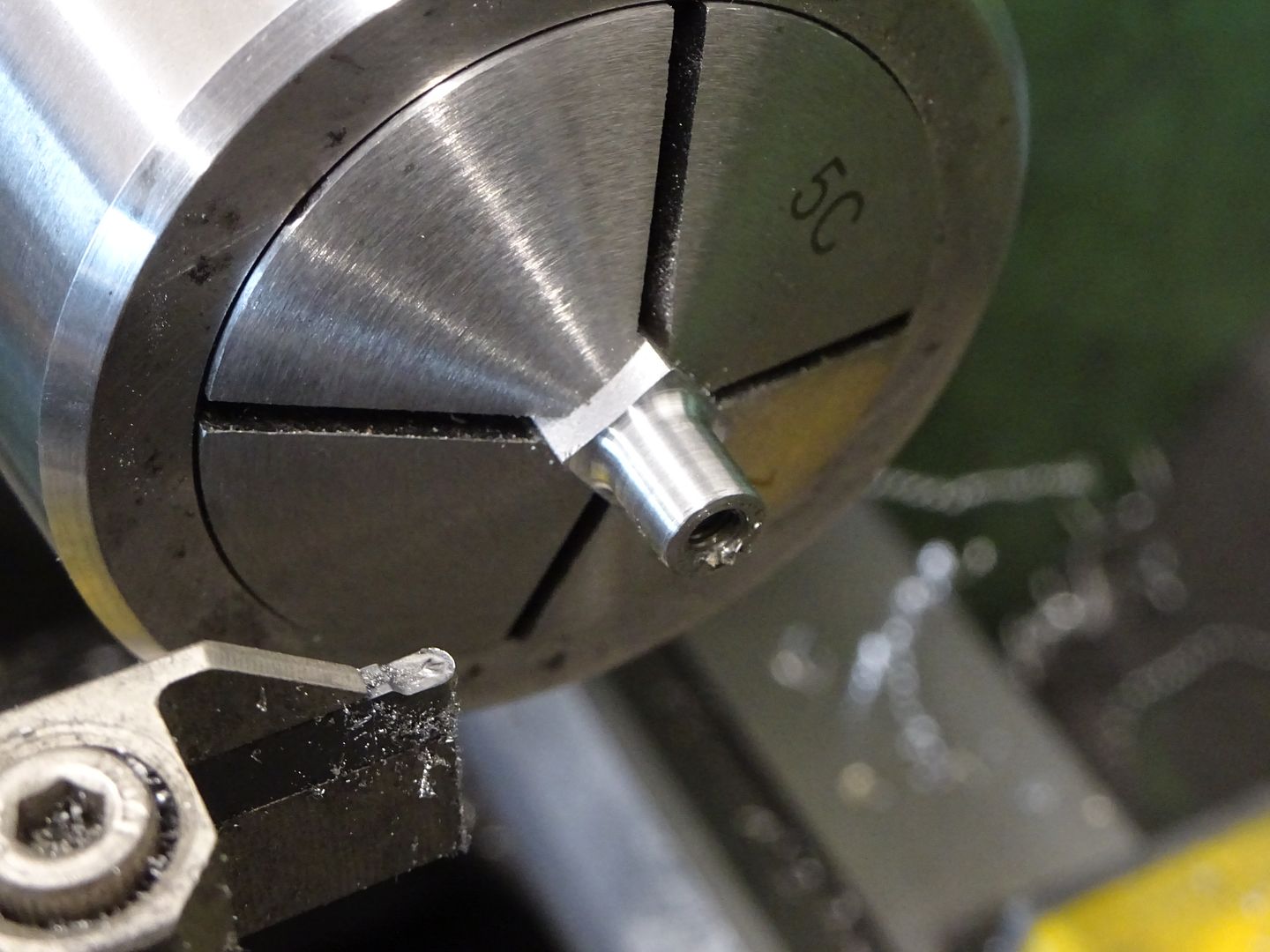

Ron, I have cut down the holders, and I cut from the underside. On some of mine, I extended the cut to the under body bulk of the tool by about 6 to 8 mm or so. I did this to reduce the overall over hang of the tooling. As I have a Dickson toolpost, the closest it can get to the long work piece is the clamp plate of the boring bar tool block. Yeah some holders are tougher going than others. What really did annoy me, was to find that there are industrial tool holders for small machines that are all in 12mm shank holders for most of the insert tooling, including TNMG16040XX inserts and for holders like you may be looking for. Mitsubishi Carbide, may well have a holder for your insert. I just checked , and they don't do that insert type in the 10-12mm holders. 16mm is the smallest for the MRMN inserts I could find. Some do a cast iron grade insert in the narrow 2mm insert. It is basically flat or inclined with no pressed geometry. These can and are used to make Special radius inserts, and can be shaped with a diamond file, or diamond mounted points with a rotary tool, or on a suitable grinder for grinding carbide. So you could create your 1.2 or 1.5mm radius. Just hold the insert forward a little , then you do not need to modify the tool holder in any way.

Ron Laden.