Drawing Standards

Drawing Standards

Home › Forums › CAD – Technical drawing & design › Drawing Standards

- This topic has 35 replies, 25 voices, and was last updated 31 January 2025 at 11:40 by

Nick Hughes.

Nick Hughes.

-

AuthorPosts

-

21 December 2012 at 20:20 #21146

John Stevenson 1

Participant@johnstevenson121 December 2012 at 20:20 #106897John Stevenson 1

Participant@johnstevenson1Pet moans, A trilogy in 4 parts.

In the beginning we had BS308, widely distributed as the shop floor needed to know what the 'erberts in the drawing office thought they meant.

Then we moved on to these new fancy GT & D standards with symbols not unlike those stupid flashing warning lights wot like you got on the dash of these new vehicles. No one knows what they mean.

On my new Donald it has a light on the dash to tell you one of the other lights has failed? If the technology is that good then why can't they substitute the light on the dash for the blown one ?

Anyway I digress.

With these new standards with hyrogylific signs, things like man having trouble erecting umbrella at the bottom of a circlip groove you can't just look them up, you need a copy of the Standards at about £100 a pop.

Hang on, they want us to use them and understand them but they won't tell us what they are ? Instead we have to shell out ??

Do a search on GT&D and all you get are pages of firms and con men who want to teach you what they are at £400 a day. BS308 was self understandable [ is that a word? well it is now, if you won't clarification it's £250 a day for the translation ] But the new standard is so obtuse it's spawned a cottage industry like the HIPPS legislation that applied to the sale of house.

Oh how I laughed when they abandoned this and a shed load of shysers got shown the door, Oh happy,happy days.

Which leads onto CAD [ Clown Assisted Drawing ] Most of these program's come pre loaded with various options like metric,ANSI, ISO, VD and bar and it's up to the user to set all these options up, things like number of decimal places, but no these wet behind the ears Eric's can't be bothered so we get dimensions running to 15 decimal place with tolerances to suit.

However I'm the last person to ask about tolerances

Don't ask because I'm not telling you.

Don't ask because I'm not telling you.Many program's like Aught to Cad, Solid Works, Solid Edge even select one of the GT&D hyrogylifics and inserts it with loads of meaningful figures [ meaningful to someone ] which then renders the part to be made impossible.

But now we get to the point where the whole way drawing are produced has changed from the manula to Clown operated and NO ONE has spotted the error.

Because Computers use one of the 127,789 fonts that Microsoft instals by default we see things like this on drawings.

Matl:- Mild Steel BS 1234,5678

If you had written that in the days of film and drawing boards you would not be drawing for a few days because your knuckles would have been red and skinned.

This is what was expected .

All drawing had to be done in lower and upper case capitals.

But no Microsoft in their wisdom push Comic Sans, Arial and New Times Roman and all the budding CAD jockeys follow form.

Why can't they set a CAD package up to follow form and use small caps. ?

The mags all follow the incorrect method and take the easy way out,

John S.

21 December 2012 at 20:42 #106898Jeff Dayman

Participant@jeffdayman43397My, that is quite a moan.

Is there a specific mag and / or article that has "the incorrect method" you are concerned about?

(I've seen plenty of iffy drawing stuff in the past 3 years in ME and MEW, and the capitalization of notes is the least of my worries. Incorrect projections, microscopic views of complicated things, large magnified views of simple things, missing dims, missing details etc. are far more of a concern to me)

Thankfully no whiz kid has started doing GD&T on loco or engine drawings in the model press, let's hope it stays that way. In industry I have probably spent more time mediating discussions between "designers" and machinists about interpretation of GD & T than anything else. It DOES drive costs up across the board to use it, at every aspect of a part's manufacture, and apart from a few very specific applications it really is not needed most of the time. However, many firms' management demands that it be used on every drawing, especially if management has a few Masters of Engineering or PhD's academics on board and few or no managers that rose up from practical experience on shop floor or toolroom. Just my observations, your mileage may vary.

IMHO CAD just lets you make garbage faster than pencil and paper, unless the chair to computer interface unit (operator) knows what should be on the drawing in the first place.

JD

21 December 2012 at 21:01 #106901 Roderick JenkinsParticipant@roderickjenkins93242

Roderick JenkinsParticipant@roderickjenkins93242I can understand John's frustration in receiving drawings that are more complex than they need to be – that just adds to the cost. I'm not sure that small caps are necessary with a machine drawn font, there isn't the possibility of misreading handwriting.

As far as contributions to ME/MEW are considered, I would happily work to a house style if there was one. At the moment it's just a best guess as to what is appropriate for the perceived audience Any comments/criticism gratefully recieved.

Rod

21 December 2012 at 21:33 #106905Andyf

Participant@andyfPosted by John Stevenson on 21/12/2012 20:20:26:On my new Donald it has a light on the dash to tell you one of the other lights has failed? If the technology is that good then why can't they substitute the light on the dash for the blown one ?

Anyway I digress..

To extend your digression: not a new phenomenon. My 1951 Jowett Javelin had a purple light to tell you that the wipers were switched on, in case you were in the habit of driving without looking through the windscreen.

Andy

21 December 2012 at 23:06 #106916Robert Dodds

Participant@robertdodds43397Without politicising this debate, was it not the EITB ( Engineering Industry Training Board ) who some years ago instituted regular reports from firms regarding the "on the job training" they were providing as a means of firms evading the Training Board Levy and so give rise to the rank of Training Provider.

The GD&T nicely fell into that era and the tutoring of GT&D satisfied the need for "the suits" to show that sufficient funds had been expended on relevant training to minimise or eliminate the EITB levy.

That, together with the introduction of new style Standards that said a lot but told you nothing specific ensured the stratospheric growth of Training Companies offering On or Off Site training courses in any subject you could dream up and charging mega bucks in the process.

It was of little concern that the subject matter was frequently nether relevant nor understood by the target audience.

As John Stevenson says, looking up GD&T brings forth all these con men but I did spot that one or two offer pocket books such as "The Ultimate Guide to GD&T" to go alongside our engineers pocket guide. Is it possibly a suitable "freebe" for our worthy editor to offer for extended magazine subscription?Meanwhile, I do hope it stops raining soon and we can all get back to cutting metal but heres wishing all a Merry christmas

Bob D

Edited By Robert Dodds on 21/12/2012 23:07:31

22 December 2012 at 01:13 #106921jason udall

Participant@jasonudall57142Posted by John Stevenson on 21/12/2012 20:20:26:Matl:- Mild Steel BS 1234,5678

This is what was expected .

All drawing had to be done in lower and upper case capitals.

Firstly I agree mostly with what you say…but I suspect you ment EN 1 A

EN designation of that type are at last two standards ago…

You like me will have been asked to supply say En( note lower case n ) 1234:5678 11SMnPb30

replacing 230M07 Pb replacing EN 1A Pb……..

all the above freecutting or otherwise MILDSTEEL

My problem comes with En…xxxxxx 11SMnPb28 on the drawing.

1) 11SMnPb28…is not a European Normative standard but an old('90's) NATIONAL GERMAN stndard Hence the En standard is used inappropiatly

2) can't source any metal to 11SMnPb28.. see 1 above

3) uk sourced says 230M07 Pb and EN 1A Pb on cert.

4) even if I can source11SMnPb30From a supplier using "new standards"

.".thats not whats on the drawing" wil cause it to be rejected

Taken to the extreem… if an engineer miss spells steel as steal (ok with spellhecker) on the drawing..well best of luck with geting those bars in

22 December 2012 at 03:35 #106922Bill Pudney

Participant@billpudney37759When I was a lad, some decades ago, like JS we used BS308 as our guide. Mind you this was in the days that a draughtsman was supposed to be the person who made sense of the Engineers' fantasies, so that the guys on the shop floor had some chance of making what the Engineer wanted. At the time, where I worked you had to be a tradesman to qualify for training to become a draughtsman.

We always used upper font characters for everything, the clarity of the character was paramount.

Then along came CAD. Some old school draughtsmen made the leap from drawing board to computer terminal. Some did, I didn't. The suits managed to lose the link between Engineer and workshop, the draughtsman became a CAD Operator, and a new specialisation was invented……Design for Manufacture.

I spent the last twenty years of my working life spending large amounts of my time doing Design for Manf. checks on new drawing packs and being amazed at the new graduates being employed as CAD Operators who had the full bottle on most aspects of Geo. Tolerancing, model manipulation, etc etc, but who didn't know the difference between a lathe and a mill, let alone how to actually make anything.

Boy am I glad I'm retired!!

cheers

Bill

22 December 2012 at 20:58 #106995Sub Mandrel

Participant@submandrelAll the packages I can think of allow you to use small caps instead of lower case – even Word.

Neil

16 January 2013 at 17:52 #108903Thomas Gude

Participant@thomasgude37285Here's my 2p as a young professional CAD jokey / Draftsman / Design Engineer:

I have never had the need to use GD&T and as such don't know how to use it. Of course most of the technical skills I have are learnt through the job rather than uni (I can feel a rant coming on regarding how universities can justify their lack of training but I will supress for the time being). I use Solidworks and AutoCAD. I use Solidworks to create 90% of my "models" as they are so easy and quick to manipulate and revise during the development period. However, unless I am sending a 3D model to RP or to a mould tool maker, published drawings are ALWAYS done through AutoCAD – numbered and dated. Forget trying to publish a drawing using Solidworks' native drafting package! Unless every supplier is solidworks compatible this is a lost cause and it pushes so much crap onto your drawing you'll end up with a headache. As such I export to dxf and create my own drawing with all dims and annotations added manually, trying to keep to BS as much as possible – setting the dimension style, tolerances and precision to how it would suit for that drawing and material.

Getting to the point: Adding revisions – I often have to annotate with the drawing equivalent of a big slap in the face to get them to pay attention to the changes – can you blame us for going outside the boundaries of accepted drawing doctrine if what we get back sometimes relates in no way to the drawing.

Edited By Thomas Gude on 16/01/2013 17:54:08

16 January 2013 at 19:28 #108925Wannabewelder

Participant@wannabewelderThe thing that I find most annoying is that standards in the U.K. have to be paid for, and as John states in his original post, at what appear to be "rip off" prices. When I was in industry my company did a lot of work for U.S. companies, and although the standards called up were sometimes very verbose they were more often than not available for download free of charge. I can't think of a better way to encourage their use and also provide a level playingfield for all potential suppliers; large or small. Regards Wannabe and P.S. How can you insert a blank line, or is it this $!**?? Windows 8?

16 January 2013 at 20:48 #108944Mark C

Participant@markcThomas, If you are designing in SW (Solidworks CAD) then exporting to DXF (Drawing Exchange Format files) to import back as dumb (no parametric relationship between the drawing entities and their dimensions) sketches into Autocad (I have another name for it but we will give that a miss!) you are making your life very very hard…..

You should be able to generate 2D (detail) drawings quicker in SW than you can move the mouse – if not, you should get better training specific to SW. I use SW as a design engineer and have worked in some places that still require ACAD drawings – but only due to a huge quantity of legacy data that they will not convert. The only other people that use ACAD (cad files with .dwg extension on the end) are those who do not have a 3D CAD system available.

I have my seat (software licence) configured to a customised BS scheme for drawing and detailing but all the standards are available should I be asked to work to something else (happens very occasionally for some of the bigger clients). As far as drawing revision goes, I use PDM Works for my office and it works great when you understand how to set it up and manage it.

So, in a nut shell and back to the original post, what really matters is whether or not the drawings are unambiguous. If they are you will get what you are expecting but if they are not then you may well get the problems mentioned. The other point about drawing in 3D is the notion that you often have to approach the job as if you were in the machine shop which does require a little shop floor experience at least (I tell fibs, it requires a boat load of thought and experience!).

Mark

16 January 2013 at 22:08 #108951Jeff Dayman

Participant@jeffdayman43397Thomas, I agree 100% with what Mark said. If you are using SW (or any professional 3D CAD package) and you are not using the onboard drawing package, you are missing out on one of the key benefits which is the associativity of drawing to model. Your drawing always shows the model intent. The model can be examined for fits, strength, thermal performance etc and once you are happy with it, the drawing matches it. I've been doing mechanical drawing on paper and CAD professionally since the 1980's and personally I find drafting in SW a doddle and so much better than AutoCAD or paper drawings it isn't even worth discussing.

You are undoing a major functionality benefit of modern CAD by exporting nonassociative DXF and drawing with that. Your bosses are likely to kick your butt hard when the first major model-to-drawing mismatch cockup occurs. If there are major iterations in the part you will soon see there are little savings in time by your method. If you were using drawing pkg inside SW the changes to your drawing views are pretty much automatic and instantaneous after your model is changed.

Mark also hit an important point – gaining shop floor experience and designing accordingly is the best thing a junior designer can do to improve his ability. Ask the guys on the floor their opinion as often as possible, talk to peers doing similar work, and BUILD STUFF whenever you can. It is often a humbling experience when you start working to your own drawings (sure was for me).

JD

16 January 2013 at 22:44 #108956Thomas Gude

Participant@thomasgude37285*formatting: something very wierd*

Edited By Thomas Gude on 16/01/2013 22:45:58

16 January 2013 at 22:45 #108957Thomas Gude

Participant@thomasgude37285Mark & JD

I don't disagree with anything you've said. It is by far an ideal situation; you certainly have to keep your wits about you when revising assemblies. I have done the SW Essentials course which almost over half of which concentrated on their drawing package (.sldrw). First impressions – absolutely great, create all my drawings at the click of a button (same for ProE) However, getting into it it was just too inflexible for me, not being able to accurately add specific dimensions and annotations (try adding a compound angle dimension for a saw set). I asked the tutor how to add certain things and he most common reply was “you can’t”, by the end of the week he was pretty pissed off that I was asking so many questions that he couldn’t give a satisfactory answer to. That combined with still having to export native AutoCAD I'm not completely sold. Not closed to options though, you guys are much more experienced after all and probably think I’m mad. Depending on the supplier I will have to send just .dwg or dwg with a form of 3D file – depending in what their using it for, but even the guys with SW have never asked for SW drawings. Perhaps it is time to dig out the chunky course manual again.

I also have to use Acad for other reasons such as putting products in situ into architectural drawings and using it to build wireframe models for other unrelated programs.

Regarding the PDM, its a small company and we only have 3 seats and no server. I suppose that's a matter of persuading the management to get with the times.

Totally agree with what you say about CAD skill. I'll open a part that I did 4 years ago and what was I thinking?

Also agree with your last point JD, I started as an apprentice as a placement year. With a lot of that in the workshop, unfortunately even though everything is designed by us we only do assembly in house no actual “making” as such (except for a few of the simpler prototypes), that is all outsourced to other UK manufacturers. Still invaluable though.

Anyway, that was a bit off topic. There will always be loggerheads / despair between the drawing office and the shop floor. I only see the office side myself, any machining / fabrication I do is drawn and made by me for me.*that's better*

Edited By Thomas Gude on 16/01/2013 22:54:55

17 January 2013 at 00:45 #108963Mark C

Participant@markcThomas, it sounds like your tutor could do with some re-training!

On the idea of letting SW detail a drawing – only when I'm in need of some entertainment…. I never use auto dimensions, I simply create my layouts (usually manually) and then dimension away using the various dimension tools (ordinates being favourite as they are very much liked by the machine shop).

It never occurred to me that you had tried to get automatic drawings out of SW, I too have been using it since '98 and enjoyed giving the technical demonstrators a hard time when they first tried to sell this function to us. One thing you certainly can do is check for missing dimensions automatically after you are done in manual mode – few things more embarrassing than a gloating machinist with a missing dimension…..

By the way, I only have one seat as there is only me in my consultancy but I have a network, server (old pc) and PDM running quite happily, all administered my me with support from my VAR.

Mark

Edited By Mark C on 17/01/2013 00:48:09

19 January 2013 at 21:34 #109299Mike Angelo

Participant@mikeangelo94956I share J.S's frustration regarding the cost of getting BS standards copies . Surely in this electronic age all these standards should be available on a public accessible website ?

If copies of standards were available in this way surely this would be a major benefit to all industry ?

8 February 2013 at 22:40 #111416mike mcdermid

Participant@mikemcdermid41977Jeff daymans sentiments are quite accurate "garbage faster"

I was trained on a drawing board so was taught the art of understanding the need to convey information

Cad systems which i have used most of them Solidworks Inventor Pro E NX and Catia allow you to create 3d models and the drawing is just an afterthought IMHO Its only recently there is no need for a drawing anymore ,the digital model is king in some larger institutions where asme y is making inroads ,However they missed the fact that a machinist likes to have a drawing pinned somewhere near a machine and it isnt going away as quick as they thought it would

As for BS whatever im sure it used to mean "British Standard" not standard which we will work around to suit everyone and their company's way of doing things hence there is a lack of standard BS8888 is certainly a hotchpotch of differing requirements for the europeans rather than the British

However you can get the kids to work to a standard if its set up Solidworks certainly allows you to define BS308 Or BS8888 and automatically draft a drawing using that however as the digital model is dumb when it comes to actually recognising what you put into it in referance to tolerances etc (PRO e is the exception here it wont actually let you define something that is at geometric odds with each other),wether the kid in front of it understands what geometric tolerance or even basic drafting projection is without googling it is a completely different matter

31 May 2013 at 11:04 #121112richardandtracy

Participant@richardandtracyIn a comment to John S's grumble, I too have a grumble about BSI. As every standard has been converted from BS to EN, the standard has fractured into many parts, the useful information extracted & discarded, then the price of each part is double or treble the price of the original.

I have seen a BSI standard that the company has got. Priced 3 shillings. Now BSI are selling the same standard at the same date issue for £72 for BSI members or £144 for others.

Then there is the stuff about structural steel. The old BS4360 grade 43 A /B/C/D/E is now BS EN 10210 grade S275 JR, J2, J3, J2G3 or whatever alphabet soup they can come up with. Then when it's delivered, we get a different alphabet soup with different numbers & three of us end up having to pour over the standards to find if what has been delivered is acceptable. It's usually easier to look at the mill certificate to find the only stuff we're interested in (temperature resistance & strength).

On the drawing side, using Soiled Waste (our term for SolidWorks), we have set the system up to use 'Century Gothic' and only use capitals. And there are 3 of us producing the same work as a manual DO of 40 and a stress office of 3 did in 1990. So, things do get skimped a bit & not enough checking is done. But the overheads are less & the company still staggers along.

Regards,

Richard.

31 May 2013 at 19:22 #121145 Nigel BennettParticipant@nigelbennett69913

Nigel BennettParticipant@nigelbennett69913"Fractured into many parts", says Richard. And how! There's actually a Standard now (can't be bothered to look up the number) that specifies a Standard Temperature for measurement. Title page… List of contents.. scope…list of references…bodies responsible…. all the usual blather. And then comes the actual nub or gist of the whole thing – 20 deg C. And they expect you to pay about thirty quid for it. No doubt they'll update it in a few years to amend the bibliography and make you buy a new one.

Going back to SolidWorks – I've been using it at work since 2001 (Pro/E before that) and I cannot comprehend why on earth anybody would want to convert it to AutoCad to produce drawings. DXF export for laser-cutting, yes. If you build the model properly in the first place, show all the model dimensions in the drawing, and then have the two-way associativity between drawing and model, what else do you need? If your drawing standards are so anal that SW can't produce drawings to your requirements, quite frankly it's time to change your drawing standards.

I take John Stevenson's original gripe about Geometric Tolerancing – I seldom if ever use it, preferring to stick a note on the drawing to the effect that the surface must be flat within whatever, and append a sketch showing how to check it. We're not aerospace, so our machine shop chaps aren't clued up on Geom Tols, because we simply don't need it for the kind of work we do.

What I like about SolidWorks is that they let you have your own copy of it for use at home. So I've used it for Proper Purposes….

31 May 2013 at 22:34 #121159Thomas Gude

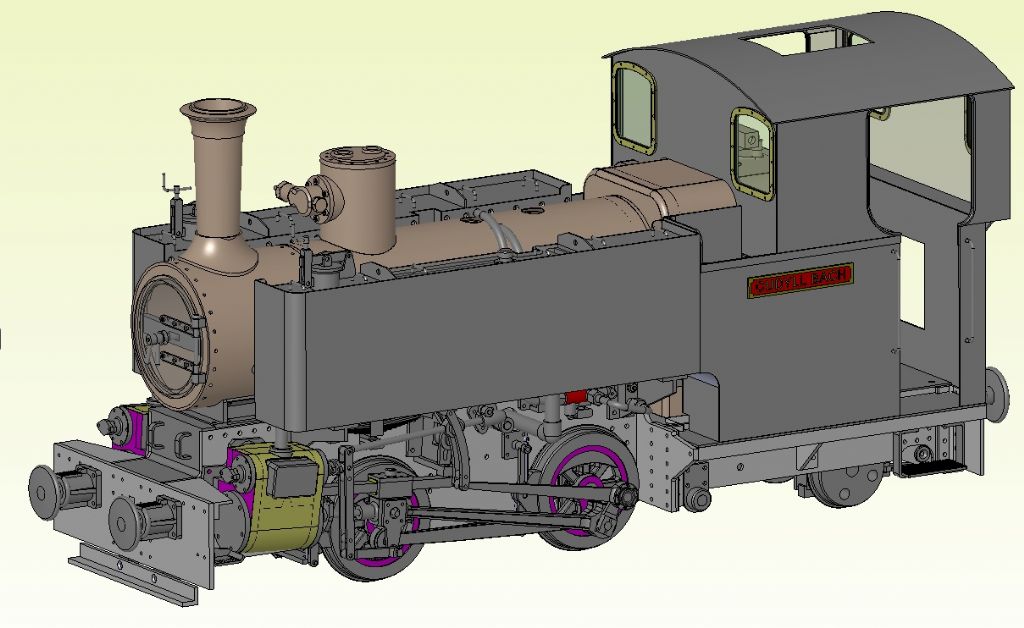

Participant@thomasgude37285First off: nice loco model!!

Second the reason I have to export to ACAD is three fold. 1. That is how the senior engineer did things and as, when starting at the company, I was the only other engineer – who am I to complain? Especially as I'd never used either before – we used ProE at college. 2. Suppliers – neither of our main suppliers use sldwrks but they do use other program's including Acad and the dwg export function of a multiple sheet .slddrw is shite. 3. Amongst many other things try dimensioning a compound angle in a slddrw – you can't. As mentioned before I went on the Solidworks Essentials course and in the second half of the week where they concentrate on the drawing side there were still many gaping holes to something which can be easily and quickly achieved in ACAD. The course teacher was interested in "teaching from the book" as it were so maybe a more enthusiastic tutor would have relished the chance of showing me how to get round my issues but this one certainly wasn't!

Don't get me wrong. My current method can be a pain in the boolox but there are many advantages to it as well. I welcome any change in method that will make things easier but only for the gain of quality and I'm not convinced I will get that.

The last thing I will say is that a side advantage of using ACAD has enabled me to view and use architectural drawings when I need to fairly well.

1 June 2013 at 00:35 #121166Mark C

Participant@markcNigel, why has your engine not got any wings and a prop on the front?

Anyway, onto the autocrap conversation – the reason we still have autocad in engineering is due to the skinflint subby shops that cant cover the cost of the software and the time to learn how to use it (minimal) or due to long in the tooth design office managers who are too stubborn to wake up and smell the coffee.

You can also have as many layers as you want in Solidworks (are you talking multi sheet or multi layer, either way the export function is pretty flexible if you know what you want and what you are doing) if you really have to deal with subbys who "insist" on dwg or dxf, but they generally want paper drawings anyway, or fax if they are modern….

Please see above for a solidworks dimensioned compound angle c/w strange angled sides and awkward to machine hole in the middle! – all done without a single bit of command line funny talk! Out of interest, that little model took about 15 min to draw and come with full associativety – if I decide I got a bit the wrong size, I just change the dimension to the new size and the drawing changes as well – you don't get that with autowatsit

Mark

1 June 2013 at 06:46 #121174richardandtracy

Participant@richardandtracyThe company I work for will only send out pdf 2D drawings. The reason is fairly simple – we sent out casting models to help one supplier, who promptly made the patterns from those models, sand cast the objects and sent them back to us as finished items. Every dimension was out of tolerance as the supplier hadn't scaled the model to allow for casting shrinkage and not once had they referred to the drawing. Now, because we want the finished article to look like the drawing, we only send out the drawing.

DXF's are only created on request only for profiles.

Regards,

Richard.

1 June 2013 at 09:52 #121184Mark C

Participant@markcRichard, if you sent out models for cast parts, how come you didn't send configurations with shrinkage added? Seems a bit unfair to dump the advanced technology for the sake of a communication issue. I use sheet metal on occasion and it always takes a bit of testing to get the bend factor correct to suit a particular fabricator and his tooling but they would rather do a few test bends and have profiles they can cut cnc than do it all manually (the fabricators seem to be more comfortable with cnc than the machine shops – perhaps is a cost thing?).

Mark

1 June 2013 at 10:03 #121185Phil P

Participant@philpI too used Autocad for more years than I care to remember, then in 2005 I was let loose on Solidworks. Our company does mainly sheet metal, a lot of fabrication and a fair amount of machining.

There is NOTHING that I would even consider using Autocad for except the odd pneumatic schematic drawing perhaps.

Use Solidworks in the way it is intended and put your Autocad discs in the drawer with DOS etc.

Phil

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › CAD – Technical drawing & design › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Vice as Broaching Press

Started by:

James Hall 3 in: Beginners questions

- 16

- 24

-

29 March 2025 at 09:33

Clive Foster

-

ME suppliers

Started by:

sonic_m1etn in: General Questions

- 10

- 11

-

29 March 2025 at 09:22

sonic_m1etn

-

Burner for Glass manipulation

Started by:

Brian Smith 1 in: General Questions

- 5

- 6

-

29 March 2025 at 08:18

Barry Smith 4

Barry Smith 4

-

Model Turbines

1

2

…

23

24

Started by:

Turbine Guy in: Stationary engines

- 28

- 596

-

29 March 2025 at 06:31

Mike Tilby

-

Hello world

Started by:

sonic_m1etn in: Introduce Yourself – New members start here!

- 5

- 7

-

29 March 2025 at 03:27

larry phelan 1

-

Beginner with newly bought lathe – many questions

Started by:

ell81 in: Beginners questions

- 13

- 20

-

28 March 2025 at 22:48

Howard Lewis

-

C Baker microscope

Started by:

old mart in: Clocks and Scientific Instruments

- 3

- 6

-

28 March 2025 at 22:42

peak4

peak4

-

Diamond grinder wheels – thoughts?

Started by:

peterhod in: Workshop Tools and Tooling

- 10

- 12

-

28 March 2025 at 22:30

Vic

Vic

-

Painting topic for stationary engines

Started by:

Steve Huckins

in: Beginners questions

Steve Huckins

in: Beginners questions

- 5

- 5

-

28 March 2025 at 22:10

Charles Lamont

-

RequiredOutside Diameter to Cut 5/16 BSF Thread

1

2

3

Started by:

James Alford in: Beginners questions

- 19

- 53

-

28 March 2025 at 22:06

Howard Lewis

-

Coin of the Realm

Started by:

Michael Gilligan

in: Materials

Michael Gilligan

in: Materials

- 10

- 13

-

28 March 2025 at 19:52

Mark Rand

-

Comm Ads

Started by:

bernard towers in: Website Questions, Comments, and Suggestions

- 2

- 4

-

28 March 2025 at 18:34

JasonB

JasonB

-

Resistor colour code help required

Started by:

Bryan Cedar 1 in: Electronics in the Workshop

- 14

- 19

-

28 March 2025 at 18:33

rjenkinsgb

-

Why use of oddball scales of 1:43 and 1:18?

Started by:

Greensands in: Miscellaneous models

- 5

- 8

-

28 March 2025 at 16:40

Michael Gilligan

Michael Gilligan

-

Further Adventures with the Sieg KX3 & KX1

1

2

…

15

16

Started by:

JasonB

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

JasonB

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 38

- 395

-

28 March 2025 at 13:44

JasonB

JasonB

-

When to grind the point on a centre punch

Started by:

Andrew Tinsley in: General Questions

- 11

- 20

-

28 March 2025 at 13:21

Fulmen

Fulmen

-

Readability / clarity in new combined magazine

Started by:

Trevor Gale in: Model Engineer & Workshop

- 13

- 20

-

28 March 2025 at 09:21

John Haine

-

First 3D metal Printed Part

Started by:

JasonB

in: 3D Printers and 3D Printing

JasonB

in: 3D Printers and 3D Printing

- 9

- 14

-

28 March 2025 at 08:12

Adrian R2

-

What Did You Do Today 2025

1

2

3

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 22

- 69

-

28 March 2025 at 07:20

Michael Gilligan

Michael Gilligan

-

Another clever metric screwcutting dial

Started by:

DC31k in: Manual machine tools

- 2

- 4

-

28 March 2025 at 05:46

Diogenes

-

Are Stan Bray’s Optical centre punch dimensions correct?

Started by:

Andrew Tinsley in: Workshop Tools and Tooling

- 3

- 6

-

28 March 2025 at 02:24

Michael Gilligan

Michael Gilligan

-

HOBBYMAT MD65 – JAMMED

Started by:

David ANDREWS 2 in: Beginners questions

- 4

- 6

-

27 March 2025 at 21:28

David ANDREWS 2

-

Trouble with a tiny screw hole

Started by:

old mart in: Workshop Techniques

- 1

- 1

-

27 March 2025 at 17:59

old mart

-

Design Advice!- Warco GH600 Solid Topslide

Started by:

Richard Kirkman 1 in: Help and Assistance! (Offered or Wanted)

- 7

- 16

-

27 March 2025 at 16:53

Richard Kirkman 1

-

Acrogrip collet holder

Started by:

Lee Reynolds 1 in: Workshop Tools and Tooling

- 1

- 1

-

27 March 2025 at 13:14

Lee Reynolds 1

-

Vice as Broaching Press

-