Removing and replacing the drill after setting the point projection before grinding the first edge gave me more consistent results.

Presumably the actual position taken up by the drill point when adjusting the projection can be slightly different from that resulting from simply putting the drill into a preset jig. Most likely due to the difference between sliding against the little rotation setting gauge on the end as you set projection and simply placing against it when merely inserting the drill. Any such effects mean the point grind will differ between the two edges.

Using identical insertion technique on both edges avoids this, very inconsistent, effect.

I also made a U section guide mount for my base. Needed to make it higher to reach the right part of my grinder so it seemed sensible to make sure it always stayed perpendicular to the wheel when setting the base. Plans to add a screw adjuster to reliably set the position and add the requisite tiny cuts between swings never reached fruition.

I did try making a tighter, more controlled swing pivot than the simple, rather flexible, plate across the cast Vee in the base. Which significantly dis-improved performance! On reflection many years later after getting my Clarkson attachment I reckon the flexible plate acts as a crude spring limiting the force on the drill point when grinding. The Clarkson has a proper spring for this. Presumably too solid a mount gives too much force on the wheel and poorly controlled grinding.

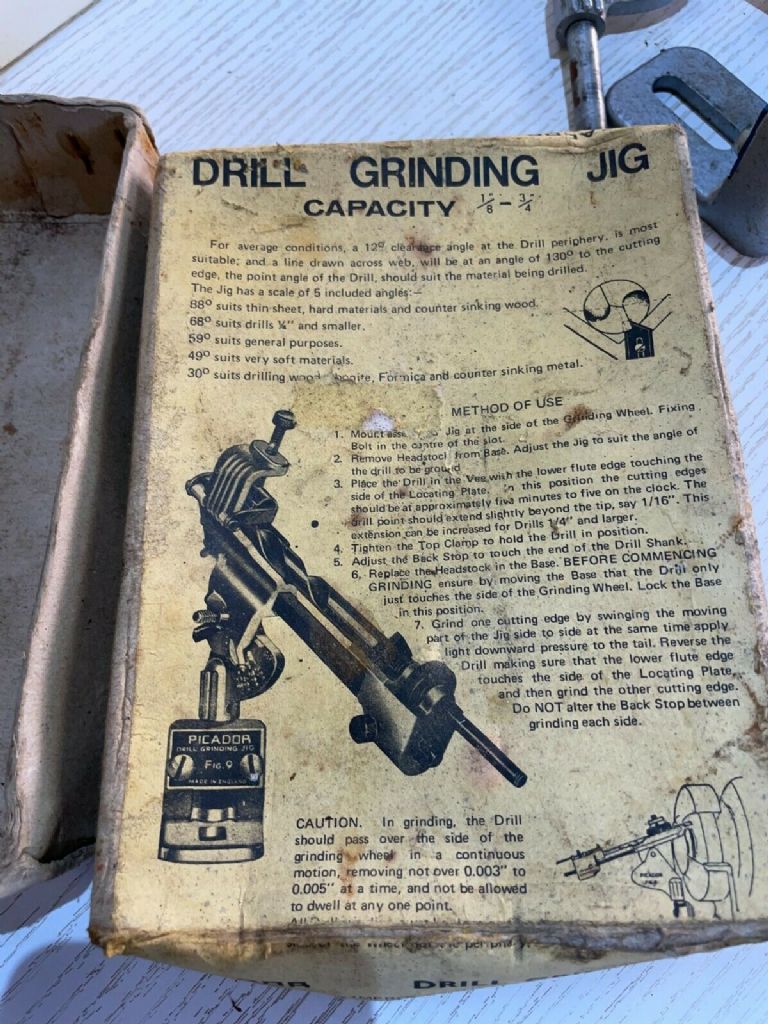

The grinding a hollow in the wheel objection is valid but probably moot given that this is a consumer grade product and that most won't get enough use to seriously consume the wheel. I put a cup wheel on my grinder. Not only a complete solution to any such worries but also letting me fit a large grinding rest perpendicular to the spindle. Simplified Hemingway Worden style. The Picador base lived underneath. Two studs and wing nuts held the table down so it could esily be removed for drill grinding.

John is a bit unfair in in his comments about cheap screw threads. Its fair to say that, as an unfortunate necessity to meet a price / performance ratio acceptable to its target market, the constructional and engineering standards of the Picador are lower than one would ideally like. As is the case with all such devices.

I got mine around 1972-74 on a special offer price, reduced from £7-50 to £5 as I recall things, when I was earning maybe £650 a year. In those days cheap crap wasn't cheap! You could buy a half decent 1/64" to 1/4" drill set for similar money.

Significantly better engineering would have been unaffordable.

If you were going to make a better device you'd use a different design.

feel its a great pity that an updated version of the concept using the ingenious flip over Vee drill carrier and drill point projection gauge used on the original PlasPlugs drill sharpening system has never been produced. This would effectively mechanically resolve pretty much all the set-up related issues.

I imagine that given the will a really nicely engineered set-up to use with your grinder could be made for less than the rather cheaply made "£40 (ish)" PlasPlugs grinder system knock offs with integral grinder from the usual suspects.

Clive

Edited By Clive Foster on 01/06/2022 09:39:29

Richard Kent 1.