My wretched typing! I'd about finished this when yet again I hit an unknown key-combination and deleted it.

Orthographic! Yes of course! Thank you gentlemen for the correction! Same root though.

Of course I am aware that CAD calls the 3D images "models", but TurboCAD's view-changing tool offers two types of view and calls one isometric. I forget the other.

I am also well aware of the industrial practice now being taken up in some ways by model-engineers, of drawing-files translated straight to CNC-machine drivers.

'

Really, for us amateur engineers the choice of whether to use CAD, and to what extent, is by budget, time, preference, learning-ability and indeed interest.

First we are assuming designing our own projects, rather than sticking to published ones; and considering their complexity. This was my starting-point, as my main project's source is merely a few scrappy old trade photographs from 1908; and I bought a copy of TurboCAD 19 Pro.

Next, unless you have a particular gift for learning extremely difficult and unintuitive software, which I do not, it can take a formidable time to grasp sufficient CAD experience just for simple orthographic drawings adequate for your own purposes.

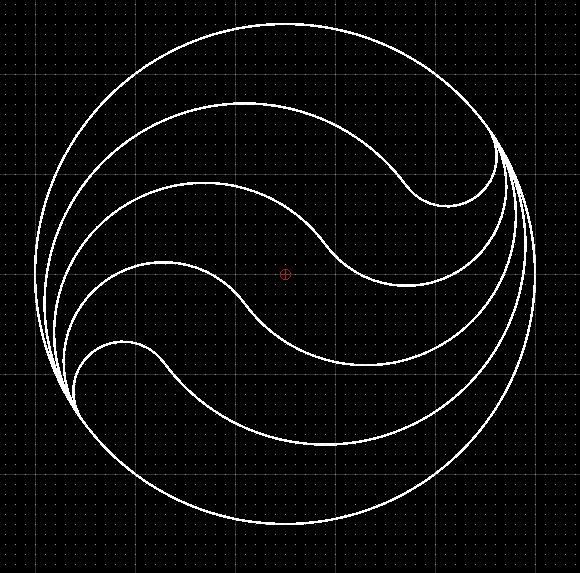

3D-model drawing adds greatly to the complexity; and when designing for yourself, you need ask why lumber yourself when you actually make the parts from 2D drawings. The one advantage I see, was that CAD enables 3D models to help determine complete assemblies. This too, helped sway my decision.

However, as engineers we should be able to visualise a 3D assembly from 3 orthographic views – depending on its nature.

So why 3D CAD for own drawings for own projects in own workshops…?

The only answers I can see are that either you have the desire, time and ability to learn it, or you've bought a CAD package that gives you no choice!

If we buy CAD because we want to design our projects, presumably we can already create engineering-drawings of appropriate standard. The trap is that of trying to learn the CAD package taking much longer than we would have spent drawing the project manually.

I bought TurboCAD but really, that it lets me draw a 3D image of, say, my engine's crankshaft does not mean I have to do so. I want to make a real crankshaft, not a pretty picture of one, and after untold hours of struggle better spent actually designing and making the engine, I was just about capable of a pretty picture of the shaft. By then I had made it, to a CAD drawing but orthographic, dimensioned and set out from the orthographic GA.

I did try other CAD packages.

I have a copy of AutoCAD 2000, which is 2D only I think, but no manual for it.

I found Fusion 360's brashness off-putting, and it assumes prior CAD-principles knowledge – to be fair, they all do.

I tried Alibre but I missed two episodes of the MEW serial. Why buy and learn a complete new package when I'd already bought TurboCAD? I thought the magazine series would make it easier to learn, than trying to teach myself what I already had. So I abandoned Alibre too – which took its publishers months to understand. Luckily, I already have a scribing-block.

Both Fusion and Alibre are based on 3D- model first – I do not use a 3D CAD/CAM system at home, so regard 3D as nice-to-have, but of limited use, extremely difficult and time-consuming to learn and frankly, not really necessary. It is for brochure artwork, not workshop drawings.

The only useful 3D images I have drawn were two geological diagrams for a caving-club magazine article.

'

Training materials?

TurboCAD's own on-line 'Help' manual is not much 'Help'; and I can't learn from videos. Far better than these is Paul Tracy's CD manual for TurboCAD, a step-by-step pdf primer.

D.A.G. Brown's general CAD primer has a very dated cover photograph, but does outline the principles of CAD engineering-drawing. Neill Hughes' more modern alternative, which I also own, is sketchier and more for the 3D-artwork people – and despite a British author and publisher, neighbours to France, it insists on calling "metres", "meters".

'

So to sum up, CAD can help us but it is not the be-all-&-end-all of model-engineering. Unless you also intend using CNC machine-tools as well, or buying a lot of profiled work-pieces, CAD is only worth buying if –

you design most of your own projects,

you need draw them accurately,

manually drawing them would take much longer than learning the CAD package sufficiently.

Alyn Foundry.

![20200701_113327[1].jpg 20200701_113327[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/869346.jpg)

![20200701_113318[1].jpg 20200701_113318[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/869345.jpg)