Hi Duncan

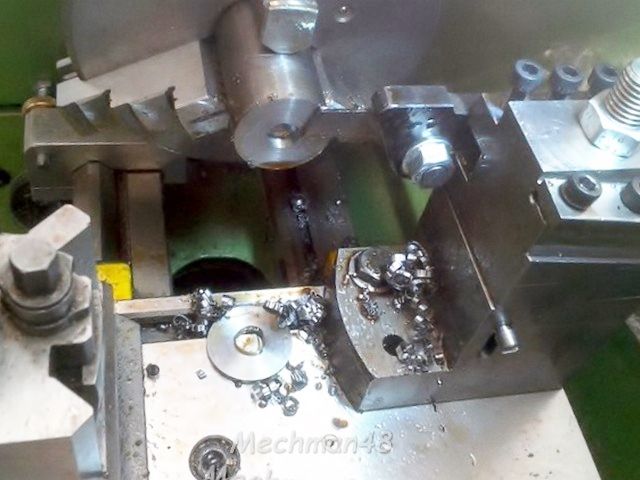

The rear toolpost I have at present is the GHT one and is on my ML7-R which I need to get around to selling, I did have one I made for the Bantam which was basically the GHT one scaled up but with different mountings to suit the non slotted Bantam crosslide. From memory the indexing turret was made from 3" square BMS , the whole thing was fabricated from steel at work on the night shift. Oh how I miss the big mill and surface grinder now I'm retired!

At the same time I made an one for the works Chipmaster , which was a general use machine, and very few people used the rear toolpost, some had never seen one before which surprised me. I agree it does speed things up when making multiple parts,

The Bantam rear toolpost was passed on to a good friend who had pestered me for years to make him one before the Bantam was sold. I couldn't find a photo, only the ones I took to advertise the lathe, but will look further. The Hemingway kit looks very similar, being an enlargment of GHT's design but is designed for Tee slot mounting ( Colchester provide a number of tapped holes at the rear of their cross slide). I have some large tipped boring tools that do not fit the Myford toolholder, so will make a spare indexing toolblock so I can use them in the 254 rear toolpost.

Dave

Sorry for edits, morning coffee not kicked in yet.

Edited By Dave Wootton on 15/04/2021 07:01:17

Edited By Dave Wootton on 15/04/2021 07:02:22

Edited By Dave Wootton on 15/04/2021 07:03:39

lfoggy.