Today I was preparing for the French Pt 2 boiler certificate which includes raising steam and leaving the blower wide open to check that the safety valve is capable of venting sufficient pressure so as not to exceed the max allowable SWP.

After confirming to myself that the safety valve was capable of achieving this requirement, I used up some of the steam by static running of the loco on the test bed. After a few minutes, there was a disturbing clunk clunk …..

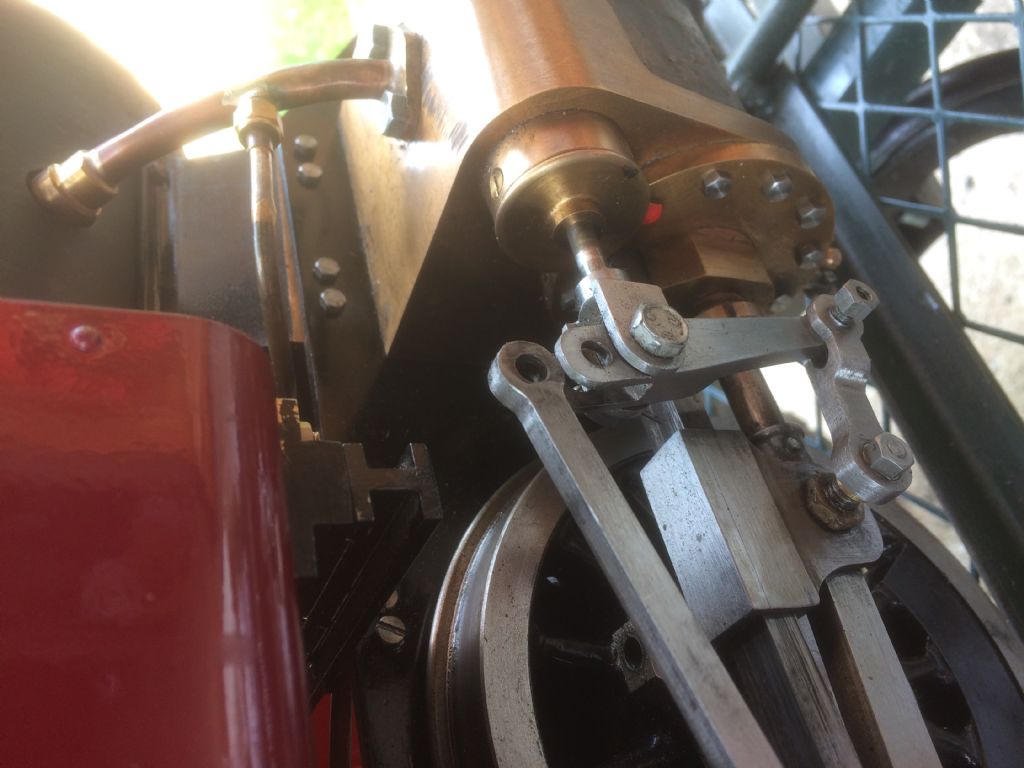

On inspection, the piston crosshead was detached from the piston rod having sheared the 5/64" taper pin, I then saw that the pin connecting the reversing rod to the valve crosshead was missing. It shows the force between the rotating motion and what I can only think was wet steam or condensate not being allowed to vent either by the cylinder drain cocks or the piston valve being at the wrong event.

The connecting pin between the rod and crosshead is a press fit into the thin walls of the valve crosshead – obviously not tight enough. A minor re-design is in progress

Speedy Builder5.