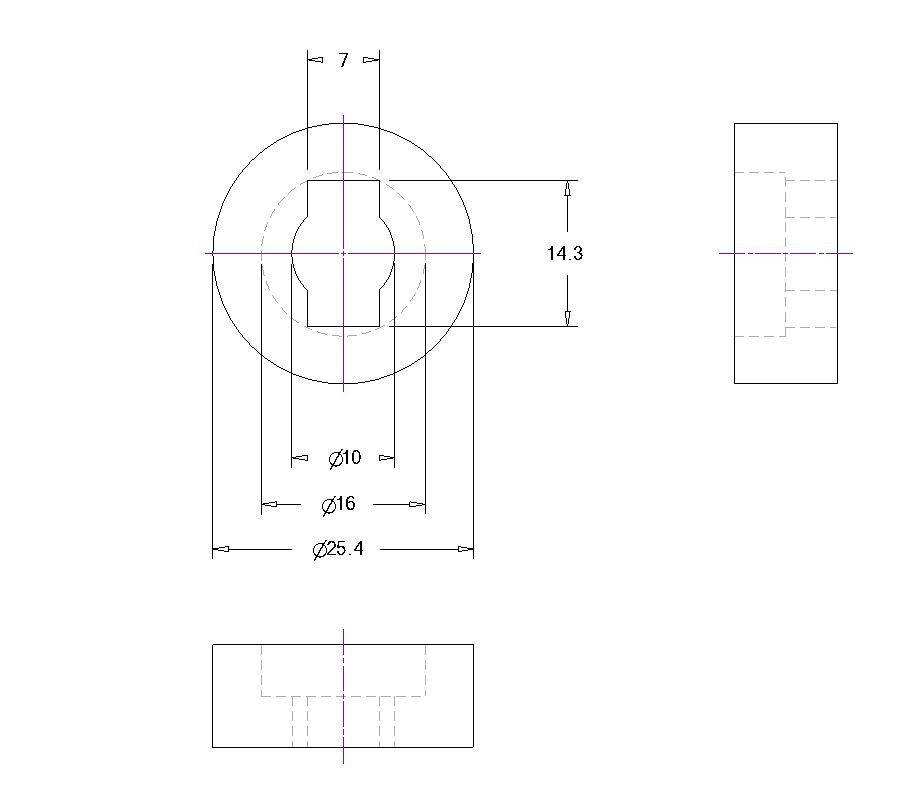

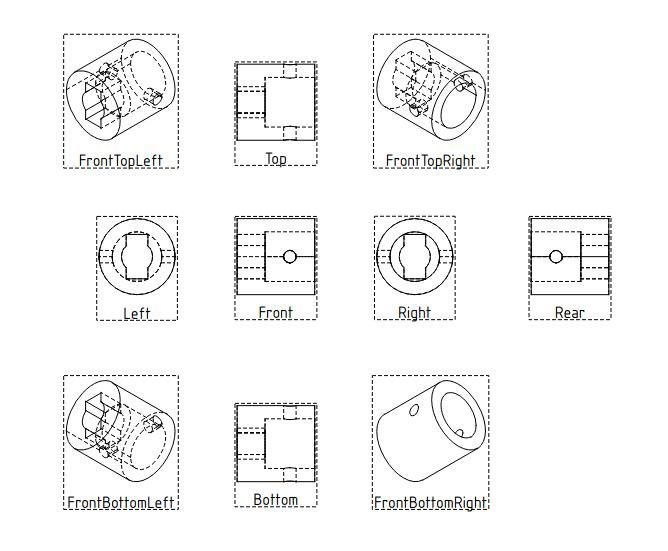

Here's the range of 2D plans and projections FreeCAD (and most other modellers can generate):

Unwise to print all of them with internal detail, centre-lines, dimensions, tolerances, labels, sections and balloons etc. In this case, I think the coupler can be completely described by the Front, Top, and Right Views, and it's helpful to add the Front Top Left and Front Top Right isomeric projections. A simple text description bottom right is needed: Title, Date, Name, dims in mm, material=Aluminium, Third Angle etc

Unwise to print all of them with internal detail, centre-lines, dimensions, tolerances, labels, sections and balloons etc. In this case, I think the coupler can be completely described by the Front, Top, and Right Views, and it's helpful to add the Front Top Left and Front Top Right isomeric projections. A simple text description bottom right is needed: Title, Date, Name, dims in mm, material=Aluminium, Third Angle etc

I'm taken by JA's "More Paper" suggestion. I can only print A4 at home, so one page for the general arrangement plus a page each for the individual views, as necessary to remove clutter.

Otherwise, I'm going to experiment with the other suggestions, like Jason getting rid of angled arrows by using linear dimensions instead. Watch this space!

On the great chain vs don't chain debate, my First Year draughtsmanship books all advise against it because it can cause errors to accumulate. As there are examples of short chains in the same books, I guess it's not always wrong! When milling, I prefer to work from a small number of reference points, which is easier when dimensions aren't chained. Again, the idea is to avoid small errors adding up into a big problem at the end.

Back to my 3D printing problem now, then another go at dimensioning.

Many thanks,

Dave

SillyOldDuffer.