Neat ideas!

I have both rhomboidal-link (ex-car) and hydraulic jacks in the workshop. They have been used for all sorts or things, including moving the table on my Progress 2G bench-drill.

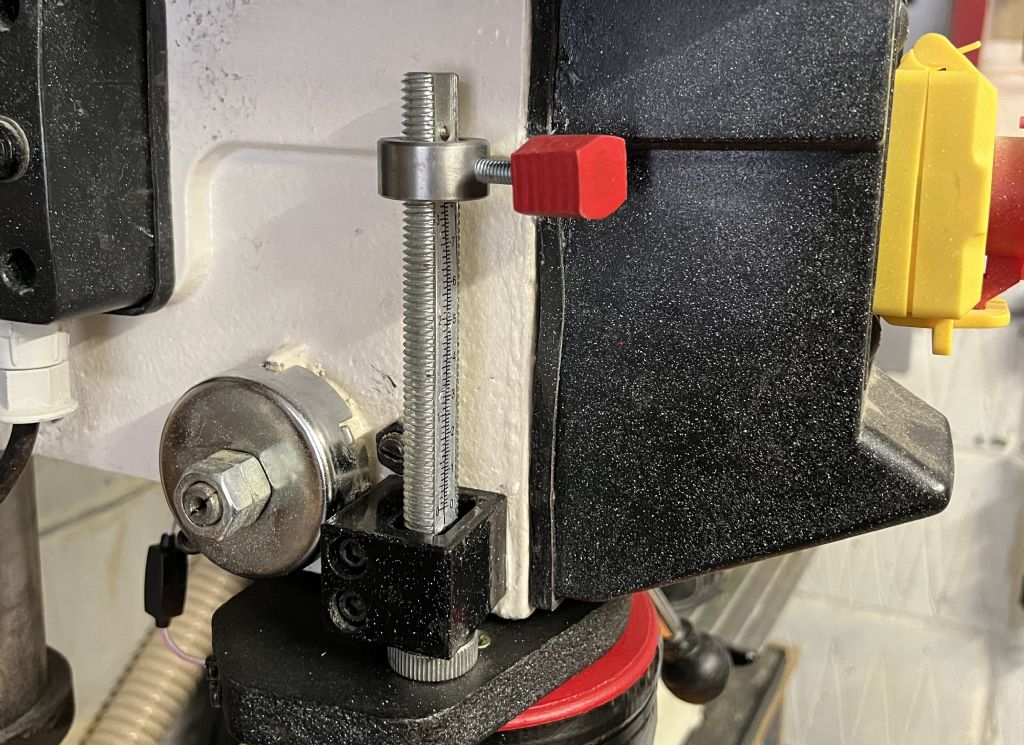

My smaller, Meddings, bench-drill, has an original depth-stop similar to your thumbscrew, and it does make life simpler than the knurled ring-nuts on the Progress. Especially as years of grubby fingers have worn the knurling nearly away!

The Meddings differs also in that the table is also the base, and the head is raised and lowered on the round column by rack-and pinion. It suffers though from excessive head-room under the chuck even on the lowest altitude, for using short drills on small work-pieces.

'

Ian, Andrew –

Electric-drives: Although the gearbox uses a worm-drive I'd be inclined still to use the normal table lock having set the height, to relieve the load on the mechanism. I think you'd need do that anyway to stop the table moving round the column.

I've long thought some way of maintaining centre would be useful on a bench-drill or pillar-drill while altering the height, as well; though I am not sure how to make that compatible with being able to swing the table or head around the column.

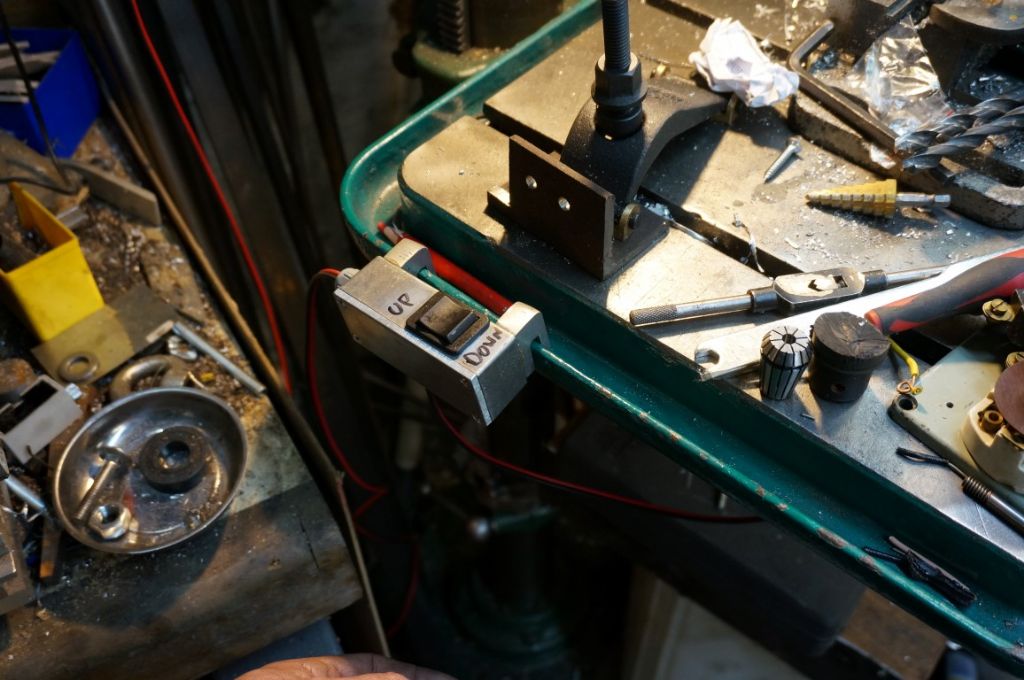

I do like that switch-box with its integral hooks.

'

VFD & 3ph motor? Depends how much you need change the speed, really.

On a milling-machine yes, though as on my Myford lathe, I use the 3ph conversion in conjunction with, not replacement for, the belts.

On bench drills, often it's low speed that is the awkward one; and motors and their electronics don't want running too slowly. Hence my "conjunction" comment.

I find the Meddings drill on its slowest speed (still a few hundred rpm) adequate for most operations, though a bit frantic for 12mm holes in steel. The Progress lives on one belt setting and two-speed gear, for larger drills and hole-sawing for which the Meddings would be much too fast.

Andrew David.