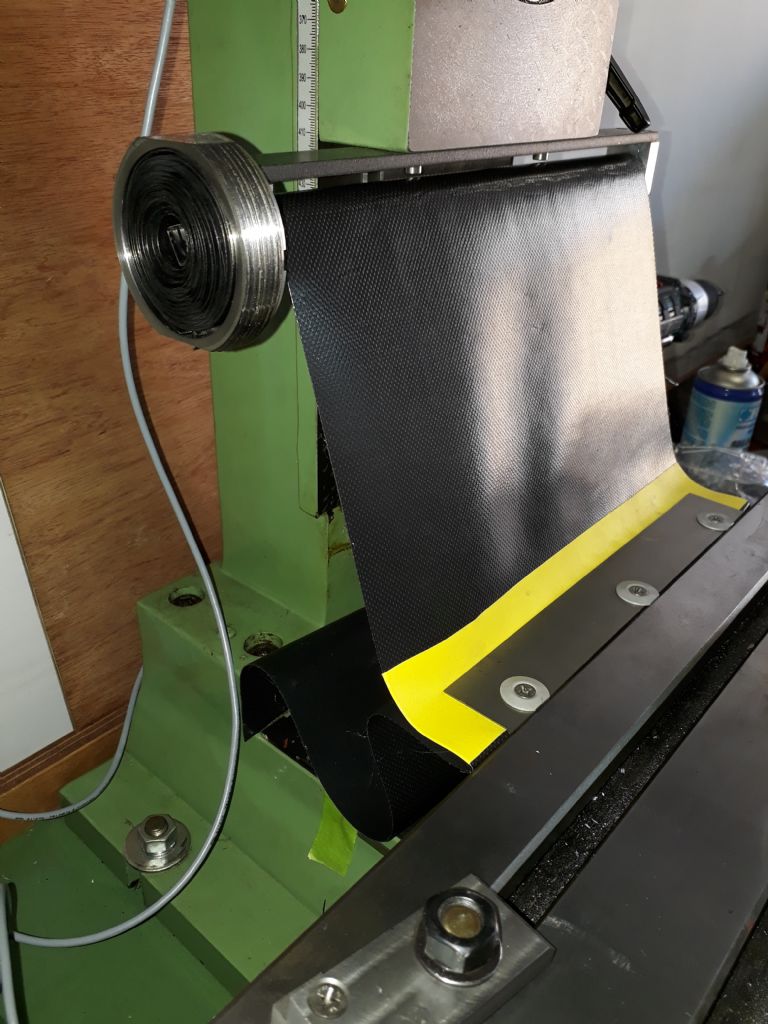

I while ago when fitting a dro to my WM18 mill I decided to replace the original column accordion way cover and rubber cover Z-axis cover with a roller blind type cover. The original covers did take some travel in both axes, so I figured a roller cover attached to the head and and the saddle will give me the maximum travel you could possibly get from the mill. Also all the chips remain on the table not fall behind the saddle.

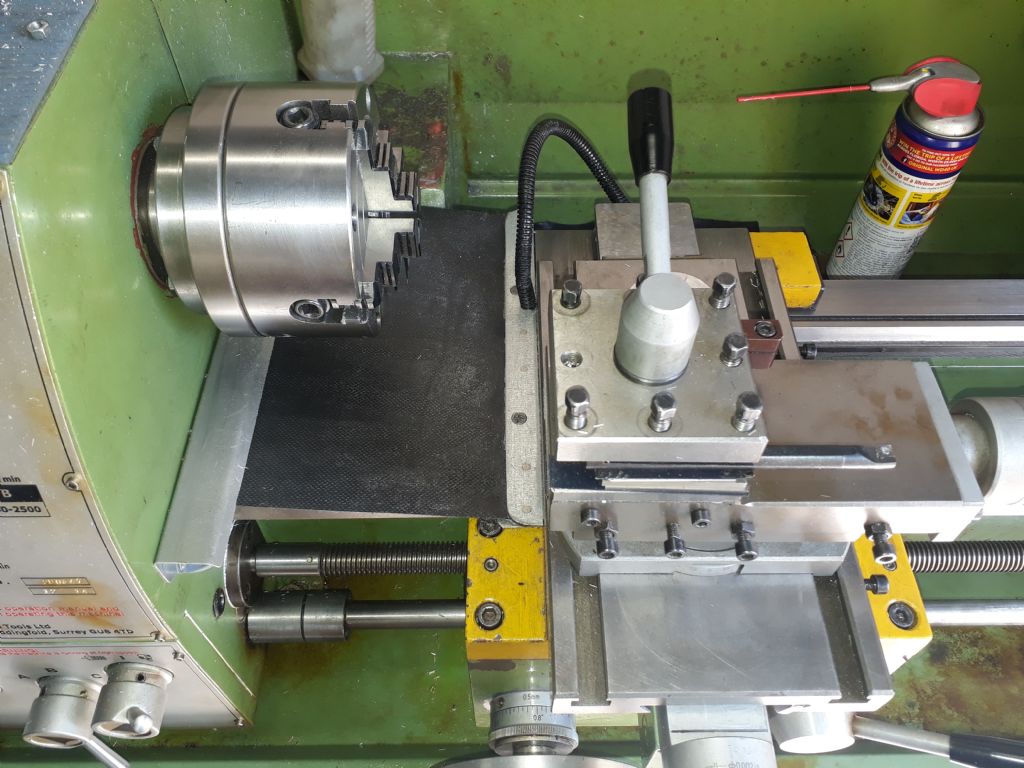

Had the cover on the mill for about a year now and I'm quite satisfied with it, so I'm turning my attention to doing something similar for the lathe.

The one on the mill was a scratch build project, so made a hairspring from packaging steel strapping and a roller from some scrap steel and the cover from thin pvc fabric. The contraption although compact in size for the mill will not work for the lathe, it needs to be smaller.

I found a small broken roller blind which I plan to gut and recycle for this project which might work. The idea is to attach the roller to the headstock under the chuck and the pvc cover to the carriage, without loosing any travel.

Ebenezer Good.