Forget thread pitches or tpi when feeding, You are not screwcutting.

The only number that matters is the feed per rev.

Surely the purpose of the feed per rev is to provide a suitable rate for roughing which does not overload the machine or the tool, and then a reduced feed rate for finishing to give a good surface finish, with a shallow depth of cut.

If the machine ha sufficient power, and rigidity you might rough at 0.5 mm per rev, and finish turn with a smaller depth of cut at 0.1 or even 0.05 mm per rev.

If these figure are not listed in a chart on the machine, they can be arrived at by calculating the gear ratio required between the chuck and a Leadscrew of known pitch.

It just needs a little thought, and some simple arithmetic to make up a gear train to give the required ratio.

You are setting up to cut a helix, but shallower and of a different form from what you normally see as a screw thread.,but, for finishing, with a very fine pitch.

You are unlikely to get a good surface finish with a high feed per rev, so just have to be patient.

Rome was not built in a day..

For a 1.5 mm pitch Leadscrew, it needs to rotate at 1/15 of the speed of the chuck to provide a feed rate of 0.1 mm per rev. So you set up a gear train to do this,

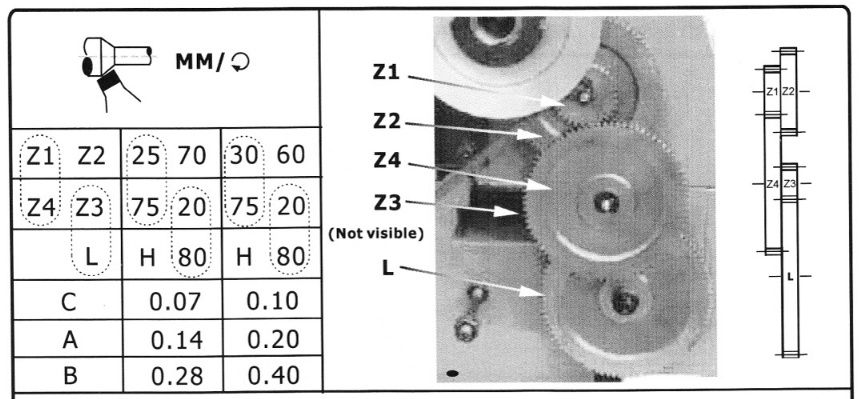

Say 20T :driving 75T/20T driving 80T (3.75: x 4:1 = 15 ) The ratio is given by DRIVERS / DRIVEN

IF the gears are available. You might need to buy in some extra spares, especially the lowest and highest tooth counts.

If the lathe has a Norton gearbox, the same logic applies.

My lathe gearbox provides a finest feed of 0.119 mm / rev with a 40T driving, via an Idler, the 40T on the input to the gearbox. By making and fitting a 80T, the feed rate is halved to 0.0595 mm /rev.

In fact by using the 127/120 compound idler, this feed can be reduced even further., to 0.0562 mm / rev

Some gear trains will involve two compound intermediates. In this case, the tumbler reverse will need to set to, apparently, reverse the direction of the Leadscrew. But because of the two "Idlers" it will rotate in the normal direction.

Howard

Edited By Howard Lewis on 04/11/2021 22:17:40

Howard Lewis.