Ian –

That is reassuring, knowing Siemens does issue proper manuals for SE. I wish IMSO would do the same for TurboCAD – its on-line "Help" is dreadful and it cannot be saved as it is. Surprisingly, as I do not have a pdf converter, I found it possible to copy the Contents page to create via 'Word' and 'Excel' a printed, alphabetical, coherent index that greatly helps searching for a particular item in the whole thing on screen.

#

Gary, Peter –

That may have been true of earlier version of TurboCAD, but certainly the edition I use has far more than that, and is very clearly intended to allow full isometric model-creation.

The Users Forum has a lot of architecural and engineering examples. A while ago one was of a fully-fitted kitchen. This was posted by a kitchen designer using TurboCAD both for the construction drawings and photo-like images to help the customer decide. I take it the contract did not include the bowl of fruit…. The 21C version of the beautiful, tinted pictorial elevations that 19C engineers used in contract negotiations.

TC is far more than an orthograhic draughting system with 3D features tacked on!

You can create solids in TC by Extruding plane figures as you say, perhaps the main technique in any CAD programme. However it also has a library of at least a dozen "Primitives" (cuboid, cylinder, sphere, etc.) and some generators such as Sweep and Revolve.

Its Add tool includes a Subtract and a couple of other moves I forget without running the thing. The Copy functions work in 3D as well as 2D, although I do not know how to copy from drawing to drawing. It is not Copy-and-Paste: you have to Copy the item in its place then Snap the copy to its location, or enter its co-ordinates. There are though array-copy tools for multiple repeats, and Mirror.

It does lack fillet and chamfer tools, I think, but there are ways round that – such as using Subtract. I believe the more modern and certainly fuller editions of TC include these and functions like Loft.

IMSI has also published an up-dated version, probably intended for W10, and again available at one-off cost at a sensible price for we amateur users who don't need massive industrial-scale editions – even if we could afford them.

'

Jason –

Don't get me wrong: I appreciate the value of an animated isometric assembly drawing!

I would find it too difficult, since even the static 3D GA would be. My version of your example is a vertical compound engine and drawing a connecting-rod or eccentric assembly in non-rectilinear positions baffles me even orthographically. The weakness is not the programme but me, and I'd probably find it in any CAD system.

Therefore I draw it as best I can to reduce the risk of parts interfering or not fitting, and more or less as I make the thing.

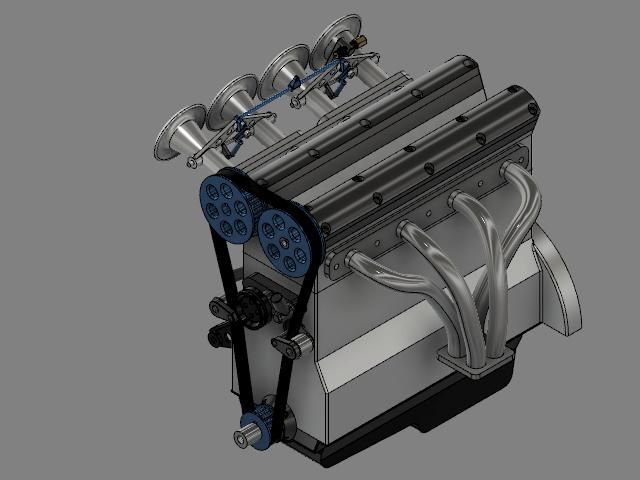

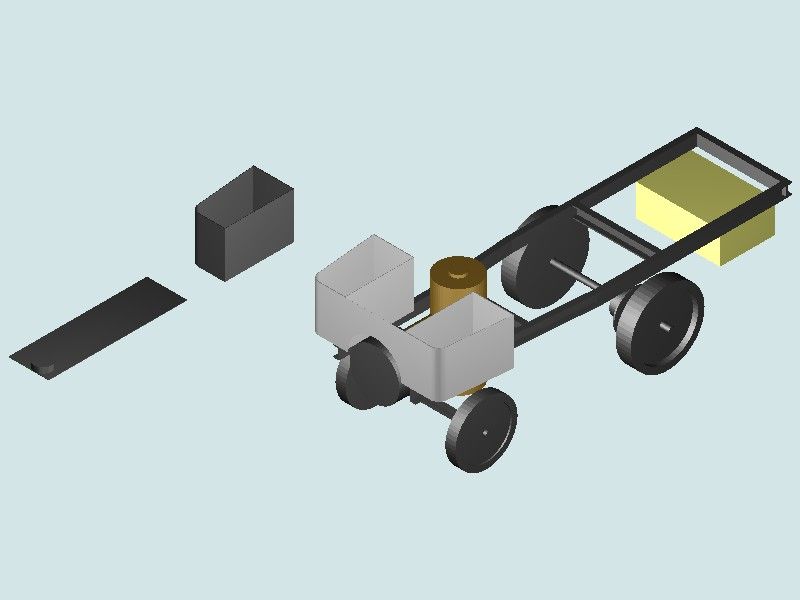

So to design the engine I created a rather sketchy outline to establish the enclosed engine's size and position in the vehicle (unusually, between the crew seats. with its mid-height at about chassis level), then started to design the works from inside out.

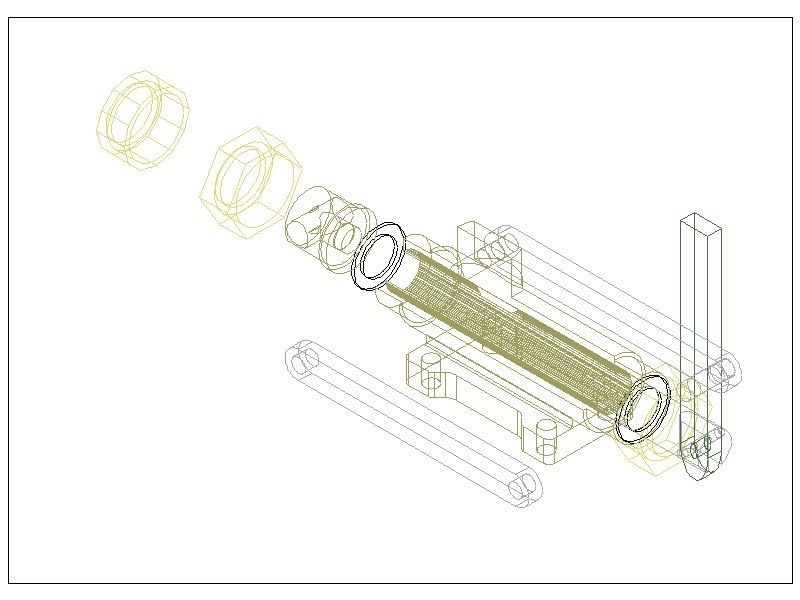

I made and assembled the crankshaft, eccentrics, connecting-rods and crossheads, and put them between bench-centres on the milling-machine table, with a substitute piston-rod in a collet, using the quill as "piston" . Thus I can measure the real main-bearing heights above the part-made baseplate, verify the eccentrics' space (remarkably greedy for room, eccentrics), hence design the plate and bearing pedestals from that.

For the valve-gear (Stephensons, the specific design adopted from K.N. Harris' re-working of LBSC's Maid of Kent) I will use a similar approach: draw and make parts; partially assemble, assess real locations and clearances and eventually design the case so the whole engine fairly represents outwardly, the conspicuous original shown in archive photos.

CAD and a DRO system on the mill has already give me useful options for making the expansion-links, dimensioned by Harris in umtee-twoths of inches. The programme will give me decimal and angle dimensions, hence milling to thous (ish), Cartesian co-ordinates and rotary-table locations.

'

To sum up, my limit of software learning is far lower than for most people here, so I need try to judge how I can work within it to the same ends, more efficiently. Same task overall, so perhaps a tool easier to operate for that task.

Hence trying to assess if SolidEdge Community might be easier than TurboCAD's equivalent for me. They are intrinsically, equally valid, very powerful, trade-level CAD tools for fundamentally the same work, so the question is of my better choice.

![]() but that reads as if whatever you download stays yours for life on your computer. It may mean that future upgrades might cost something.

but that reads as if whatever you download stays yours for life on your computer. It may mean that future upgrades might cost something.